1

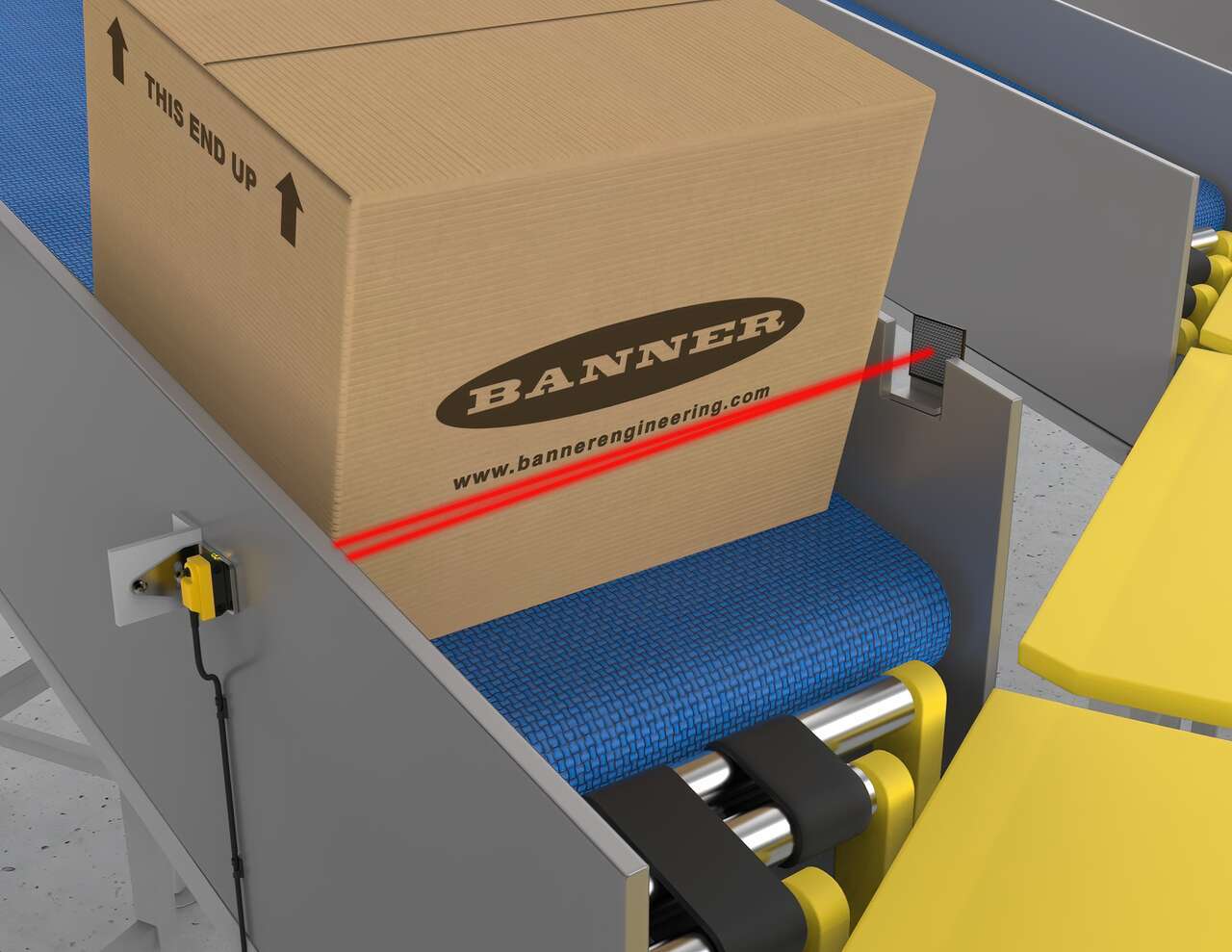

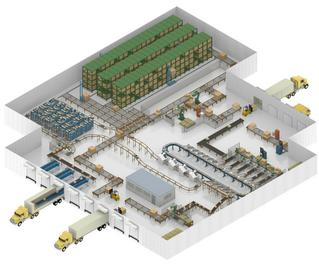

Extendable Reach Conveyor

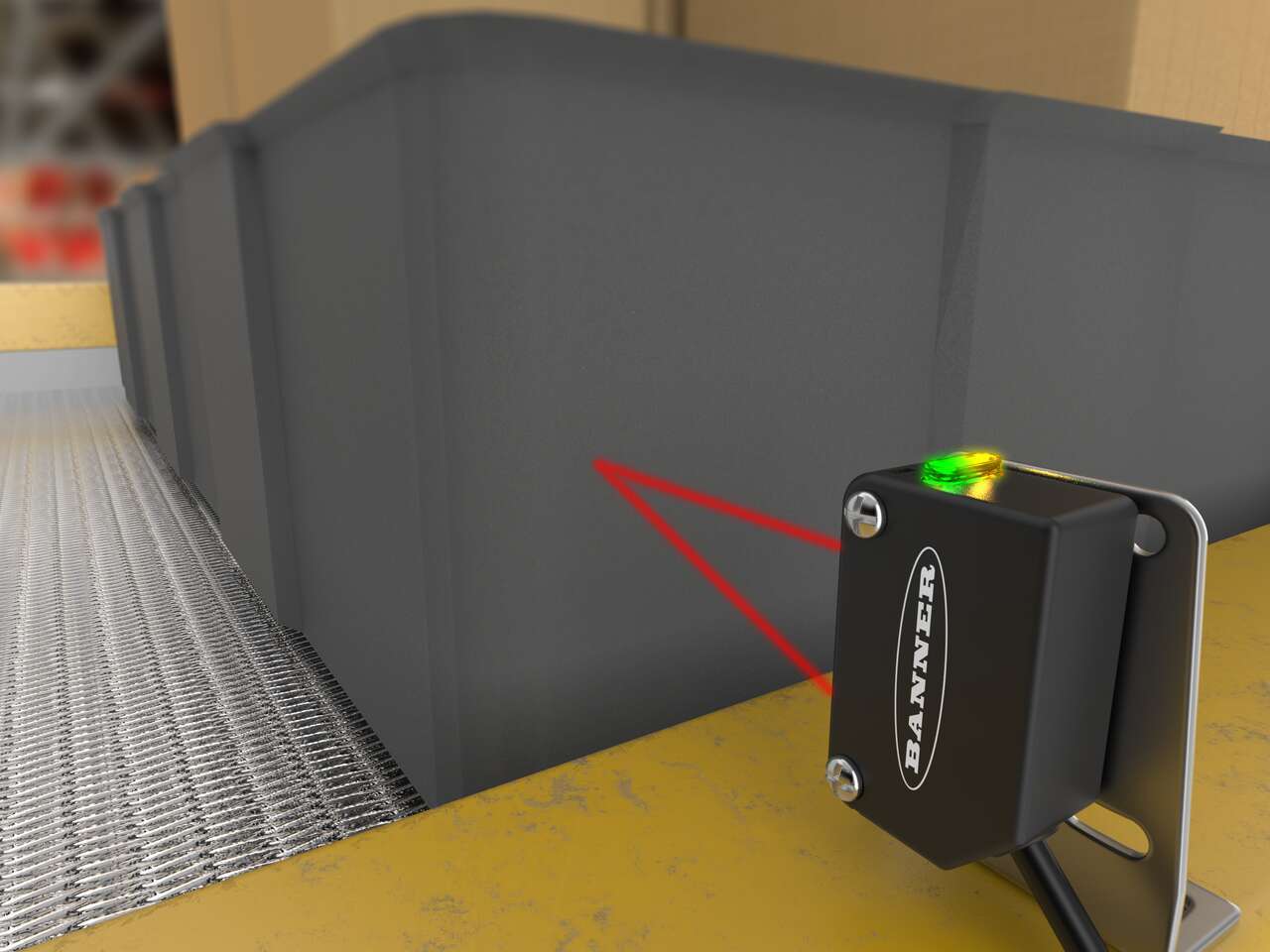

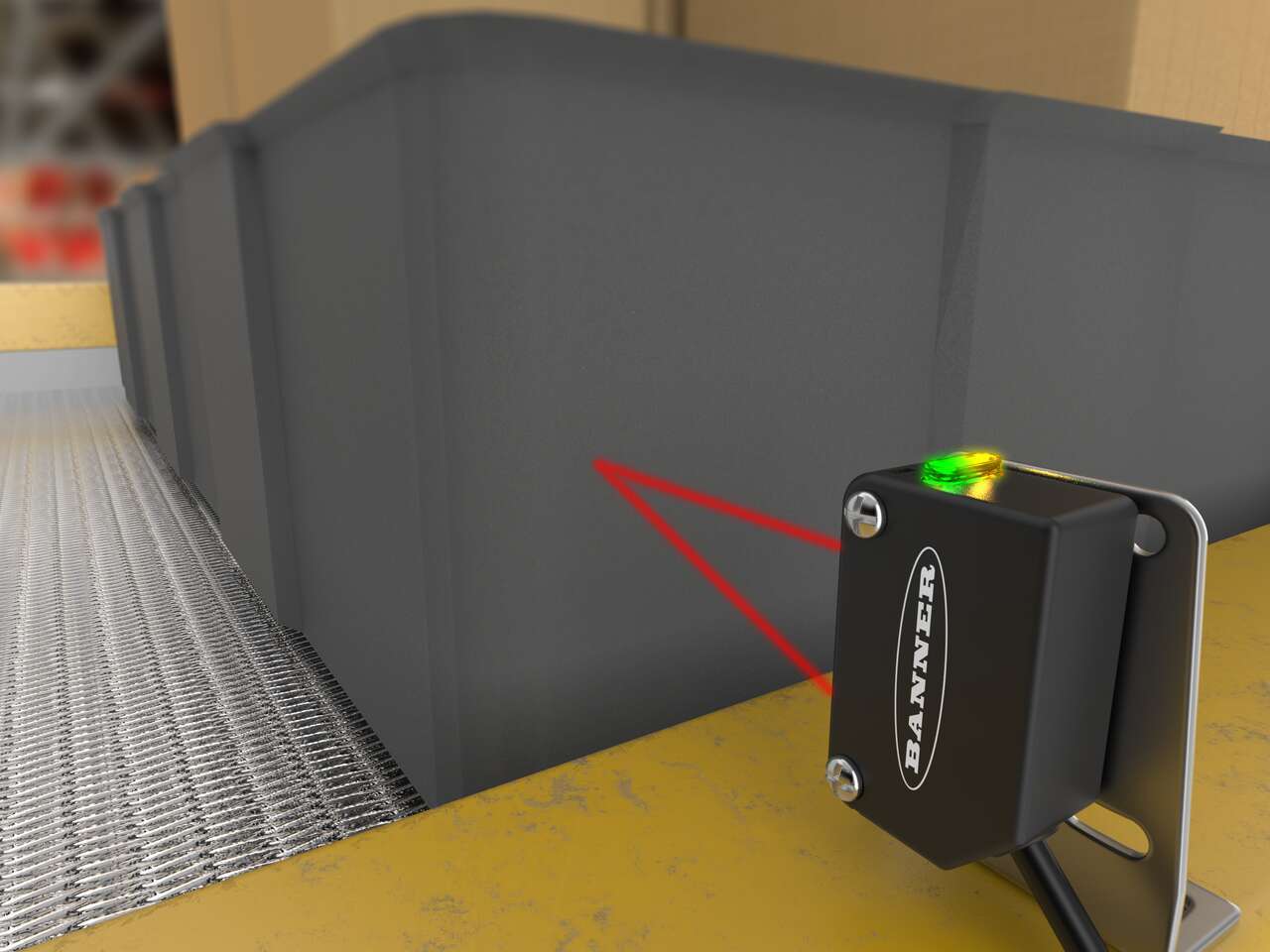

Banner provides sensing and industrial LED lighting solutions to help minimize carton and product damage inside a container. Banner’s QS18FF with background suppression has a fixed range of up to 100 mm with an 850 microsecond response time, allowing for easy detection of the packages/cargo and ensuring the extendable conveyor does not crush cartons.

Banner’s WLB32 is a cost-effective, LED lighting solution available in AC and DC versions with a high lumen output that ensures proper illumination.

Learn More

2

Monitoring Arrival and Departure of Trucks at a Loading Dock

Sensor solution for outdoor truck detection for safety prevention purposes.

Learn More

3

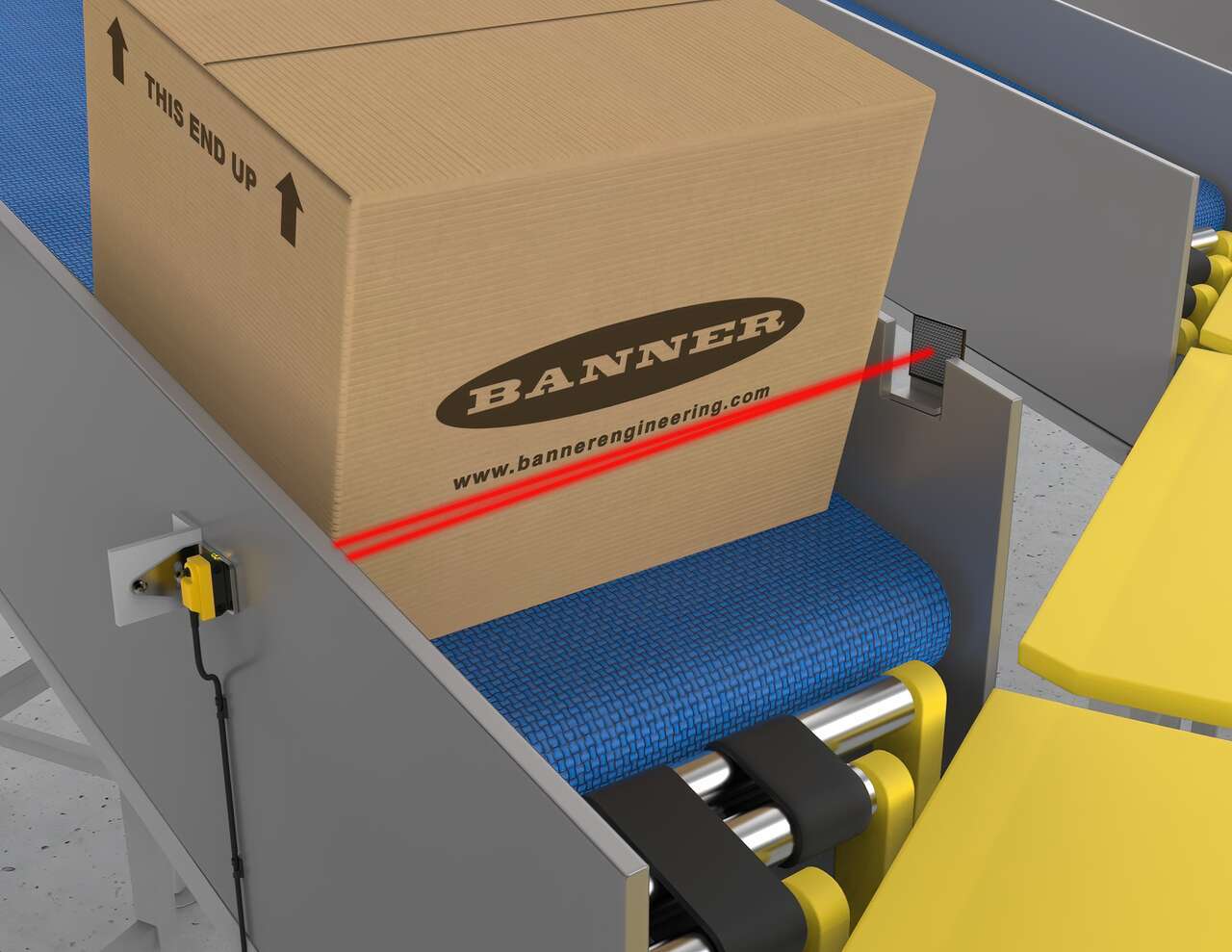

Parcel Collision Avoidance

Banner’s DS18 sensor coupled with a zone control modules offers a cost-effective solution that gives an output and shows a change in state for optimal flow of products. This helps prevent box collisions and stops the zone so contents of packages are preserved.

Learn More

4

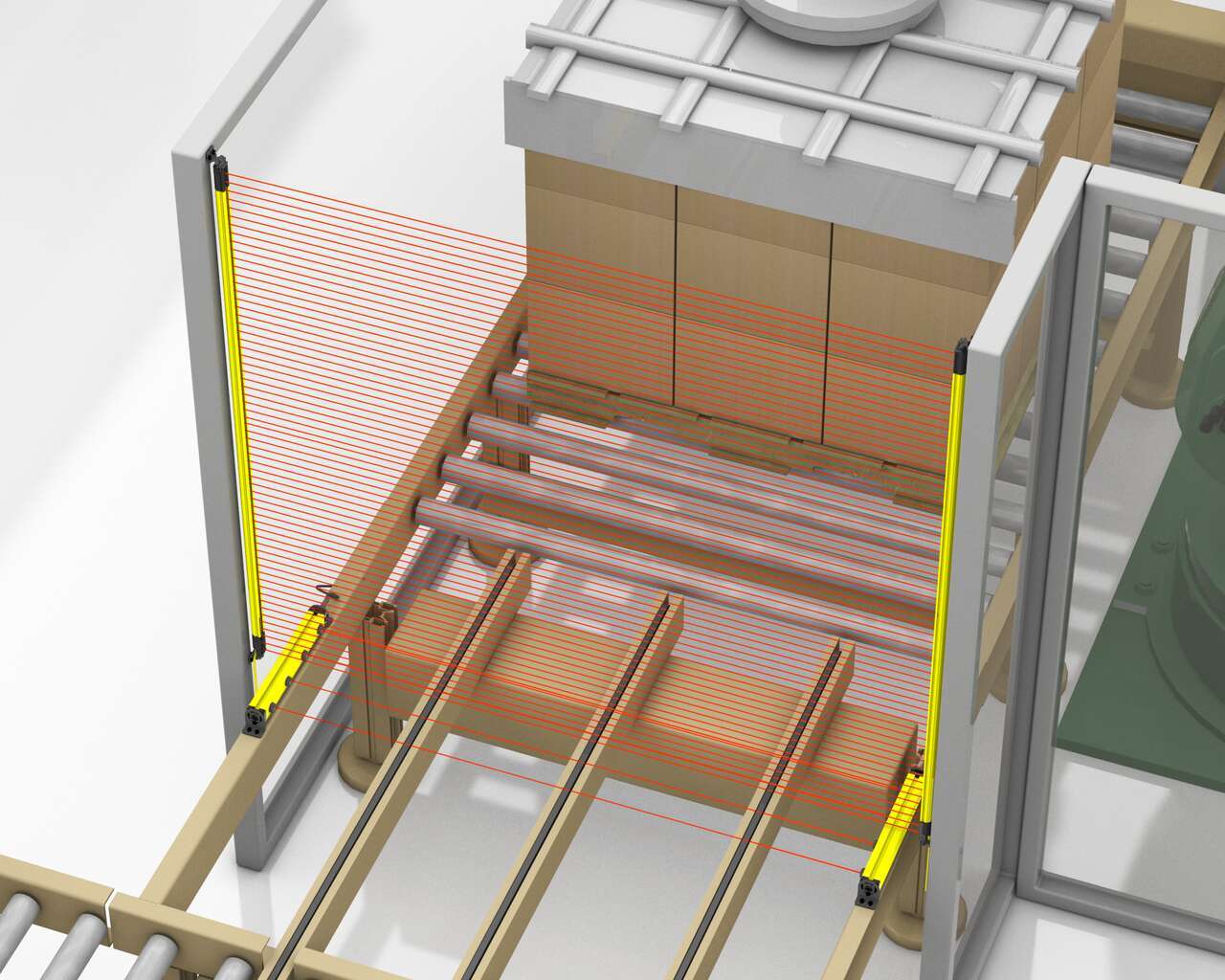

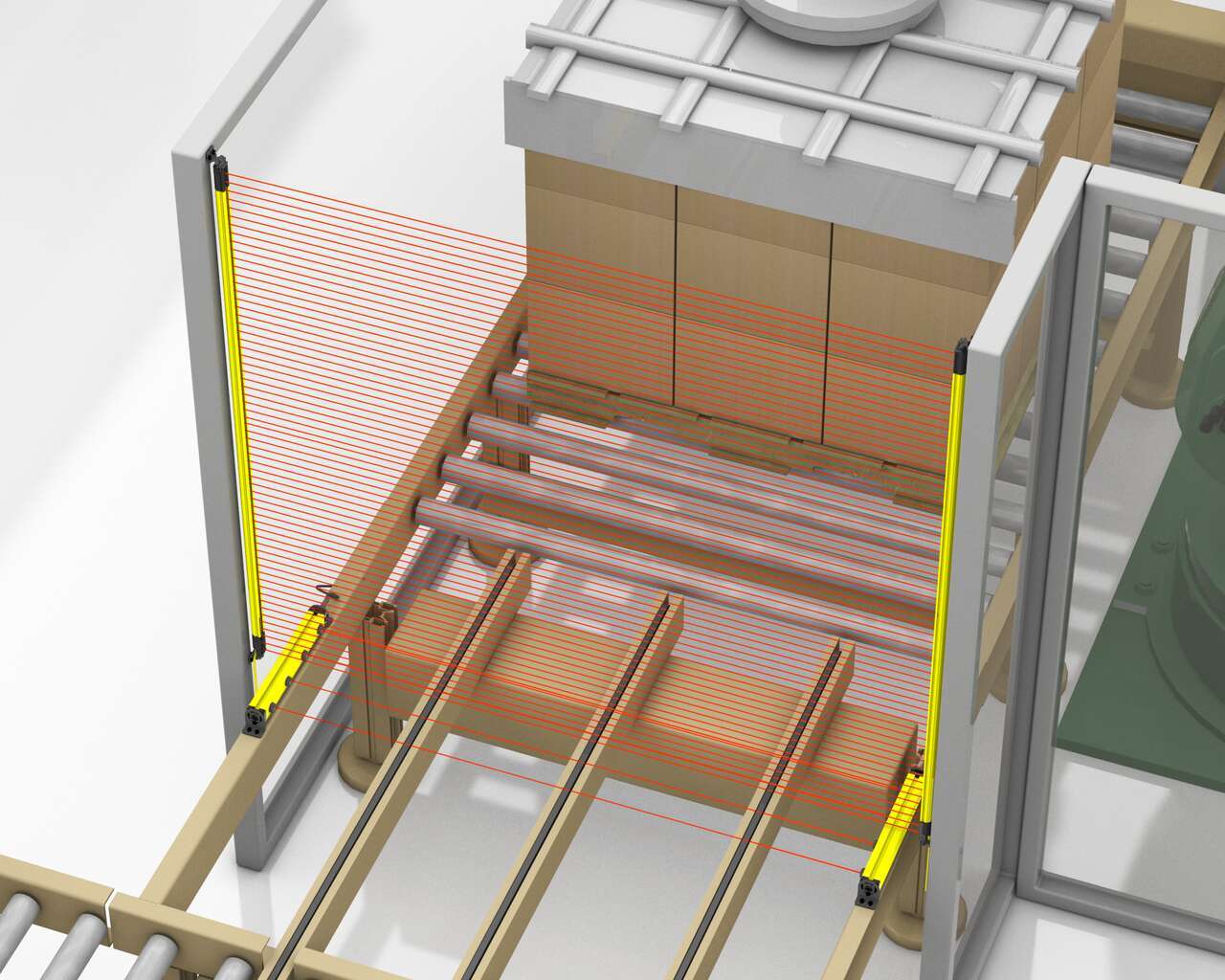

Depalletizer Guarding with Muting

LS light curtains are intuitive, easy-to-use safety devices used for machine safeguarding. They are built to withstand challenges commonly found in manufacturing and packaging environments.

LS-S models require no PC software, DIP switches, or other devices for quick, easy configuration. Highly visible alignment indicators and intuitive diagnostics simplify setup, facilitate troubleshooting, and minimize system downtime.

Learn More

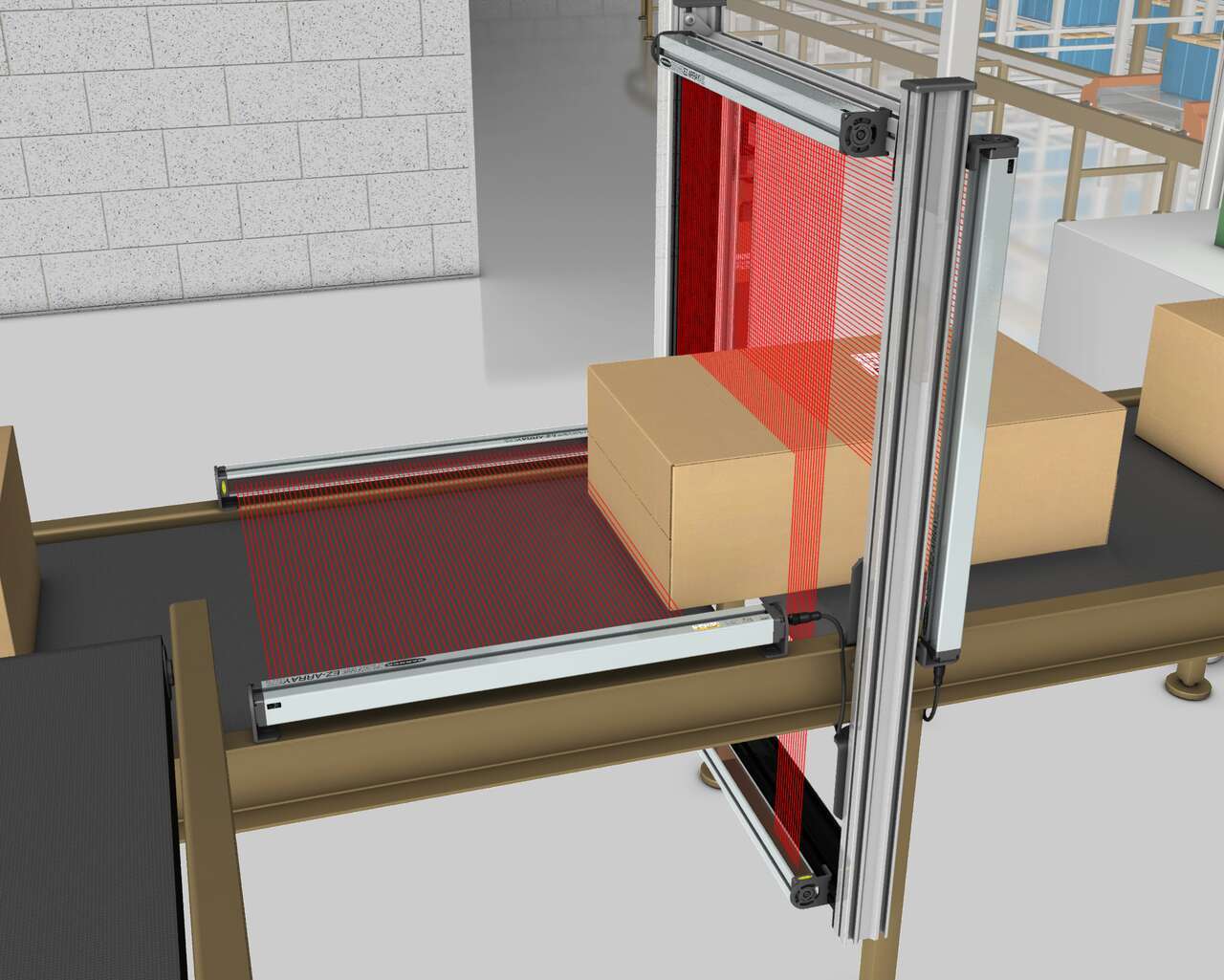

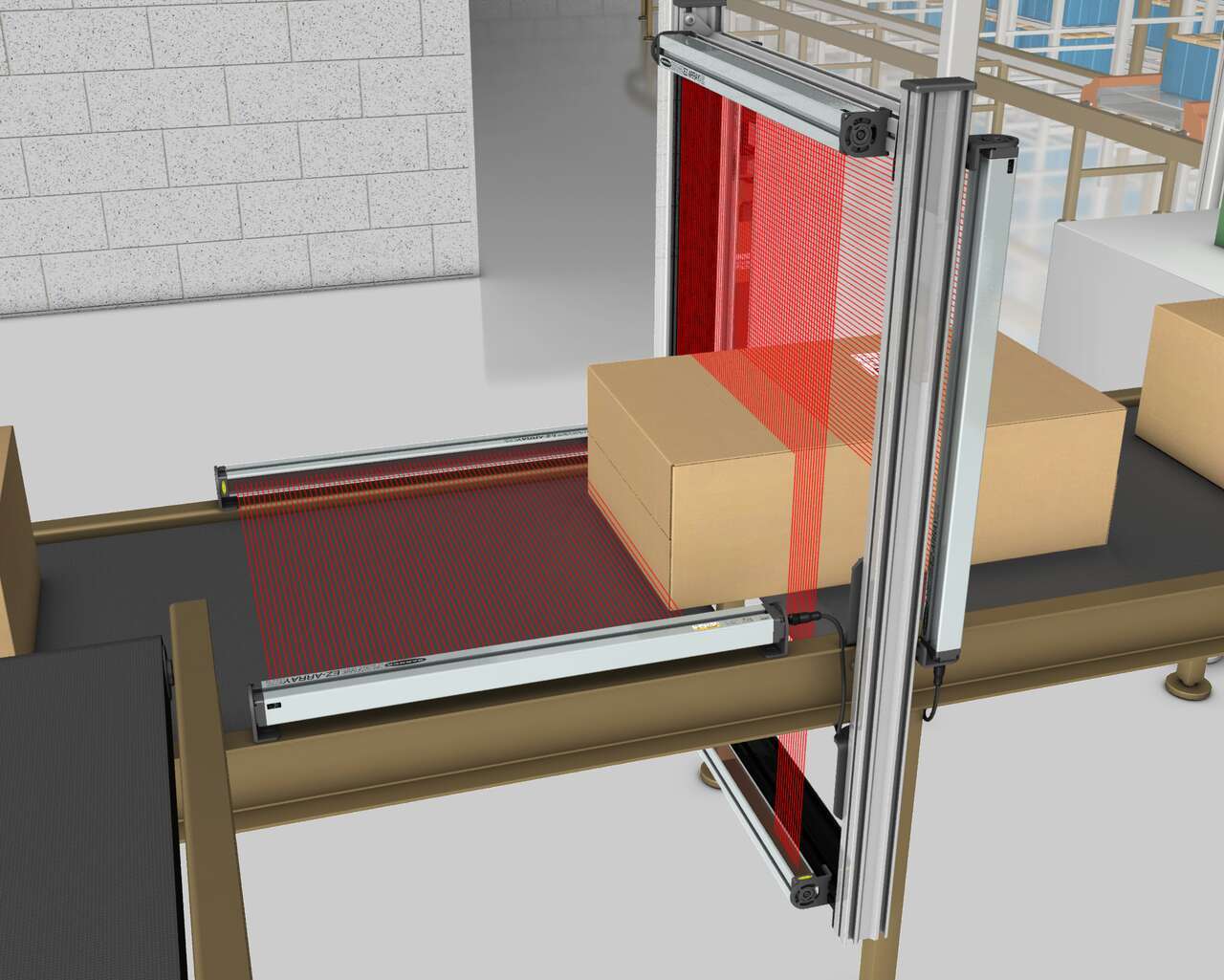

Banner’s EZ-ARRAY measuring light curtains detect items as small as 5 mm wide with an edge resolution of 2.5 mm, and have high excess gain for detecting opaque objects. These features allow for reliable detection and measurement of packages that pass through the light curtains.

The total number of beams blocked for each pair indicates the size, which is sent to a sorter as an analog signal. A PLC then diverts each carton to the appropriate storage location.

Learn More

6

Tracking of Received Goods

Banner’s TCNM linear barcode scanner quickly and easily detects up to 10 linear barcodes on packages, helping maintain accountability and an efficient flow of packages throughout a distribution center.

The TCNM linear barcode scanner is ready to scan right out of the box with SMART TEACH, providing scan rates of 500 to 1,000 scans per second. The linear barcode scanner can read barcodes in ranges from 40 to 600 mm.

Learn More

The Q20 WORLD-BEAM Polarized Retro sensors are mounted on the rails of the multishuttles, to confirm that product stays within the safety zone and confirms a product is positioned correctly to avoid hanging off the “safe zone.”

Q20 sensors are cost effective and accurately detect presence and placement, making them ideal for a warehouse environment. The compact size and ease of installation make the Q20 a robust product for these applications.

The Q20 sensors have a distance range up to 4 m and the sensor functionality of noise immunity and cross-talk avoidance allows the operator to test the system before use.

Learn More

8

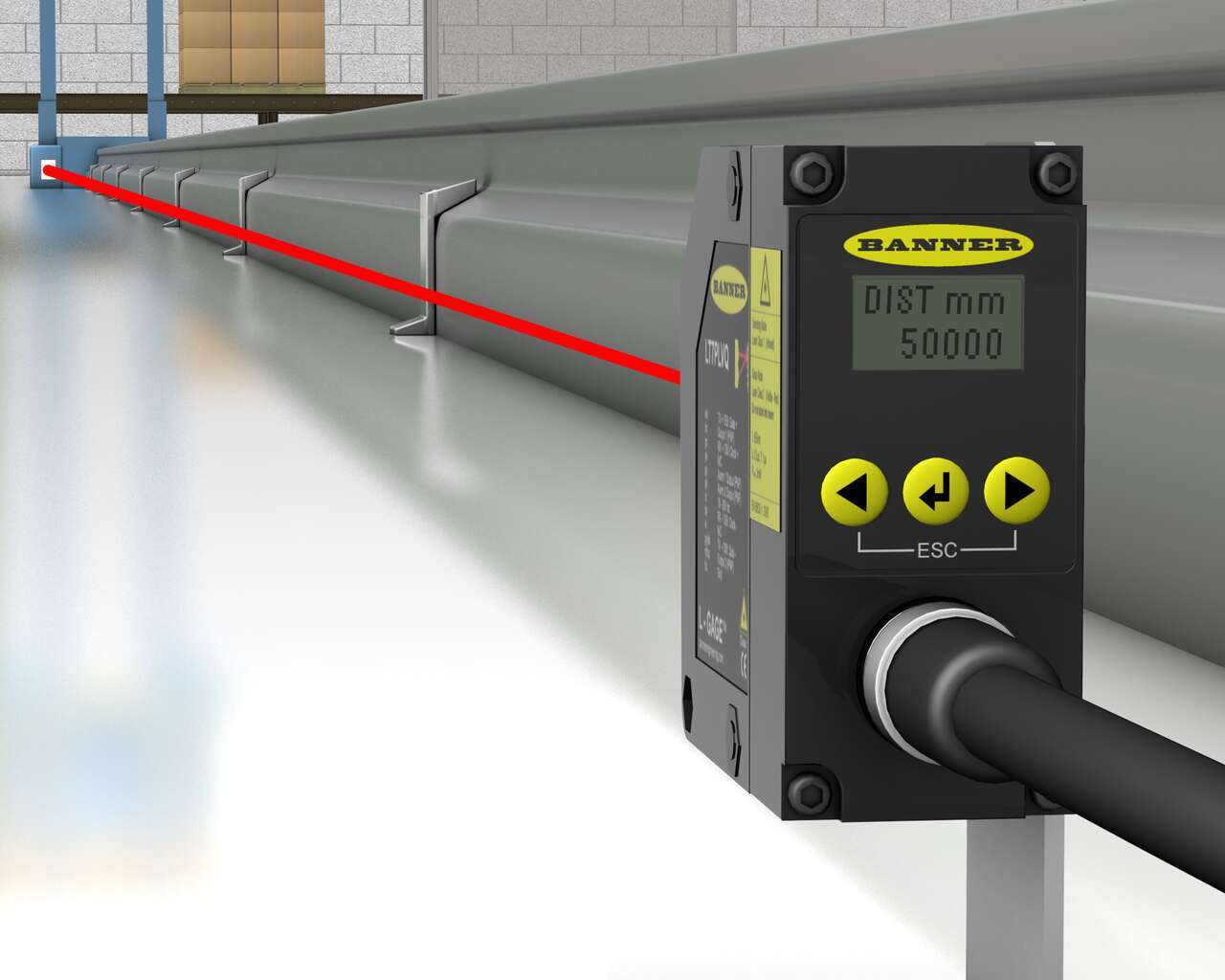

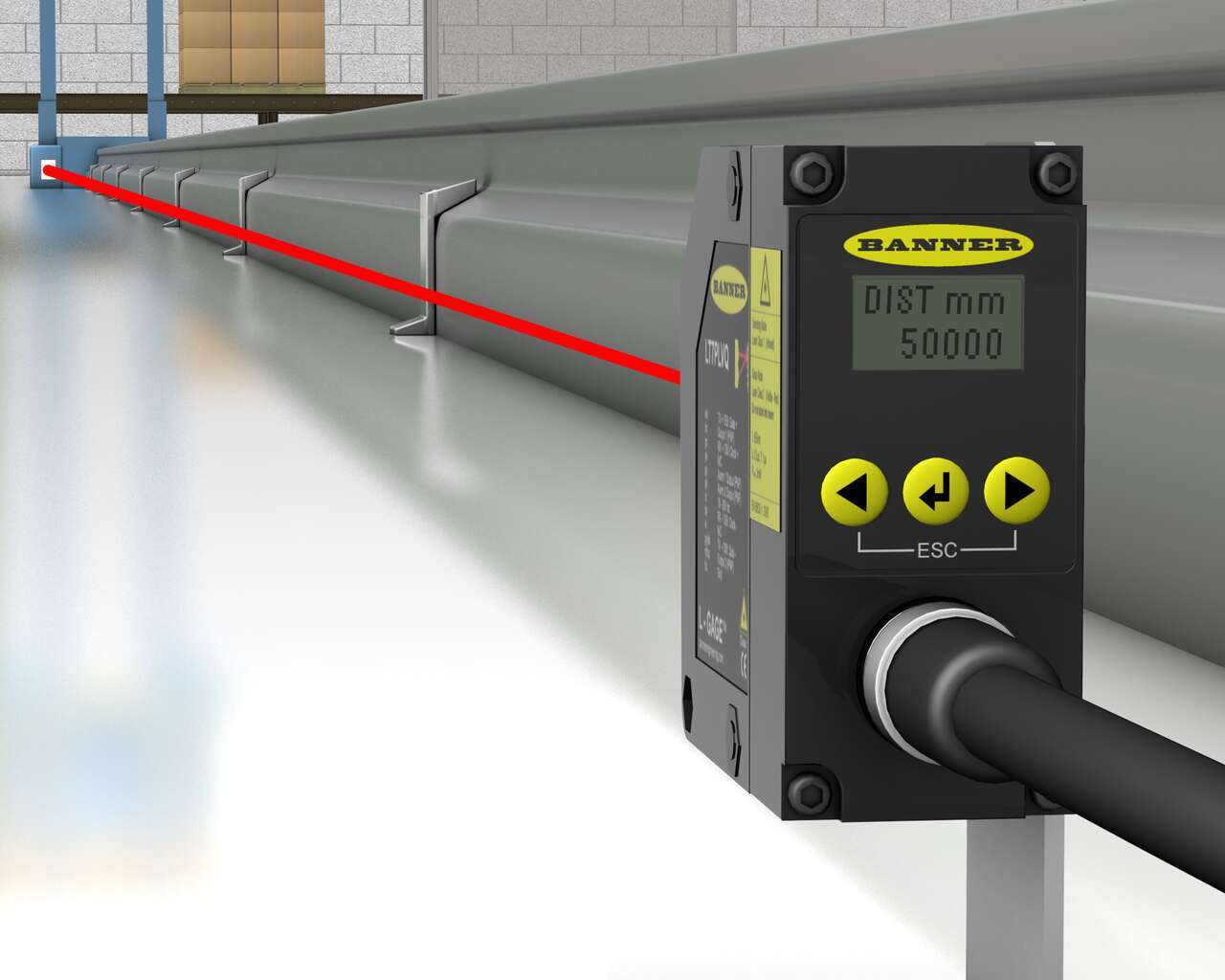

Stacker Crane Positioning

Banner’s time-of-flight LT7 laser sensors provide long-distance ranges up to 250 m with a visible red laser spot for easy alignment.

Depending on range needed, a diffuse or retroreflective time-of-flight laser sensor can be used. Retroreflective LT7 laser sensors provide ranges up to 250 m and diffuse LT7 laser sensors provide long-range background suppression up to 10 m.

Learn More

9

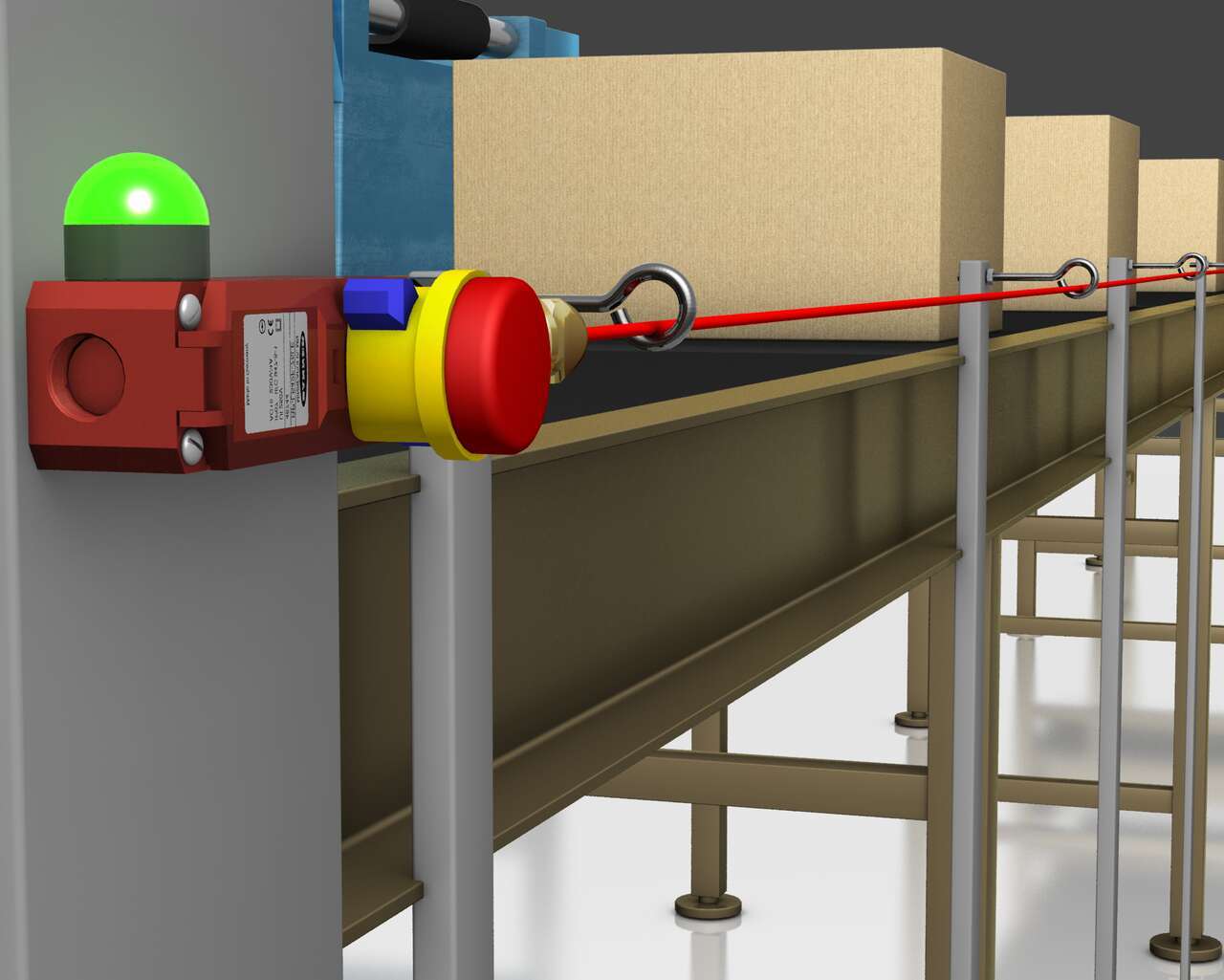

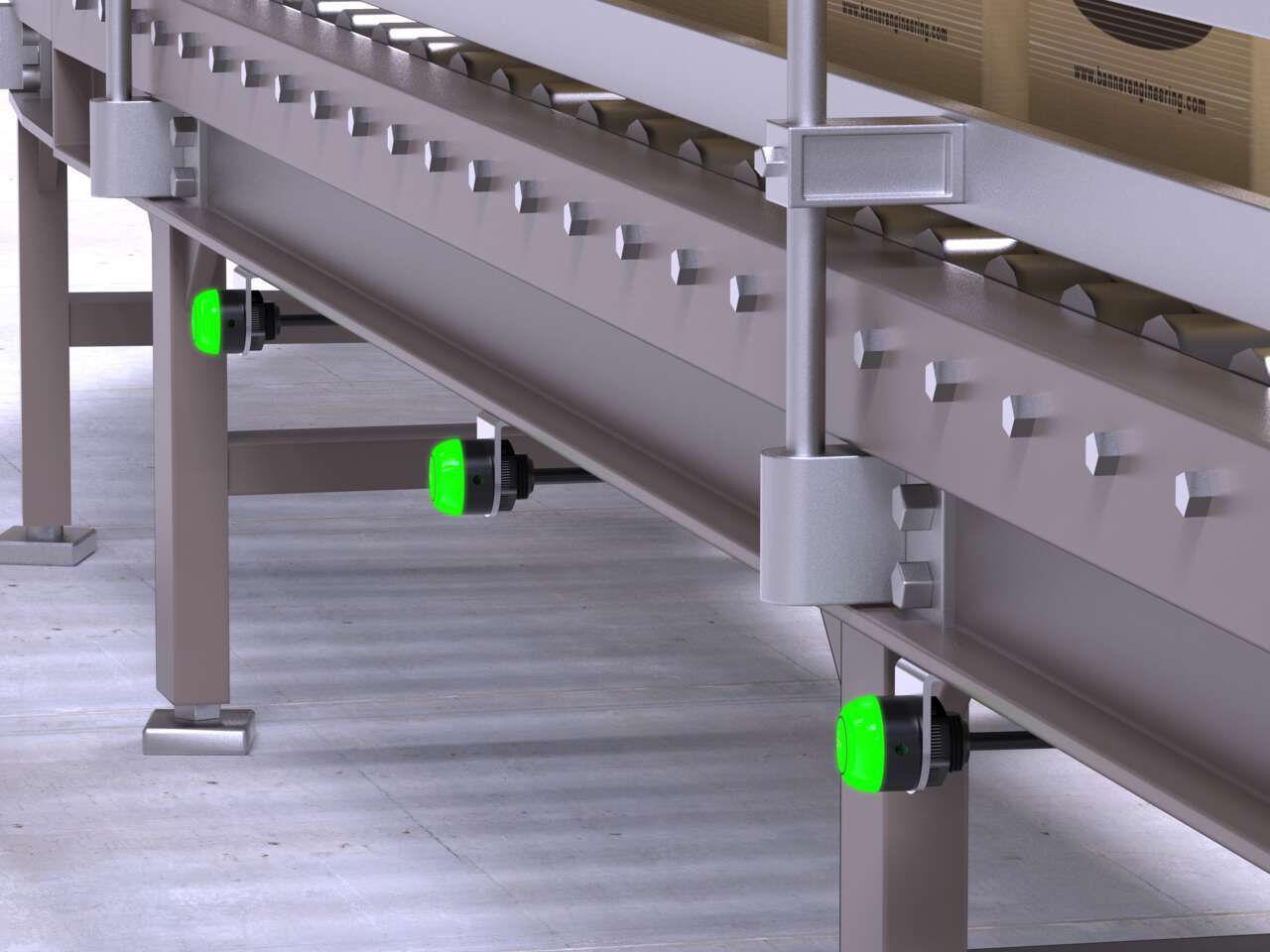

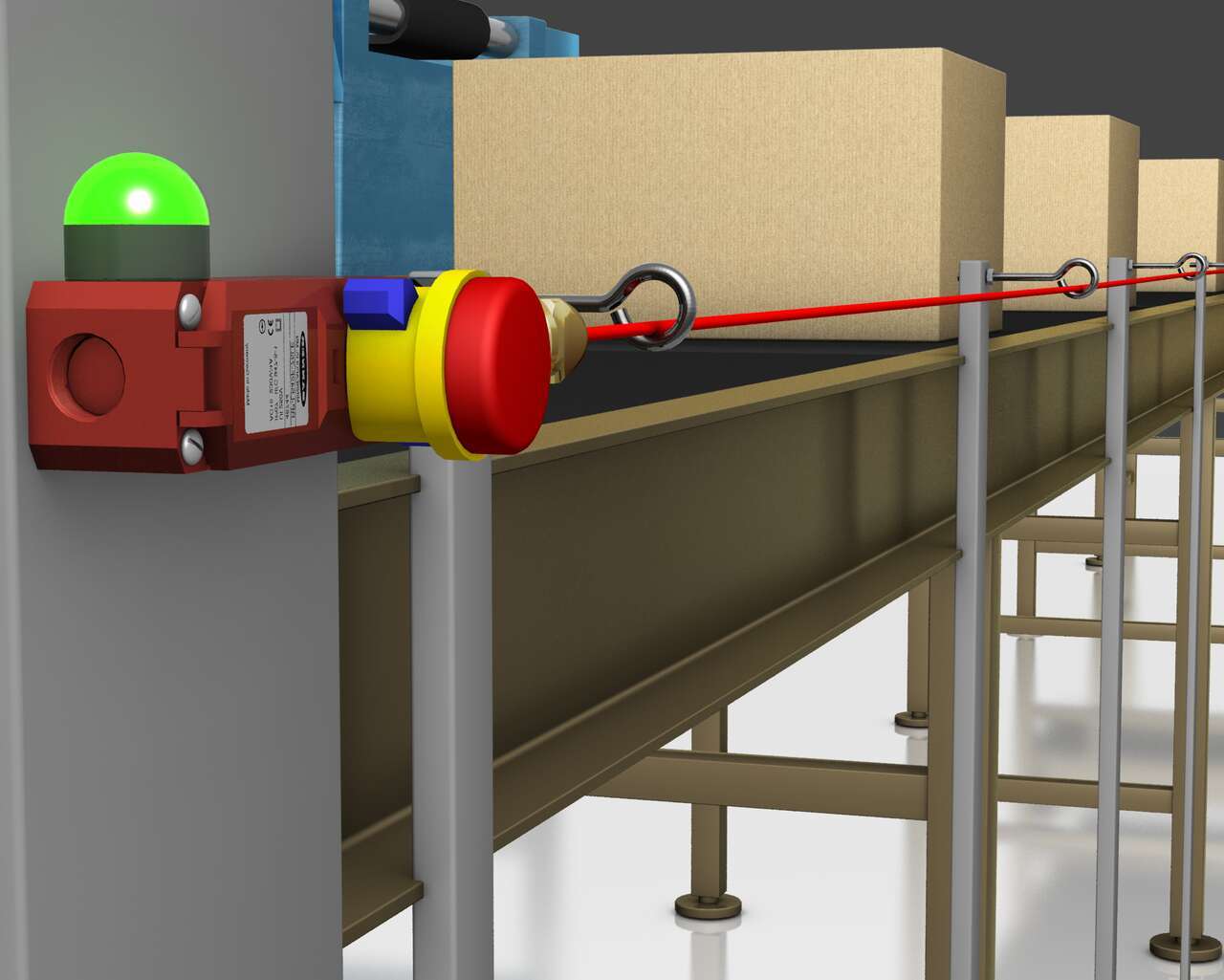

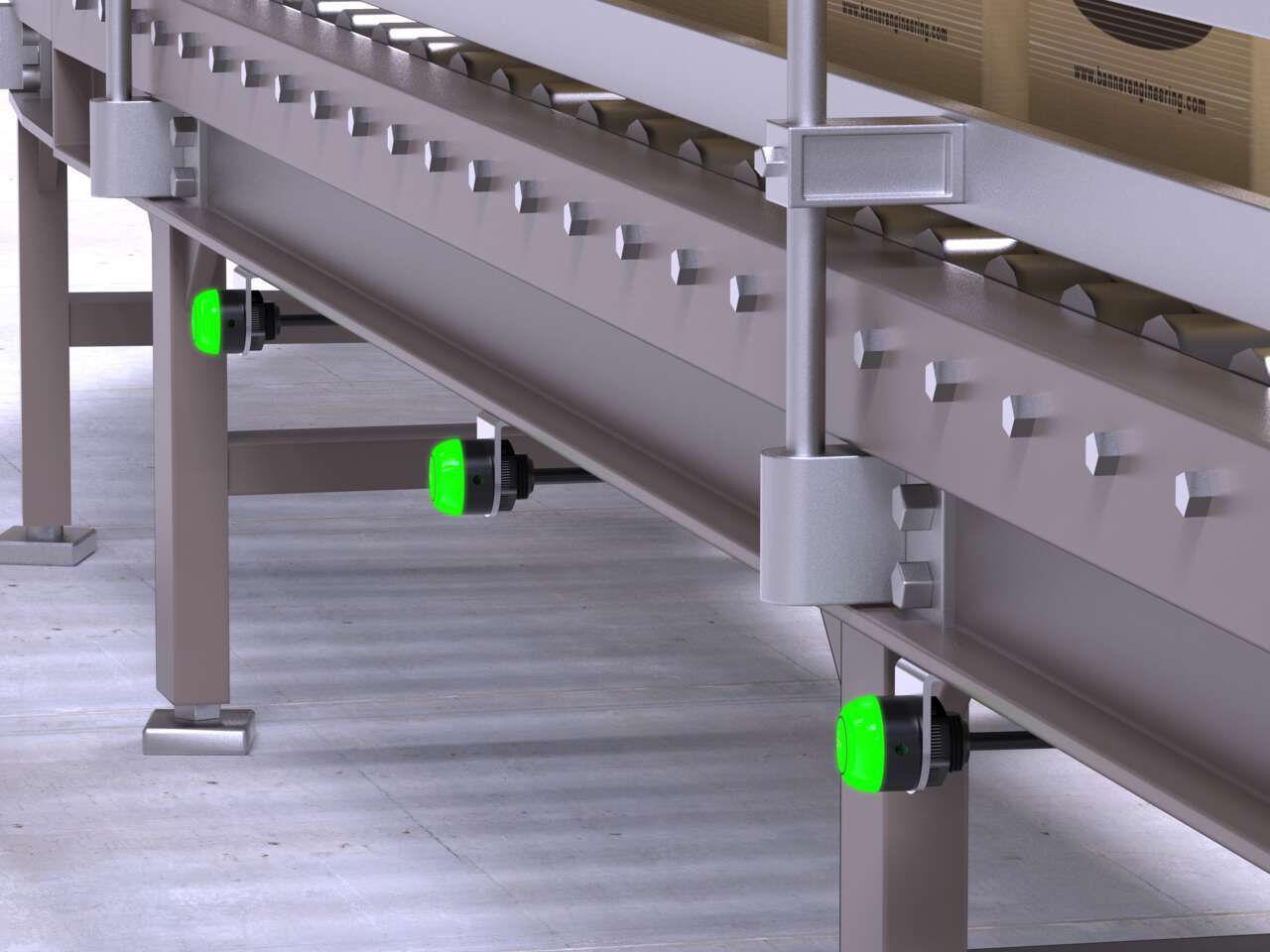

Emergency Indication on Conveyors

Banner’s RP-LS42 safety rope pulls line conveyors as a way to indicate emergencies and immediately shut down conveyors. If a rope pull is used during an emergency, it can be difficult to locate exactly where it was pulled.

A K30 indicator light can be paired with the rope pulls in order to provide indication as to where the rope was pulled. This allows for quick and easy indication of where an emergency occurred, helping to return to normal operations as fast as possible.

Learn More

10

Sortation Auto Induction Station

S18-2 retroreflective sensors provide long-range, effective sensing along an auto-induct conveyor station. Polarized sensors can help with shiny surfaces by reducing false triggers.

The S18-2 retroreflective sensors are cost-effective sensors with a barrel mount style, making them easy to install along a conveyor for verification purposes and are available in retroreflective, thur-beam, diffuse or fixed-field models.

Learn More

11

Presence and Absence Item Detection

A VE Series Smart Camera, is an ideal solution to be able to detection the presence or absence of an object. The camera comes in a 5MP resolution giving a precise detection of objects. The VE reduces costly downtime facilitating fast product changeover. With its robust metal housing and optional lens covers the VE can be used in harsh environments where heat, vibration and moisture exist.

Learn More

12

Exit Chute Jam Indication

Banner’s Q30FF600 background suppression sensor confirms when a product enters the exit chute to ensure it came off the sortation system and that there isn’t a jam in the product chute. The Q30FF600 has long range sensing up to 600 mm, which is the standard width of many chutes.

Learn More

13

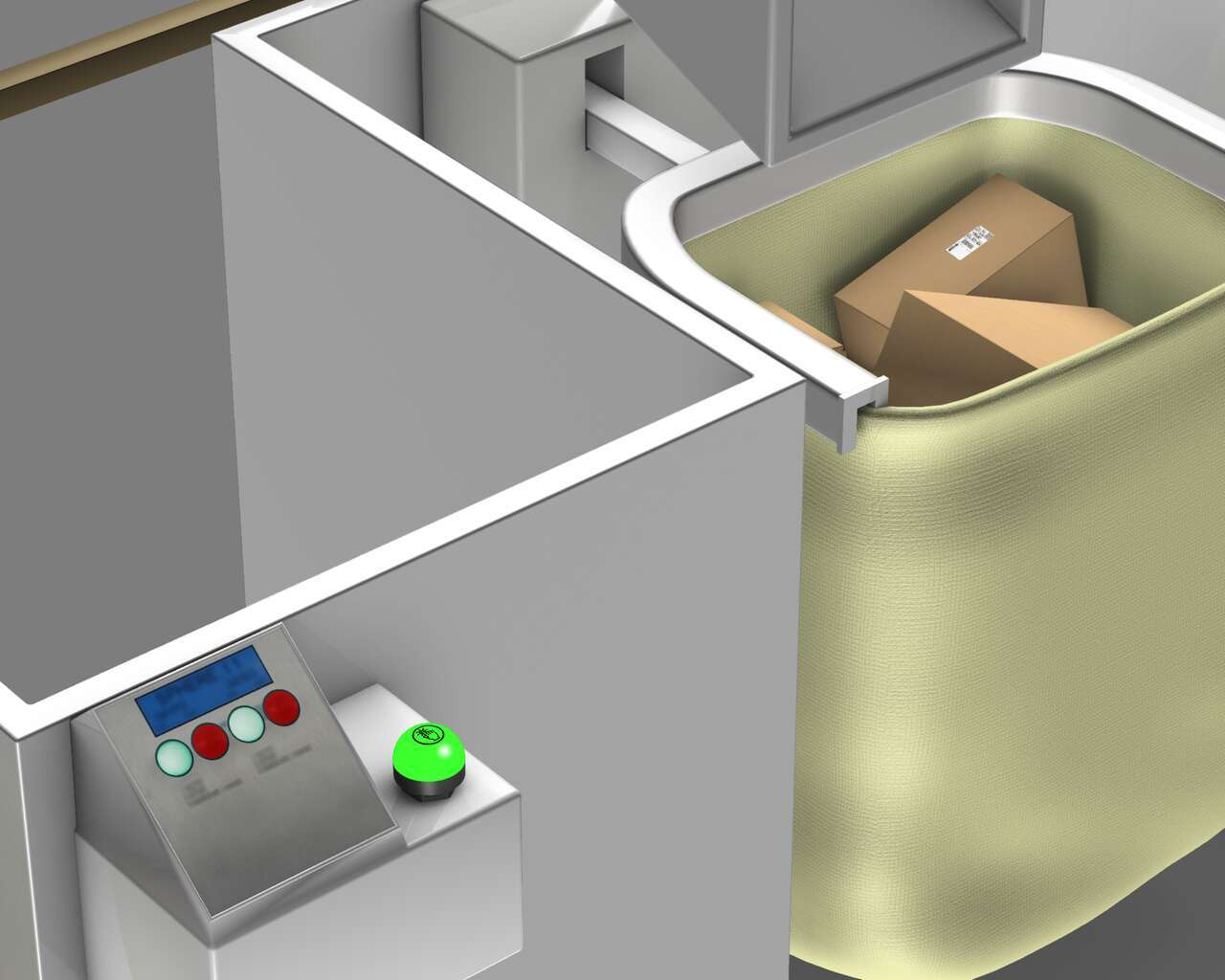

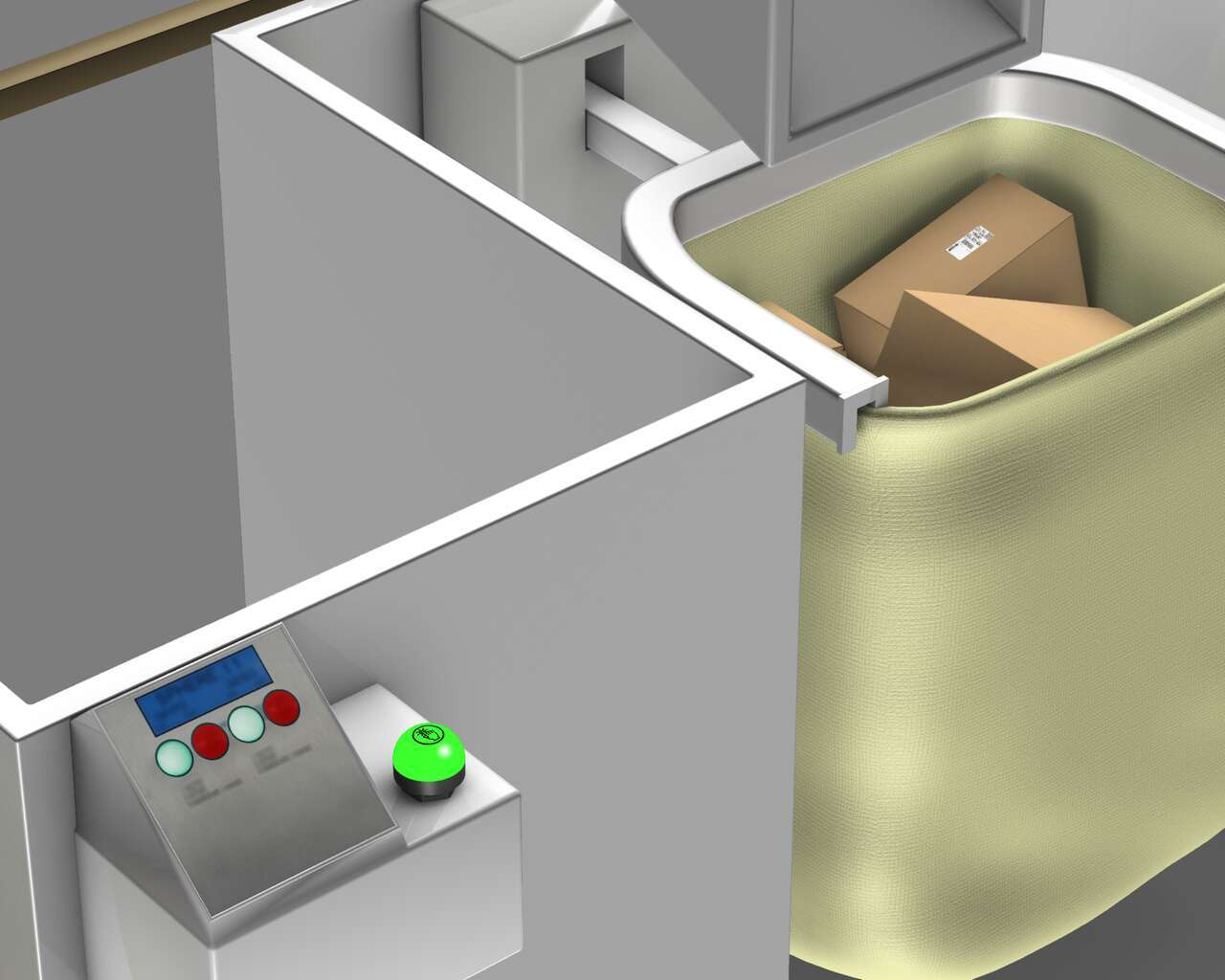

Full Tote Indication and Verification

In order to properly identify and use visual management, a sensor is triggered when the bag is full and then sends a signal to a K50 touch button to light red, which represents a full tote.

The K50 touch visually shows operators the bag needs to be removed and changed with an empty one. In order to show the bag is ready for more packages, the operator presses the ergonomic K50 touch button, changing it back to green to show the bag is ready for more packages.

Learn More

14

Wireless Forklift Signaling

Banner’s Q45 wireless call sensor communicates to a wireless DX80, signaling that forklift drivers can remove the completed pallet for shipping. This helps keep the conveyor clear, keep it moving faster and leads to more productivity. Since forklift drivers are being called to action more quickly, it allows for more productivity.

Learn More

ABR Series barcode readers can be used to solve track and trace applications, offering increased resolution to read smaller codes, over a larger target area, and at greater distances. Polarization is now available in both 1.3 MP and 2 MP ABR 7000 models for improved performance on targets with reflective surfaces or where glare is present.

Our highest resolution camera, the VE is also available in only-barcode reading models, as well as the original vision camera-only model. This makes our VE series is the highest-resolution barcode reader in our portfolio, designed to better solve complex applications.

Learn More

16

Plastic Roll Diameter Measurement

Banner’s LE550 is factory configured with a range of 100 to 1000 mm and can start measuring immediately. If the range needs to be adjusted, the laser sensor has an intuitive user interface with a two-line, eight-character display, making it easy to automatically or manually adjust settings. The LE550 provides repeatability and accuracy across challenging targets, from metal to black rubber, allows for reliable measurement of the shrink wrap.

Learn More

17

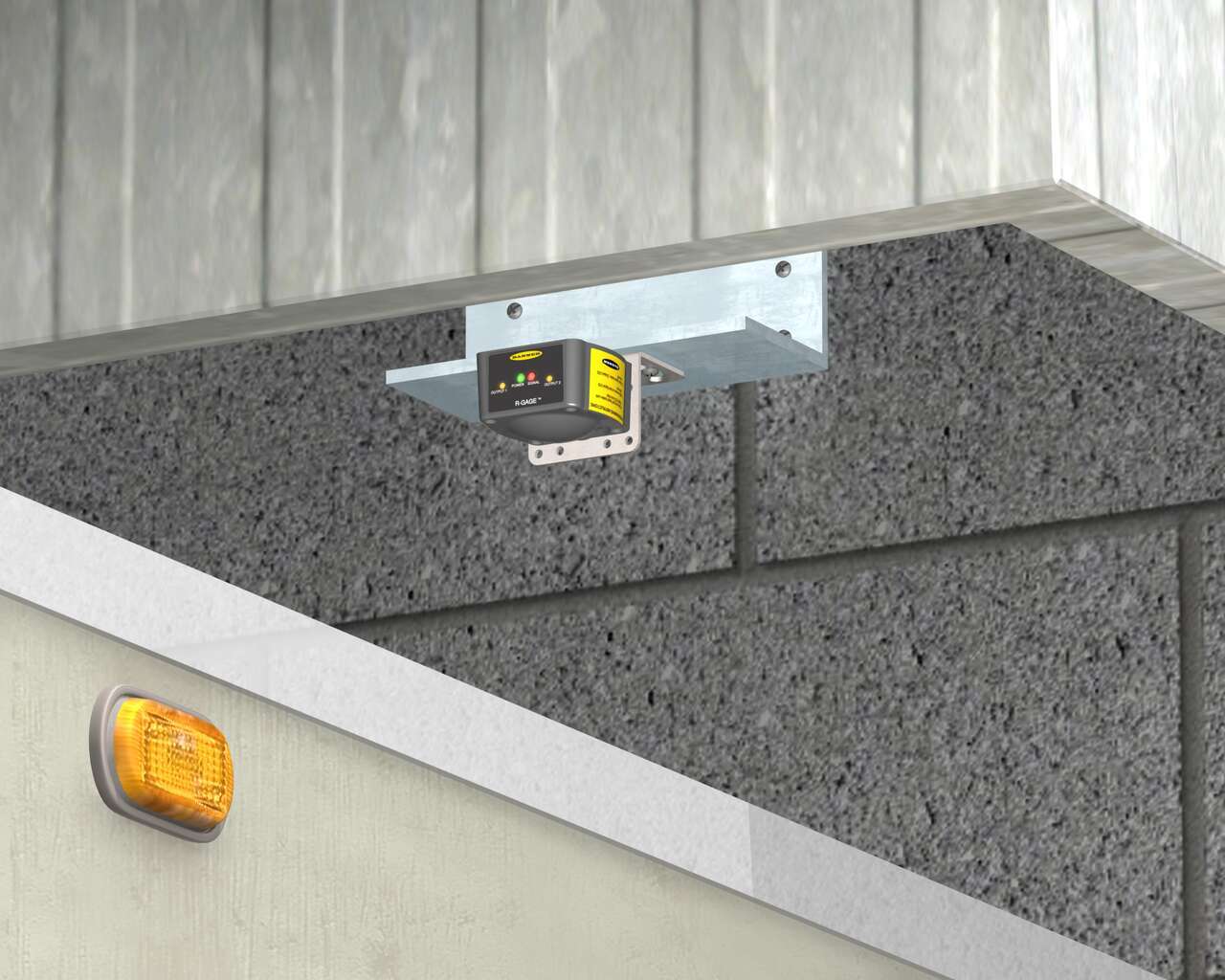

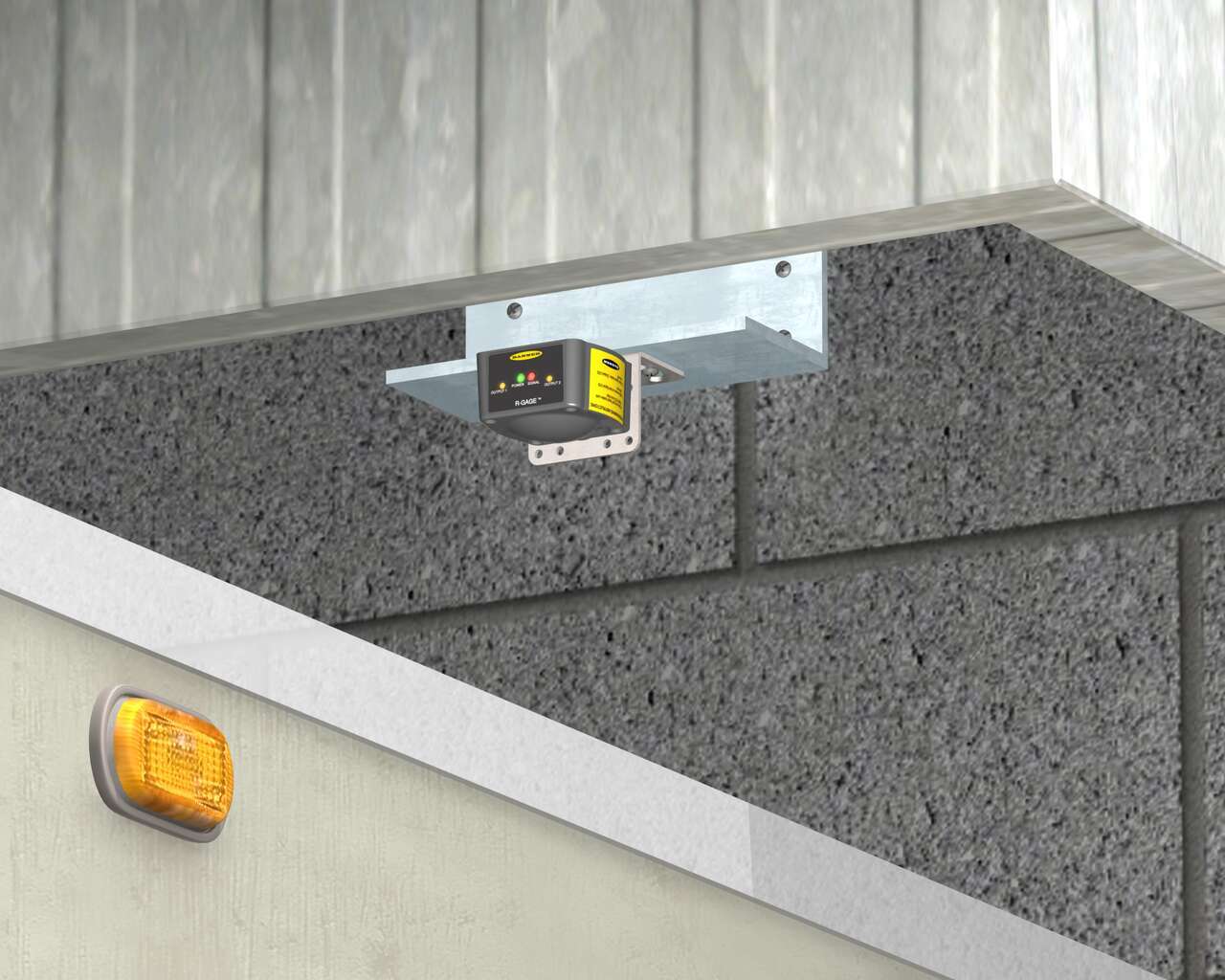

Vehicle Detection at Loading Docks

Vehicle detection at a loading dock can be used to identify available bays, facilitate fast load and unload times, verify vehicles are in the correct position before opening doors, and more.

Learn More

18

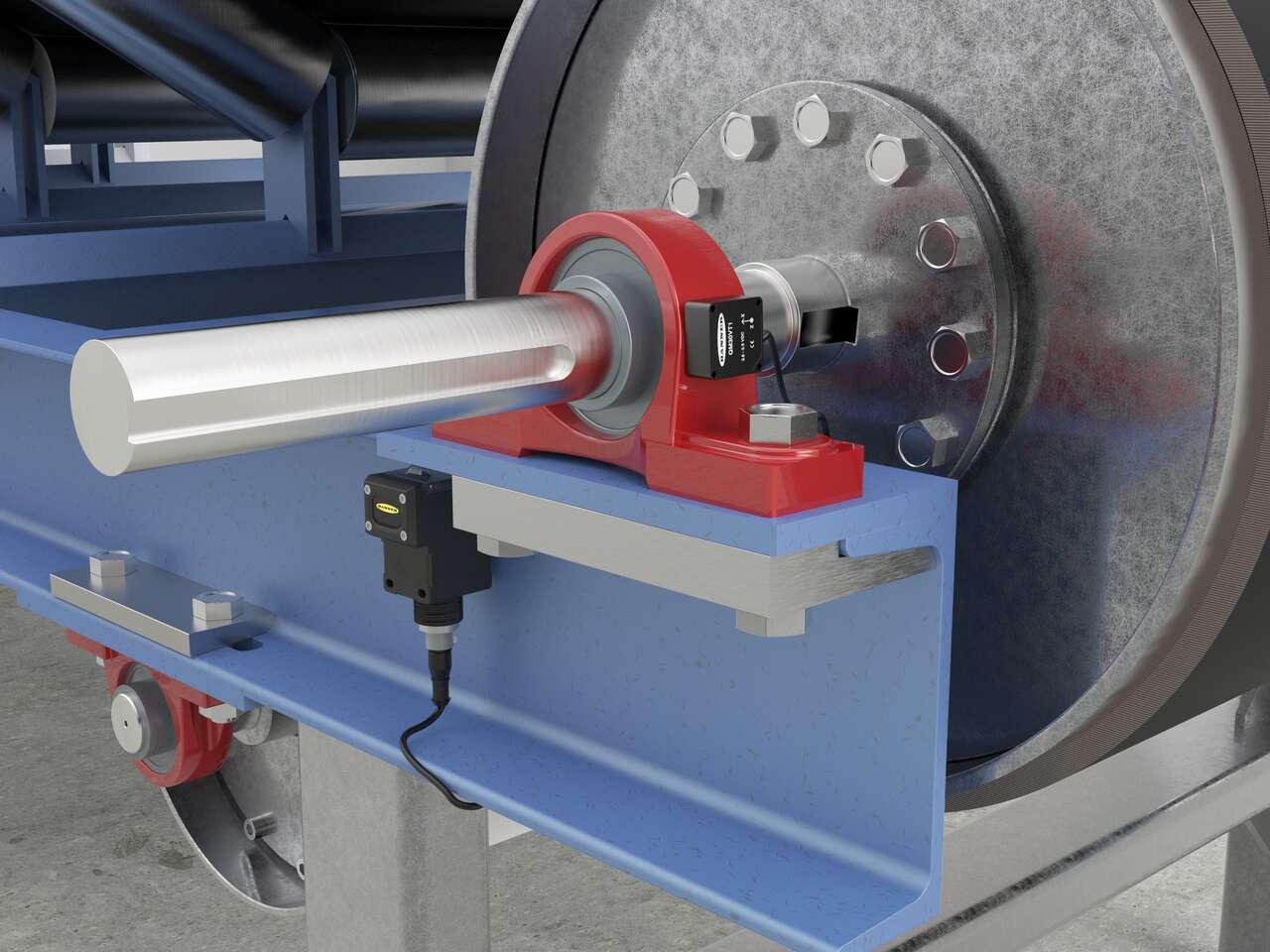

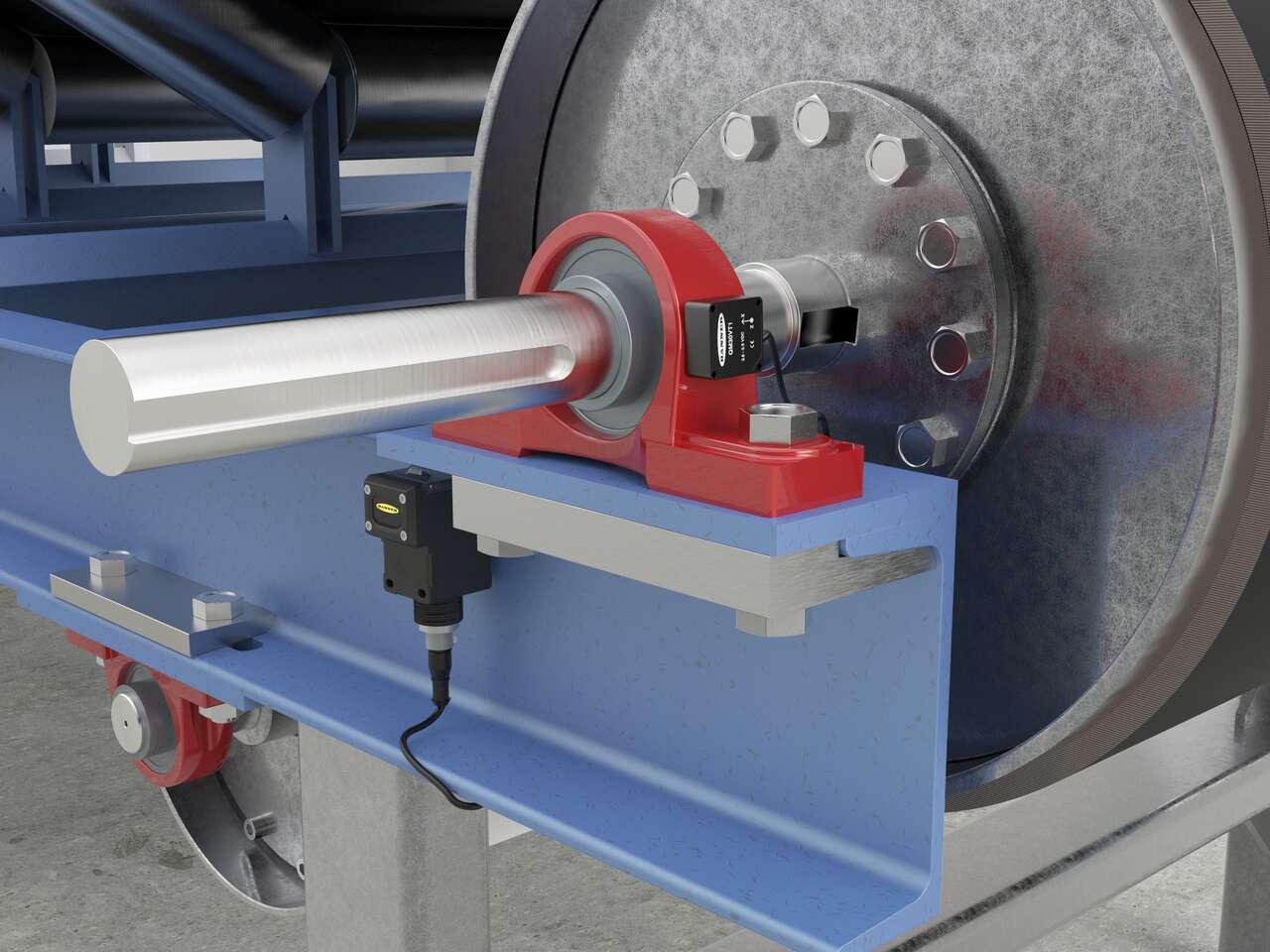

Condition Monitoring on Conveyors

Banner’s wireless solutions can have multiple gateways tied to respective nodes, allowing for elimination of all wires and providing flexible mounting options. The wireless structure of gateways and nodes are responsible for communicating the critical I/O throughout the facility.

Even with multiple wireless products, the wireless communication system is efficient and has no cross talk interference and does not interfere with the IT department.

Learn More

19

Operator Indication on Conveyor Systems

Learn how a facility used the K30 Pro Touch Button to improve operator control and guidance.

Learn More

20

Retrofitting for Pallet Detection

Banner’s Q76E retroreflective sensor uses a wide vertical beam. The beam from a single Q76E crosses the path of the conveyor horizontally to a corresponding reflector, which delivers light back to the sensor. This provides superior detection for any leading edge that interrupts the beam, at any angle, which makes it ideal for retrofitting conveyor systems to reliably identify the presence or absence of palleted items.

Learn More

21

Inbound and Outbound Status Indication at Loading Dock

In a recent material handling application, facility managers needed to find a solution that would alert them to the status of trailer capacity at loading dock doors in real-time.

Learn More