Power Logic and Motion from a Single L-Code Line

Challenge

A conveyor section that previously ran continuously now needs to respond to product detection, upstream system logic, or sensor input. To enable that control, a DXMR90 is added to manage an R50C Motor-Driven Roller Controller (MDR) at that location. The MDR runs on 16-amp L-code power already available along the conveyor. The DXMR90 needs 4-amp A-code power, but there's no A-code available at that location, and pulling a new line would add cost, wiring complexity, and installation time. The challenge is how to power both the R50C MDR and the DXMR90 at the same point—using the existing L-code run—without changing the system layout or adding hardware to the cabinet.

Solution

The R50 M12 Power Splitter solves this integration problem by providing both L-code passthrough and A-code power breakout from a single device. Installed directly in the L-code line, it delivers 16-amp power downstream to daisy-chained R50C MDRs without interruption, while simultaneously providing two 4-amp A-code power drops—one of which powers the DXMR90. No modifications to the panel are required, and no separate A-code line or external splitter hardware is needed. The R50 M12 Power Splitter replaces loose splitter cables and junction blocks with a single, integrated device—installed directly in the existing L-code line. This allows smarter, event-based activation of motor-driven rollers, saving power, reducing wear, and extending equipment life.

Featured Products

-

R50C Motor-Driven Roller Controller

Banner’s compact, rugged, R50C MDR Controller provides precision control and configuration that easily integrates into motor driven roller systems.

-

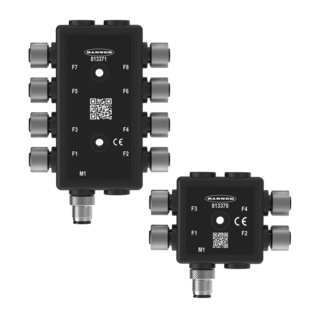

Side Exit

Molded Junction Blocks easily consolidate wires from different sources into one convenient, customized central hub. They can be installed in extremely wet, dusty, hot, or cold environments by virtue of their compact, overmolded design.