Automotive: Press Shop & Stamping Solutions

-

Industrial Barcode Verification on Clear Labels

Industrial Barcode Verification on Clear Labels

An iVu BCR with UV ring light is an ideal solution for detecting barcodes in a low contrast situation. The iVu is coupled with UV illumination for an all-in-one solution that improves contrast on clear labels so bar codes are easily detected.

-

Vision Sensor to Read QR Codes

Vision Sensor to Read QR Codes

iVu Plus BCR Gen 2 with 25 mm Micro Lens replaces hand held barcode readers to collect data from dense, difficult-to-read QR codes on vehicle transmissions. A WL50S high-intensity LED spot light illuminates the target area.

-

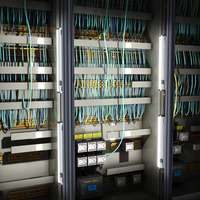

LED Lights Illuminate Control Cabinet

LED Lights Illuminate Control Cabinet

Operators access machine systems through the control cabinet and need Intense illumination of the cabinet facilitates for maintenance and management.

-

Superior Light Distribution with LEDs

Superior Light Distribution with LEDs

American Hoffmann Corporation chose WLB32 LED light bars to illuminate work areas, enclosures and control cabinets, replacing fluorescent light fixtures. The superior light distribution offered by the WLB32 LED lights lights, as well as the ease of installation were key factors in the company's decision.

-

Sheet Metal Thickness Measurement

Sheet Metal Thickness Measurement

Precise and consistent sensing while material moves down a conveyor measuring thickness at micron levels.

-

Multiple Point Inspection on Stamped Metal Parts

Multiple Point Inspection on Stamped Metal Parts

To verify the expected number of holes exists on a small metal part, the iVu Plus TG Image Sensor with Multipoint Inspections can be configured for multiple regions of interest (ROIs) to ensure holes exist and were punched in the correct place. When set up for area inspection, the iVu will scan multiple points on the stamped part to verify the presence or absence of a feature or features of interest.

-

Detecting Parts Ejected from Die

Detecting Parts Ejected from Die

In the manufacturer's facility, operators manually insert and remove metal parts from the die press. When complete, the parts are sent into a bin via a metal chute. In order to prevent die crash (having double parts in the press at once) the customer needed a sensor that could detect various parts on the chute and send a signal to the control system, indicating that the press is free and allowing the operator to perform another stroke. The solution needed to be installed without cutting slots in the chute sides or mounting sensors at the end of the chute, which could create catch points for traveling parts.

-

Wafer Cassette Detection Under Water

Wafer Cassette Detection Under Water

Silicon wafers are transported from one process to another in cassette on a conveyor that is totally submerged in de-ionized water. A D10 sensor has teflon-encapsulated opposed-mode fibers that are located on either side of the conveyor. When the cassette is present, the opposed beam is broken.