Safeguarding at Palletizer Station with Sticky Liquids Present

Application: Personnel protection at palletizer machine

Challenges: Contents of bottles are under pressure and are subjected to an occasional unintentional impact

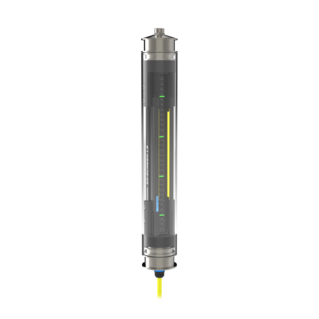

Solution: EZ-SCREEN LS safety light curtains in hygienic tubular enclosures

Benefits: Clean, hygienic, and easy-to-clean design with IP67/IP69K rating

Palletizers take cases of filled beverage containers and stack them onto pallets, layer by layer. The filled pallets then move into a wrapping station where they get prepared for safe shipment to stores and distribution facilities. Palletizer machines require safeguarding because they have moving components that could injure operators. Filled bottles may explode at the palletizing stage and create a mess on the machinery and sensing equipment. Bottles filled with sticky or corrosive liquids, such as soda, juice, or flavored water could damage the safety light curtains and cause performance issues.

Safety Light Curtains with a Hygienic Tubular Enclosure

The EZ-SCREEN LS safety light curtain in a hygienic tubular enclosure offers personnel protection while remaining easy to clean and protected from liquid ingress. Beverage lines are cleaned with high-pressure and high-temperature chemical washdowns, and the light screens with new hygienic enclosures are rated to IP67/IP69K to withstand frequent cleaning. The enclosure is made from materials such as stainless steel and polycarbonate that will not corode or degrade when exposed to cleaning chemicals.

The enclosures were designed with hygienic standards in mind. They have hydrophobic vents to eliminate a pressure differential inside the enclosure, which prevents condensation from occurring and stops water or chemicals from entering. Each sanitary enclosure is constructed to have a smooth, rounded design so that water and other debris does not accumulate on the surface.

The EZ-SCREEN LS with hygienic enclosure is available with remote fixed blanking so that beams can be blanked out to ignore permanent or temporary objects such as conveyors while still protecting operators working in the same area. The light screen system does not require software or DIP switches for configuration and has bright alignment indicators for a fast and easy setup. The EZ-SCREEN LS with hygienic enclosure is sold pre-assembled with the light screen already conveniently installed inside the enclosure.