What to Look for in a Laser Measurement Solution

Reliable Sensing

Data from sensors and other field devices was once inaccessible. For many manufacturers, these field devices offer untapped potential for greater visibility into their operations and more advanced, data-driven decision making.

Rugged Design

With the trend of Industrial Internet of Things (IIoT), device-level data can now be made accessible to operators and plant managers, providing valuable insight into machine performance, process inefficiencies, and more.

What is Your Challenging Distance Measurement Application?

Banner engineers are here to help! Let us know about your distance measurement challenges, and our engineers can help you find the right solution for your application.

Solutions

Solves difficult distance-based applications including black foam on black plastic, black rubber in front of metal, multicolor packaging and targets of all colors.

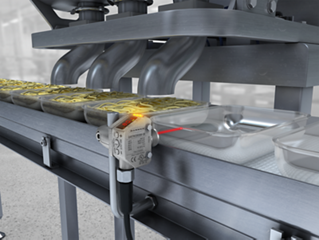

Black Plastic Tray Detection at a Hopper and Filling Station

Learn how the Q4X detects dark colored trays at hopper and filling station in the food industry.

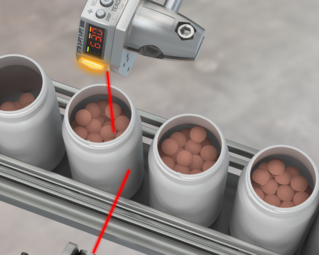

Bottle Fill Level Detection

Measure fill level, provide feedback on height of pills

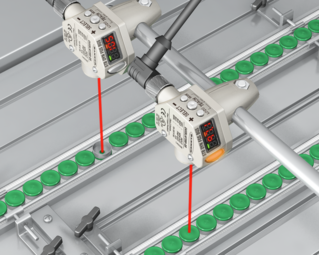

Cap Orientation Verification

Sanitary environment, subjected to aggressive chemical washdowns

Carton Stack Height

Frequent product changeovers, reduce setup time

Clear and Reflective Targets

Detecting clear and reflective objects are some of the most challenging sensor applications. Light can burn through a target or be reflected away erratically, making accurate detection difficult.

Clear Tray Detection at Hopper Food Storage Units

Learn how the Q4X detects clear plastic trays at hopper and filling station in the food industry.

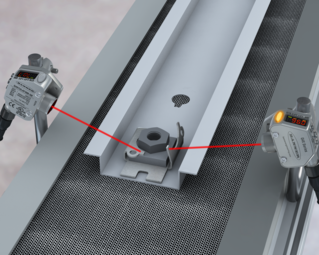

Close Proximity Error Proofing on Assembly Line

Multiple sensors, confirm part presence and position

Counting Multicolored Reflective Packages on a Conveyor

Counting reflective and wrinkled packaging on a conveyor

About Banner Engineering

Founded in 1966, Banner Engineering is a global company and a globally recognized leader in the field of process and industrial automation. Our sensors and vision sensors, LED lights and indicators, wireless and safety products are used by companies large and small, from industry leaders in the Fortune 500 to innovators just entering the market.