-

Products

-

Lighting and Indication

-

Touch Buttons

-

VTB Series Illuminated Verification Touch Buttons

- Replaces capacitive touch switches and mechanical push buttons

- Features illuminated base (to provide a bright, easy-to-see job light) solid, flashing or multiple color models available

- Offers choice of models with red, green or blue job light

- Require no physical pressure to operate, eliminating hand, wrist and arm stresses associated with repeated switch operation

- Offers a cost-effective and easy-to-install pick-to-light solution for areas that cannot accommodate a light screen

- Cuts through heavy airborne contamination to function in almost any environment

- Withstands exposure to a variety of chemicals, depending on model

VTB Series Illuminated Verification Touch Buttons

Applications

-

A worker has detected a problem that might cause a quality problem down the line. The worker inserts a finger into the saddle of the EZ-LIGHT VTB, which triggers an audible alarm and displays the location on an andon board, so the supervisor can decide whether the problem merits shutting down the line.

-

Each bin has an EZ-LIGHT VTB Verification Touch Button connected to a process controller programmed with each order manifest. The VTB's LED base glows to indicate which lens to select to fulfill an order. After selecting the lens, the worker places a finger in the touch zone of the VTB to verify the pick. The worker does not have to apply any pressure to, reducing the risk of repetitive motion injury.

-

Sensor solution to signal the presence of a truck at a dock door with bright illumination.

-

To reduce the risk of error in an assembly operation, a one-piece EZ-LIGHT PVD pick-to-light sensor with a 400 mm range is interfaced with a process controller programmed with the correct assembly sequence. The controller makes the PVDs light up in the correct order, to show the assembler which part to pick. After the PVD detects that the assembler's hand has entered and left the bin, the controller signals the PVD of the next bin in the pick sequence to light up.

-

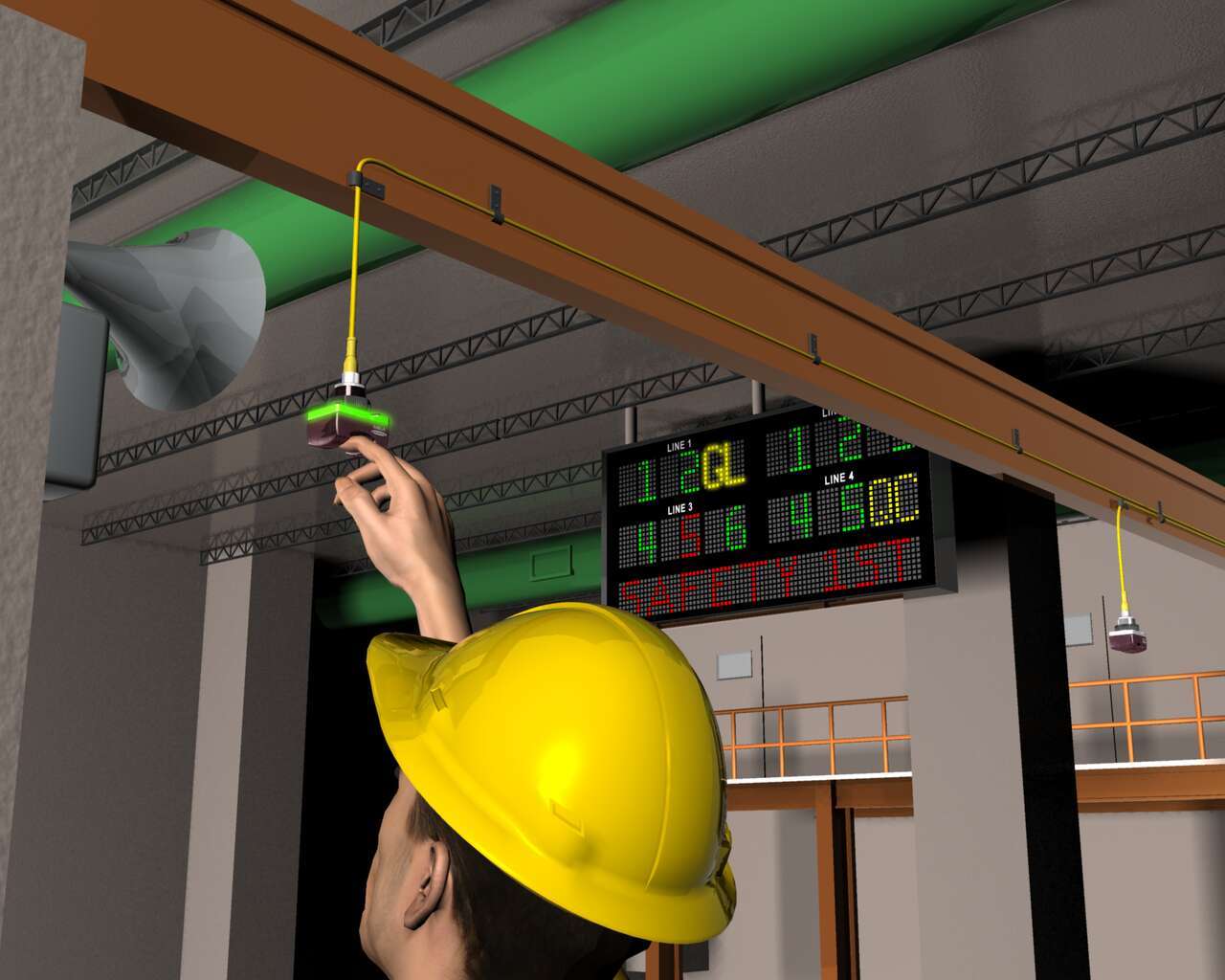

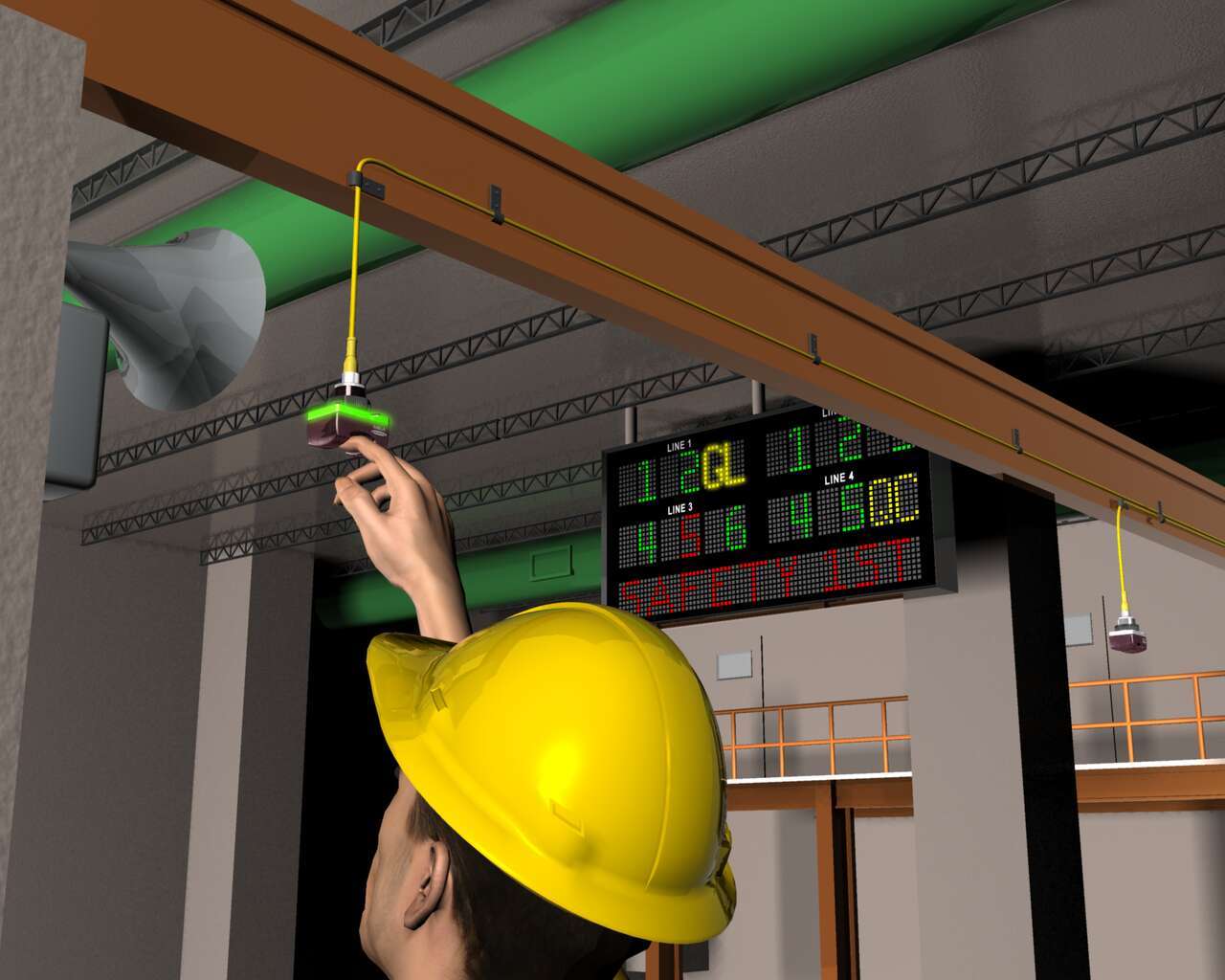

Line Problem Call

A worker has detected a problem that might cause a quality problem down the line. The worker inserts a finger into the saddle of the EZ-LIGHT VTB, which triggers an audible alarm and displays the location on an andon board, so the supervisor can decide whether the problem merits shutting down the line.

-

Part Pick Verification for a Camera Lens

Each bin has an EZ-LIGHT VTB Verification Touch Button connected to a process controller programmed with each order manifest. The VTB's LED base glows to indicate which lens to select to fulfill an order. After selecting the lens, the worker places a finger in the touch zone of the VTB to verify the pick. The worker does not have to apply any pressure to, reducing the risk of repetitive motion injury.

-

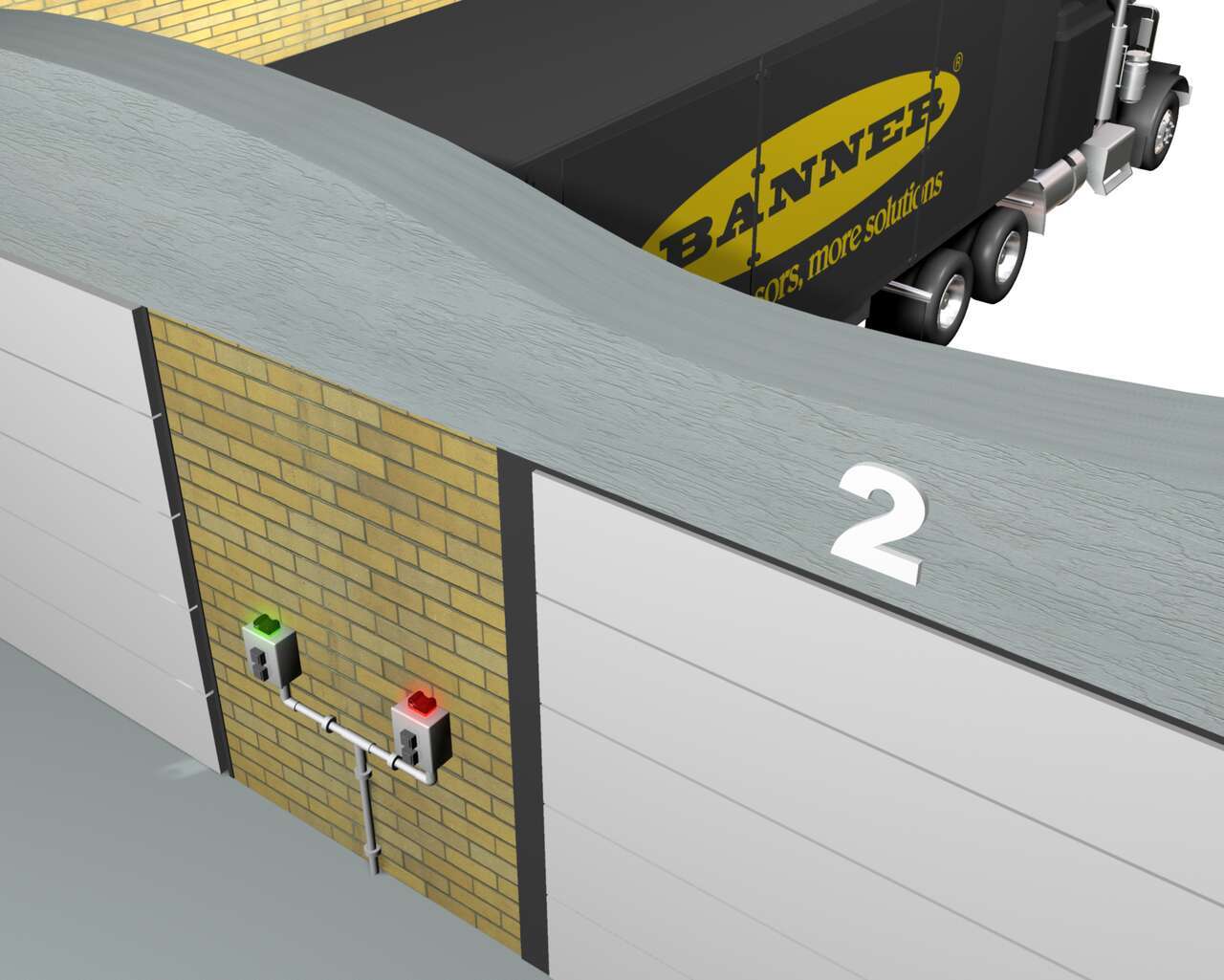

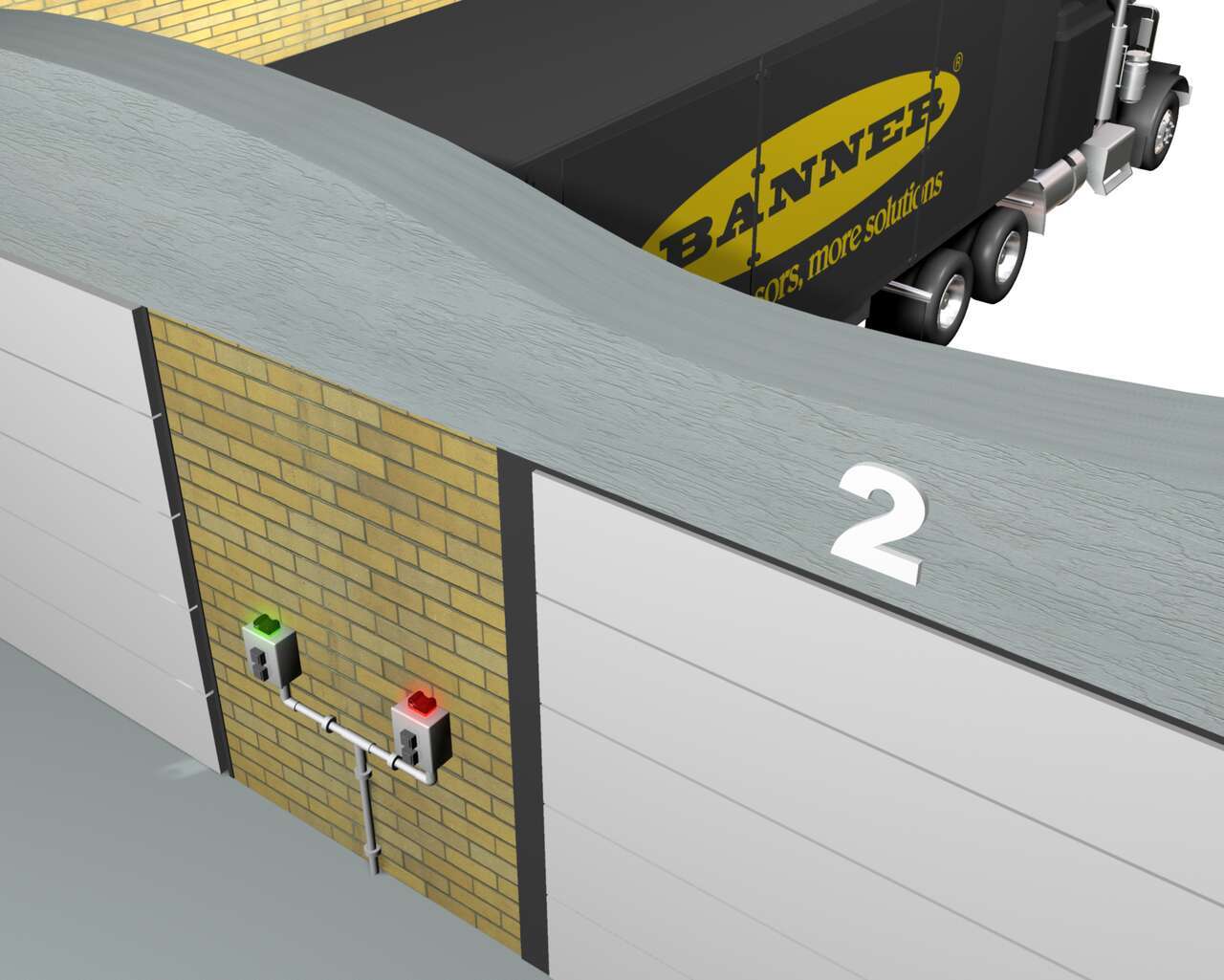

Loading Dock Monitoring and Truck Presence Indication

Sensor solution to signal the presence of a truck at a dock door with bright illumination.

-

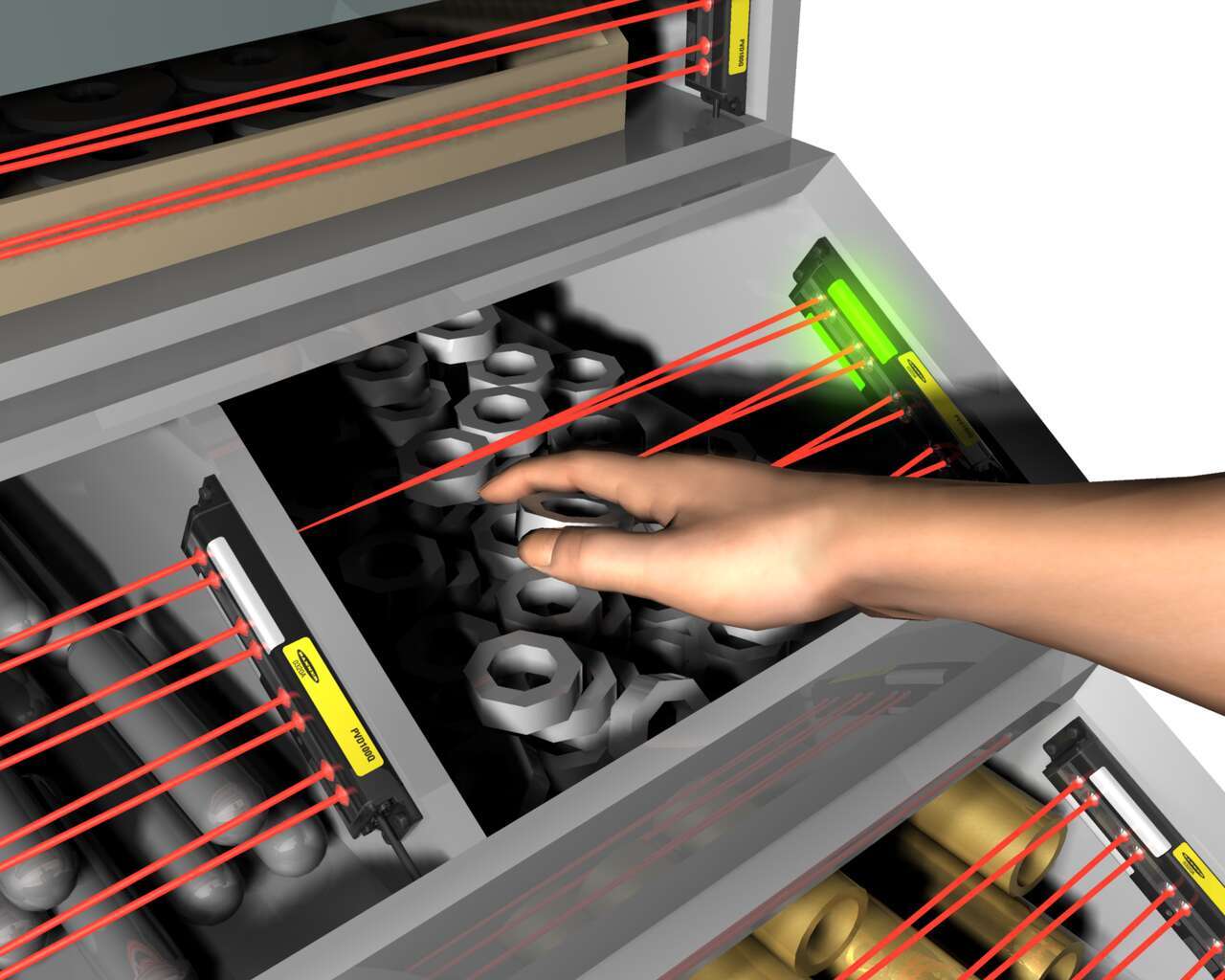

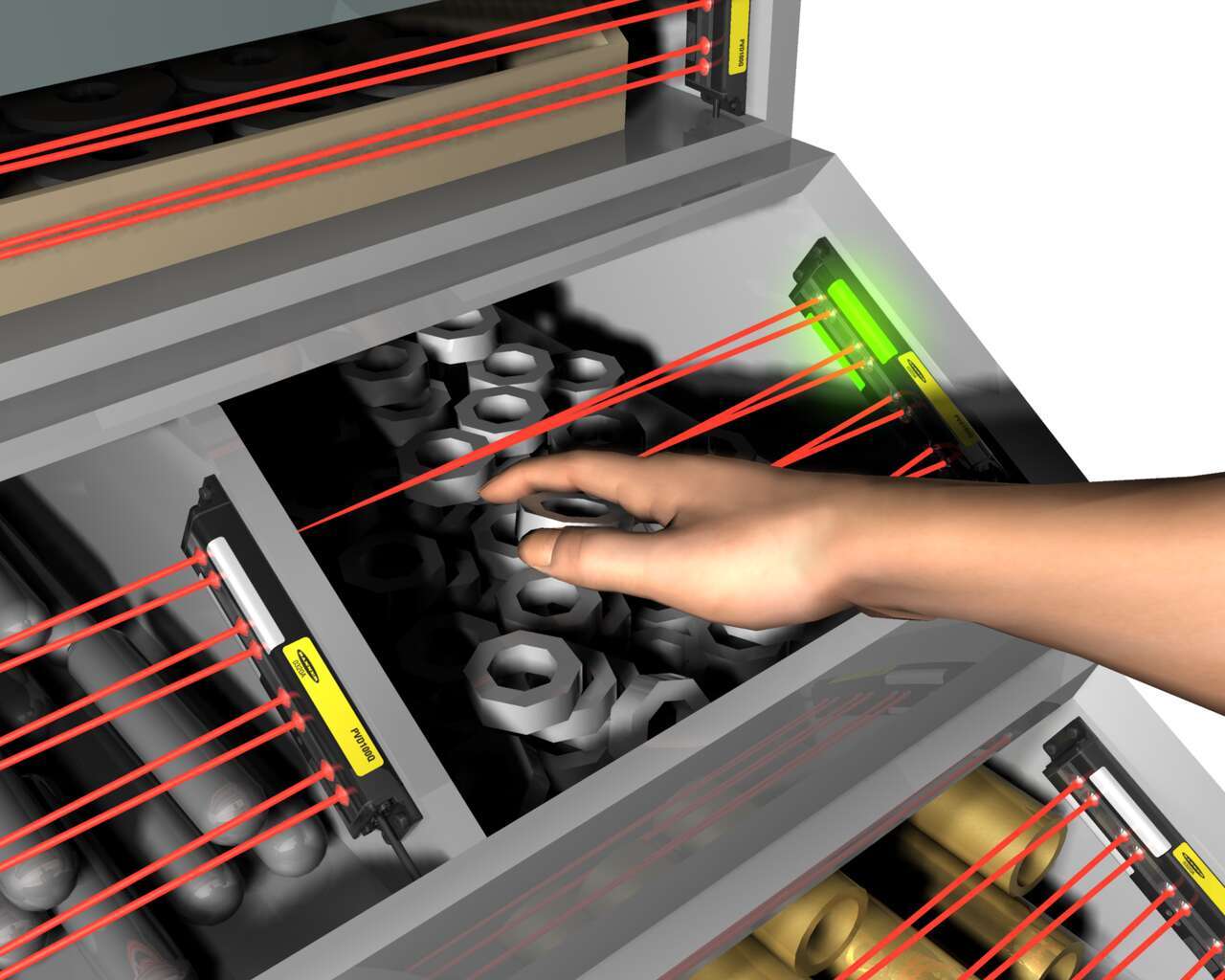

Part Pick Indication for Small Bins

To reduce the risk of error in an assembly operation, a one-piece EZ-LIGHT PVD pick-to-light sensor with a 400 mm range is interfaced with a process controller programmed with the correct assembly sequence. The controller makes the PVDs light up in the correct order, to show the assembler which part to pick. After the PVD detects that the assembler's hand has entered and left the bin, the controller signals the PVD of the next bin in the pick sequence to light up.

Incomplete Checkout

Share Your Checkout Experience

We noticed you didn’t finish your online checkout. We're dedicated to providing the best shopping experience possible and would love to hear if you faced any challenges. Let us know how we can make your experience even better.

Downloads

English Documents

Have a Technical Question?

Our application engineers are here to help with expert guidance and support. Send us your inquiry, and we’ll get back to you as soon as possible. We’re here to make sure you get the answers you need.