EVP Series Machine Vision Inspection System

.jpg/jcr:content/renditions/cq5dam.web.1500.1500.jpeg)

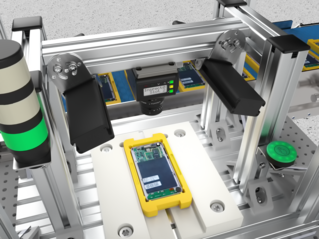

- Industrial-grade rugged housing, high-quality components make the product more stable performance

- The new design, Intel multicore chips to detect the speed of the product faster and more powerful

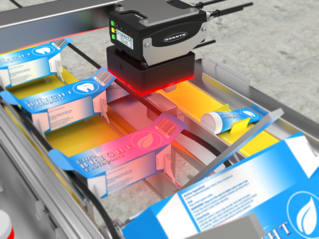

- Support for multiple Gigabit Ethernet POE GigE cameras, cables up to 100 meters

- The camera resolution from VGA up to 5M pixels

- Products with two major series six models to meet different customer needs

- Depending on the model, controller with NPN or PNP output

- External Software License

- 300,000 / 2,000,000 / 5,000,000-pixel resolution, monochrome and color CCD