Carton Assembly Solutions for Food Packaging

Once the trays are sealed and have passed all checks, they need to be packed into the correct boxes. A cartoner machine takes flat food packaging boxes and assembles them, sealing the food inside for storage and sale.

As trays are placed into each carton, the flaps are sealed and then the cartons continue on to the next packaging stage. Flap detection, carton stack height, and barcode reading are the most common applications found on this machine.

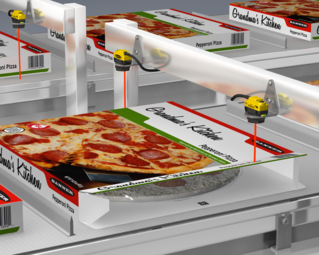

Barcode verification is one way to ensure that the food is packaged into the correct carton. This process is very important because if the carton labels are incorrect, there is potential for undisclosed allergens, which is a major source of recall.

In addition, quick and accurate recognition of barcodes prevents slowdowns and backups on the production line. Flap and glue detection ensures that glue is present on the flaps so that they are then sealed properly. Incorrectly sealed boxes could also lead to potential recall and product waste.

Line changeovers result in different graphics or colors on the packages. Versatile sensors are required to ensure reliable detection of variety of diverse packages without lengthy downtime for changeover. Banner Engineering offers multiple solutions that reliably detect a variety of colors, surfaces, and materials, including laser displacement sensors like the Q4X which are particularly adept at detecting challenging packages with shiny foils and vibrant graphics with irregular presentation.

Featured Applications

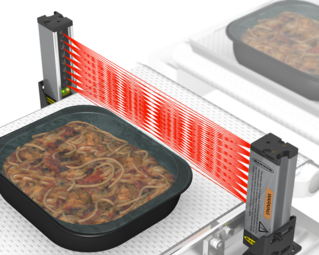

Leading Edge Detection of Packages with a Thin, Flexible Edge

Banner’s LX Series is an economical solution for detecting the leading edge of flat objects, such as the frozen dinner containers. With a web of modulated light, the LX Series part-sensing light screen can detect any item—in any position—passing through the light screen.

Illuminating Inside A Cartoner

Banner’s WLS28 LED Light Strips allow operators to identify frozen dinners that have not properly entered a carton and fix the problem with minimal downtime. Their long-lasting and durable cool white light means they’re an energy-efficient solution for illuminating the inside of a cartoner. IP69K rated, they can handle frequent machine wash down procedures.

Carton Stack Height

Frequent product changeovers, reduce setup time

Flap Detection on Packaged Frozen Dinners

The QS18LD laser diffuse sensor scans across the top of the package to see if any flaps are open. The laser diffuse sensor provides accurate detection to verify whether the frozen packages are sealed properly.

Carton Trigger For Date/Lot Code Printing

With a narrow beam that projects a small bright spot, the QS18LLP laser, polarized, retro-reflective sensors provide precise position control when triggering various devices. In this application, the QS18LLP is able to correctly detect the glossy carton as it travels down the conveyor—without proxing—and trigger the ink jet printer to print the date/lot code on the carton. The second sensor triggers the P4 OMNI to inspect the date/lot code and verify it is legible and correct.