All Food Solutions

-

Thermal Remediation Temperature Measurement

Thermal Remediation Temperature Measurement

The EPA has placed restrictions on the use of many fumigants citing a correlation between their use and ozone depletion. As an alternative, a large-scale flour mill performs three to four thermal remediations per year to eradicate flour beetles. The temperature inside the mill is brought up to 122° F (50° C). This is done gradually to minimize equipment and building strain caused by heat expansion.

-

Industrial Refrigeration System Pressure Level Monitoring

Industrial Refrigeration System Pressure Level Monitoring

Performance Series all-in-one wireless pressure sensors make it easy to monitor pressure levels in large and complex systems from any network-enabled location.

-

Sanitary Detection of Clear Plastic Food Containers

Sanitary Detection of Clear Plastic Food Containers

Clear, thermoformed plastic containers, trays and clamshells are used to package a wide variety of products. Packagers must be able to detect the leading edge.

-

Clear Glass Jar Detection for Food and Beverage Splash Zone

Clear Glass Jar Detection for Food and Beverage Splash Zone

Sensor solutions to detect clear glass jars to be filled with food in a strict sanitary environment where frequent, high-pressure washdowns and IP69K ratings.

-

Detecting Reflective Packages on a Conveyor

Detecting Reflective Packages on a Conveyor

Sensor solutions to detect reflective food wrappers such as Mylar with conveyor belt presence verification, utilizing foreground suppression.

-

Controlling Line Pressure of Clear Food Trays at Denester

Controlling Line Pressure of Clear Food Trays at Denester

Using a sensor in clear object sensing mode to ensure proper staging of plastic trays during denesting process.

-

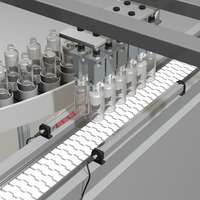

Monitoring Flow of Transparent Plastic Bottles on a Conveyor

Monitoring Flow of Transparent Plastic Bottles on a Conveyor

Sensor solutions to monitor a conveyor to ensure there are no stuck bottles when bottles are clear plastic in a large sensing area.

-

Clear Tray Detection at Hopper Food Storage Units

Clear Tray Detection at Hopper Food Storage Units

Learn how the Q4X detects clear plastic trays at hopper and filling station in the food industry.

-

Safety Measures for Meat Slicing Machine in Harsh Conditions

Safety Measures for Meat Slicing Machine in Harsh Conditions

Safety light screens on a meat slicer protect operators from sharp blades while in operation. The environment is harsh and frequently exposed to chemical washdowns. The EZ-SCREEN LS with hygienic enclosure keeps personnel safe while preventing water and chemical damage to the light screen.

-

Monitoring Safety Doors on a Case Packer

Monitoring Safety Doors on a Case Packer

Learn how SI-RF Series safety switches can be used to monitor multiple guard doors, ensuring the highest levels of safety, and making it easy to identify and resolve issues.

-

Illuminating Inside A Cartoner

Illuminating Inside A Cartoner

Banner’s WLS28 LED Light Strips allow operators to identify frozen dinners that have not properly entered a carton and fix the problem with minimal downtime. Their long-lasting and durable cool white light means they’re an energy-efficient solution for illuminating the inside of a cartoner. IP69K rated, they can handle frequent machine wash down procedures.

-

Carton Stack Height

Carton Stack Height

The two-point teach option on the Q4X analog laser measurement sensor is used to teach the full and empty magazine. Manual adjustment can be used to fine tune the output. The analog output provides a real time gauge of the stack height. This allows the cartoner machine to have several “call for parts” set points without having to manually move the sensor. The Q4X is a robust, rugged stainless steel sensor ideal for use in many industrial, factory environments.

-

Consistent Dough Height Measurement

Consistent Dough Height Measurement

The dough for one of the company’s many popular breakfast cereals must fall within specific height parameters to ensure that it will have the perfect flake. Dough that is too thick will emerge from baking stiff and heavy. Dough that is too thin will crumble easily. This impacts the quality, taste and texture of the final product as well as product weight and packaging. Any product that does not meet the rigorous quality standards of the company will not be shipped or sold on the consumer market.

-

Accurately Measuring Bakery Ingredients

Accurately Measuring Bakery Ingredients

Baking is a mixture of creativity, precision and attention to detail. The Wilkinson Baking Company has added technical innovation to the mix. The Wilkinson Bread Bakery is a compact, completely self-contained and fully automated bread bakery. This unique machine combines technology with tradition to transform simple raw ingredients into bakery fresh bread at 40 loaves an hour.

-

Monitoring Content Levels inside a High-Volume Hopper

Monitoring Content Levels inside a High-Volume Hopper

Banner’s LTF Series Laser Measurement Sensor features high excess gain, superior signal control and automatic adaptive laser power control. These features enable reliable detection of the chewing gum from up to 12 meters away, regardless of color or reflective surfaces inside the hopper.

-

Monitoring Plastic Tray Levels on a Denester Machine

Monitoring Plastic Tray Levels on a Denester Machine

Tracking tray levels on a denester machine ensures that product is replenished in a timely manner and does not affect production.

-

Tank Level Monitoring

Tank Level Monitoring

Using K50U ultrasonic sensors and Q45U wireless nodes paired to a DXM100 wireless controller, we can develop a wireless monitoring system for multiple tank level measurements that is easy to set up, interpret the results, and monitor locally through a cloud-based system.

-

Tension Loop Control for Clear Plastic

Tension Loop Control for Clear Plastic

The S18U Series Ultrasonic Sensor monitors loop control on a food packaging line to detect any breaks or tears in the clear plastic film. The S18U detects targets regardless of color or transparency.

-

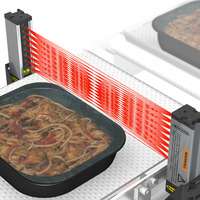

Leading Edge Detection of Packages with a Thin, Flexible Edge

Leading Edge Detection of Packages with a Thin, Flexible Edge

Banner’s LX Series is an economical solution for detecting the leading edge of flat objects, such as the frozen dinner containers. With a web of modulated light, the LX Series part-sensing light screen can detect any item—in any position—passing through the light screen.

-

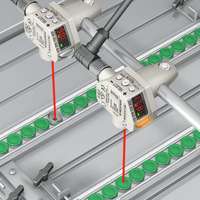

Refrigerated Breakfast Roll Detection on Multi-Lane Conveyor

Refrigerated Breakfast Roll Detection on Multi-Lane Conveyor

Dark packaging with multiple colors transitions can be difficult to detect with traditional red LED sensors. Banner Engineering’s miniature VS8 photoelectric sensor with blue LED works well with low reflectivity labels to detect refrigerated food packaged in pressurized cans. The small sensors fit into tight spaces and work well for short range applications. The blue LED works with the small spot size to minimize the effects of color transitions on the labels.

-

Cap Orientation Verification

Cap Orientation Verification

Banner’s Q4X laser sensor, made of 316L grade stainless steel, is very suitable for pharmaceutical environments and other aseptic filling areas. The Q4X has a sensing range of 25 to 300 mm, precise beam spot size and can effectively detect the orientation of caps as they exit a feeder bowl. If any caps are upside down, the Q4X will detect a height difference and reject the cap.

-

Checkweigh Station Indication of Pass/Fail Status

Checkweigh Station Indication of Pass/Fail Status

Alert operators of the fail status on a checkweigh station on a food processing line in a harsh washdown environment.

-

Black Plastic Tray Detection at a Hopper and Filling Station

Black Plastic Tray Detection at a Hopper and Filling Station

Learn how the Q4X detects dark colored trays at hopper and filling station in the food industry.

-

Flap Detection on Packaged Frozen Dinners

Flap Detection on Packaged Frozen Dinners

The QS18LD laser diffuse sensor scans across the top of the package to see if any flaps are open. The laser diffuse sensor provides accurate detection to verify whether the frozen packages are sealed properly.

-

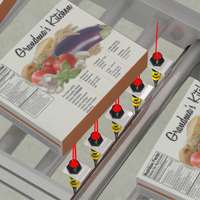

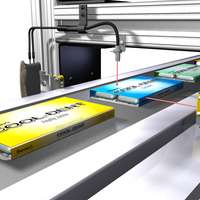

Date/Lot Code Inspection

Date/Lot Code Inspection

To verify each package has a date/lot code printed on it, an iVu Series sensor is configured for a Match inspection. An image of the date/lot code is captured. When the inspection is running, if the sensor detects a package without the date/lot code the sensor sends a fail output to the line, and the product is rejected.

-

Food Packaging Label Inspection

Food Packaging Label Inspection

To verify each box is correct, an iVu Series sensor is configured for a Match inspection with 360 degree rotation enabled. An image of the correct box is captured and when the inspection is running, if the sensor detects an incorrect box, the sensor sends a fail output to the line, and the product is rejected.

-

Detecting Tamper-Evident Band Position and Presence

Detecting Tamper-Evident Band Position and Presence

Banner iVu TG vision sensor with multi-point inspections is ideal for detecting and evaluating the position of tamper-evident bands. In this application, the band should be positioned around both the cap and the neck of a bottle. A seal positioned too high, too low, or completely missing would be considered unacceptable. With multi-point inspection, the iVu TG vision sensor can simultaneously detect missing and poorly positioned bands.

-

Labeling Detection

Labeling Detection

In an application with limited space, the WORLD-BEAM Q20 sensor is easily positioned to verify the presence of a label before it is applied to the product.

-

Inspecting for Missing Chocolates on a Packaging Line

Inspecting for Missing Chocolates on a Packaging Line

Banner sensors are positioned above a conveyor inspecting each passing box for missing chocolates. When a passing box breaks the trigger beam created by a pair of Q12 opposed-mode sensors, an array of QS18AF sensors mounted above the box inspect each location for missing chocolates. When a box containing the wrong amount of chocolates is detected, an output signal is relayed to a main controller at the packaging line warning of the failed condition.

-

Detecting Different Size Packages on a Conveyor

Detecting Different Size Packages on a Conveyor

Banner’s S18-2 barrel sensor is a cost-effective, reliable sensing method for this type of application. Its small size makes it easy to integrate along the manufacturing line, and its competitive price means it is well-suited for applications requiring multiple sensors. With a powerful and bright visible red emitter beam, the S18 sensors are easy to align during set up.

-

Carton Trigger For Date/Lot Code Printing

Carton Trigger For Date/Lot Code Printing

With a narrow beam that projects a small bright spot, the QS18LLP laser, polarized, retro-reflective sensors provide precise position control when triggering various devices. In this application, the QS18LLP is able to correctly detect the glossy carton as it travels down the conveyor—without proxing—and trigger the ink jet printer to print the date/lot code on the carton. The second sensor triggers the P4 OMNI to inspect the date/lot code and verify it is legible and correct.

-

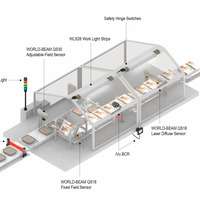

Packaging Frozen Dinners on a Cartoner

Packaging Frozen Dinners on a Cartoner

WLS28 Work Light Strips: Bright, long-lasting LED light strips provide optimal visibility inside the cartoner for operator access and easily fit on the machine without obscuring access Safety Hinge Switches: Stainless steel, load-bearing safety hinge switches support the cartoner’s machine door and will shut down the machine if the doors are opened, and minimize the risk of intentional defeat

-

Counting Food Cartons for Correct Packaging

Counting Food Cartons for Correct Packaging

Banner’s WORLD-BEAM QS18LP laser sensor accurately inspects every carton that passes on the conveyor, ensuring the robot is triggered to load cartons into the package. With a visible laser sensing beam, the QS18LP provides precise position control, which is ideal to ensure accurate counting of cartons at a close range. The rugged QS18LP is also ideal for confined spaces and is easily set up along a conveyor for accurate sensing. With highly bright LEDs, operating status is visible from 360⁰.

-

Color Sorting

Color Sorting

The D10 sorts gum packets by color—yellow, blue, or green—using dual-discrete outputs. The two outputs of the D10 Expert are programmed as follows: yellow is both outputs ON, blue is both outputs OFF, and green is one output ON and one OFF. The output wire of a Q12 sensor is connected to the inhibit wire of the D10 to ensure that the outputs are off when a packet is not present, so the sensor does not erroneously signal that a blue packet is present.

-

Conveyor-Triggered Checkweigh Station for Food Trays

Conveyor-Triggered Checkweigh Station for Food Trays

Banner Engineering's QM26 washdown sensor detects dark plastic food trays as they approach a checkweigh machine that confirms the correct weight of the filled trays.

-

Monitoring Clear Film in a Tray Sealer

Monitoring Clear Film in a Tray Sealer

After food trays have been filled they need to be properly sealed and packaged with a layer of clear film. Installing a VSM series sensor in a heat sealer accurately monitors the level of film material remaining on a roll.