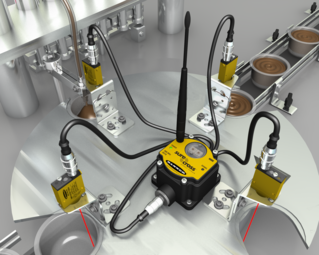

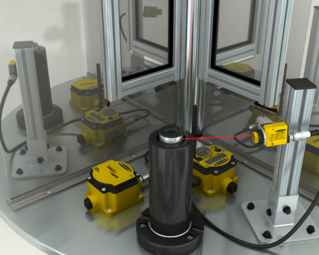

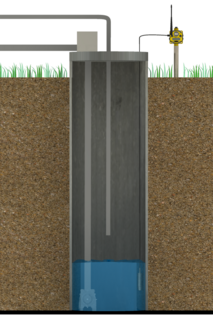

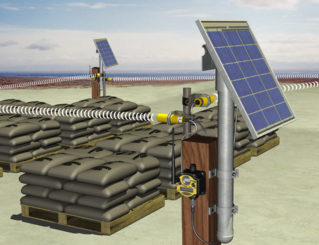

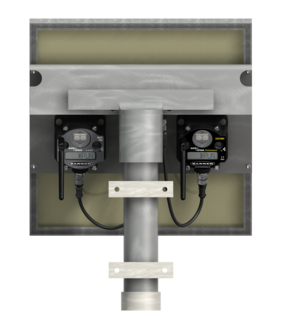

SureCross DX81 FlexPower Supplies

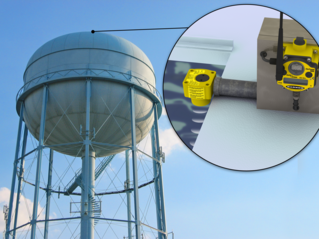

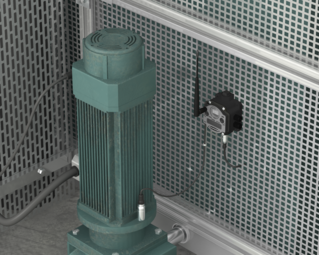

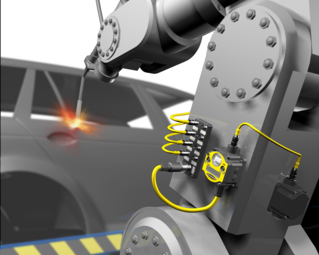

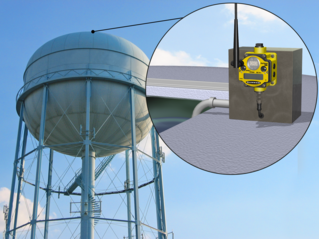

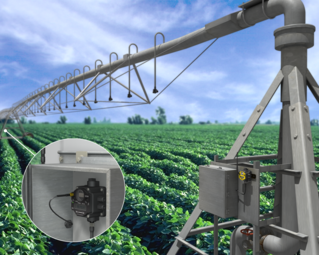

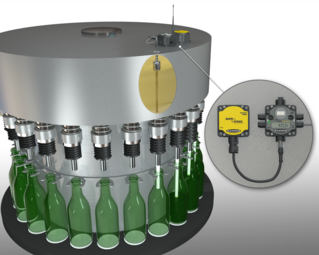

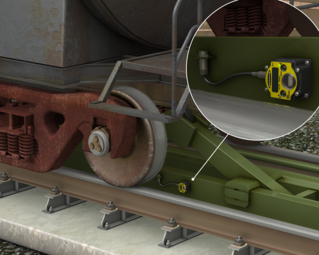

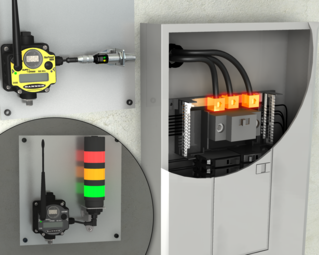

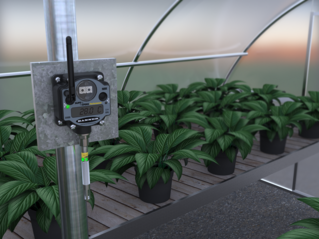

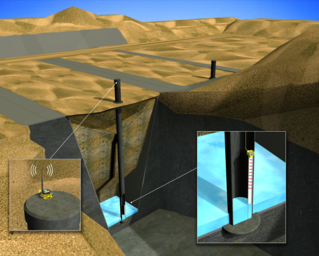

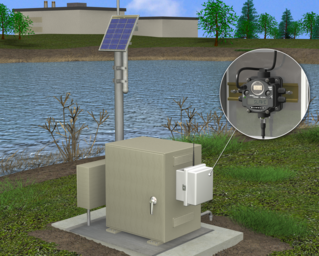

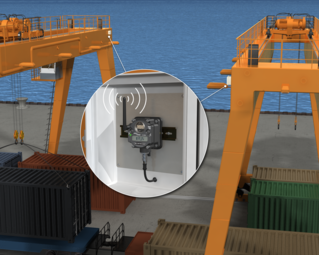

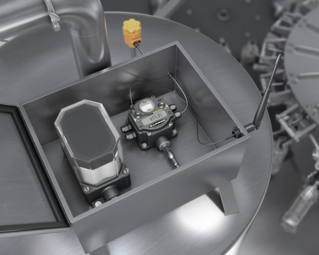

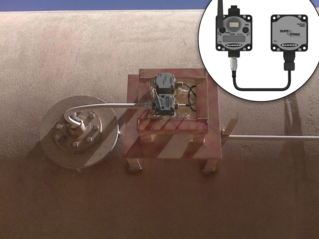

FlexPower supplies provide a reliable solution for remote power and hard-to-access locations.

- FlexPower battery modules supply power to FlexPower Nodes. The DX81 module uses one lithium primary battery.

- FlexPower batteries feature efficient power management technology.

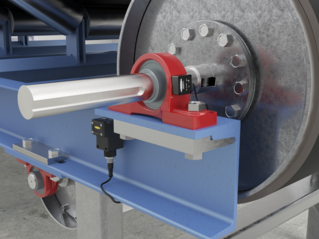

- The battery provides brief switchpower voltage to activate a sensing device.

- Once activated, the input reads the sensor, and then the switchpower shuts off to prolong battery life—up to 5 years.

- The actuation voltage, time on and sample are configurable parameters, with voltage up to 24V dc.

Downloads

Technical Literature

Date

Type

Size

Date

Type

Size

05/01/12

Datasheet

3MB

Date

Type

Size

Brochures & Catalogs

Date

Type

Size

Date

Type

Size

Date

Type

Size

Product Selection

Product data is currently unavailable.

.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)