All Agriculture Solutions

-

Frost Protection and Soil Moisture Control in Cranberry Bogs

Frost Protection and Soil Moisture Control in Cranberry Bogs

Soil moisture and air temperature sensing ranges are typically under a mile, but the Site Survey tested the signal out to two miles. With the MultiHop Radio and its antenna installed very low to the ground, the Master Radio was installed with a large omnidirectional antenna to maximize the communication range.

-

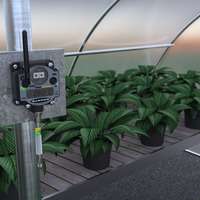

Greenhouse Temperature and Humidity Monitoring

Greenhouse Temperature and Humidity Monitoring

A Sure Cross FlexPower™ Node with internal battery directly connected to a temperature and humidity sensor can provide these measurements without costly conduit or cabling, eliminating the need to manually collect data from multiple sensor locations. IP67 electronics and a variety of filter options make this product suited for the wide temperature and humidity ranges encountered in a greenhouse.

-

Refrigeration System Monitoring with a Wireless Network

Refrigeration System Monitoring with a Wireless Network

A resistance temperature detector senses the temperature of a walk-in cooler and sends the data to a SureCross FlexPower Node. The Node in turn sends that data to a Gateway, which issues an alarm to management if the temperature exceeds acceptable limits. The DX80 FlexPower Nodes have a IP67 rating for rugged environments and work well in the cold.

-

Monitoring Temperature During Composting

Monitoring Temperature During Composting

Manual data collection is eliminated using a SureCross FlexPower™ Node equipped with two thermocouples to automatically monitor the temperature at two depths within a compost windrow or stack.

-

Monitor Leaks in Your Critical Applications

Monitor Leaks in Your Critical Applications

Monitor leaks in your critical applications and receive real time alerts when they occur.

-

Bring In IO-link Sensor Data for Tank Level Applications Wirelessly

Bring In IO-link Sensor Data for Tank Level Applications Wirelessly

Wirelessly integrate IO-link sensor data for tank level monitoring with Banner's DXM controllers and T30R sensors for accurate, remote data analysis.

-

Fill Level of Dry Material in a Hopper

Fill Level of Dry Material in a Hopper

An L-GAGE LT3 laser distance-gauging sensor, mounted above the hopper, measures the distance to the material's irregular surface, enabling a PLC to calculate the bin’s fill level.

-

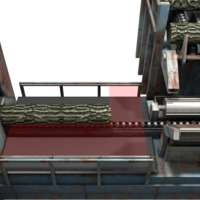

Log Measurement

Log Measurement

In this application, an EZ-ARRAY measuring light screen is being used to measure the length of the log. The EZ-ARRAY determines the total number of beams that are blocked by the log and communicates the length of the log to an operator station by sending the information to the system controller in the form of a MODBUS RTU-485 output. The operator station controller then provides a number of options to the operator, who selects which cuts are made.

-

High-Speed Soybean Counting

High-Speed Soybean Counting

To solve this application, Banner Engineering has paired the technology of the D10D Expert with fiber optic arrays optimized for small object counting to create the D10 Expert Small Object Counter. The preconfigured fiber optic arrays of the Small Object Counter make alignment and object positioning control less critical than when using single point emitter and receiver fiber optic assemblies. This assures reliable, consistent small object counting.

-

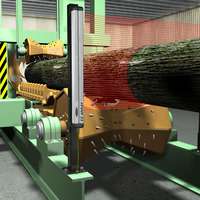

Debarking Control

Debarking Control

As a log moves toward the debarker, an EZ‑ARRAY receiver determines the total number of beams that are blocked. It sends an analog signal to the debarking station logic controller, which determines the diameter of the log and adjusts the log grippers and debarking blades to the log’s size. Accurately determining the log's size provides process stability and prevents damage to the debarking machine.