-

Industries

-

Assembly & Robotics

Assembly & Robotics

Improve Efficiencies in Assembly and Manufacturing

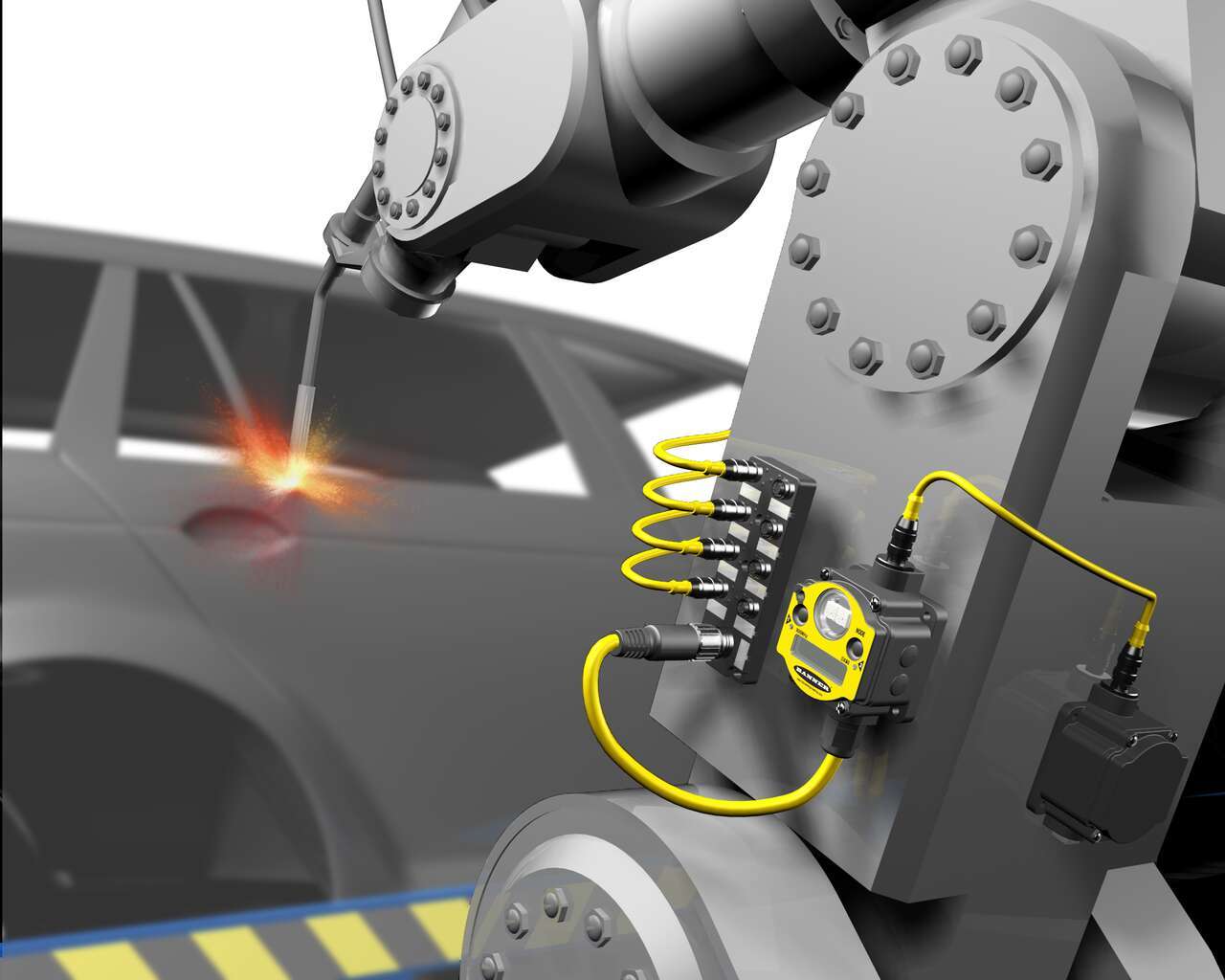

Fully automated, semi-automated, robotic, and manual assembly lines require reliable, well-designed products and solutions to maximize operations. Cutting-edge Banner devices help companies large and small enhance robotic welding cells, manual feed stations, final assembly and test cells, and pick-to-light and kitting stations—every stage of production.

From automation safety, operator guidance, and status indication to error-proofing and part inspection and verification, Banner’s extensive industrial automation expertise is improving reliability, productivity, and repeatability for assembly lines worldwide.

Start with Banner

Manufacturers adopt a broad range of assembly methods to meet their production requirements for volume, product mix, and cost structure. But whether you rely on manual workstations or highly automated production lines with robotics, there are opportunities to maximize production efficiency, ensure product quality, and gain a competitive advantage in the global marketplace. Banner develops and provides the devices, tools, and expertise to improve assembly-line throughput, maximize safety, and reduce costly downtime.

We are experts in automation technologies, offering a comprehensive catalog of more than 10,000 products, including sensors and measuring devices; lighting, indicators, and displays; connectivity technology; condition monitoring solutions; machine safety products; industrial wireless systems; remote I/O, barcode scanners, and machine vision. By listening to customers and engineering solutions that remove production constraints, Banner is helping them drive efficiencies, improve output and system accuracy, and reduce errors and expenses.

Tour Industry-Leading Banner Solutions

Provide at-a-glance machine status indication and send machine status information to a wide range of devices.

Learn More

Identify small problems before they become major issues that impact machine performance and uptime.

Learn More

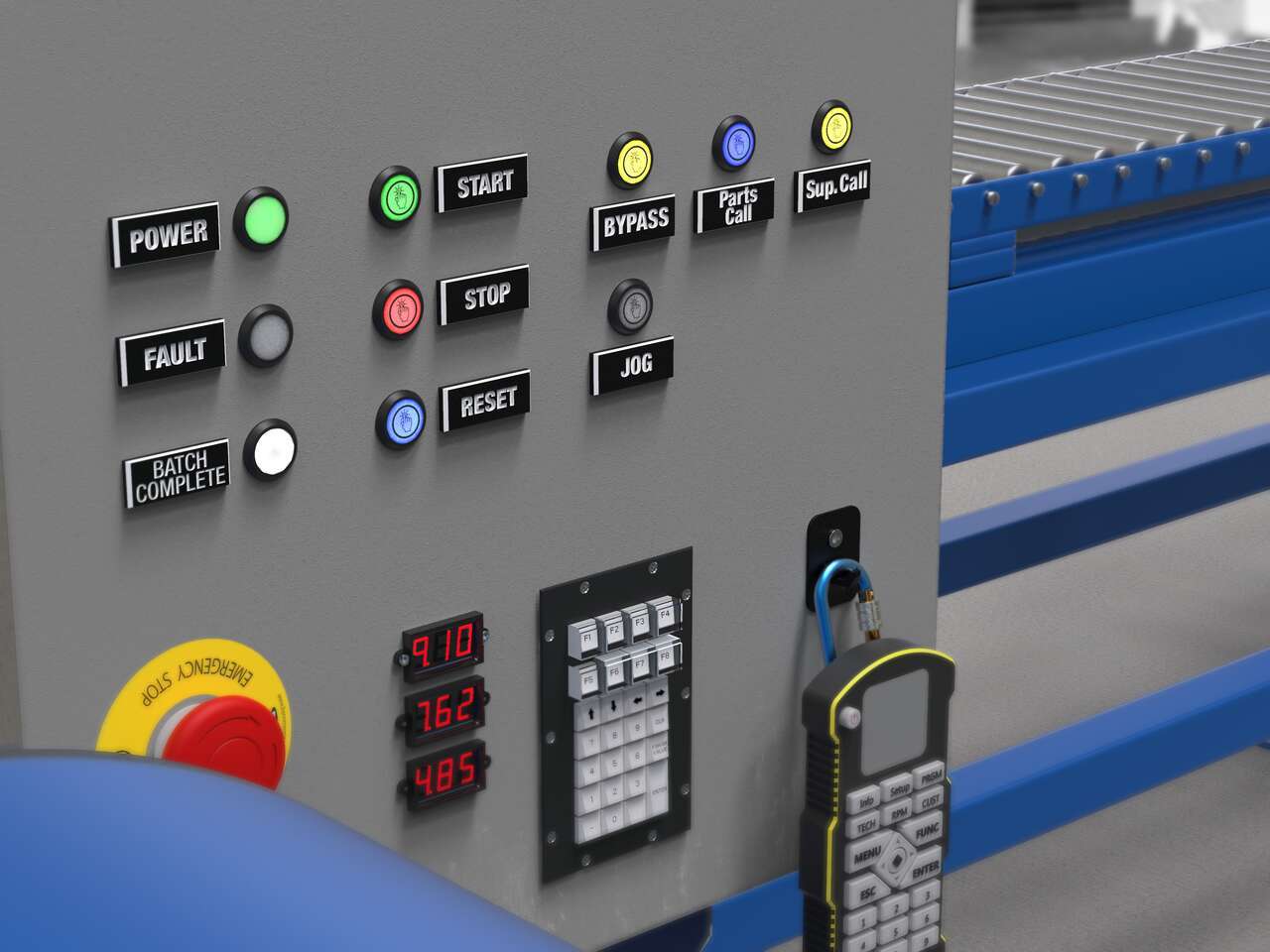

S22 Pro Series touch buttons and indicators simplify control panel design and improve operator experience and performance. Pro Editor software expands the built-in display capabilities available with the S22 Pro Series, enabling custom displays.

Learn More

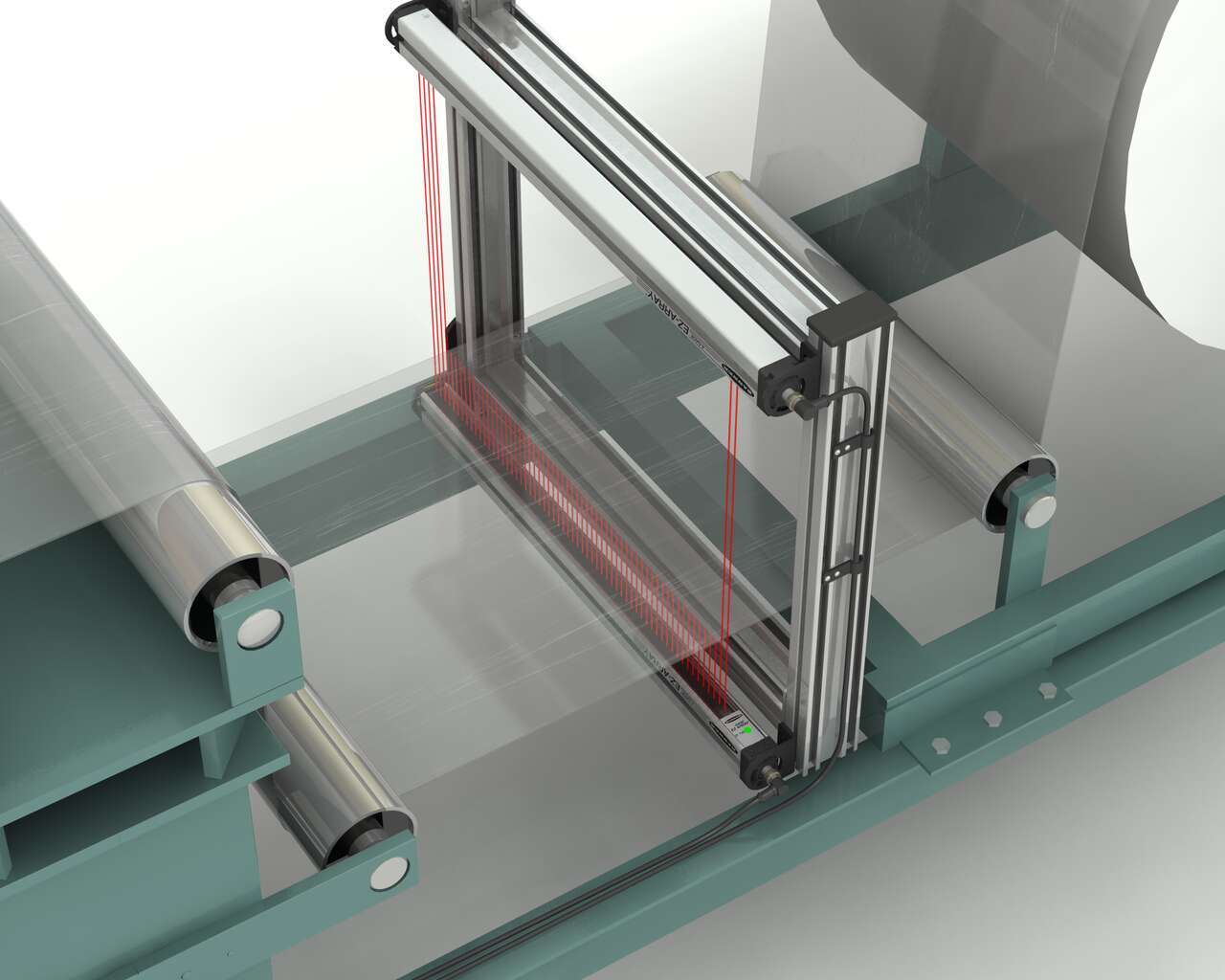

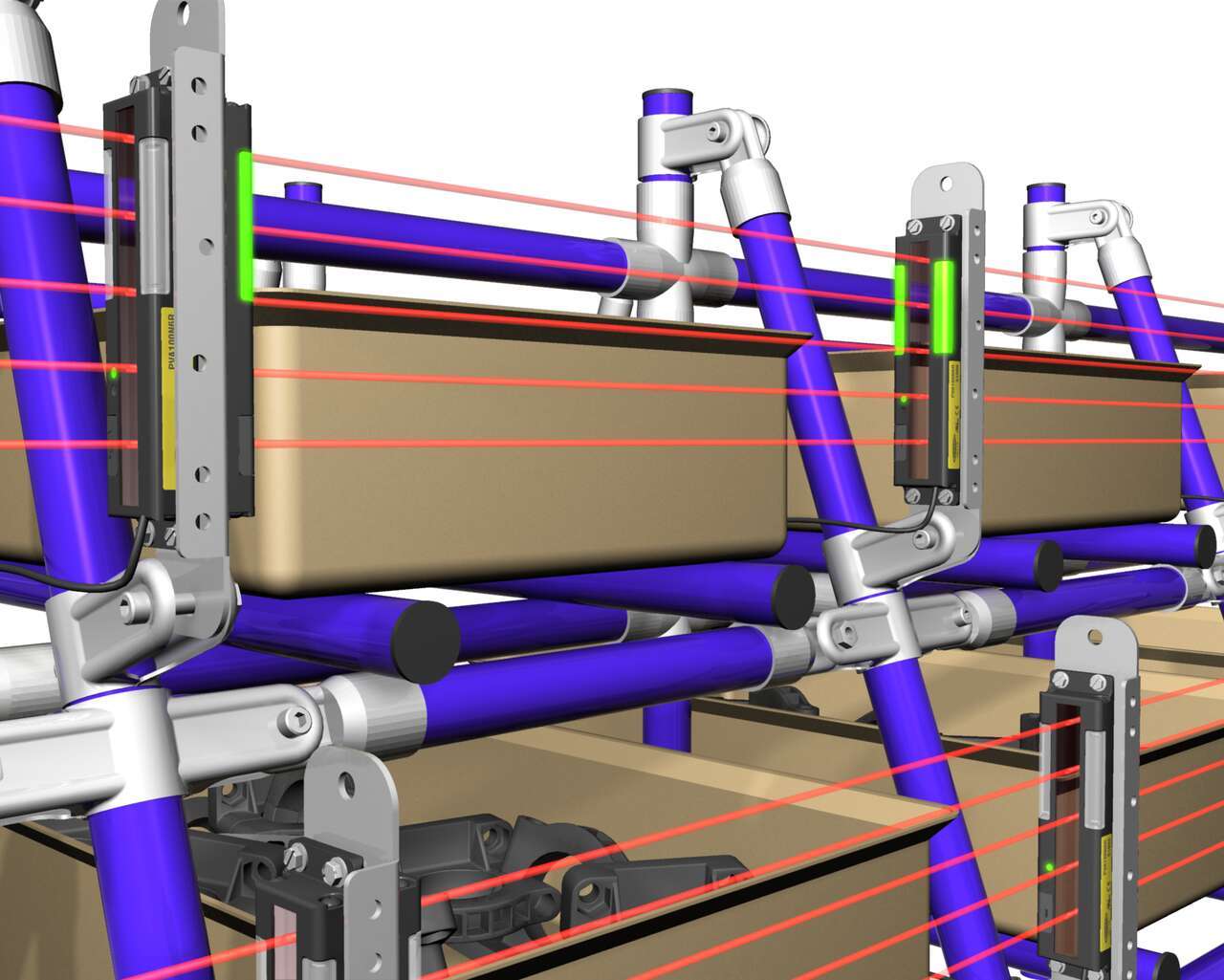

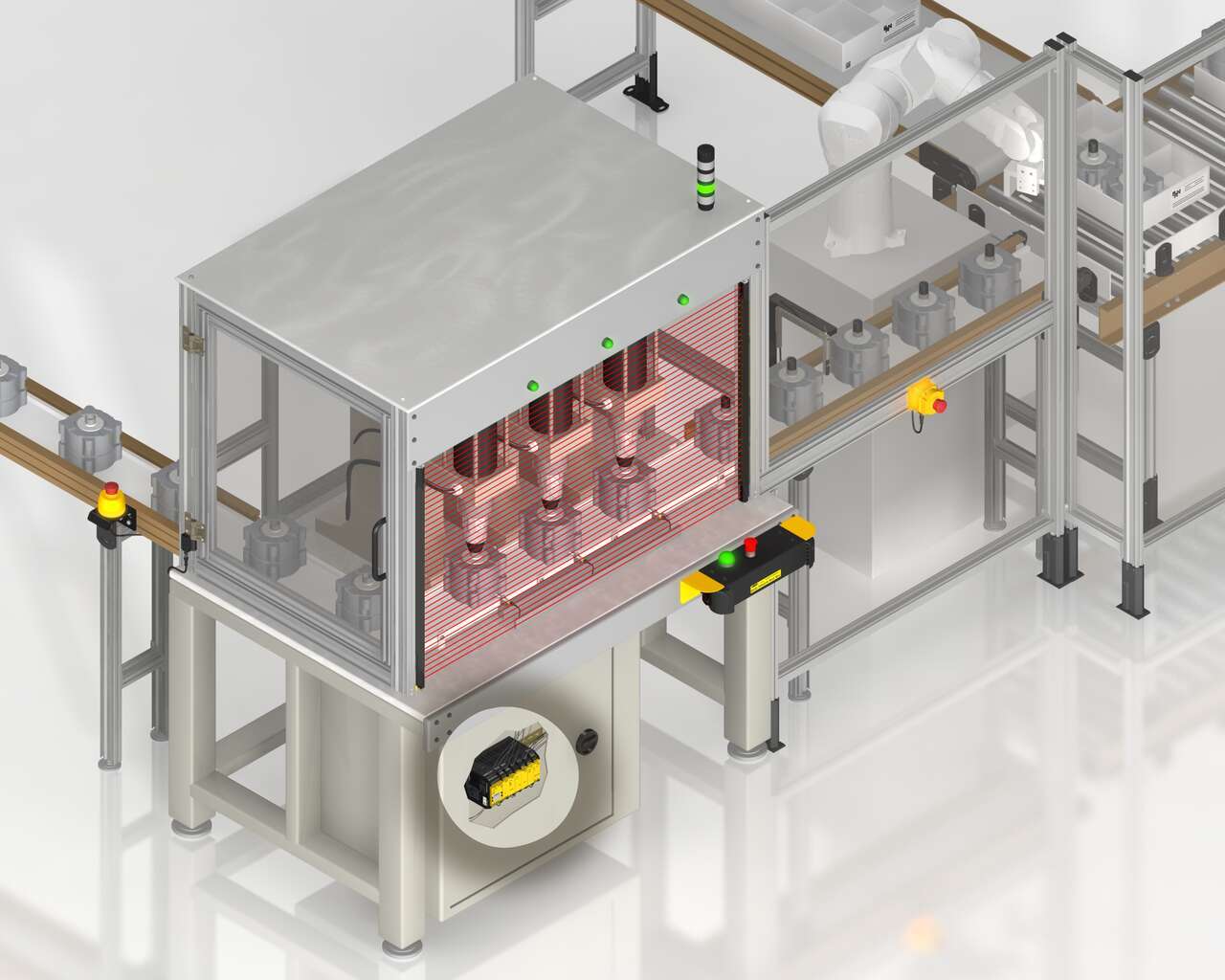

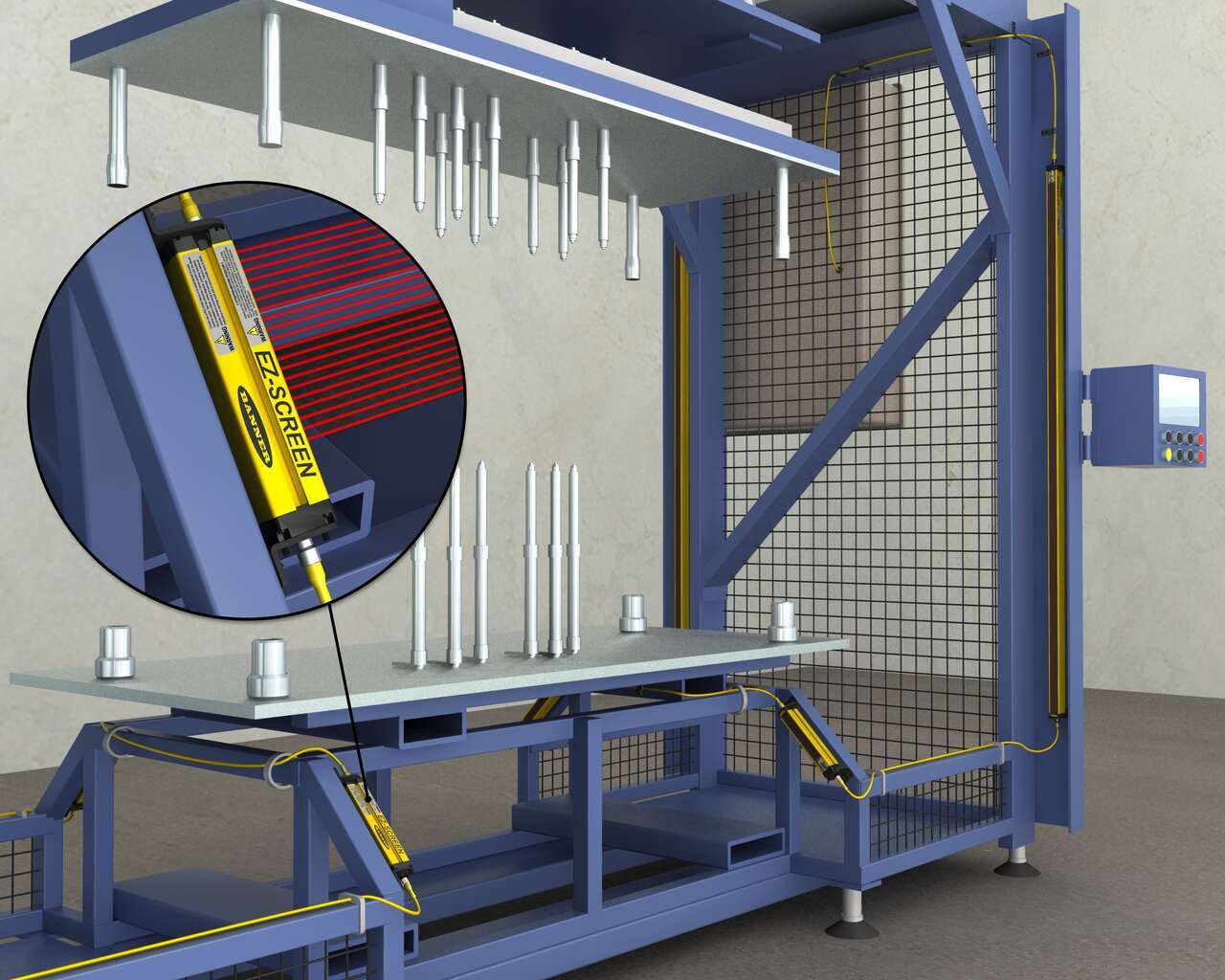

EZ-SCREEN LS safety light curtains have no DIP switches, feature end-to-end sensing, and can be easily installed with automatic configuration. The use of side mount brackets creates a quick and simple installation with adjustments made from the front side of the EZ-SCREEN LS arrays, saving time during setup. Maximizing machine uptime and reducing repair and replacement expenses helps companies remain competitive.

Learn More

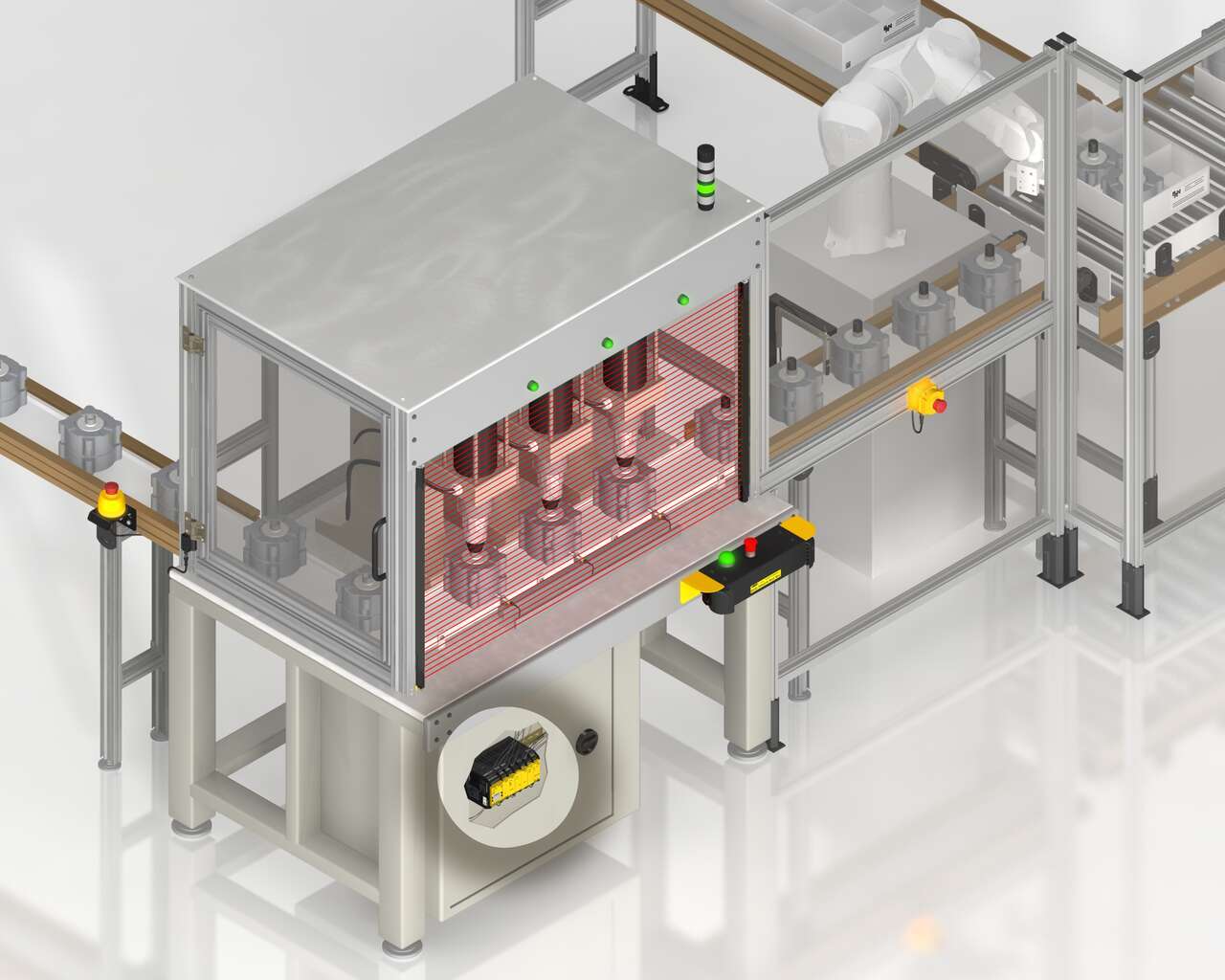

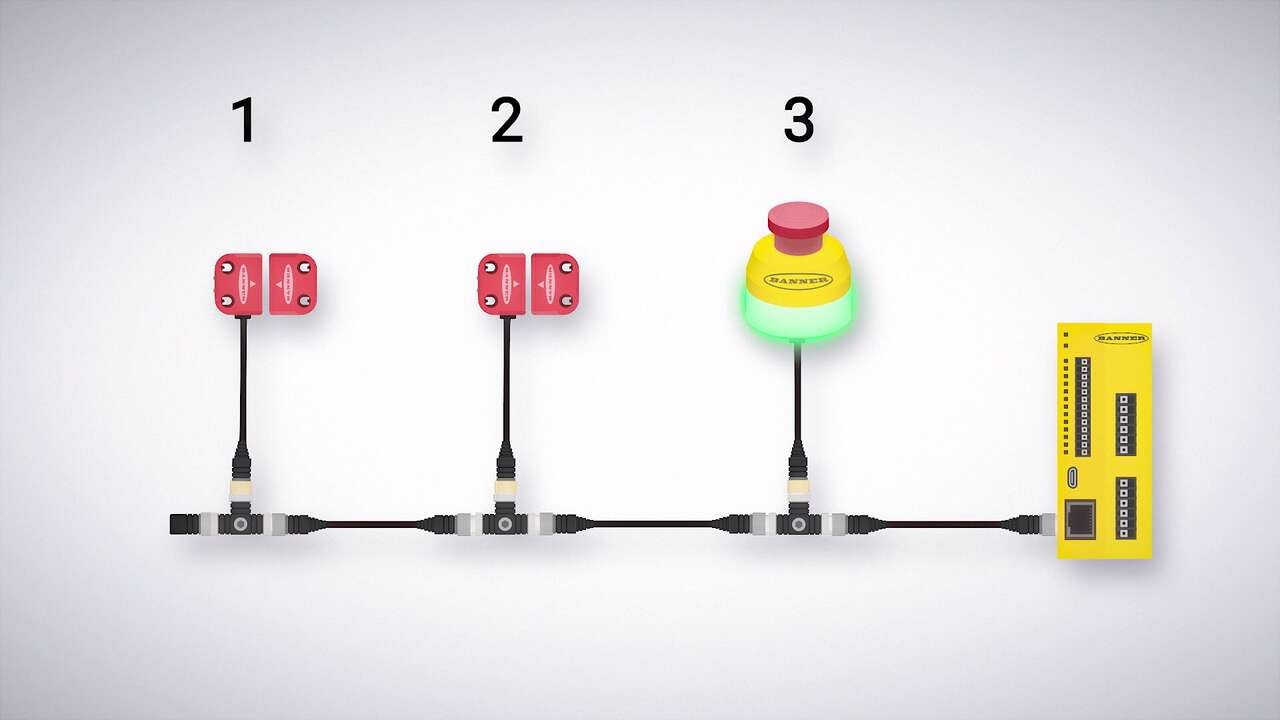

Banner’s XS26-2 expandable safety controller is a scalable safety solution that can be tailored for a wide variety of machines, including large scale machines with multiple processes. With the ability to add up to eight I/O expansion modules, the XS26-2 has the capacity to adapt to larger footprint machines with multiple hazards and access points. Several preconfigured safety function and logic blocks are available in the intuitive programming software.

Learn More

Banner’s SC26-2 is a flexible, easy-to-use safety controller with an intuitive programming environment. The programmable safety controller can manage all of the safety devices with one module. The SC26-2 communicates the status of safety devices via Ethernet IP and controls a tower light for visual indication of safety device statuses. The base controller allows eight of the 26 inputs to be configured as outputs for efficient terminal utilization.

Learn MoreAssembly and Robotics Solutions

-

-

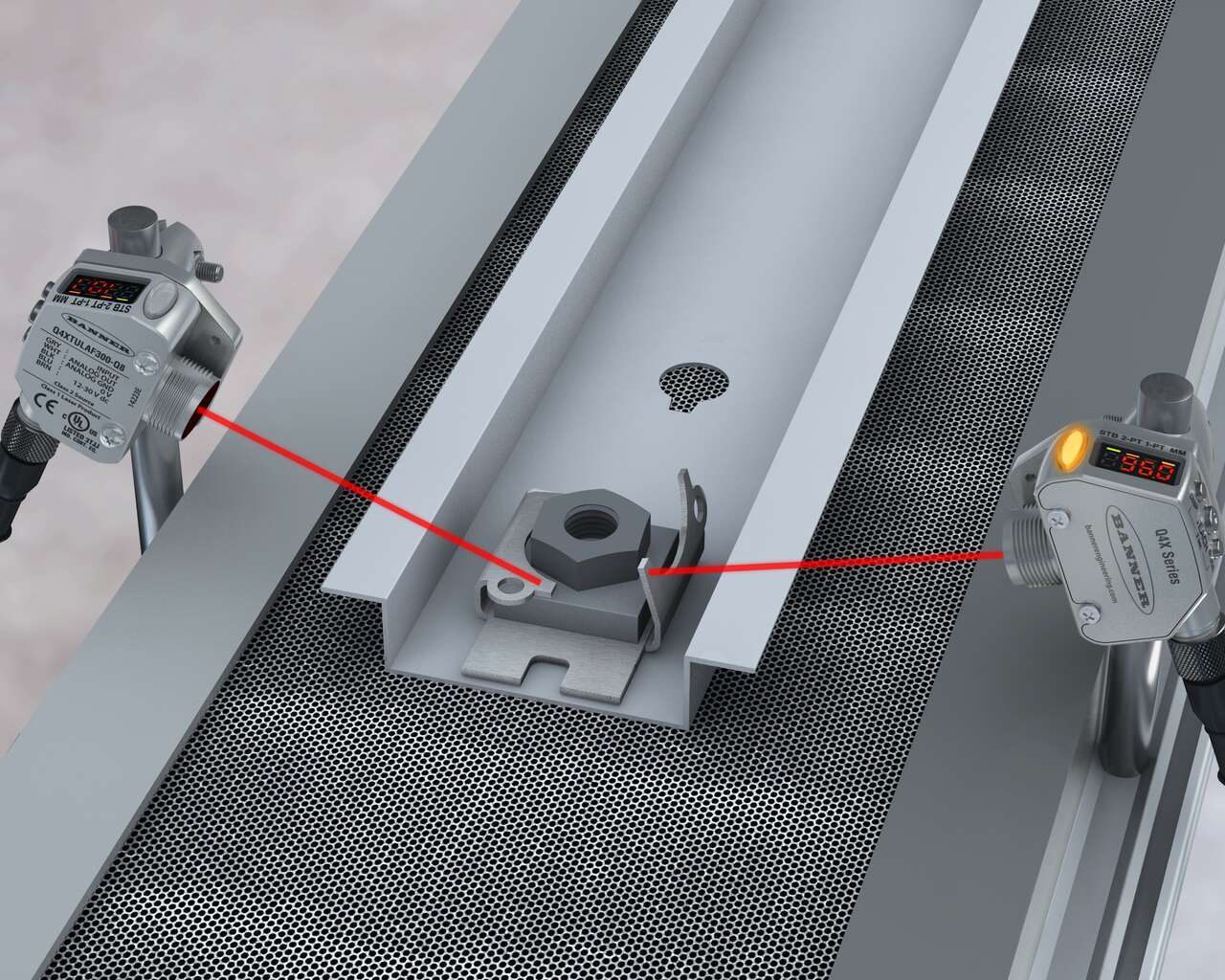

Sizing, Profiling and Guiding Clear Objects

-

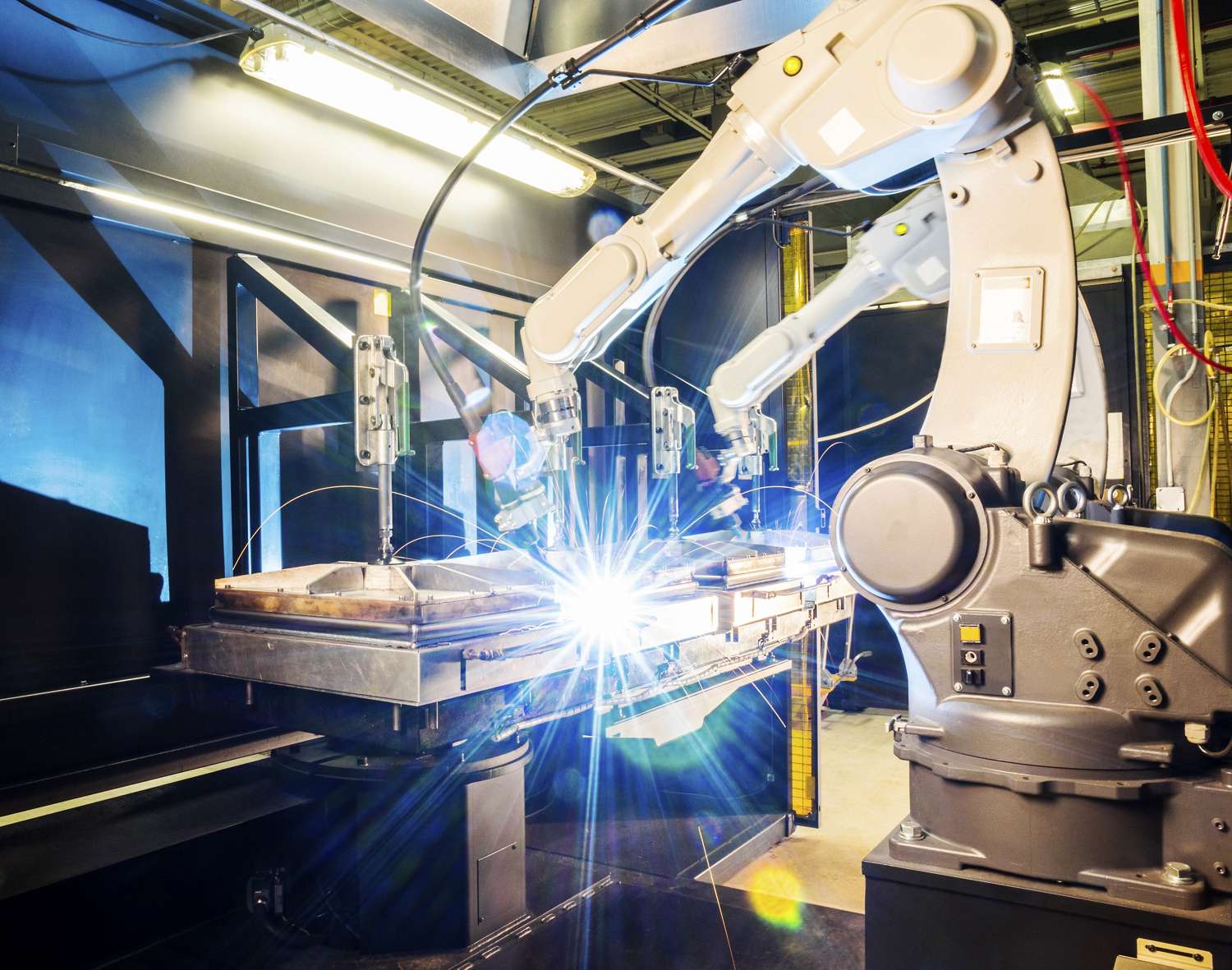

Safeguarding a Single-Station Robot Weld Cell

-

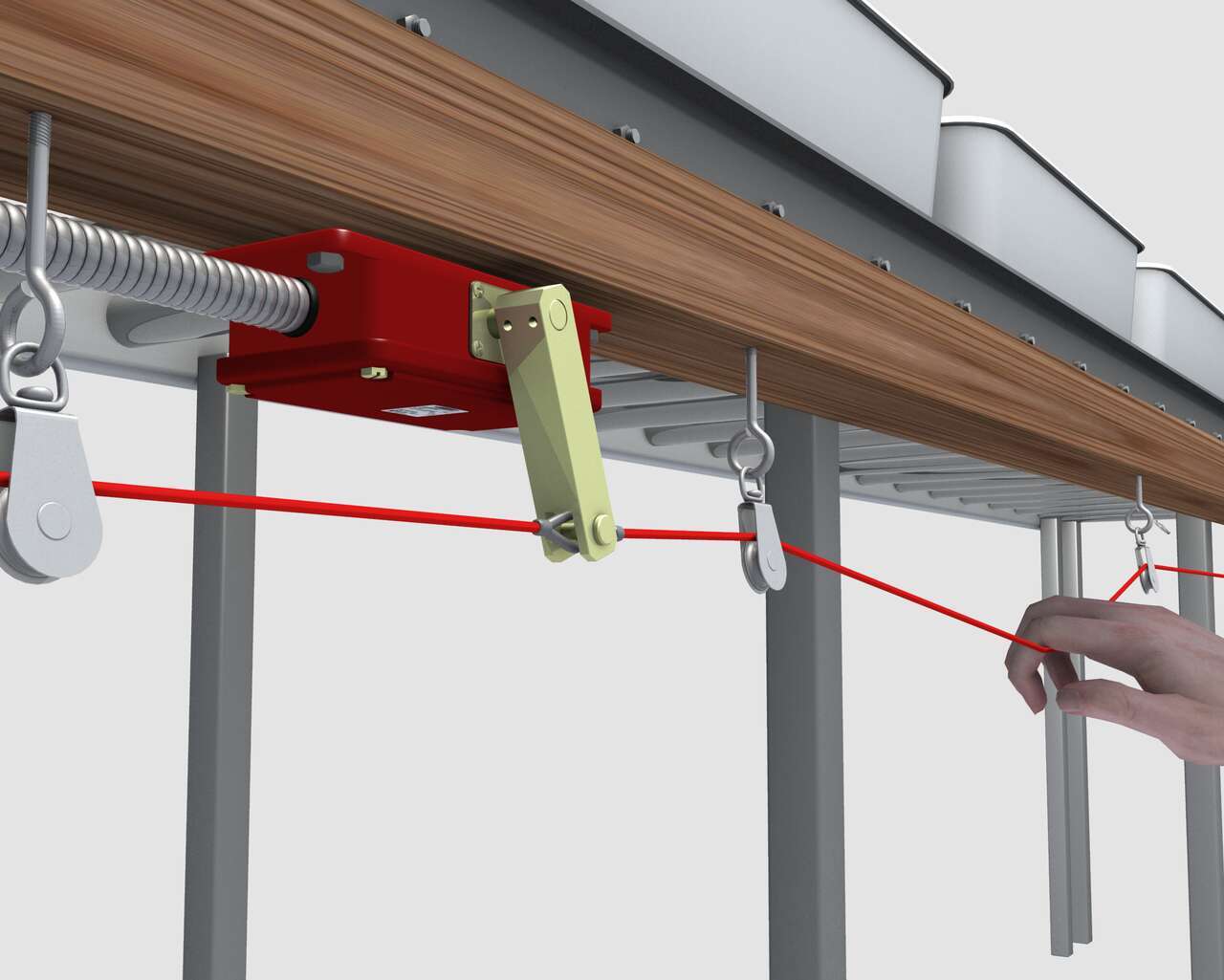

Emergency Stopping (center-mounted rope pull)

-

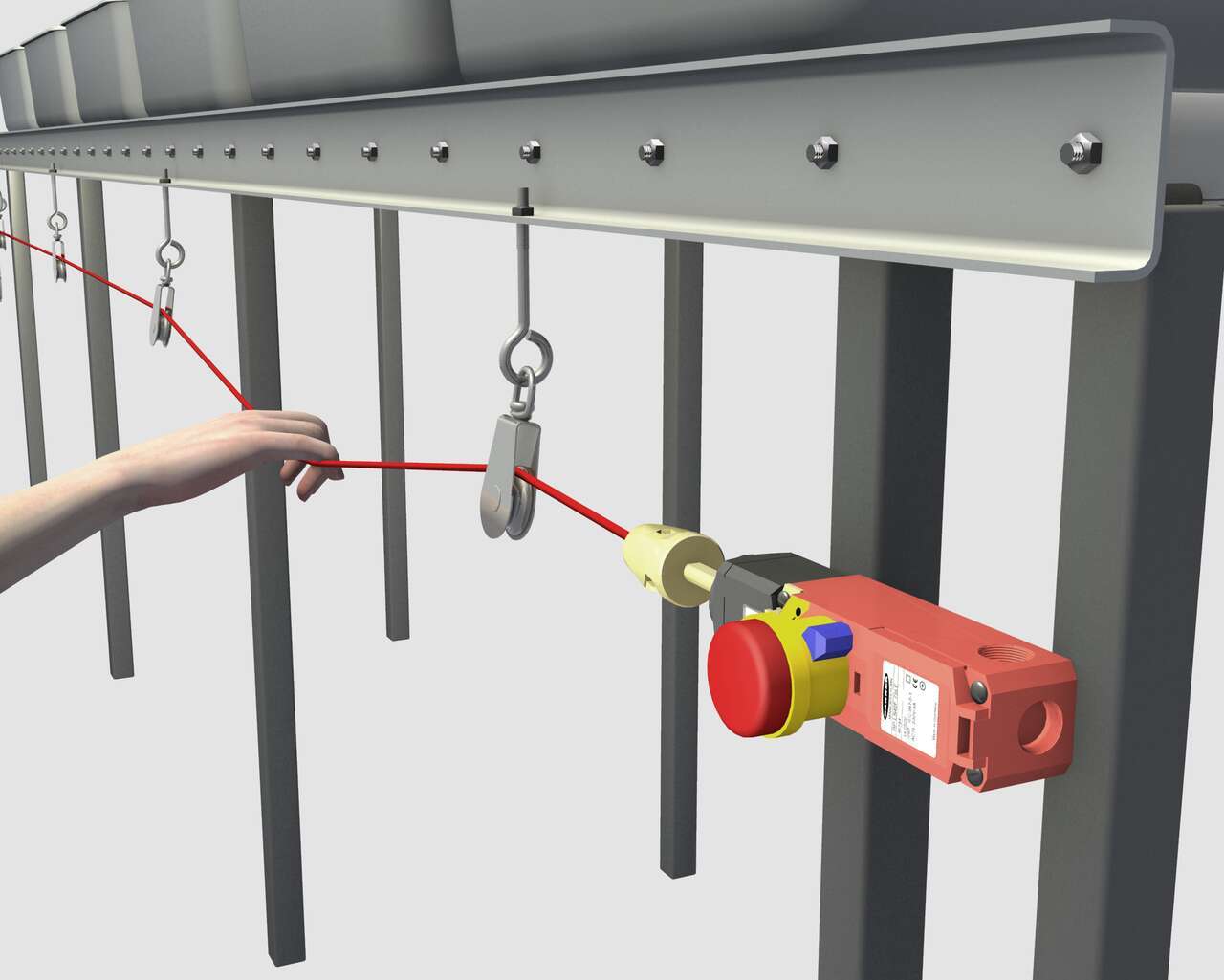

Emergency Stopping (end-mounted rope pull)

-

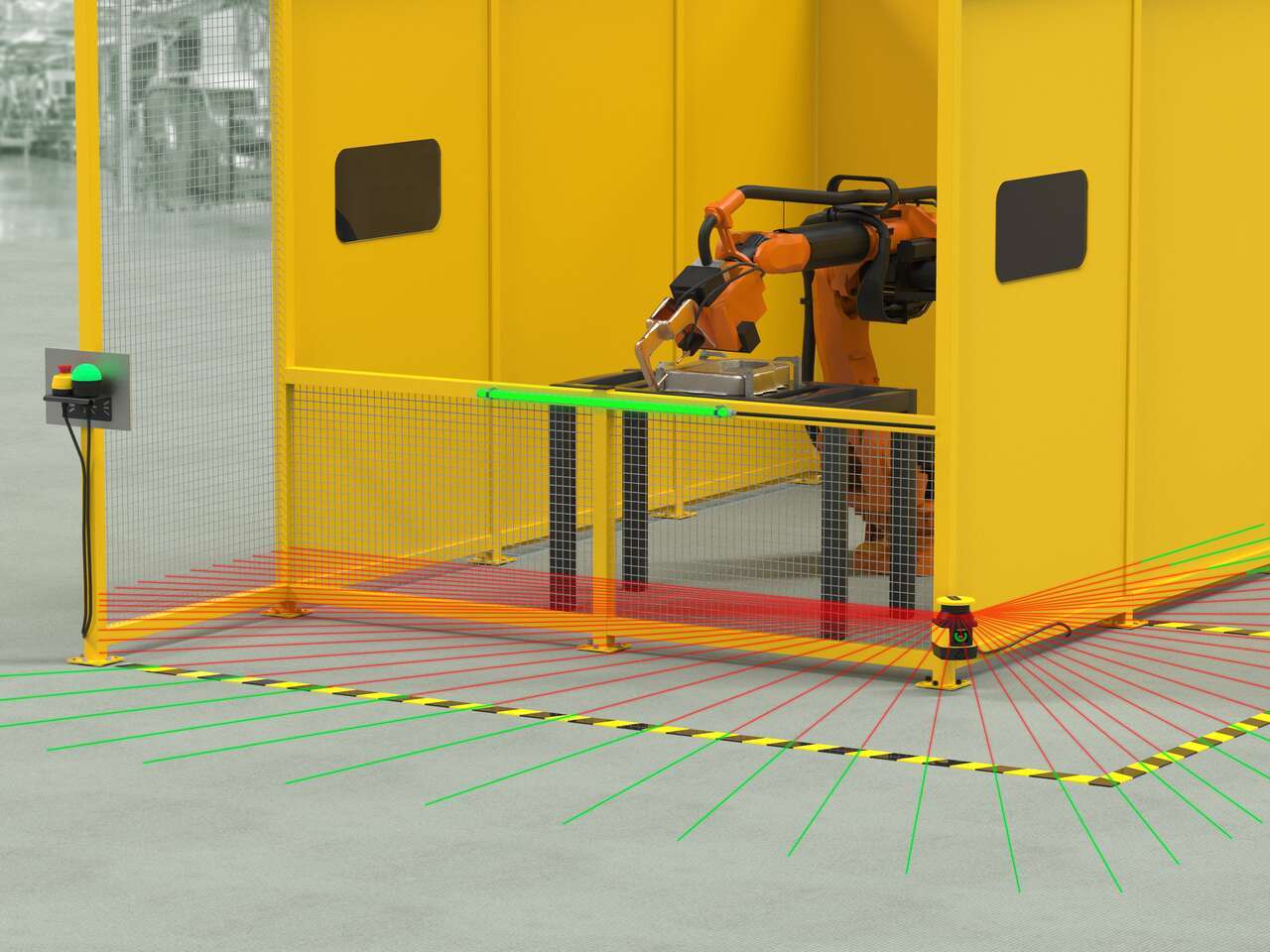

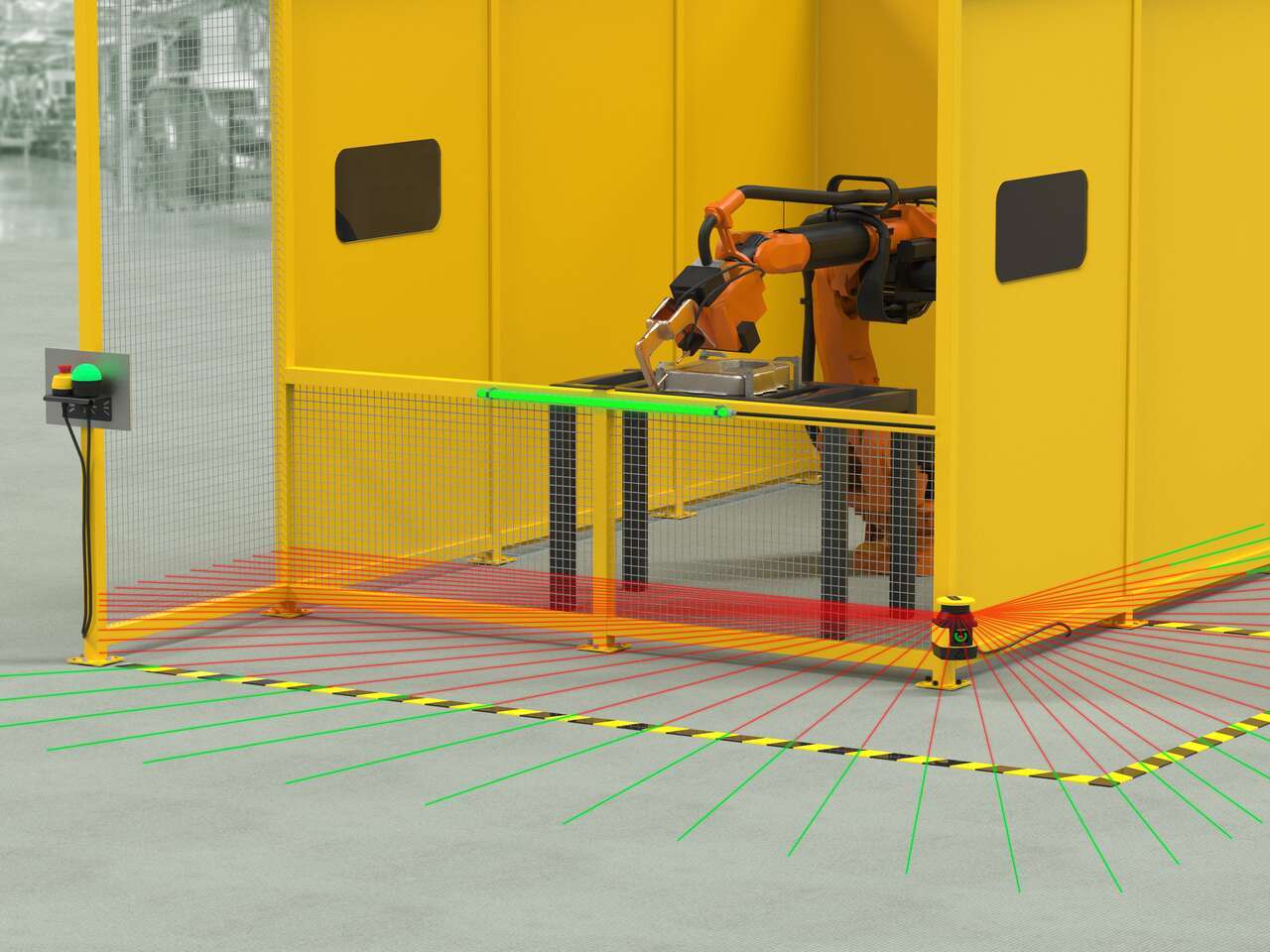

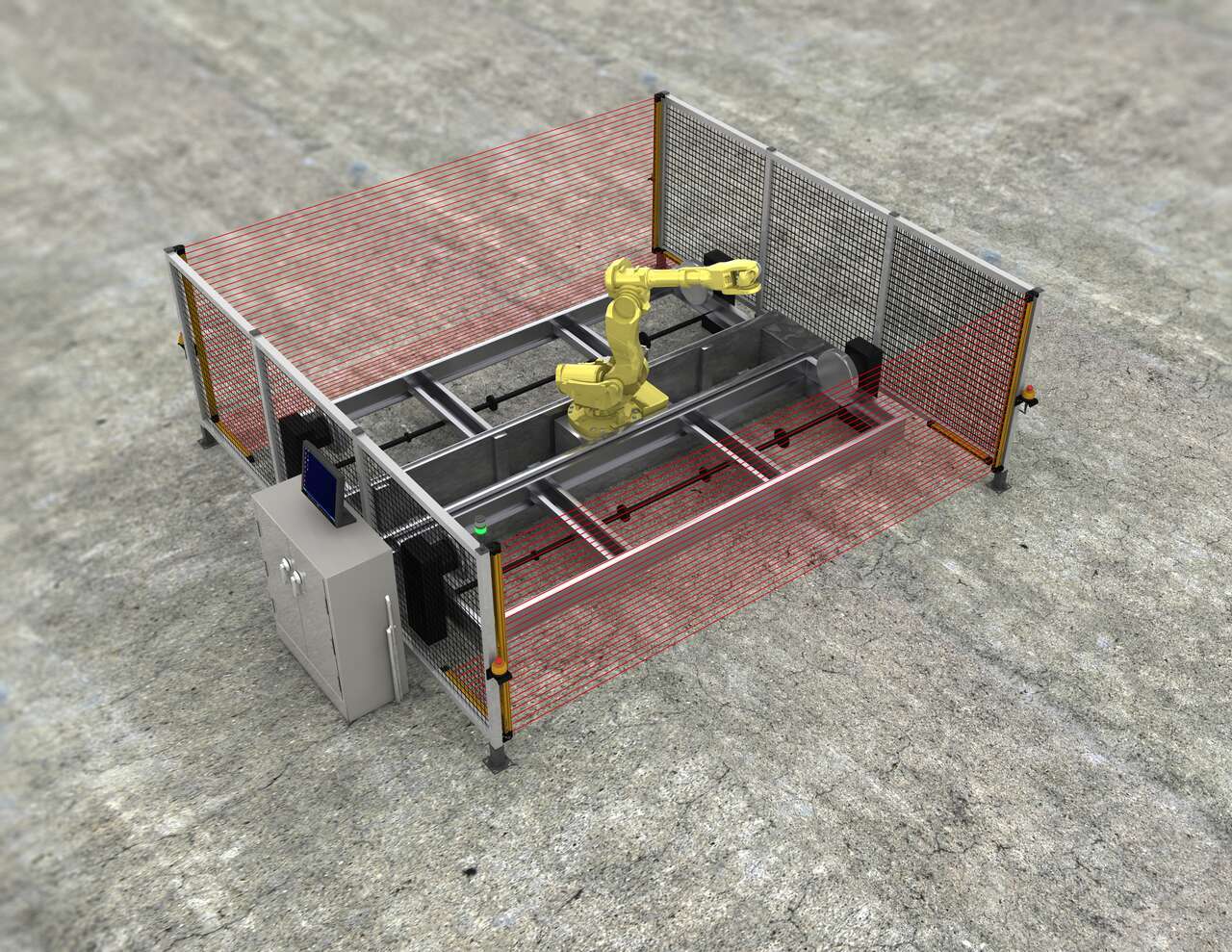

Safeguarding a Robotic Weld Cell

-

Safeguarding of a Power Press

-

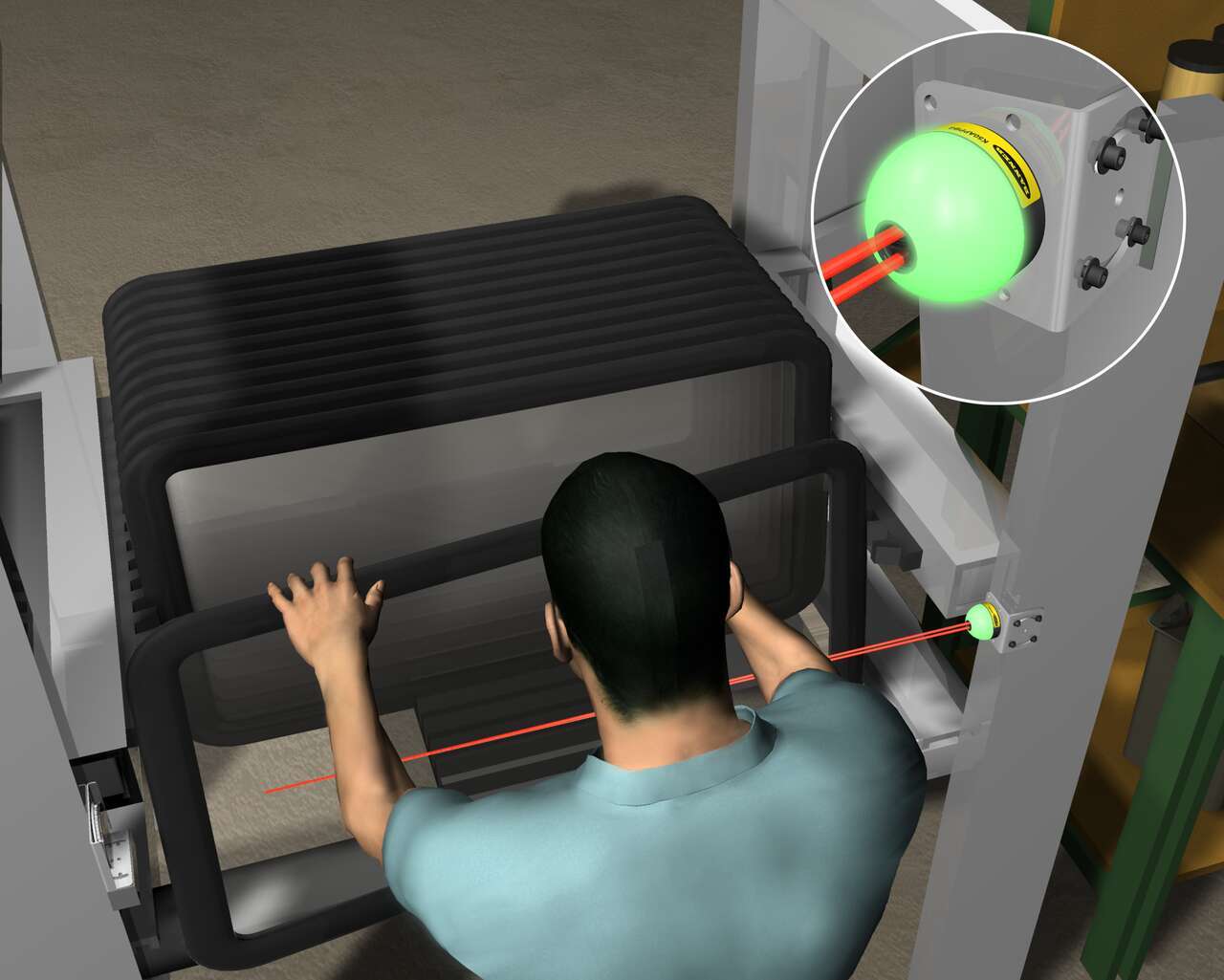

Small Assembly Station Protection with Light Curtains

-

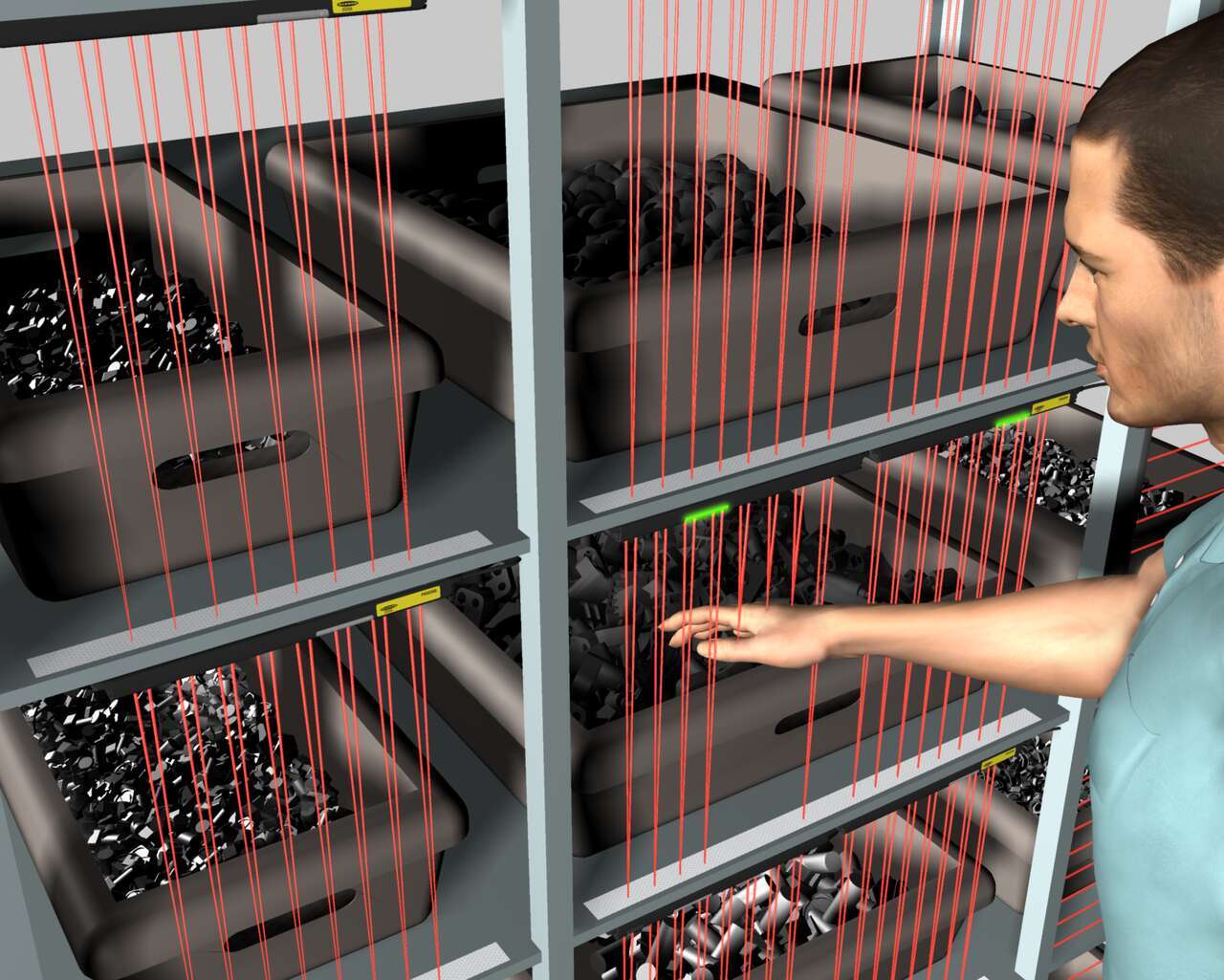

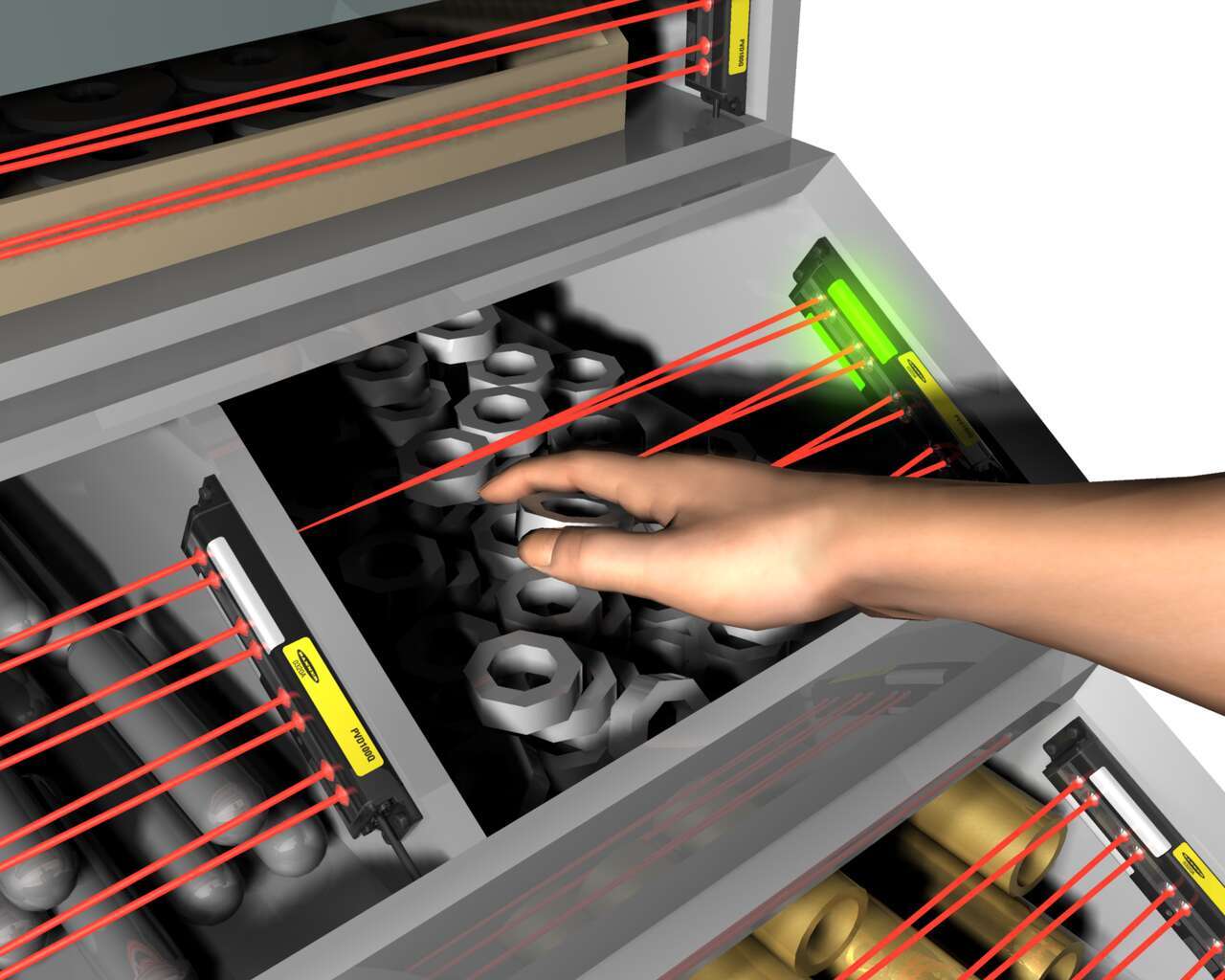

Part Pick Verification for Large Bins

-

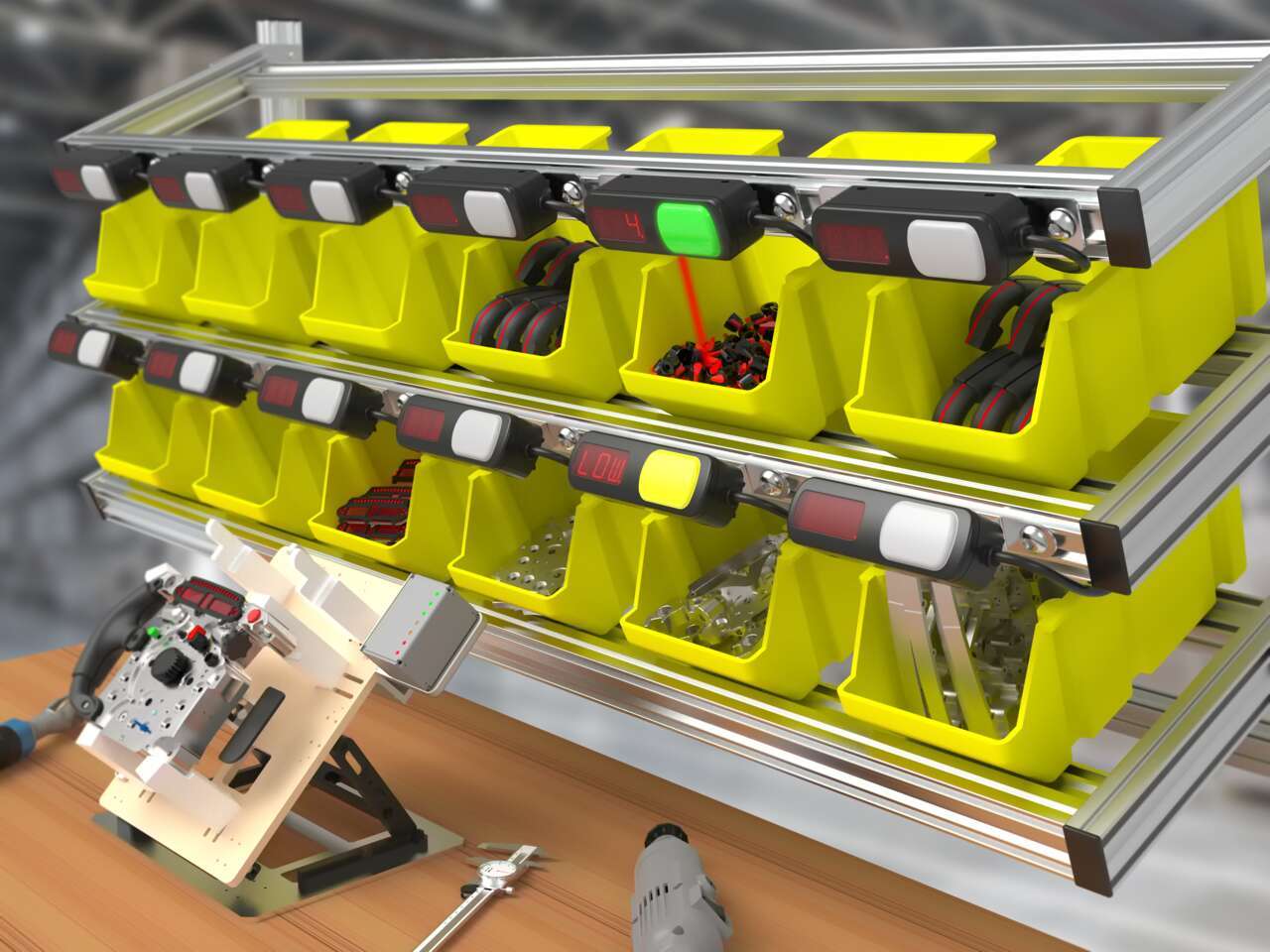

Long Bin Pick-to-Light

-

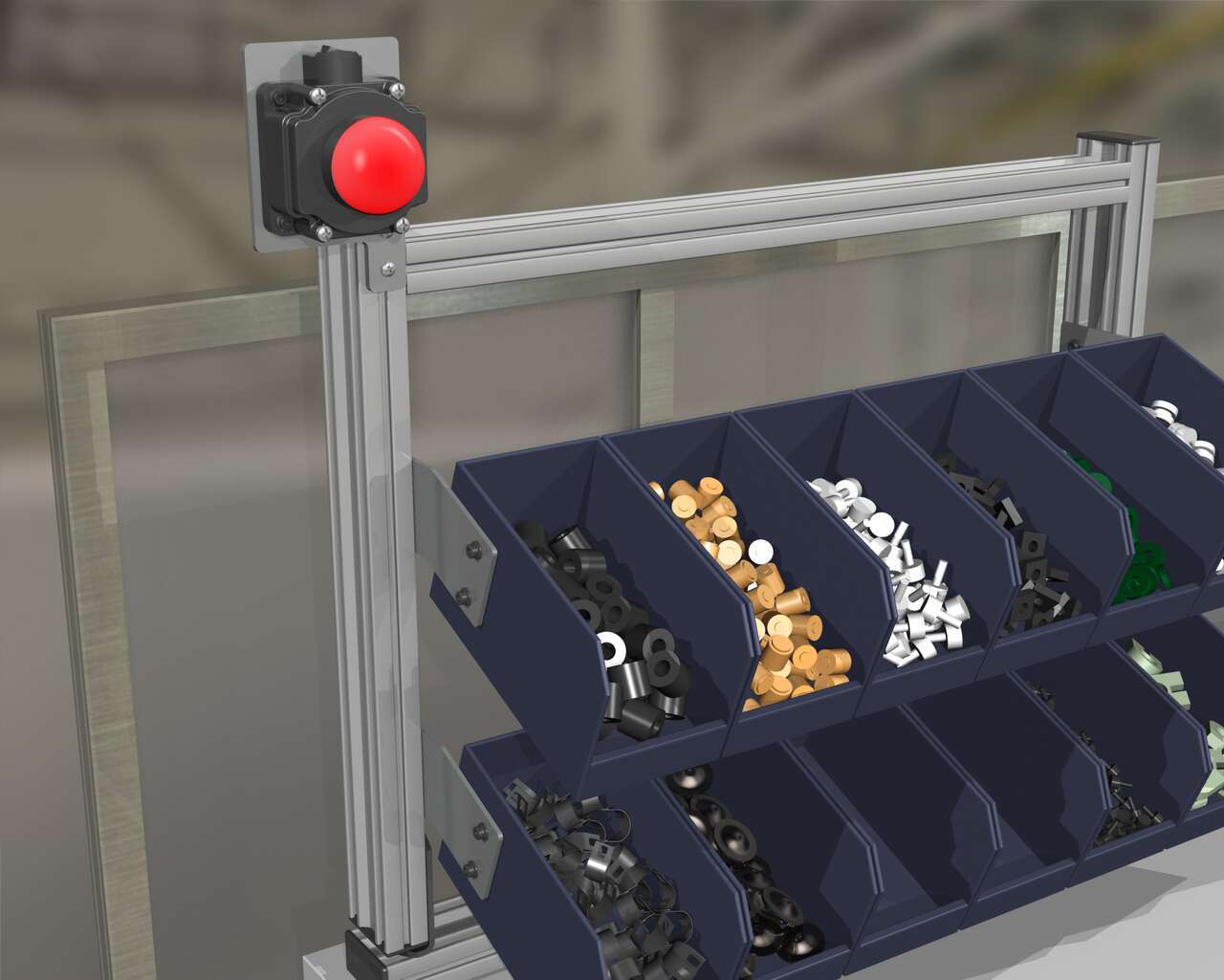

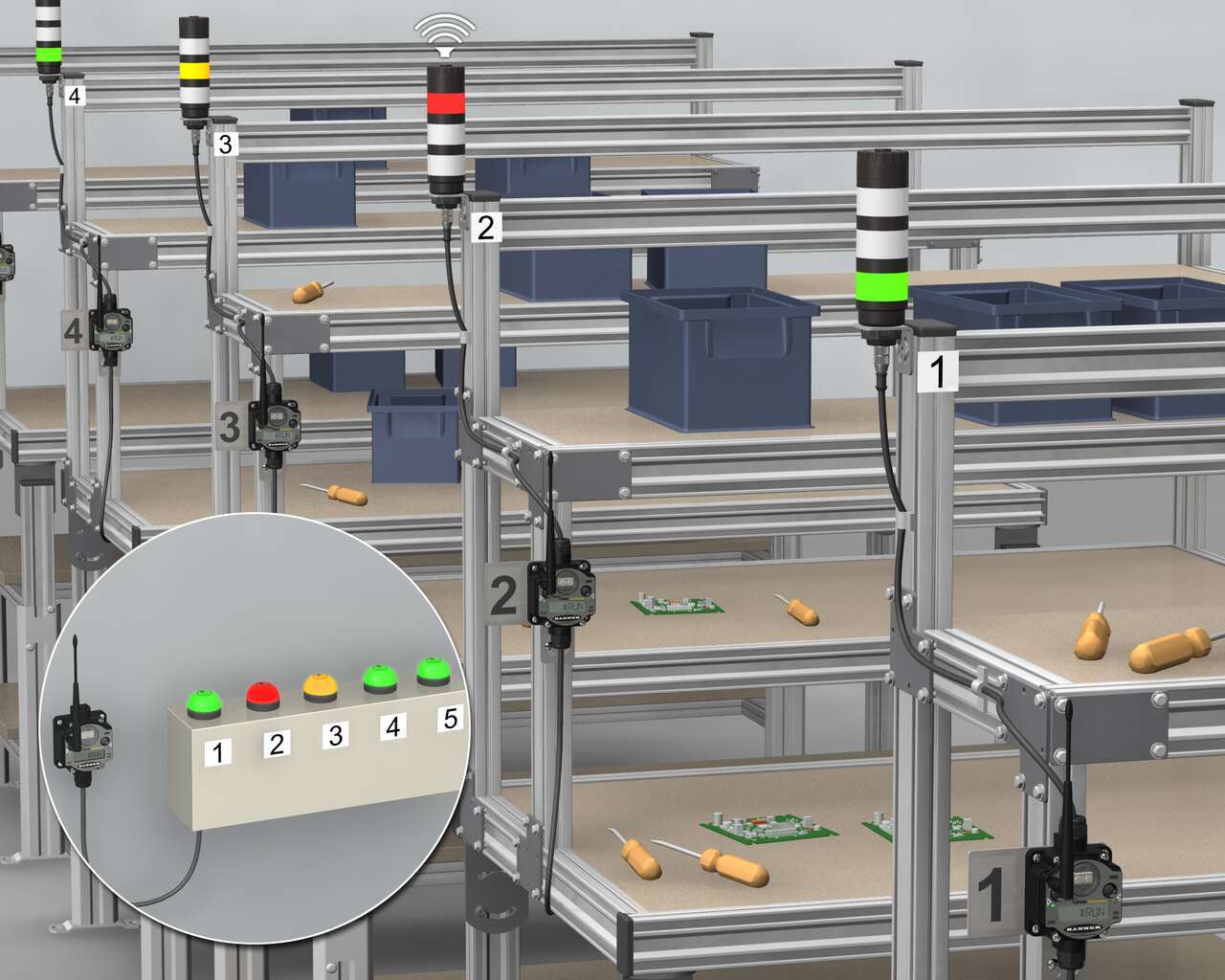

Call for Parts

-

Robotic Guarding in Work Area without Limiting Access

-

Scalable Safety Control for Large Assembly Processes

-

Call For Parts

-

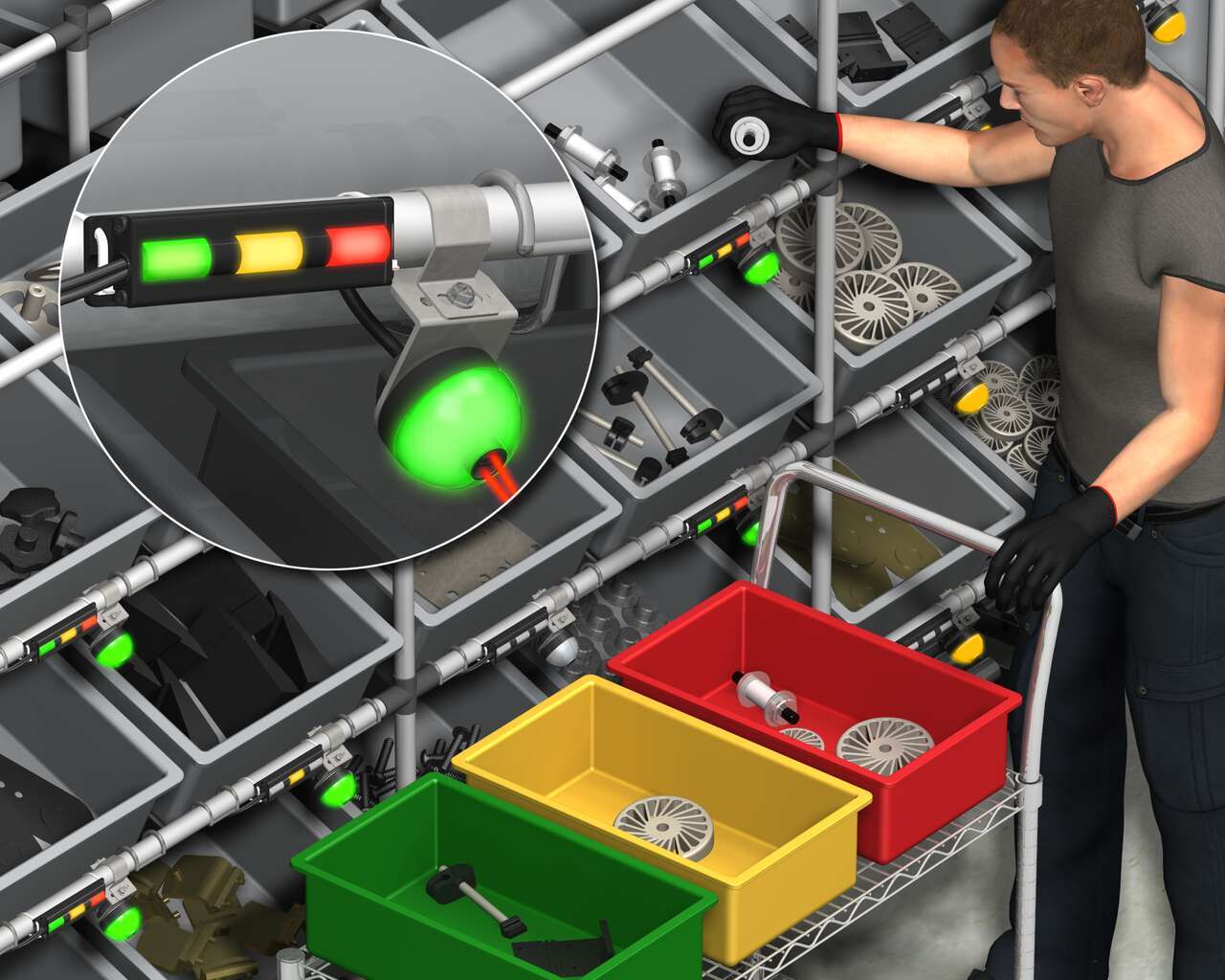

Part Pick Indication for Small Bins

-

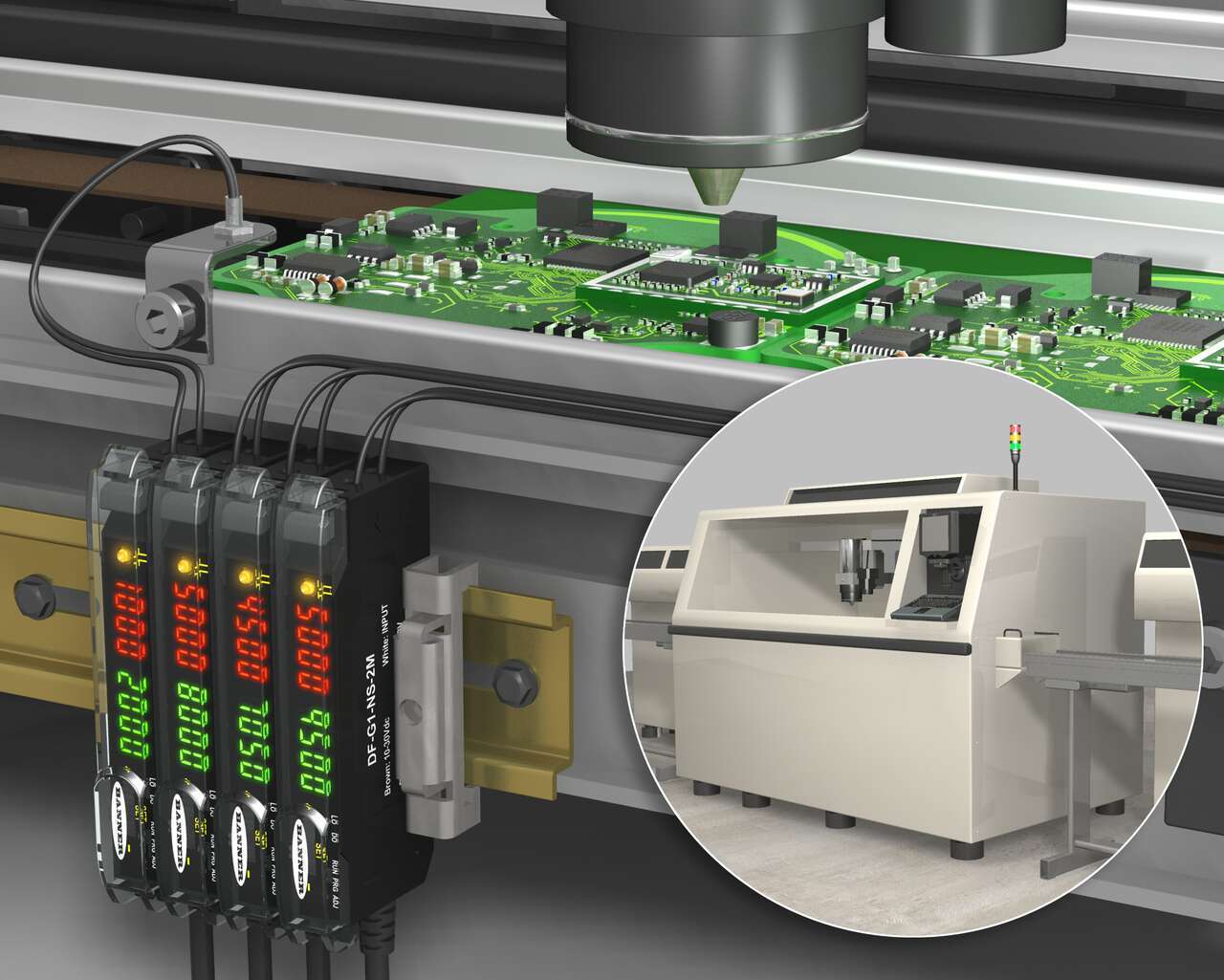

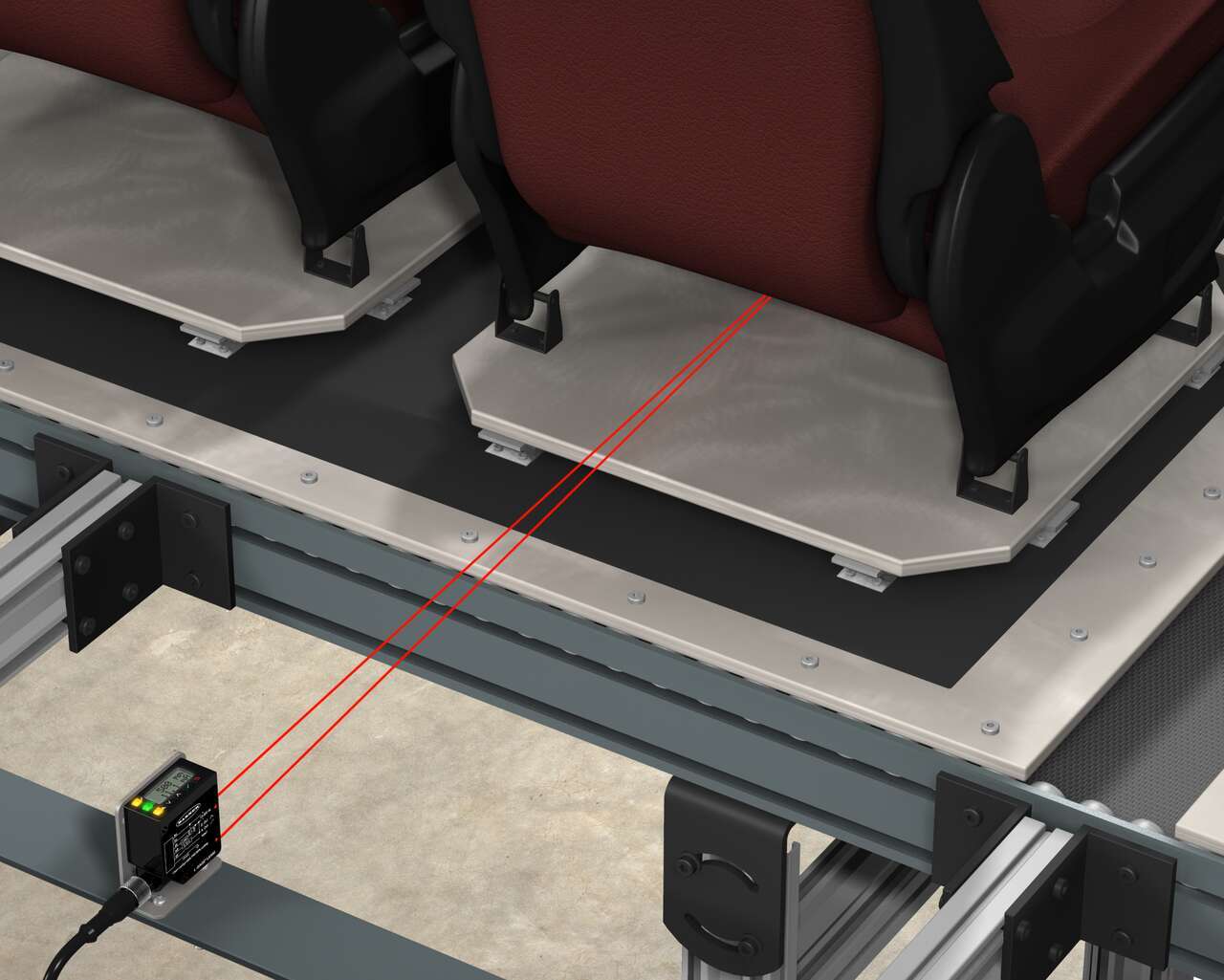

Pick and Place Machine Leading Edge Detection

-

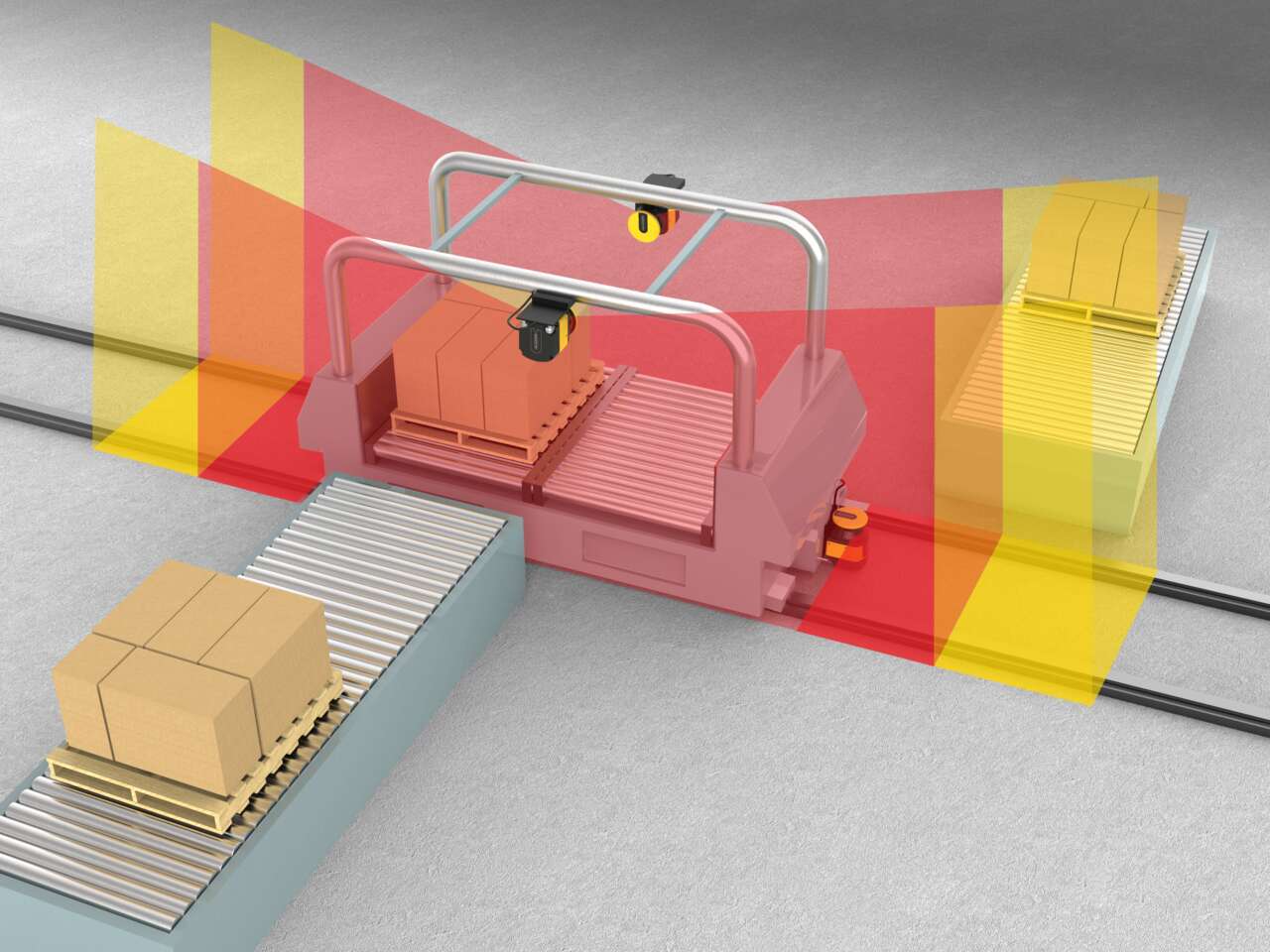

Calling an AGV for Parts

-

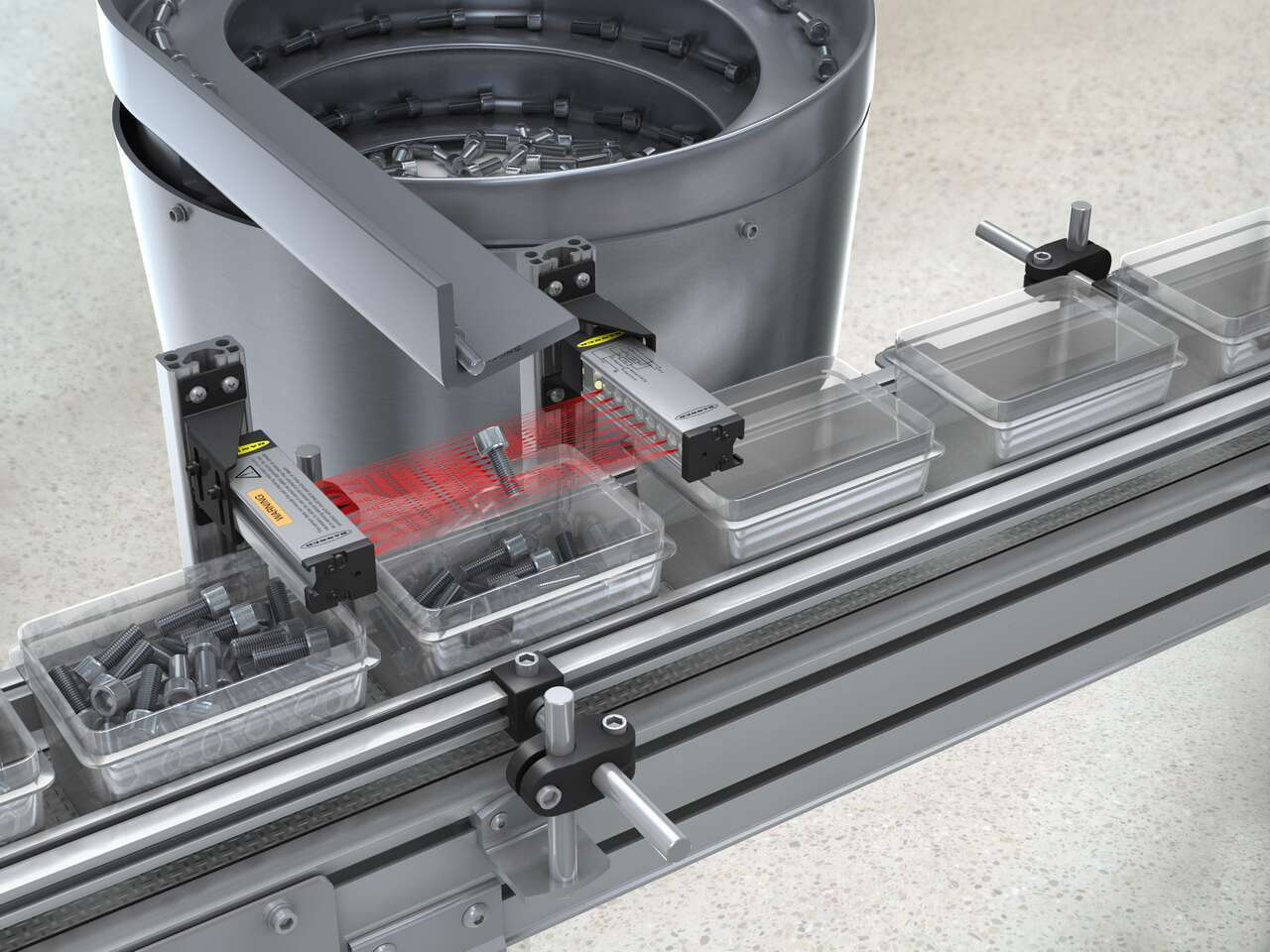

Counting Dropping Parts with an LX Sensor

-

Retrofit for Robotics

-

Improving Production with Pick-to-Light Systems

-

Automatic Storage & Retrieval System

-

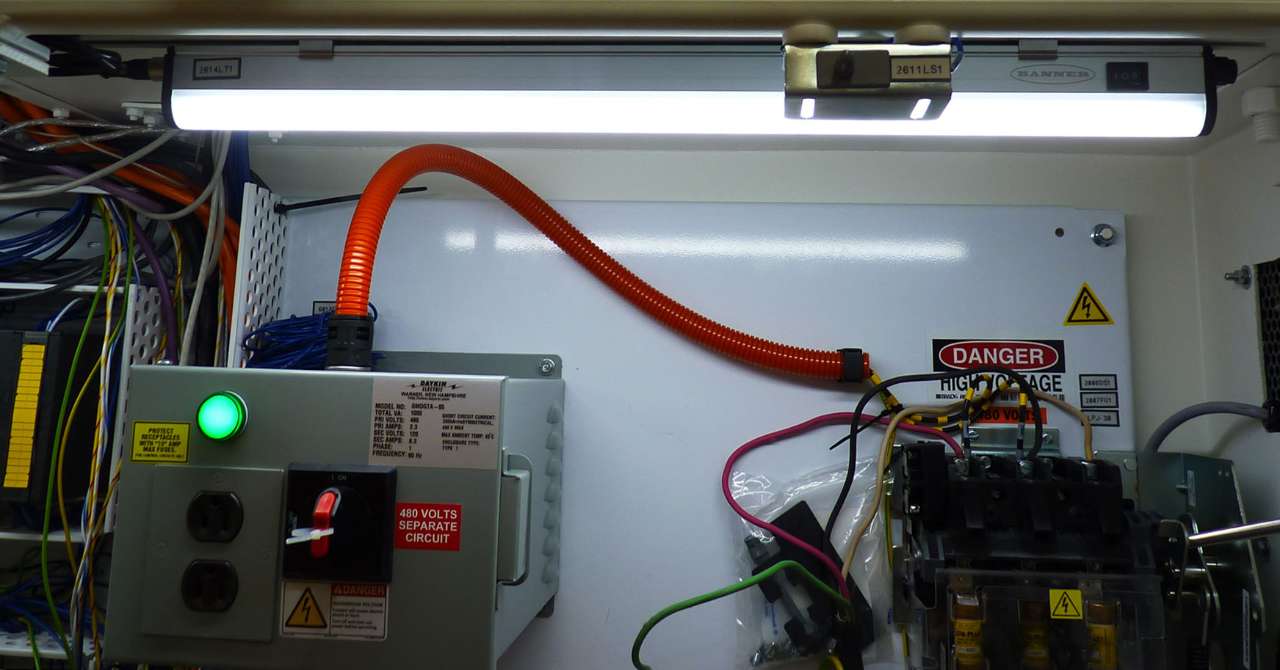

Environmental Monitoring inside a Machine Control Panel

-

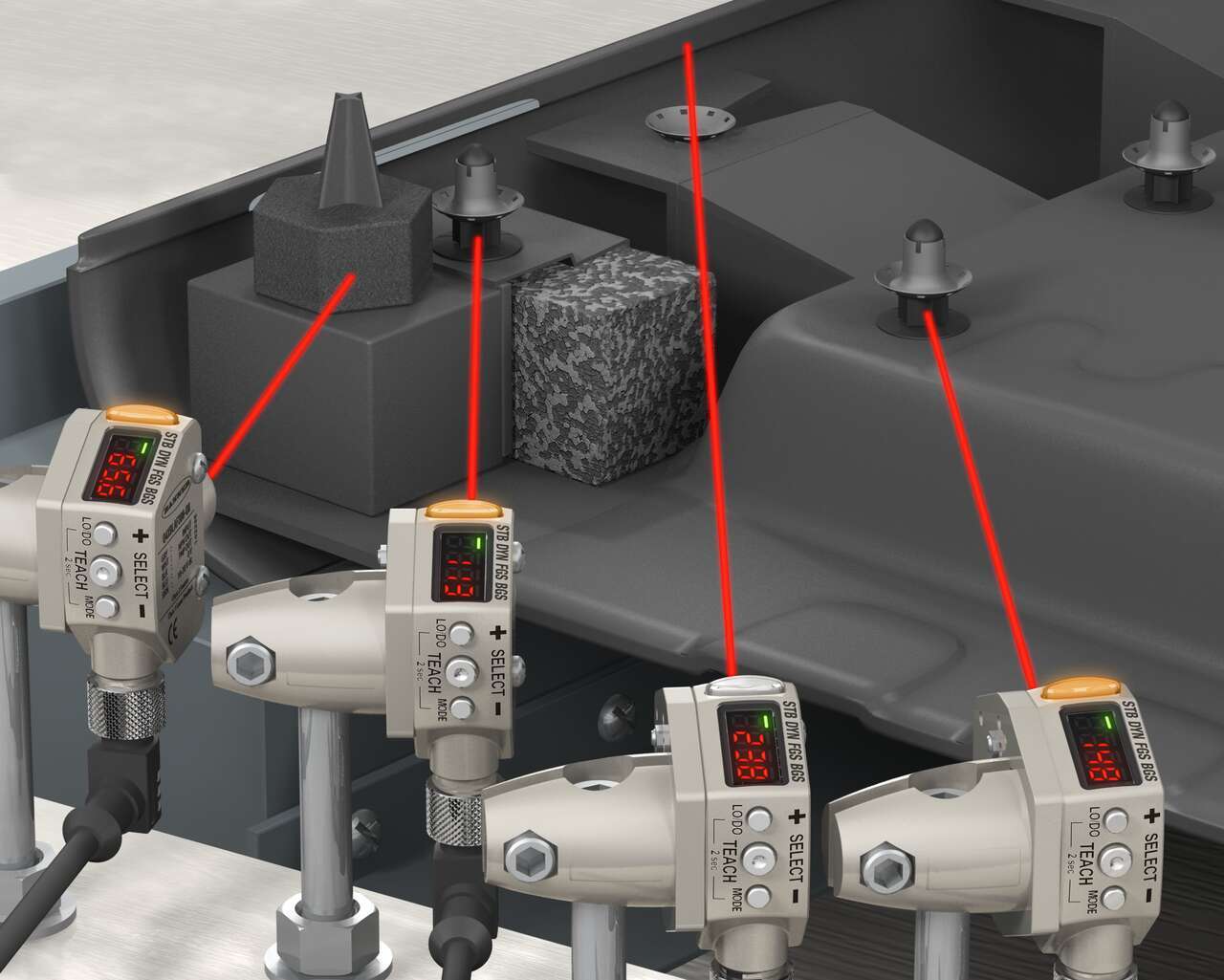

Error-Proofing Assembly Applications

-

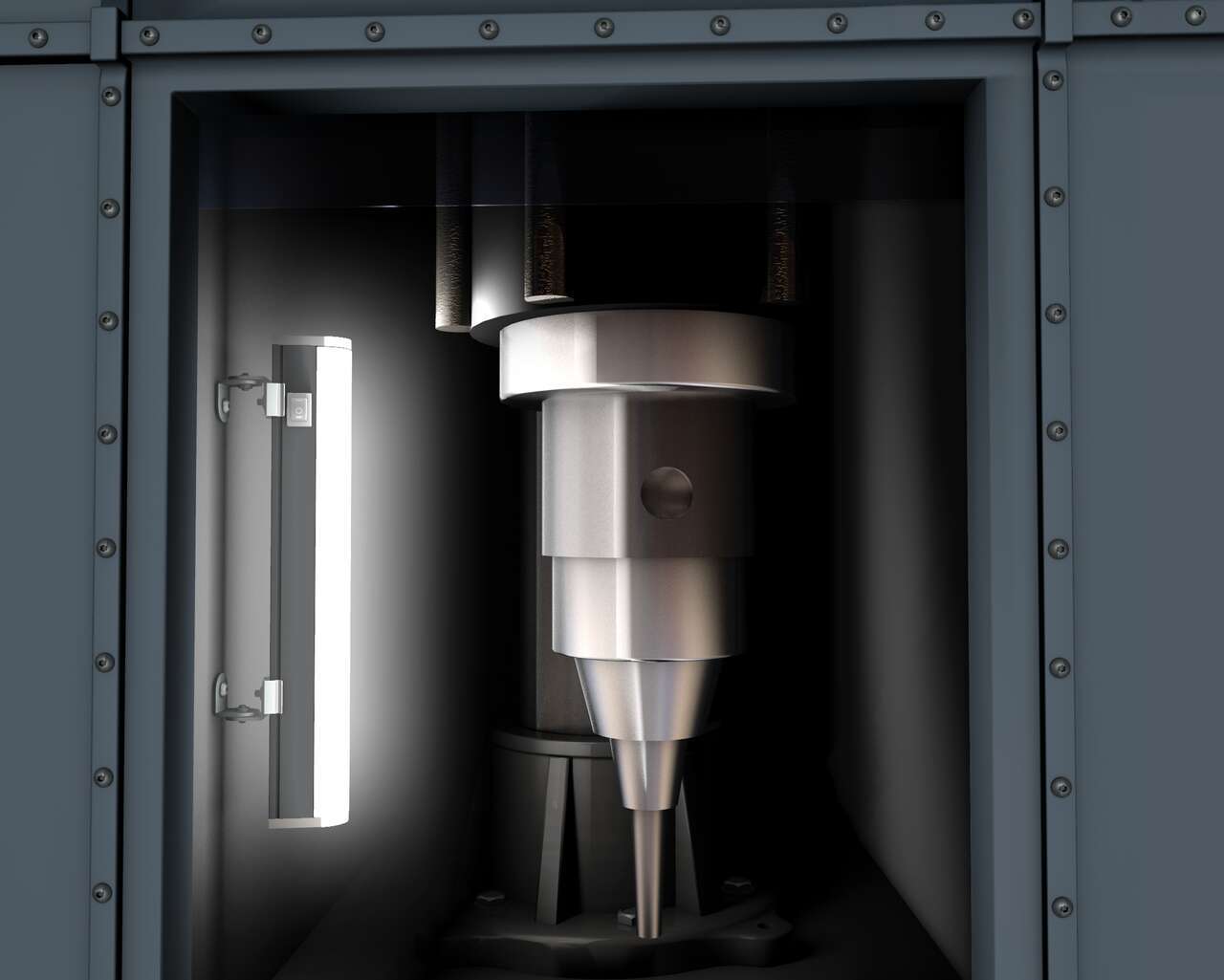

Robotic Work Cell Lighting

-

Call for Parts (Put to Light)

-

Kitting Operation with Gloves

-

Multiproduct Light-Guided Assembly Station

-

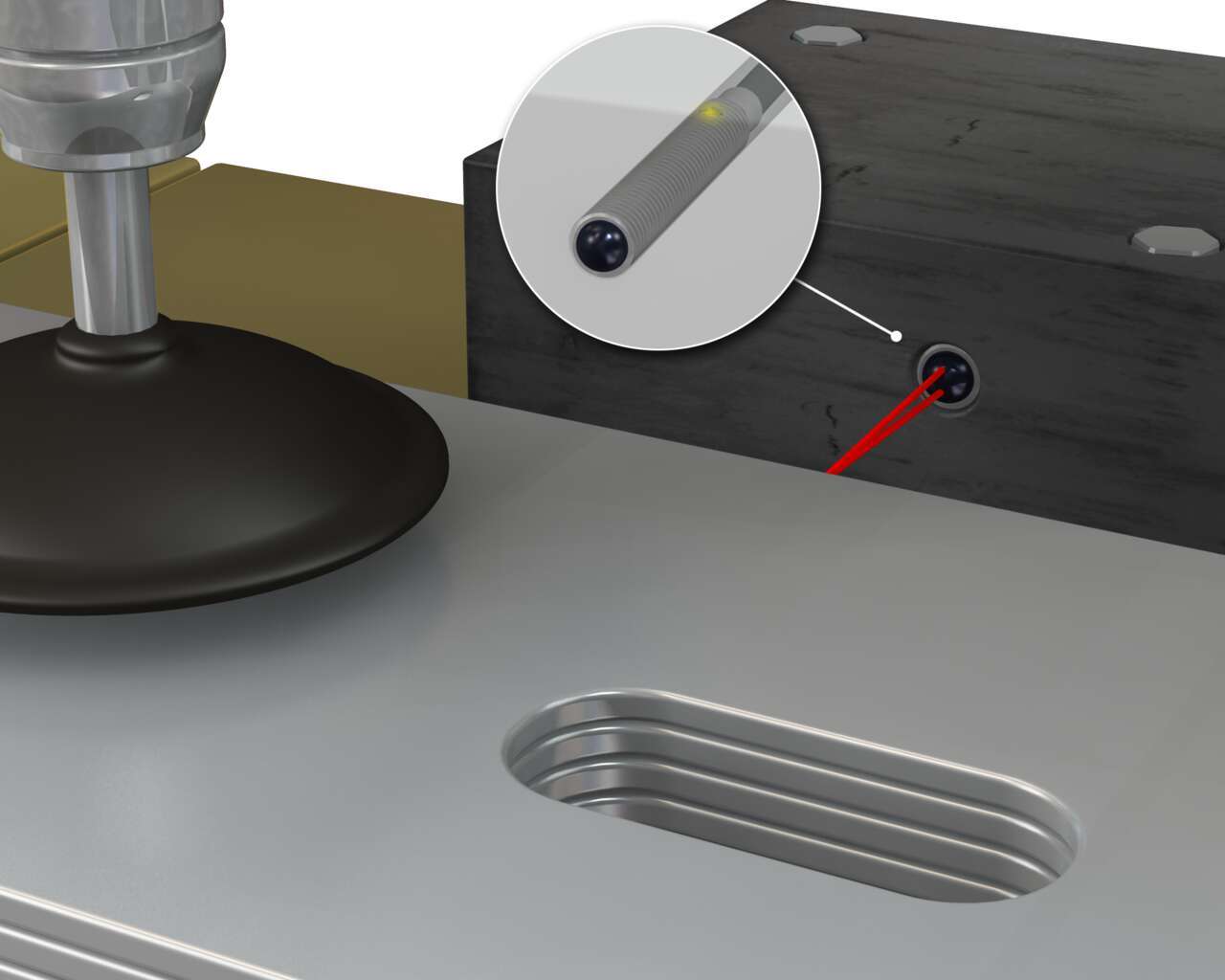

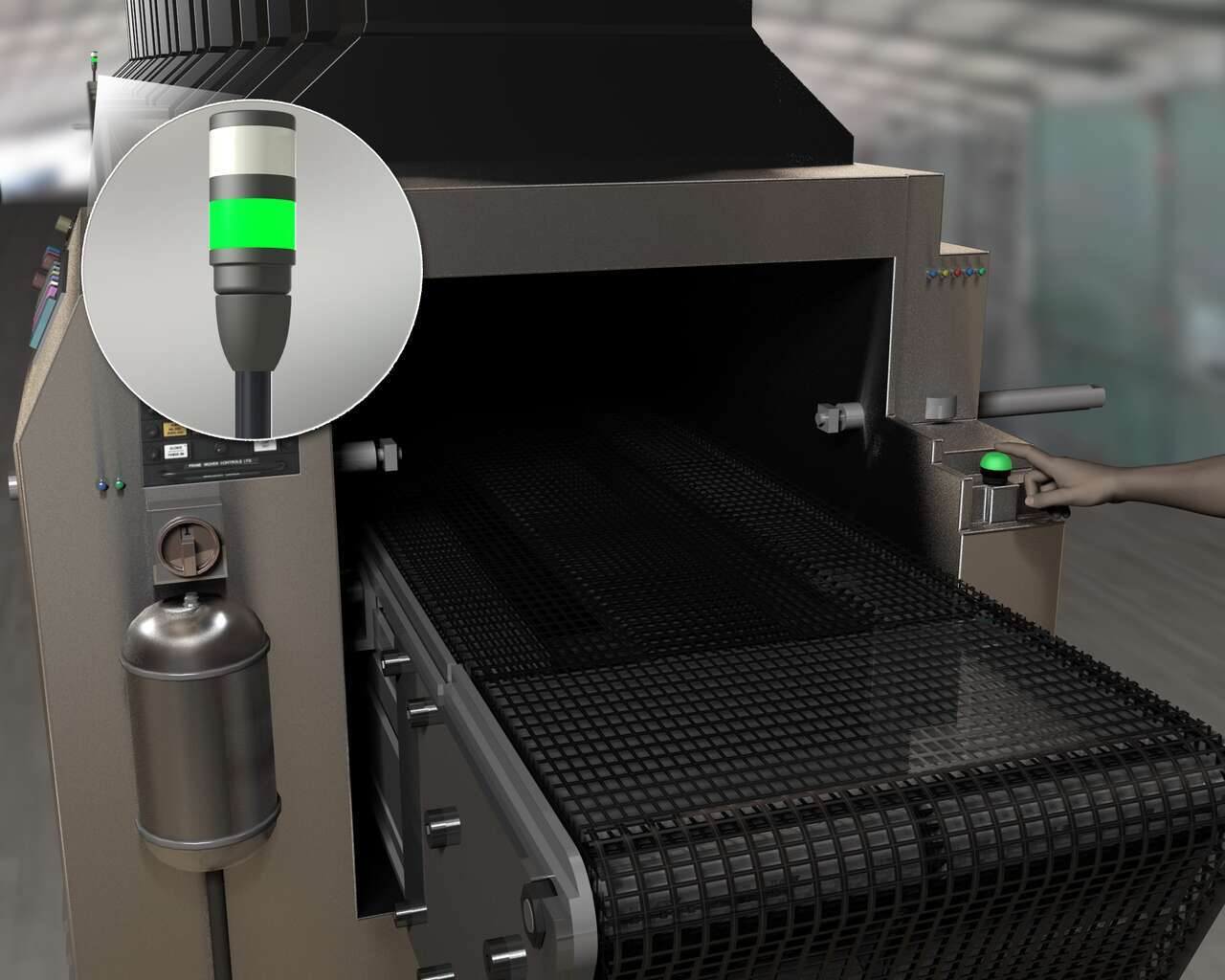

Part Loaded Indicator

-

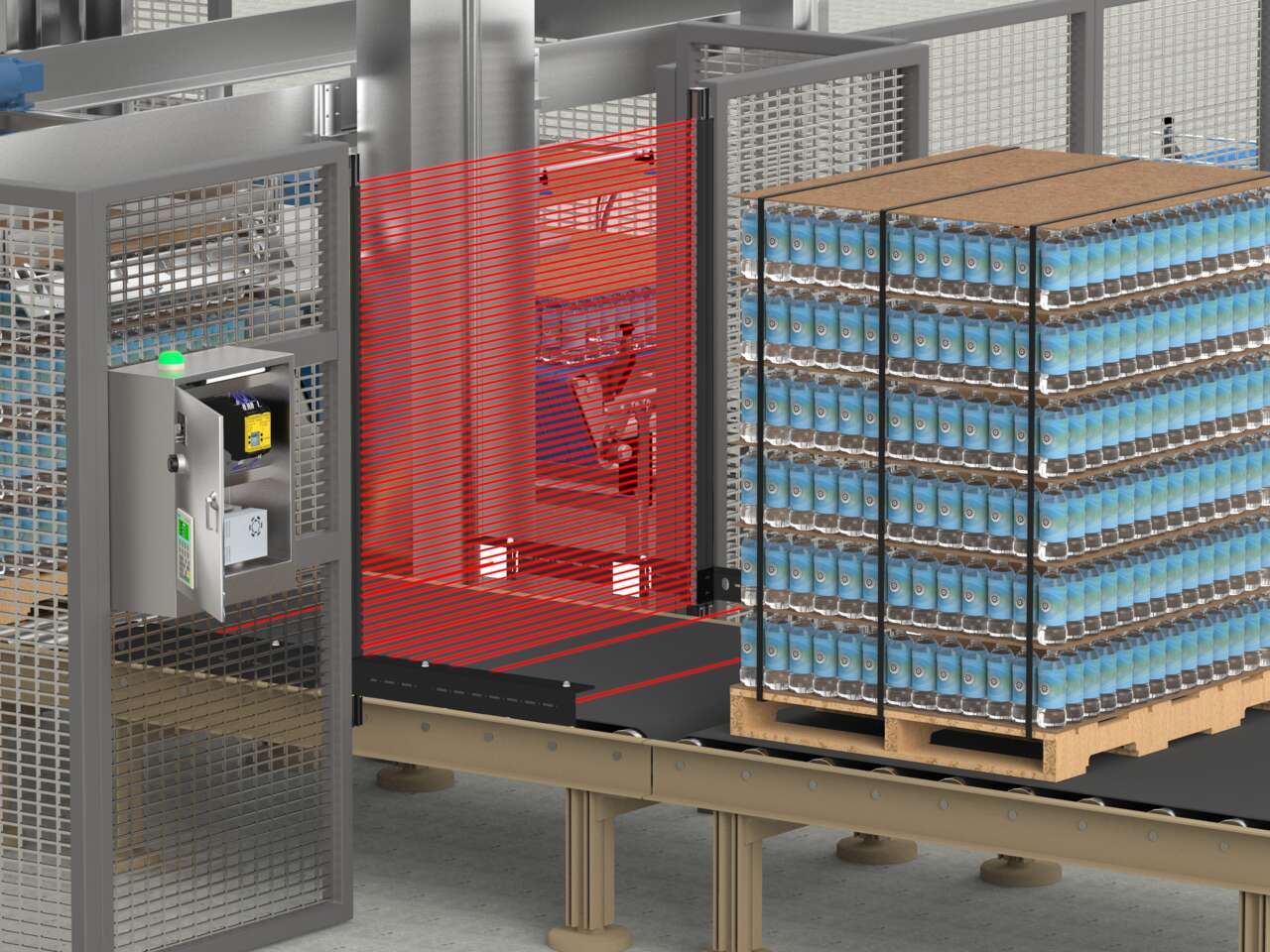

Robotic Palletizer Safeguarding

-

Safeguarding Access Points to a Depalletizer

-

Heat Stake Machine Safeguarding

-

Safeguarding a Robotic Palletizer

-

Close Proximity Error Proofing on Assembly Line

-

Detecting Black Parts on Black Door Panel

-

Stack Height Detection of Metal Parts

-

Dual-operator Robotic Work Station

-

Call for Parts at a Furniture Manufacturer

-

Equipment Monitoring from a Supervisor's Station

-

Wireless Call for Parts

-

AGV Status Indication

-

Delivering Pinpoint Diagnostic Information to Robotic Sortation Systems

Assembly and Robotics Successes

-

Sensors to Measure Movement Range

-

Vision Sensor to Read QR Codes

-

Superior Light Distribution with LEDs

-

Presence Detection on Rotating Lathe Turret

-

Inspecting Small Connectors

-

LED Lights Illuminate Control Cabinet

-

Illuminate Web Inspection Stations with Rapid-Install LEDs

-

.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

Efficient LED Light Bars Reduce Build Times and Expenses

-

Remote Monitoring Calculates Machine Run Time

-

Indicate Robot Positioning

-

LEDs Replace Fluorescent Fixtures in Machine Enclosures

-

Streamlining Call for Parts or Service

-

Communication in a Busy Manufacturing Site

-

Photoelectric Sensors | QS18

QS18 Series All Purpose Photoelectric SensorAll purpose photoelectric sensor with universal housing design and 18 mm threaded barrel is an ideal replacement for hundreds of other sensor styles.

-

Fiber Optic Amplifiers | DF-G2

DF-G2 Series High Speed Fiber Optic AmplifierFiber amplifier with IO-Link capability for high speed (10 μs) for applications like part counting or registration mark detection. Output: NPN or PNP.

-

Safety Light Curtains | 14/30

14/30 Traditional Type 4 Safety Light CurtainsModels available in 14 & 30 mm resolutions and up to 2400 mm (7.9 ft) lengths in three robust housing options. Suitable for detecting fingers, hands, and ankles as well as guarding perimeters.

Keep up-to-date on what is happening here at Banner and in the industry with our Newsletter.

Thank you for Subscribing!

Thank you for your submission. Please look in your email inbox for our newsletter.