Error-Proofing Assembly Applications

Application: Error-proof picking stations

Challenges: Indication needs to be easy to use and easily seen

Solution: EZ-LIGHT K50 Optical Pick-to-Light Series

Benefits: Bright LED lights with simple installation

To improve efficiency and accuracy in assembly applications, it’s important for the assembler to be able to quickly and easily identify the next pick location. A pick-to-light solution is needed that will clearly identify the correct bin for the assembler to pick from, detect that the pick has been made, and then notify the assembler of the location of the next pick.

Description

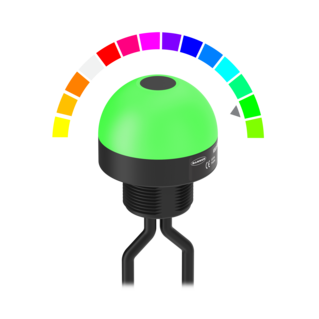

Banner Engineering’s K50 Series of single-point pick-to-light sensors are a simple, easy-to-use error-proofing solution in assembly applications. In this application, the job light is Green while the job input is active, indicating the correct bin for the next pick. The presence of the assembler’s hand initiates an output change of state, turning the job light red. The job light above the next pick location will then turn Green. The K50 sensors will efficiently guide the assembler and will reduce errors in the assembly process.

The large 50 mm translucent domes of K50 Series single-point pick-to-light sensors house highly visible LEDs for clear indication. They are available in fixed-field background suppression models for tight mounting areas, or polarized retroreflective models with an extended 2 m sensing range to meet a variety of application needs. The rugged design assures long lasting operation, and numerous mounting options make these sensors a versatile error-proofing solution.