-

Industries

-

Packaging

-

Primary Packaging

Packaging: Primary Packaging

Flexible packaging automation support growing customer needs

All around the world, consumer packaged goods (CPGs) are made available in a broad range of packaging styles, materials, sizes and shapes.

A single beverage producer may offer their drinks in multiple sizes of PET bottles, 2-liter plastic containers, or small folded paper cartons. Drinks can be powdered and sold in multi-serve ridged plastic containers or single serve flexible packets. They can even be sold as a gel and packaged in stand-up pouches. All these variations require flexible packaging machinery and automated quality controls. Banner Engineering supports packaging automation and diversity by offering a comprehensive collection of intelligent sensors to thoroughly inspect products and packaging and for flow and process control purposes.

Applications

Monitor Production I/O for Better Equipment Effectiveness

Monitoring production inputs and outputs provides machine operators and managers with critical data about their processes and equipment and can help them identify and resolve problems on the production line more quickly.

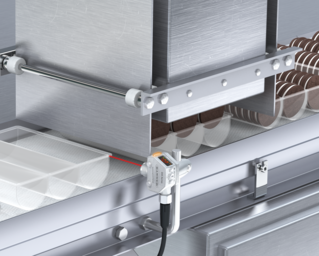

Cap Sorter Detection

Banner’s R55F fiber optic sensors have the capability to detect the presence of caps regardless of their color or size – a clear advantage in an industry that has a wide variety of bottle caps and frequent line changes. In this type of application, the fiber optic sensors are used to recognize long pauses between the caps which would then signal a jam to the operators of the machine. The fibers are compact and can be easily mounted in confined and typically inaccessible spaces.

Label Alignment Inspection

As each salad dressing bottle leaves the label station, an iVu Series vision sensor, configured to use the Match tool, inspects the label, comparing it to a preconfigured reference image to ensure that the label is present and has been correctly applied.

Reading Multiple 1D and 2D Barcodes

Barcode position can change with the location of each box on a conveyor and the height of the boxes can vary. An ABR 7000 barcode reader decodes multiple 1D and 2D barcodes over a large area in a single inspection, regardless of position or orientation.

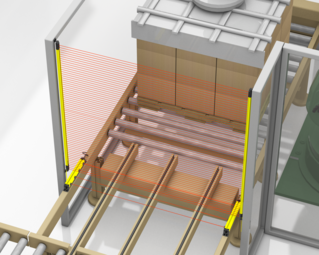

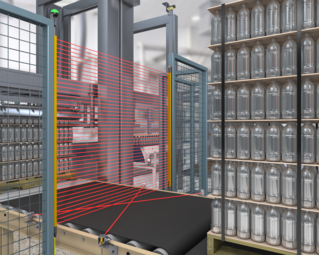

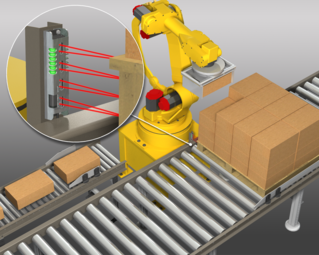

Depalletizer Guarding with Muting

LS light curtains are intuitive, easy-to-use safety devices used for machine safeguarding. They are built to withstand challenges commonly found in manufacturing and packaging environments. LS-S models require no PC software, DIP switches, or other devices for quick, easy configuration. Highly visible alignment indicators and intuitive diagnostics simplify setup, facilitate troubleshooting, and minimize system downtime.

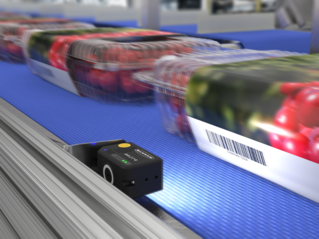

Tracking Products through Packaging

Barcodes used to track packaged produce through the supply chain contain important product information that must be verified at multiple points during packaging. An ABR 3000 barcode reader ensures that the barcode on each package is present and correct.

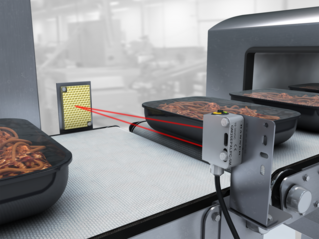

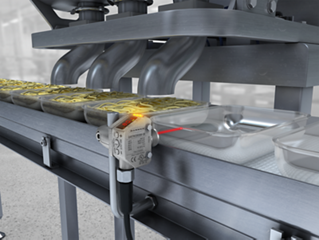

Conveyor-Triggered Checkweigh Station for Food Trays

Banner Engineering's QM26 washdown sensor detects dark plastic food trays as they approach a checkweigh machine that confirms the correct weight of the filled trays.

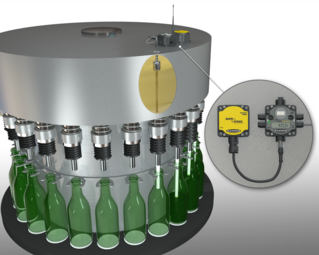

Level Monitoring On Rotary Filler System

Banner’s Sure Cross wireless system can easily transmit temperature, pressure and fill levels to a local PLCs. The wireless system will seamlessly alert operators if bottling is occurring below the desired fill level. This helps prevent errors and leads to greater consistency in bottled beverages. Consistent fill levels mean no recalls—and no wasted products. Using a wireless system also eliminates the need for slip rings on the rotary filler, which in turn reduces maintenance costs.

Sanitary Detection of Clear Plastic Food Containers

Sanitary environment, IP69K ratings required

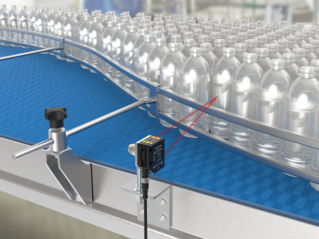

Detecting Transparent Bottles in a Washdown Environment

Detect accumulations to regulate line pressure

Detecting Bottles in Washdown: Glass & PET Plastic

Washdown environment, IP69K ratings required

Clear Tray Detection at Hopper Food Storage Units

Learn how the Q4X detects clear plastic trays at hopper and filling station in the food industry.

Clear Glass Jar Detection for Food and Beverage Splash Zone

Detecting glass jars in a strict cleaning environment

In-Line Accumulation on Single Filer

The Q5X laser sensor reliably detects when the staging area is clear of bottles and the system is ready for the next layer of containers, despite the transparency of the bottles and unstable signal.

Detecting PET Bottles to Regulate Product Flow

Identifying gaps and accumulations to regulate product flow

Depalletizer Guarding with Muting Pair

A company needed a way to safe-guard the area where pallets of empty bottles or cans enter into the depalletizer. Learn how Banner Engineering's XS26-2 Safety Controller with EZ-Screen safety light and LS-S safety light curtains helped maintain a continuous flow of pallets while protecting hazardous areas of a machine from workers.

Non-Contact Fill Level Verification

Banner’s QS30H2O sensor is a specialized sensor developed to address challenges with sensing the presence of water and water-based liquids. The QS30H2O operates in a through beam sensing mode and the emitter uses a wavelength that is tuned to not pass through water. The high excess gain of the sensor makes it powerful enough to see through an assortment of plastic and glass containers. Two pairs of sensors can be utilized to determine that the fill level has met minimum but is not overfilled and wasting product. Apertures can be placed on the receiver end to minimize the beam pattern and increase accuracy of the application. This ensures products that do not meet fill level criteria are not processed or shipped.

Black Plastic Tray Detection at a Hopper and Filling Station

Learn how the Q4X detects dark colored trays at hopper and filling station in the food industry.

Detection of Cap Orientation

The Banner Q3X laser diffuse sensor is ideal for applications that require orientation detection with small contrast differences.

Monitoring Clear Film in a Tray Sealer

After food trays have been filled they need to be properly sealed and packaged with a layer of clear film. Installing a VSM series sensor in a heat sealer accurately monitors the level of film material remaining on a roll.

Hygienic Sensor Detects Variety of Bottle Types on a Rinser

Verification that a bottle is present before the rinser jets are powered on.

Rope Pull on Conveyors

Banner’s RP-LS42F rope pull switches run along the length of a conveyor so the operator can grab and pull it from anywhere to immediately stop the conveyor. Spans of rope range from 6 m to 100 m, providing the flexibility to safeguard long or short conveyors. The RP-LS42 switches are compact and have a variety of accessories available for easy installation and rope tension. They are also made with heavy-impact thermoplastic housing for use in demanding industrial settings.

Featured Products

Q4X Series Rugged Laser Distance Sensor

Rugged Q4X laser distance sensor solves many challenging applications and comes in a rugged IP69K rating with FDA food grade stainless steel housing.

WLS27 Shatterproof LED Light for Harsh Environments

Fully encased in a shatterproof, chemically resistant housing. Rated IP69K for washdown. Multiple color options combine illumination and indication.

QS30 Series High-Performance Long-Range Sensor

High power sensing with ranges up to 200 m, e/m relay output models available.

XS26 Expandable Safety Controllers

The XS26 is expandable for complex safety applications where 3 or more safety relays are typically used. Five different communication protocols are available, including EtherCAT (via communication module). Supports up to 154 safe inputs and up to 68 safe outputs using expansion modules.

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

SC26 Series Safety Controllers

Flexible safety controller for machines that typically use 3 safety relays. Supports 26 inputs and 2 dual channel outputs with 0.5 amps each.

R58 Series Registration Mark Sensor

Detects subtle color contrasts in common product and material registration applications found in printing, packaging, and pharmaceutical industries.

Success Stories

Detecting Various Registration Marks

Hamer, LLC is a Minnesota-based manufacturer of automated packaging equipment for a wide variety of applications and world-wide customers. From pet food to pellet fuels, Hamer machinery packages products in a variety of weights and sizes at speeds up to 60 bags per minute. A vital component of Hamer’s equipment is registration mark sensing—the ability to detect marks on packaging as it passes at high speeds. When a mark is detected, the equipment cuts the packaging at the designated location, eliminating waste and ensuring each bag is consistent.

Combined Inspections Used to Meet Quality Standards

Bottles incorrectly packed into bliss trays for sale in club stores did not properly display product labels and had to be returned to the company.

Pallet Detection for Conveyance Equipment

A leading manufacturer of conveying equipment designs and builds high-quality, low-cost conveyance solutions. The pallet equipment they develop is expected to reliably convey, palletize and depalletize thousands of pallets and unit loads annually. This equipment must be able to sense a wide range of different pallet types and sizes to ensure the proper packing and unpacking of pallets and avoid line slow-downs, pallet crashes and collapses.

Simplifying Safety Feature Management

Algus Packaging Inc. is a leader in the heat seal and thermoform packaging industry. They design, develop and manufacture high-performance sealing machines, thermoformed packaging and offer full service contract packaging. The machinery and services offered by Algus provide their customers with the ability to change and grow as business needs dictate, now and in the future.

Accurate Label Inspection

The company was experiencing several quality control issues—bottles were coming off the line with missing, skewed and double labels. As a result, the customer was scrapping over 2,000 bottles a month, a process which requires them to cut out the mislabeled portion of the bottles and re-grind the plastic for reuse. Further, the labeling errors began prompting serious customer complaints. To avoid scrapping additional bottles and losing loyal customers, the company came to Banner for a label inspection solution.

Preventing Shipping Errors at a Large Distribution Center

The customer was looking for a single-output solution that senses packages quickly, is easy to install and maintain, and was affordable enough to buy in bulk quantities if needed.

Shrink Sleeve Labeling at High Speeds

A leading manufacturer of labeling equipment offers high-speed shrink sleeve label applicators designed to process 800 bottles per minute. To maximize the machine’s performance potential, the company wanted to install sensors capable of consistent detection and output for high-speed bottling.