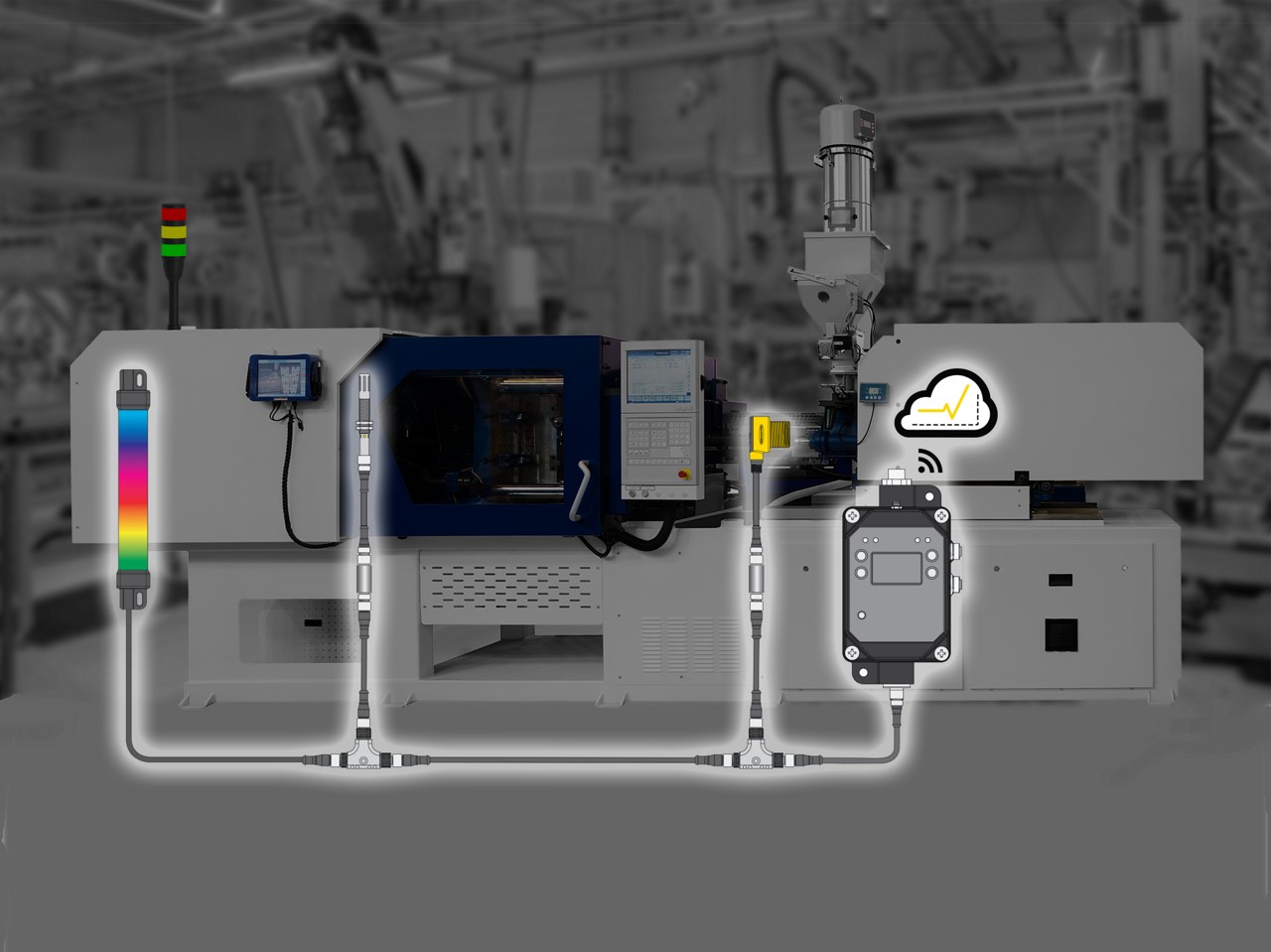

Increase Productivity on an Injection Molding Machine

Make your legacy injection molding machine smart – Give it Industry 4.0 capability – with Snap Signal.

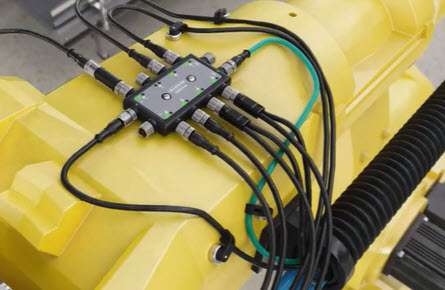

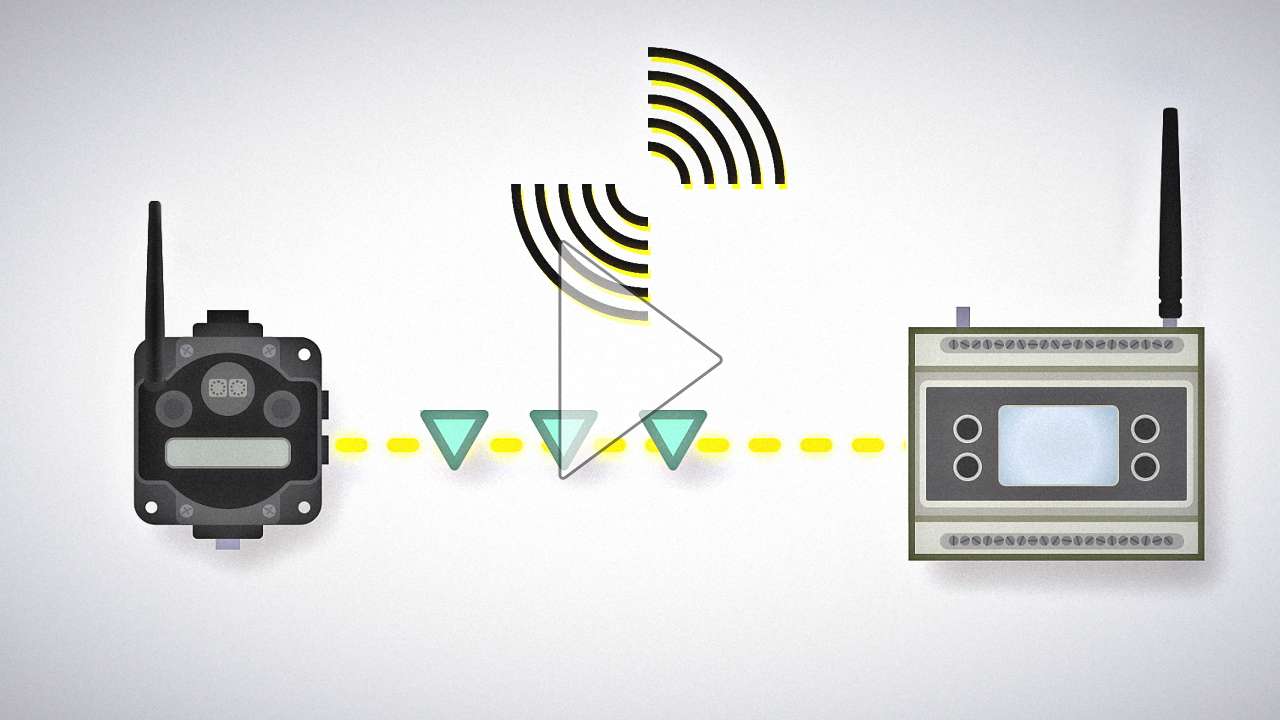

DXM Series industrial wireless controllers are designed to facilitate Ethernet connectivity and Industrial Internet of Things (IIoT) applications. Available with an internal DX80 Gateway or a MultiHop Data Radio, these powerful Modbus communications devices connect local wireless networks with the internet and/or host systems.

Gateways

Make your legacy injection molding machine smart – Give it Industry 4.0 capability – with Snap Signal.

• Expand available data beyond local indication</br> • Gather information necessary to react quickly</br> • Drive efficiency improvements based on data previously unavailable</br>

Monitoring production inputs and outputs provides machine operators and managers with critical data about their processes and equipment and can help them identify and resolve problems on the production line more quickly.

The K50U wireless ultrasonic sensor was designed specifically as a non-contact level monitoring solution. Monitoring the levels of epoxy in drums during refill alerts staff of potential overflows before they become a problem.

![Vibration Monitoring a Main Air Handler [Success Story]](/content/dam/banner-engineering/photography/success-story-photography/ball_bearings/Ball_Bearings_5.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

When the main air handling unit in a boiler room of a local corporate building was exhibiting potential issues, workers wanted to find a long-term solution so that they could identify maintenance issues with accuracy and in a timely manner.

Wireless products enable predictive maintenance in the port industry. Motors and gearboxes on cranes are prone to high vibration and temperature which can cause them to degrade. Predictive maintenance allows employees to interfere and solve problems before they completely fail and cause unplanned downtime and lost profit.

• Remove completed pallets from assembly stations quickly </br> • Enable direct communication from assembly stations to AGVs </br> • Improve process efficiency using turnaround time data to </br>

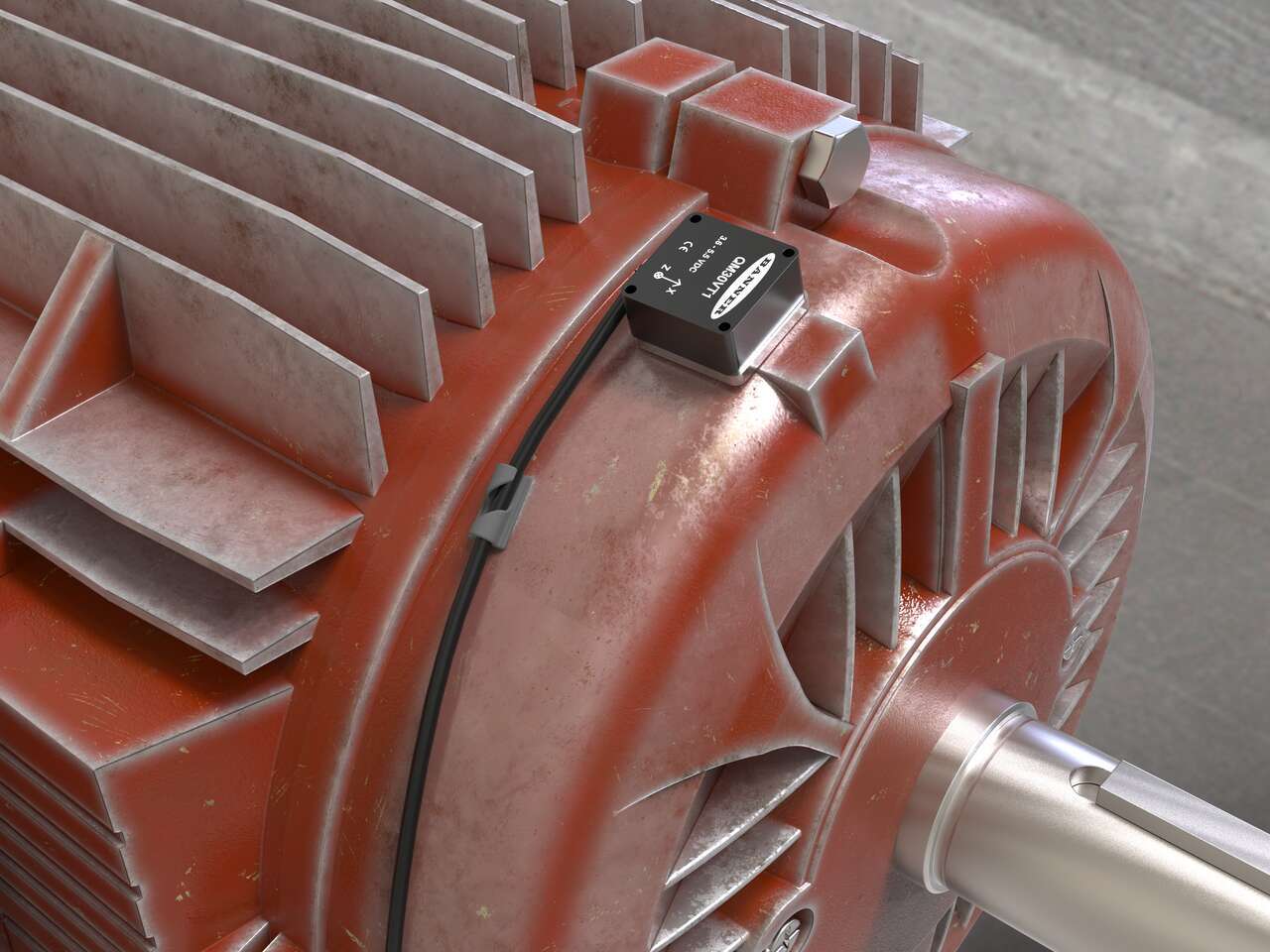

Banner’s wireless vibration and temperature sensor measures RMS velocity, in inches per second or millimeters per second, and temperature. Mounting it as close as possible to the bearings enables you to monitor the machine’s health by detecting increases in vibration and temperature. It is easy to mount using the standard bracket, the magnetic bracket or two sided thermal transfer mounting tape.

Identify machine problems before they cause serious damage or unplanned downtime and alert staff of changes in condition via text message or email as well as provide at-a-glance local indication of machine status.

Predictive maintenance enables users to more accurately anticipate when machine maintenance will be needed based on real-time data from the machines themselves.

Wireless monitoring of rotating parts on coal conveyors throughout a large port allows operators to utilize predictive maintenance to prevent failure and save money while reducing downtime.

Learn how the installation of Banner wireless vibration sensors and data from the DXM wireless gateway prevented unplanned downtime in this application.

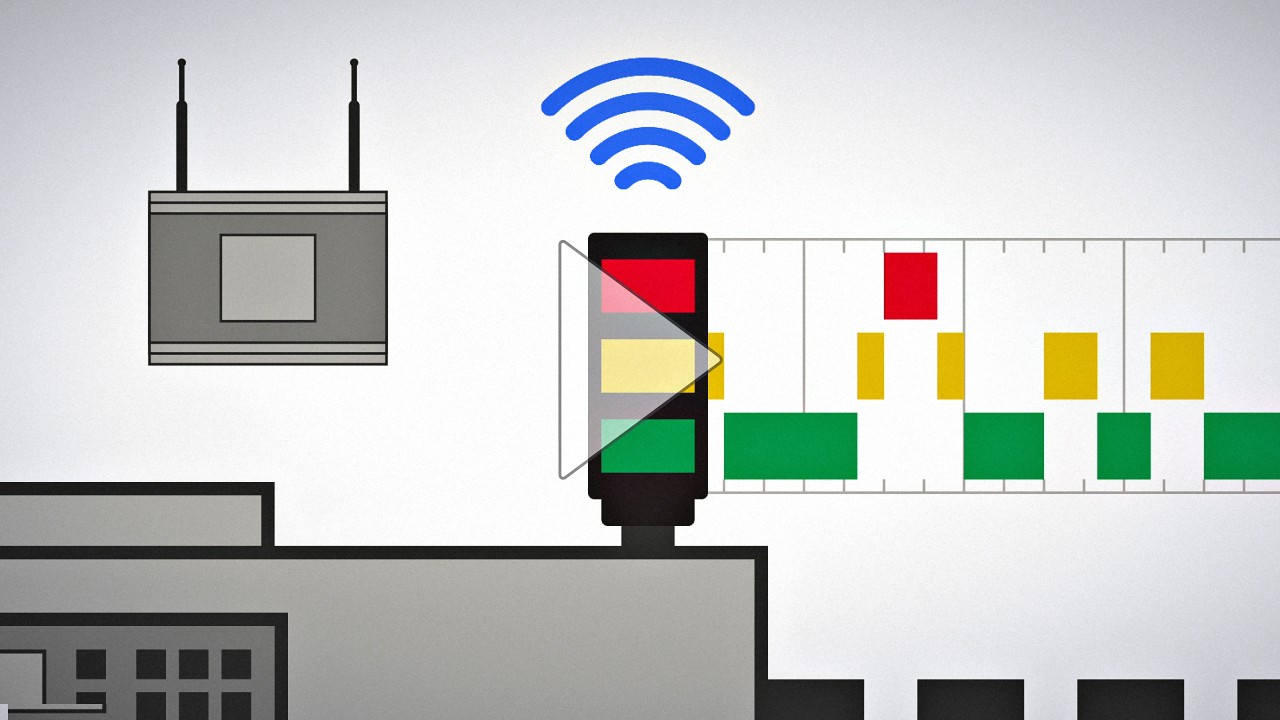

Remote monitoring enables increased visibility into the performance and efficiency of machines, processes, and people.

Provide at-a-glance machine status indication and send machine status information to a wide range of devices.

Increase production efficiency by developing a wireless call-for-parts, service, and Andon system that allows for up to 35 work stations to call out to 12 forklifts/Hi-Los using the EZ-Light K70 Touch to wireless Direct Select operator interface.

In a recent material handling application, facility managers needed to find a solution that would alert them to the status of trailer capacity at loading dock doors in real-time.

Learn how In the Ditch™, an Idaho-based manufacturer of award-winning products for the towing industry, was able to make substantial improvements to the efficiency and accuracy of their picking processes by implementing a complete pick-to-light system from Banner Engineering.

We noticed you didn’t finish your online checkout. We're dedicated to providing the best shopping experience possible and would love to hear if you faced any challenges. Let us know how we can make your experience even better.

Additional Technical Notes available in the Wireless Reference Library.

Learn how to connect the Banner DXM Gateway series with the Ignition SCADA software.

Learn about Banner's DXM Series Wireless Controller in this seven-part tutorial.

Monitor machine health utilizing predictive maintenance by continuously monitoring for vibration and temperature changes.

Learn how to improve communication and maintain a steady workflow with Banner Engineering's wireless call for parts solution.

Calculating Overall Equipment Effectiveness (OEE) can help you improve efficiency and productivity. With a wireless system, you can track uptime, validate throughput, monitor quality, and optimize your operation.

Banner Engineering offers a simple, flexible, and effective solution for an office area cleaning program. Operators work as normal and receive an indication when it is time to clean the space.

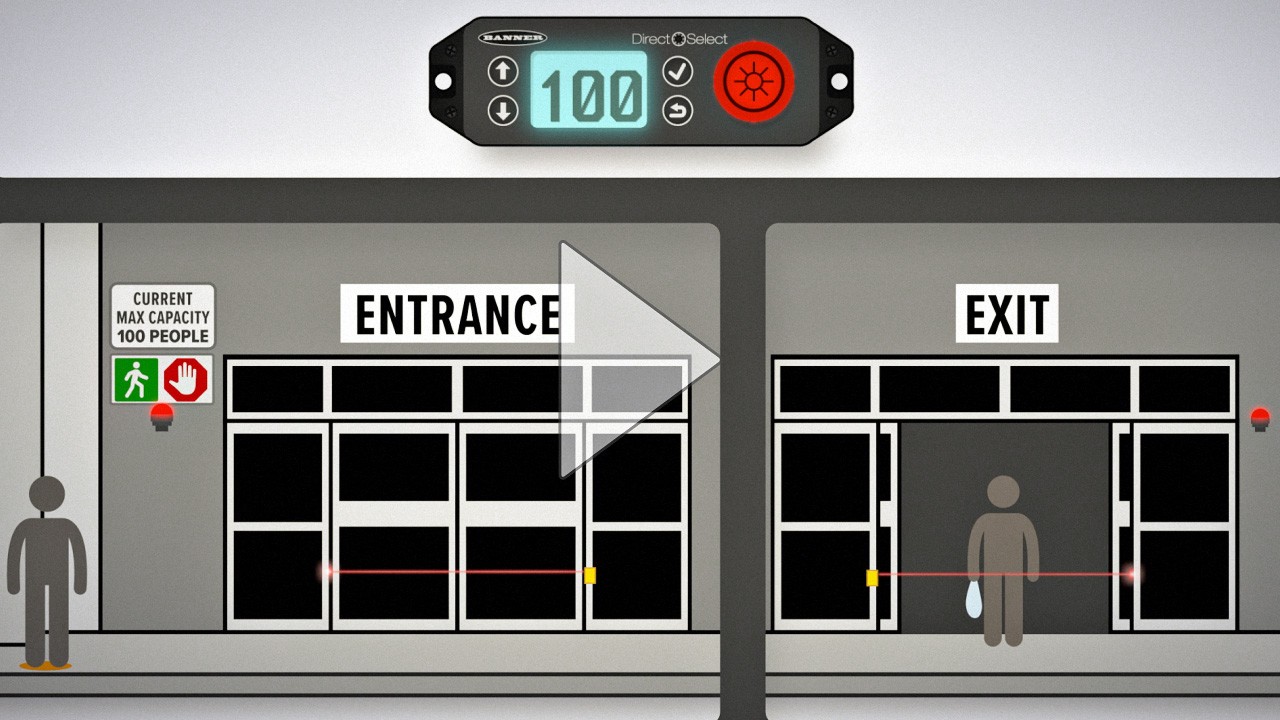

Creating a safe environment for customers and staff is essential for retail establishments. Wireless technology can be used to support social distancing initiatives by making it easy to monitor and control the number of customers inside a store.

Banner’s occupancy monitoring solution automates the monitoring of entrances and exits and provides easy-to-understand visual indication to customers when they can enter the store.

IIoT solutions from Banner Engineering provide companies with greater visibility into their operations by enabling access to critical performance and production data, making it easy to solve problems, identify trends, and make better, data driven decisions.

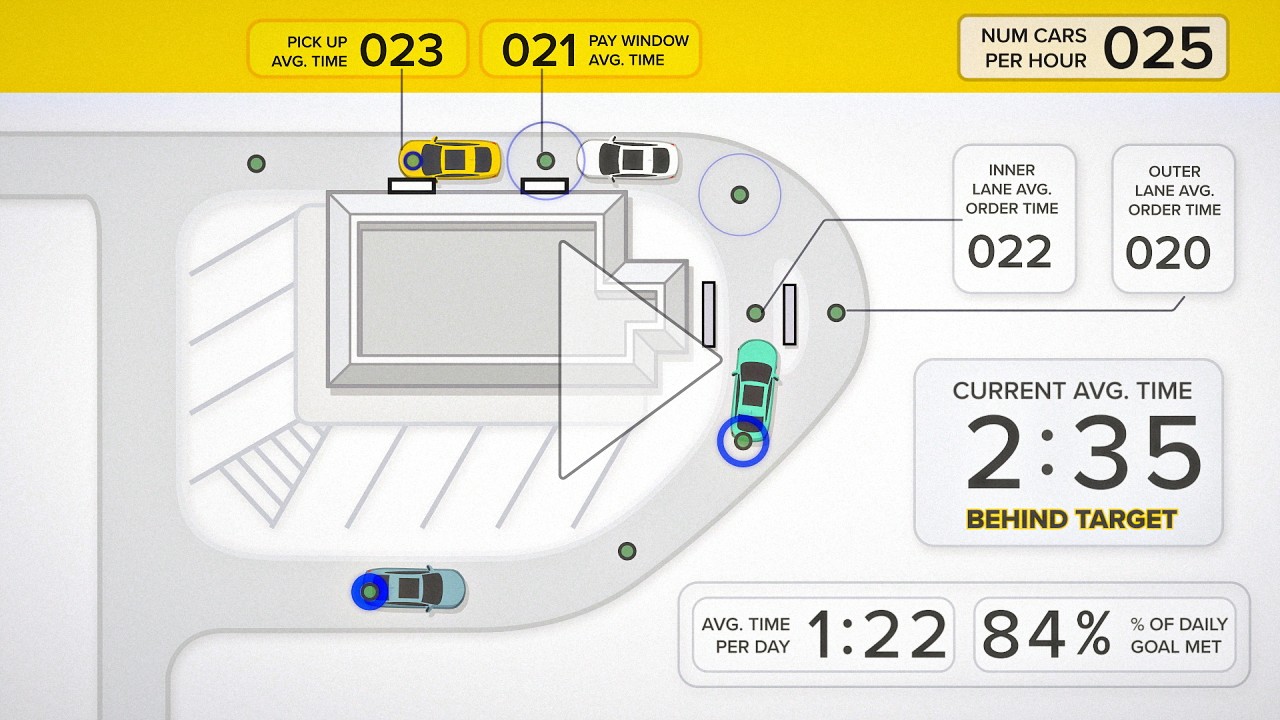

Wireless vehicle detection at a quick serve restaurant drive-thru ensures speed of service and efficiency.

A secure wireless solution not only protects your network, it will also ensure both data security and data integrity. Learn how Sure Cross solutions from Banner Engineering keep your network and data safe.

Have a question about this product series? Our application engineers are here to help with expert guidance and support. Send us your inquiry, and we’ll get back to you as soon as possible. We’re here to make sure you get the answers you need.