Compliance with Safety Standards

Implementings safety measures can help reduce liability for employers and demonstrate compliance with safety standards to appropriate regulatory agencies.

OEMs who integrate safeguarding into their machines enjoy a ready market for their easy-to-use, pre-integrated machines.

Increased Productivity

Safeguarding machines benefits workers and manufacturers alike by reducing lost work days due to injury, increasing productivity, and improving worker morale.

Banner engineers are here to help! Let us know about your washdown needs, and our engineers can help you find the right solution for your application.

Learn about more washdown solutions from Banner Engineering.

Clear Container Detection in a Clean-in-Place Rotary Filler

Track bottles as they move through the rotary filter.

Clear Glass Jar Detection for Food and Beverage Splash Zone

Detecting glass jars in a strict cleaning environment

Detecting Bottles in Washdown: Glass & PET Plastic

Washdown environment, IP69K ratings required

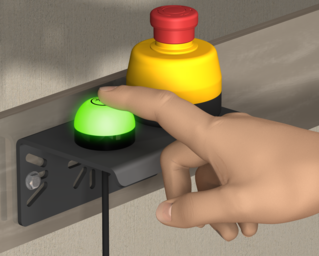

Emergency Stop Indication

With the all-in-one enclosure, the emergency stop pushbutton combined with the K50 Touch lighted indicator communicates simple status indication in emergency conditions.

Heavy-Duty Machine Lights in CNC Washdown Environment

Determining a lighting solution for the CNC machine is simple with Banner’s LED heavy-duty machine light, which provides enhanced chemical and thermal resistance in tough environments. The ultra-bright light is oil, chemical and water resistant with IP68, IP68g and IP69K ratings, making it an ideal choice for many industrial lighting applications, including the CNC washdown environment.

Hygienic Sensor Detects Variety of Bottle Types on a Rinser

Verification that a bottle is present before the rinser jets are powered on.

Illumination in High-Temperature Areas in a Paper Mill

Lighting inside of paper drying machines is helpful during maintenance and general operation of the paper production line, but illumination is difficult because of the high heat in the machine and the wet environment. The WLH60 high temperature LED light can withstand heats as high as 100° C and is rated IP67, IP68G, and IP69K for water, oil, and chemical resistance.

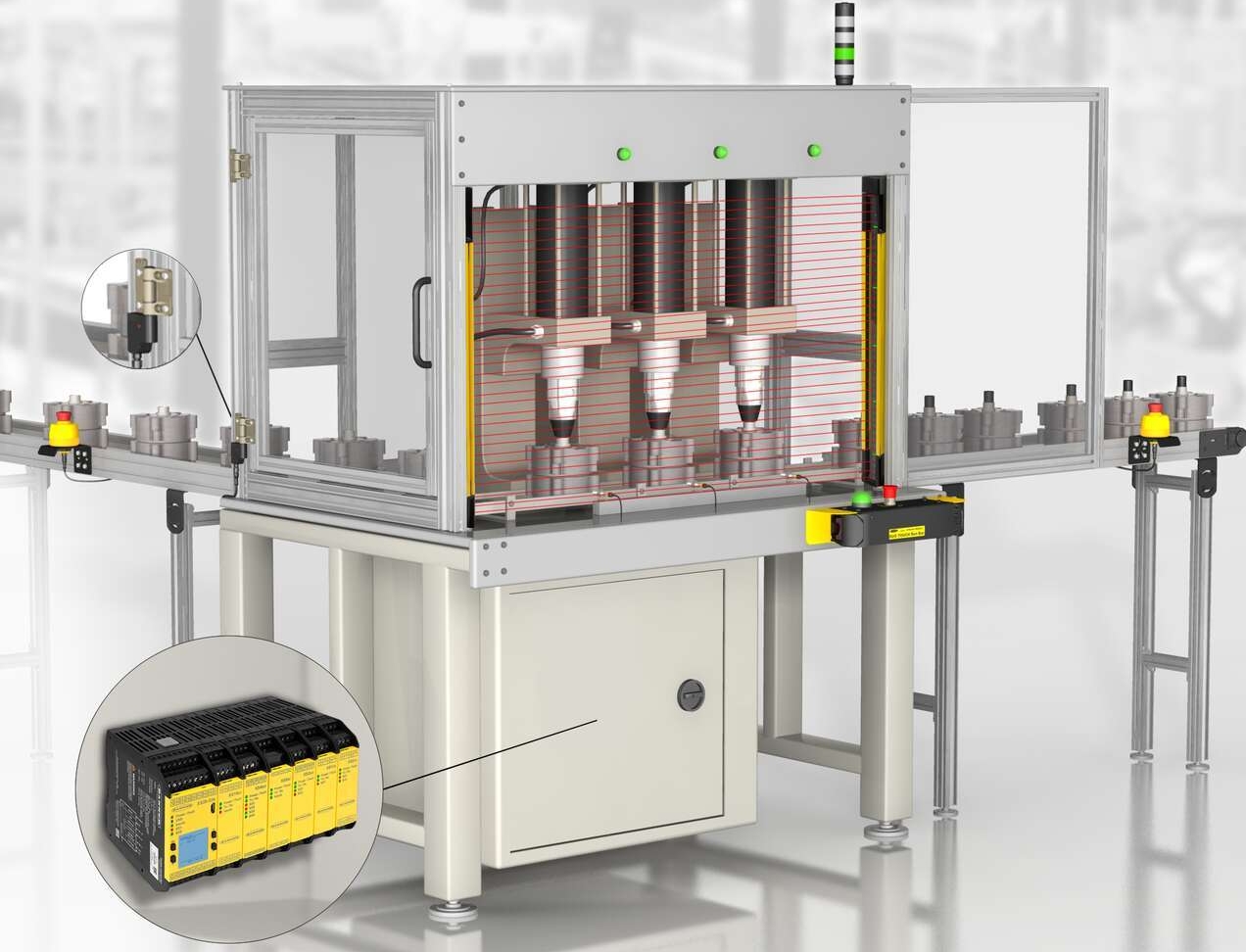

Safety at Palletizer Station with Sticky Liquids Present

Safeguarding palletizer machines can be difficult because bottles are under a lot of pressure and can contain corrosive liquids such as soda or juice. Hygienic enclosures protect light curtains from corrosive liquids, meet sanitary requirements, and do not affect the performance of the sensor.

About Banner Engineering

Founded in 1966, Banner Engineering is a global company and a globally recognized leader in the field of process and industrial automation. Our sensors and vision sensors, LED lights and indicators, wireless and safety products are used by companies large and small, from industry leaders in the Fortune 500 to innovators just entering the market.