Indicating Stack Level on a Robotic Case Erector

Challenge

Robotic case erectors construct boxes and send them down conveyor lines. Most of the end-of-line packaging equipment is automated, but the detection needed to ensure the robot has material is often a manual process. In a recent packaging application, a facility manager sought a visual monitoring solution that would show the operators material level at-a-glance. The maintenance team wanted to streamline their existing setup, which included various sensors, indication devices, and cordsets. When considering similar alternatives, there were budgetary concerns to replacing or upgrading their existing devices. They needed a product that could both detect stack height and provide intuitive visual indication.

Solution

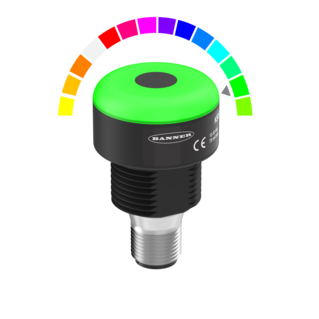

The facility manager replaced the existing products with the two-in-one K30 Pro Optical Sensor on the robotic case erector station. A sensor with a configurable indicator light, the K30 monitored and displayed the stack height of boxes. By using the K30’s distance mode, operators who were tending multiple stations could quickly verify the stack level of boxes and prioritize refill activity to eliminate downtime due to material shortage. When there was a full stack of boxes, the indicator was fully green, and when boxes were consumed, red began to cover green. When boxes were at a critically low level, the light was completely red, and a discrete output from the K30 would send a signal back to the control system to alert the supervisor. With this intuitive and highly visible transition from green to red, a single operator could easily identify when boxes needed to be refilled at multiple workstations. This sensing plus status indication solution helped operators to ensure the robotic case erector was running smoothly and avoid unplanned downtime.