Intrinsically Safe Sensors, Lighting, & Wireless Radios

There is an increased risk of fire or explosion in areas where flammable liquids, gasses, vapors, dust, or other combustible materials are present, even in areas where they are potentially present. Sparks or elevated temperatures from electronic equipment can ignite these materials. Electronic equipment that utilizes an intrinsically safe (IS) design can be used to mitigate risk in hazardous areas like these.

IS design limits the power and heat created by an electronic device to a level below that required to ignite a specific hazardous atmosphere. This eliminates the need to isolate electronic equipment in explosion-proof enclosures, reducing the overall cost of a deployment and simplifying implementation. Additionally, IS design devices can be accessed and serviced without requiring a complete venting of atmospheric hazards in the work area, a process that can bring production to a halt for an extended period of time.

When implementing an IS design strategy in a Class I, Division 1 hazardous area, it is important that all the equipment used be IS certified and that the entire system designed to IS standard. This requires the use of an approved isolated barrier located in a non-hazardous area. In the event of a fault, excess voltage is transferred behind the barrier where it can safely pass to ground.

Banner Engineering offers a number of sensors, indicators, and wireless products that feature IS design for use in hazardous environments.

-

HLS27 Series Bright LED Strip Light for Hazardous Locations

HLS27 Series Bright LED Strip Light for Hazardous Locations

Shatterproof, UV-stabilized, polycarbonate shell ideal for harsh indoor and outdoor applications. Automatic temperature protection built into the unit.

-

HLS28 Hazardous Enclosure LED Strip Light

HLS28 Hazardous Enclosure LED Strip Light

Banner's HLS28 Hazardous Location LED Strip Light has a sturdy aluminum housing, shatterproof windows, and low-profile, space-saving design for use in certified enclosures in hazardous locations. The light is available with integrated motion sensor for auto-on when the enclosure door is opened, or anytime motion is detected.

-

SMI30 Series Intrinsically Safe Barrel Sensor

SMI30 Series Intrinsically Safe Barrel Sensor

Use with approved amplifiers and intrinsically safe barriers in explosive environments. Totally sealed, self-contained, threaded-barrel.

-

Q45 Series Rugged Rectangle Sensor

Q45 Series Rugged Rectangle Sensor

The Q45 line of sensors offers an advanced, economical solution with limit switch replacement body style and timing options.

-

Mini-Beam Series Industry Standard Sensor

Mini-Beam Series Industry Standard Sensor

Comprehensive sensor line with a series of emitter LED colors, gain pots/TEACH modes and ac or dc models.

-

T30 Series 60 m Range IP69K Washdown Rated Sensor

T30 Series 60 m Range IP69K Washdown Rated Sensor

T-style IP69K housing and 30 mm threaded lens for reliable sensing without adjustments. Sensing range up to 60 m.

-

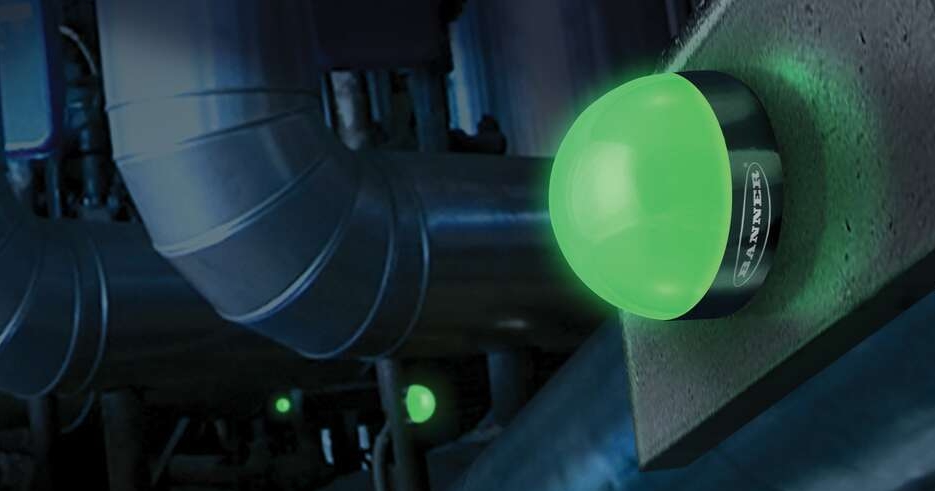

K50 Core Series 50 mm General Purpose LED Indicator

K50 Core Series 50 mm General Purpose LED Indicator

Our most popular indicator light. The 50 mm general-purpose indicator is available in both AC and DC supply voltage.

-

K30 Core Series 30 mm General Purpose LED Indicator

K30 Core Series 30 mm General Purpose LED Indicator

Compact, 30 mm diameter, illuminated dome provides easy-to-see operator guidance.