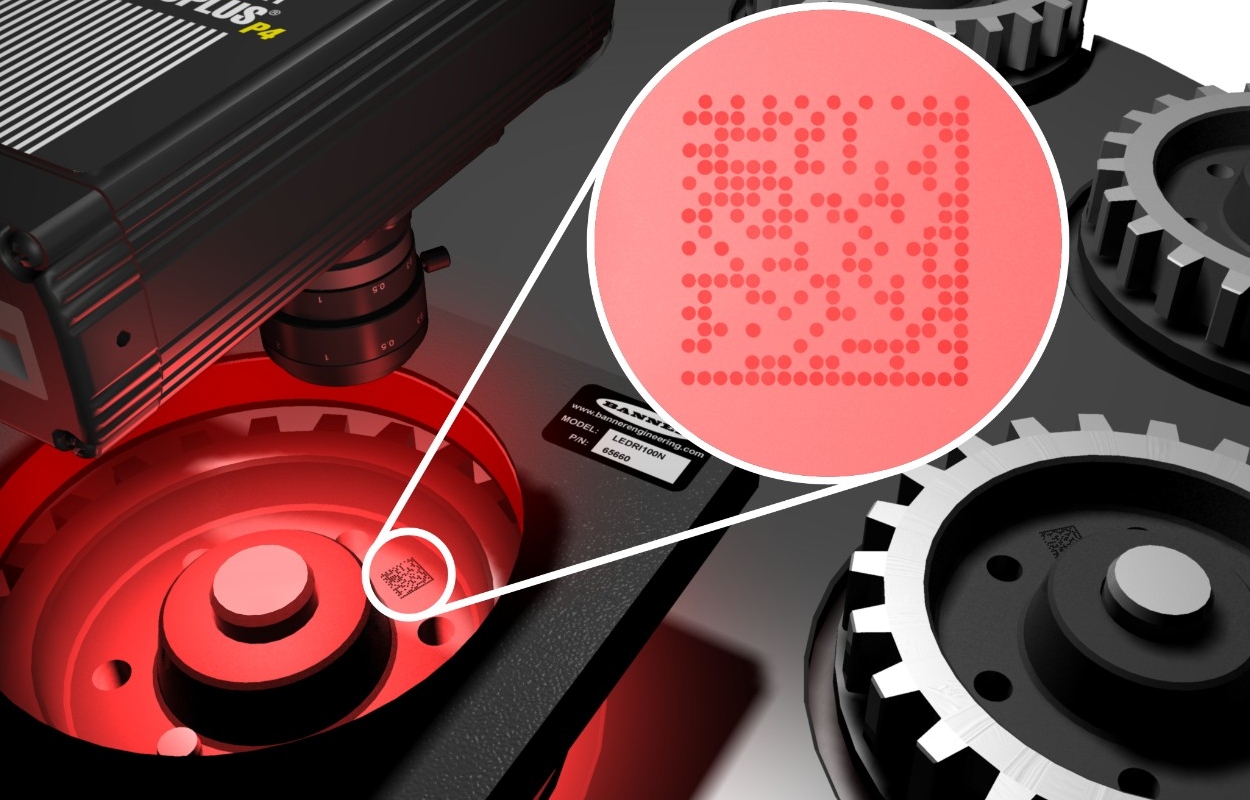

Direct Part Mark (DPM) Code Reading

Extremely Challenging Codes

Direct Part Marks (DPM) are codes, symbols, and text that are etched or printed directly onto the surface of a part instead of affixed by a label. DPM codes, which are most commonly Data Matrix or QR codes, are used for track and trace purposes in a variety of industries, particularly automotive and electronics manufacturing.

The benefit of DPM codes is that they are permanent and cannot be easily removed, obscured, or damaged. DPM codes are also a popular choice for parts with textured surfaces (label will not stick) and very small parts (label will not fit). Because DPM codes last as long as the part itself, the piece can be identified easily identified throughout its entire lifecycle, also known as "cradle-to-grave" traceability.

However, DPM codes can be extremely challenging to read due to poor contrast, so finding a DPM code reading solution is essential for reliable identification.

Since they are etched directly onto the part, DPM codes are very low contrast compared to traditional black barcodes printed on a white background. Plus, there can be significant variability in DPM codes, where and how they are printed on a surface, and features of the surface itself that can significantly impact code readability.

For example, many DPM codes are etched onto reflective, curved, or uneven surface which can be very challenging for barcode readers to identify reliably.

Also, the surface is rarely uniform, meaning that it may also contain granules, stripes, streaks, or other irregularities and imperfections that can further interfere with reliable code reading.

Advanced imager-based code readers use special DPM code reading algorithms to solve these applications reliably. Besides, low angle lighting or the use of different color LEDs can be used to create additional contrast and improve code visibility.

Imager-Based Code Reader with Multicolor LEDs

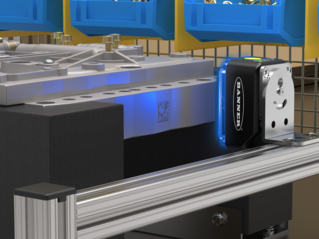

- In automotive manufacturing, to ensure that vehicle components can be traced throughout their entire life cycle, Data Matrix and other 2D codes are permanently etched into the surface of each component.

- A barcode reader with dark-field illumination like the ABR 7000 is ideal for applications where the DPM code has been etched onto a reflective surface. Dark-field illumination utilizes blue LED lights built into the barcode reader to make the code appear much darker than the surrounding area.

- The enhanced contrast between the code and the surface of the component allows the barcode reader to capture a detailed image of the inspection area with every aspect of the Data Matrix code well defined.

- The information contained in the code is then verified and sent over an Ethernet connection to the factory management system which logs the data for traceability.

Reliable Code Reading in Confined Spaces

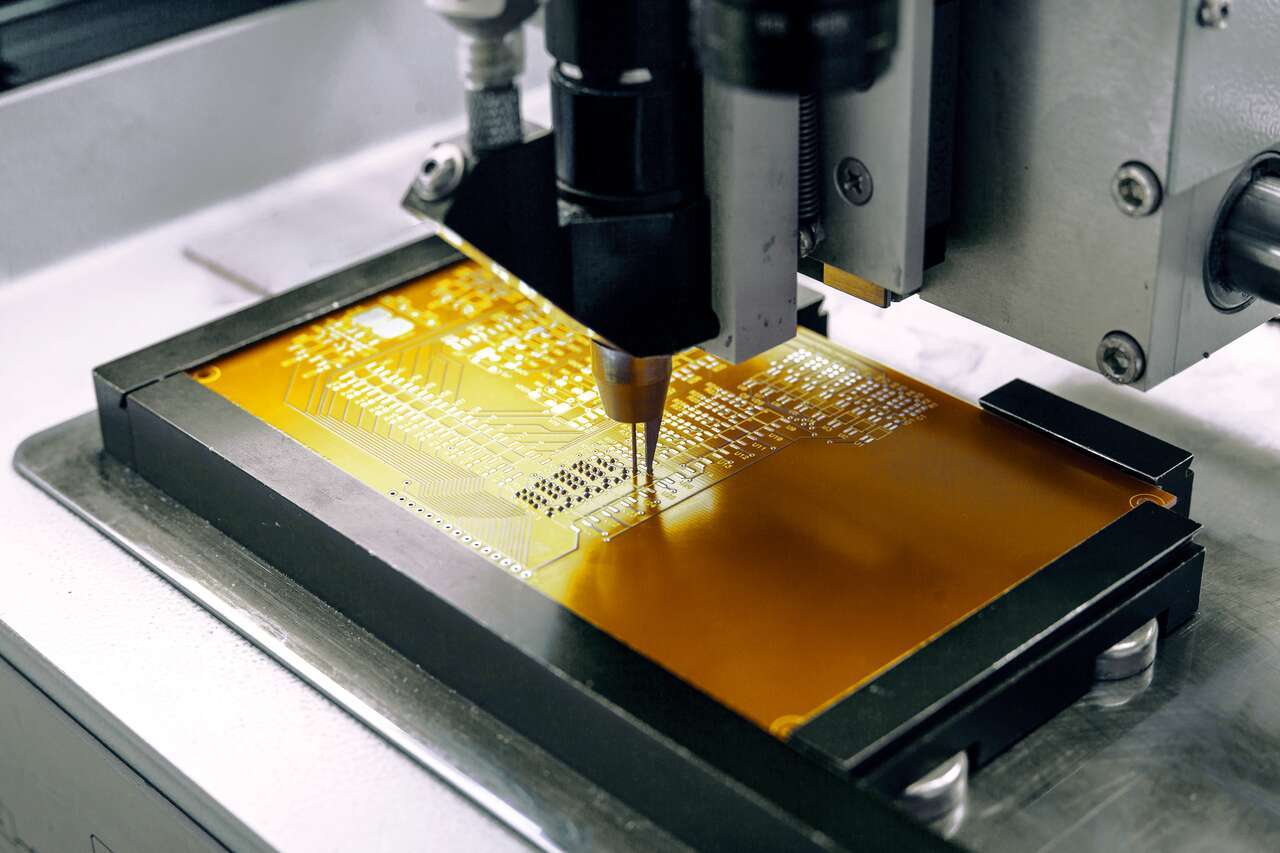

- DPM codes are also standard in electronics manufacturing.

- These codes are especially challenging because, in addition to being low contrast, the codes are also tiny, as they are printed directly onto electronic components.

- Also, there is often limited space to mount a code-reading device.

- A compact barcode reader, like the ABR 3000, is perfect for tight spaces common in the electronics industry.

- The imager-based code reader uses unique algorithms to reliably identify small, low contrast DPM codes and can send data via Ethernet to PLC controls for traceability.

Imager-Based Barcode Readers from Banner

Need to read other challenging codes besides DPM codes? Imager-based barcode readers reliably read 1D and 2D barcodes in any orientation.

Banner Engineering offers code reading solutions that can reliably decode difficult-to-read, low quality, and damaged codes—as well as codes printed on highly reflective surfaces.

Watch the video to learn more about what's new, or browse our selection of imager-based code reading products.

Imager-Based Barcode Reader

ABR 7000 barcode readers offer superior decoding capability and are in multiple resolutions and a wide range of lens options.

- ABR 7000 barcode readers provide advanced features including extended reading distance and field-of-view, advanced lighting, a variety of focal lengths (including autofocus) and the ability to link multiple readers together.

- Powerful decoding capability to read even difficult 1D and 2D codes, including DPM and low contrast codes

- Quick configuration with on-board push buttons or a PC using Barcode Manager, Banner’s free operating software

- Integrated LED lighting and easy focus adjustment in one package for maximum application flexibility

- Versatile lens options are available to simplify setup and configuration, including a software adjustable autofocus which easily adapts to changes in reading distance

- Factory communication options include Ethernet and serial for integration on the manufacturing floor

- Embedded web server interface for monitoring images and statistics over any network

Compact Imager-Based Barcode Reader

ABR 3000 barcode readers offer superior decoding capability in a compact form factor, multiple resolutions, and a wide range of lens options.

- Powerful decoding capability to read even difficult 1D and 2D codes

- ABR 3000 is ideal for tight spaces and close-range code reading

- Compact metal housing for industrial environments

- Quick configuration with on-board push buttons or a PC using Barcode Manager, Banner’s free operating software

- Integrated LED lighting and easy focus adjustment in one package for maximum application flexibility

- Factory communication options include Ethernet or USB for integration on the manufacturing floor

- Embedded web server interface for monitoring images and statistics over any network

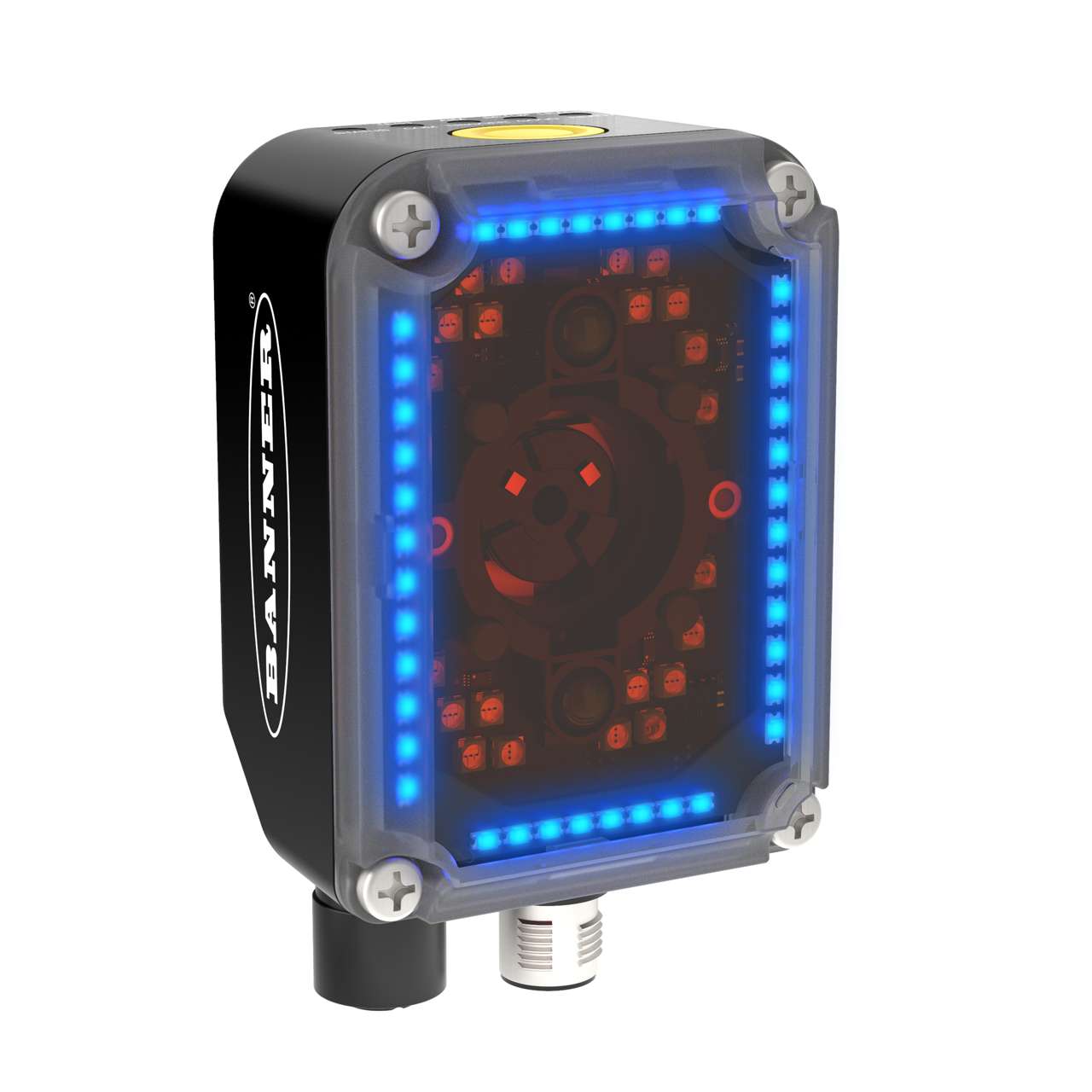

iVu BCR Series

Imager-Based Barcode Reader

iVu BCR Series barcode readers combine powerful decoding capabilities with ease-of-use to solve challenging traceability applications. These versatile barcode readers are available with a range of lens, lighting, and user interface options.

- Reads a broad range of 1D and 2D barcodes, including damaged, distorted, and other difficult-to-read codes

- Capable of reading multiple barcodes in any orientation in a single inspection

- Setup, manage, and monitor inspections using an integrated touch screen, remote touch screen or PC interface

- Ethernet and serial communication protocols simplify device integration and enable IIoT data collection

- Rugged, IP67-rated housing ideal for tight spaces and industrial environments

- Numerous integrated lighting options simplify installation and optimize contrast

- Interchangeable lenses, including a wide range of standard and C-Mount options to meet the needs of any application