Predictive Maintenance and Condition Monitoring

Maintenance Based on Data from the Machine Itself

Predictive maintenance is becoming essential to the smart factory. Predictive maintenance enables users to more accurately anticipate when machine maintenance will be needed based on real-time data from the machines themselves.

The ability to accurately track machine performance and anticipate failures before they occur is helping manufacturers improve productivity and reduce wasted time and costs.

What It Is and Why It Matters

Predictive maintenance is the process of tracking the performance of crucial machine components, such as motors, to minimize downtime needed for repairs. Predictive maintenance enables users to more accurately anticipate when machine maintenance will be needed based on real-time data from the machines themselves.

Traditionally, plant managers relied on preventative maintenance schedules provided by a machine’s manufacturer, including regularly replacing machine components on a suggested timeline. However, these timelines are only estimates of when the machine will require service, and the actual use of the machine can greatly affect the reliability of these estimates.

For example, if bearings wear prematurely or a motor overheats, a machine may require service sooner than anticipated. Furthermore, if a problem goes undetected for too long, the issue could escalate to further damage the machine and lead to costly unplanned downtime. Predictive maintenance helps avoid these problems, saving time and costs.

Vibration & Temperature Indicate Machine Health

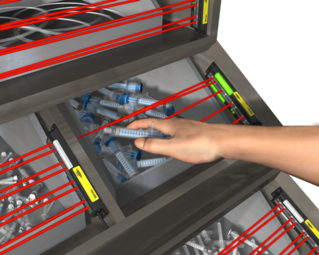

Condition monitoring plays a key role in predictive maintenance by allowing users to identify critical changes in machine performance. One important condition to monitor is vibration. Machine vibration is often caused by imbalanced, misaligned, loose, or worn parts.

As vibration increases, so can damage to the machine. By monitoring motors, pumps, compressors, fans, blowers, and gearboxes for increases in vibration, problems can be detected before they become severe and result in unplanned downtime.

Vibration sensors typically measure RMS velocity, which provides the most uniform measurement of vibration over a wide range of machine frequencies and is indicative of overall machine health. Another key data point is temperature change (i.e. overheating).

Automatically Set Baseline & Alert Thresholds

Machine learning takes condition monitoring data and automatically defines a machine's baseline conditions and sets thresholds for acute and chronic conditions so that you know in advance--and with confidence--when your machine will require maintenance.

After mounting the vibration sensor onto your machine, most sensors require you to collect enough data to establish a baseline for the machine. Machine learning removes the chances of human error by automating the data analysis.

A condition monitoring solution with machine learning will recognize the machine’s unique baseline of vibration and temperature levels and automatically set warning and alert thresholds at the appropriate points. This makes the condition monitoring system more reliable and less dependent on error-prone manual calculations.

Real Time Alerts, Long Term Optimization

When a vibration or temperature threhold has been exceeded, a smart condition monitoring system provides both local indication, such as sending a signal to a tower light in a central location, and remote alerts like emails or text messages. This ensures that warnings are addressed quickly.

In addition, a condition monitoring solution that allows you to log the collected data over time enables even more optimization. With a wireless system, vibration and temperature data can be sent to a wireless controller or programmable logic controller (PLC) for in-depth, long-term analysis.

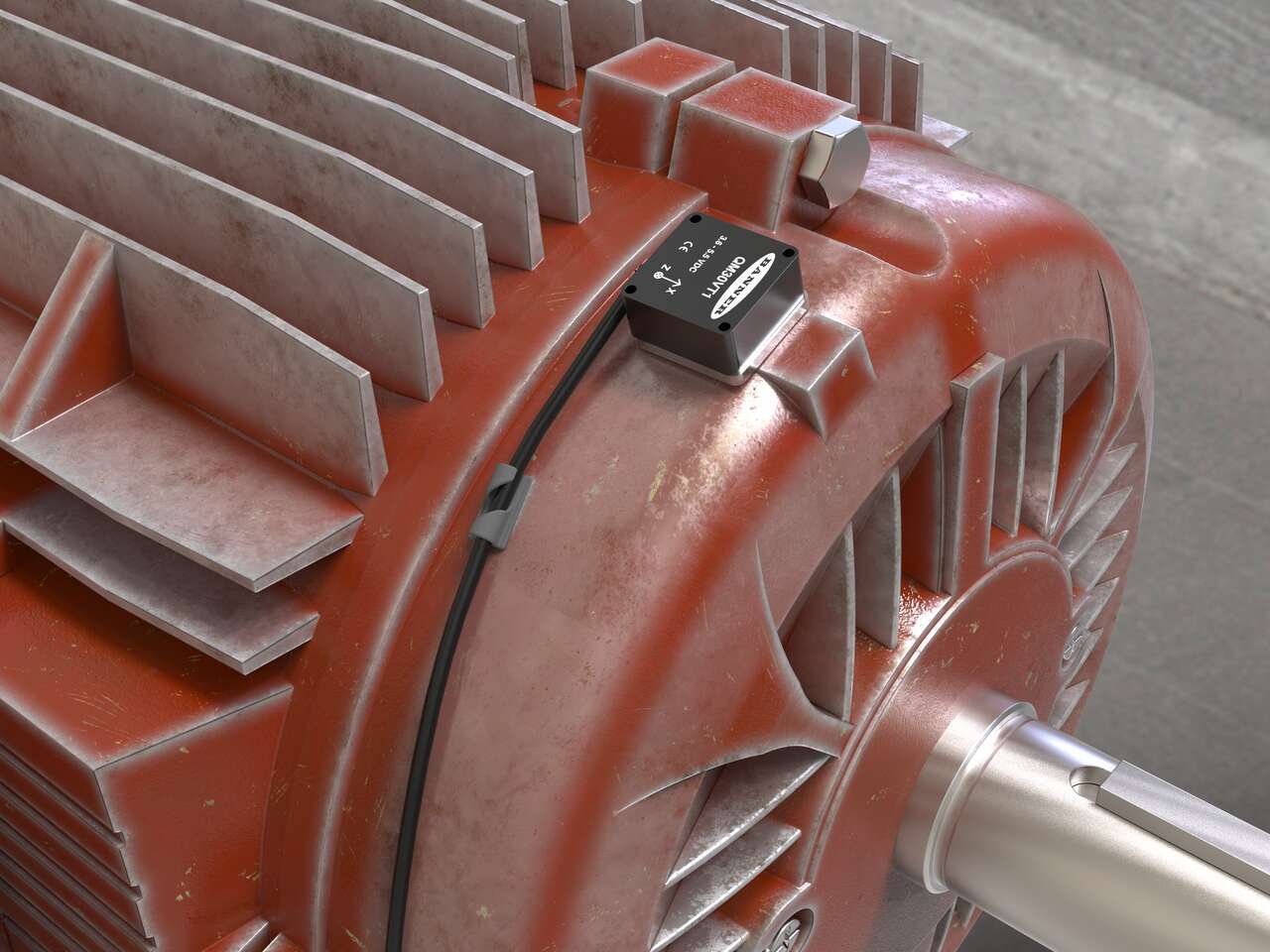

Vibration and Temperature Sensor

QM30VT Series sensors have a low-profile design and rigid metal construction that reduces resonant interference and increases surface contact, enabling exceptional levels of accuracy in measuring RMS velocity and temperature. They are able to detect even slight increases in machine vibration and temperature for early identification of potential problems.

- Communicates performance data using a MultiHop Modbus Radio or 1-Wire Serial Node to a DXM Series wireless controller or gateway

- Detects potential problems on motors, fans, pumps, and any machine with rotating motion or vibration

- Ultracompact design fits easily in small spaces

- Available in models with a 316L stainless steel housing or a heavy-duty aluminum housing

- Fully compatible with Cloud Data Services software and the Wireless Solutions Kit for Vibration and Temperature

For Vibration Monitoring

Wireless Solutions Kits are fully integrated and easy-to-use solutions for monitoring assets and solving specific applications. They are designed to make it easy for users of any experience level to setup a wireless network, collect remote data, and create visualization tools, warnings, and alarms.

- No programming is required. Plug in the box, bind the nodes through the HMI screen, install the sensors and nodes, and start collecting data

- Includes pre-programmed DXM700 wireless controller, pre-programmed 25.5 cm (10.1 inch) touchscreen HMI, and 5-port industrial Ethernet switch

- HMI provides graphical displays of collected data, baselines, thresholds, warnings, and alarms

Wireless Controller for IIoT Applications

DXM Series industrial wireless controllers are designed to facilitate Ethernet connectivity and Industrial Internet of Things (IIoT) applications.

- ISM radios available in 900 MHz and 2.4 GHz for local wireless network

- Converts Modbus RTU to Modbus TCP/IP or Ethernet I/P

- Logic controller can be programmed using action rules and text language methods

- Micro SD card for data logging

- Email and text alerts

- Cell modem for cellular connectivity