Pharmaceutical & Medical

Solutions for the Pharmaceutical and Medical Industries

Around the world, companies operating in the pharmaceutical, biotech, and medical manufacturing industries rely on Banner Engineering for our industry knowledge, experience and expertise to provide products and solutions that improve automation efficiency, maintain product quality, and protect operator safety.

We are experts in advanced optics, LED, laser, and photoelectric circuits, offering sensors for tablet fill level monitoring and count verification, cap and closure inspection, print and label verification, and product identification and serialization. We have the industry’s most complete family of safeguarding devices, allowing customers to design the highest level of safety into a machine, without compromising productivity. LED products from Banner provide clear status indication and bright, uniform illumination for machines, processes and workstations. We have a complete line-up of actuators, ideal for medical assembly, medical kitting and storage retrieval systems. Our proprietary wireless products enable the monitoring of critical sensing points for flow, level, temperature and other processes on remote assets. For demanding environments, we offer a number of products designed for high pressure wash-down, Clean-in-Place (CIP), Sterile-in-Place (SIP), chemical resistance (Ecolab Certified), and hazardous areas.

Segments of the Pharmaceutical and Medical Industry

-

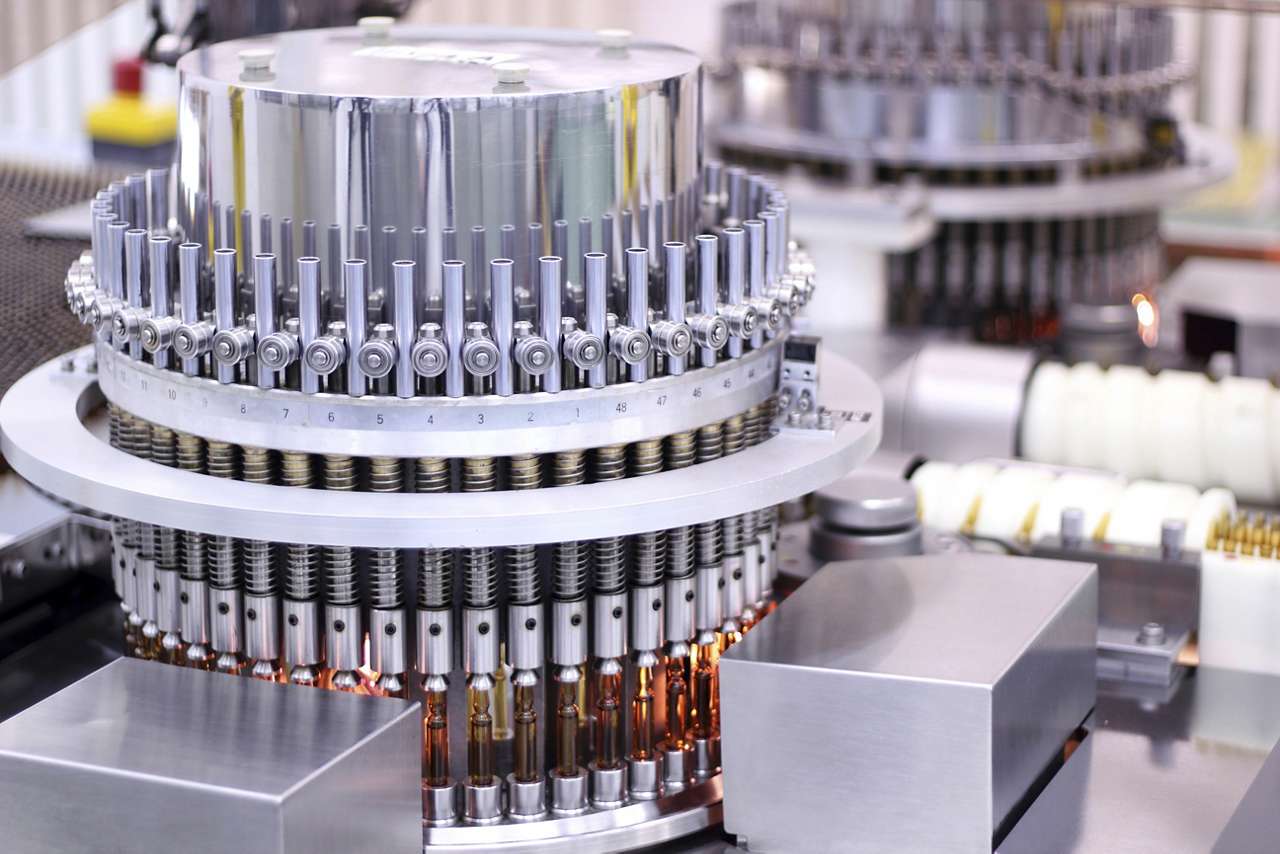

Primary Pharmaceutical Packaging

In the pharmaceutical industry, filling the correct amount of solid or liquid products into the correct container is critical. With different drug delivery methods and packaging schemes, companies rely on banner sensors to ensure that the proper amounts of the right products are packaged correctly.

-

.jpg/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

Secondary Pharmaceutical Packaging

From ensuring caps are in place and labels are correct to closing up cartons and loading them on pallets, Banner solutions ensure that packaging is applied properly and efficiently and that product are secure and safe for shipment.

-

Pharmacy Automation

At all levels of pharmacy automation, companies rely on Banner’s extensive industry experience, application knowledge and comprehensive product offering to solve challenging applications.

-

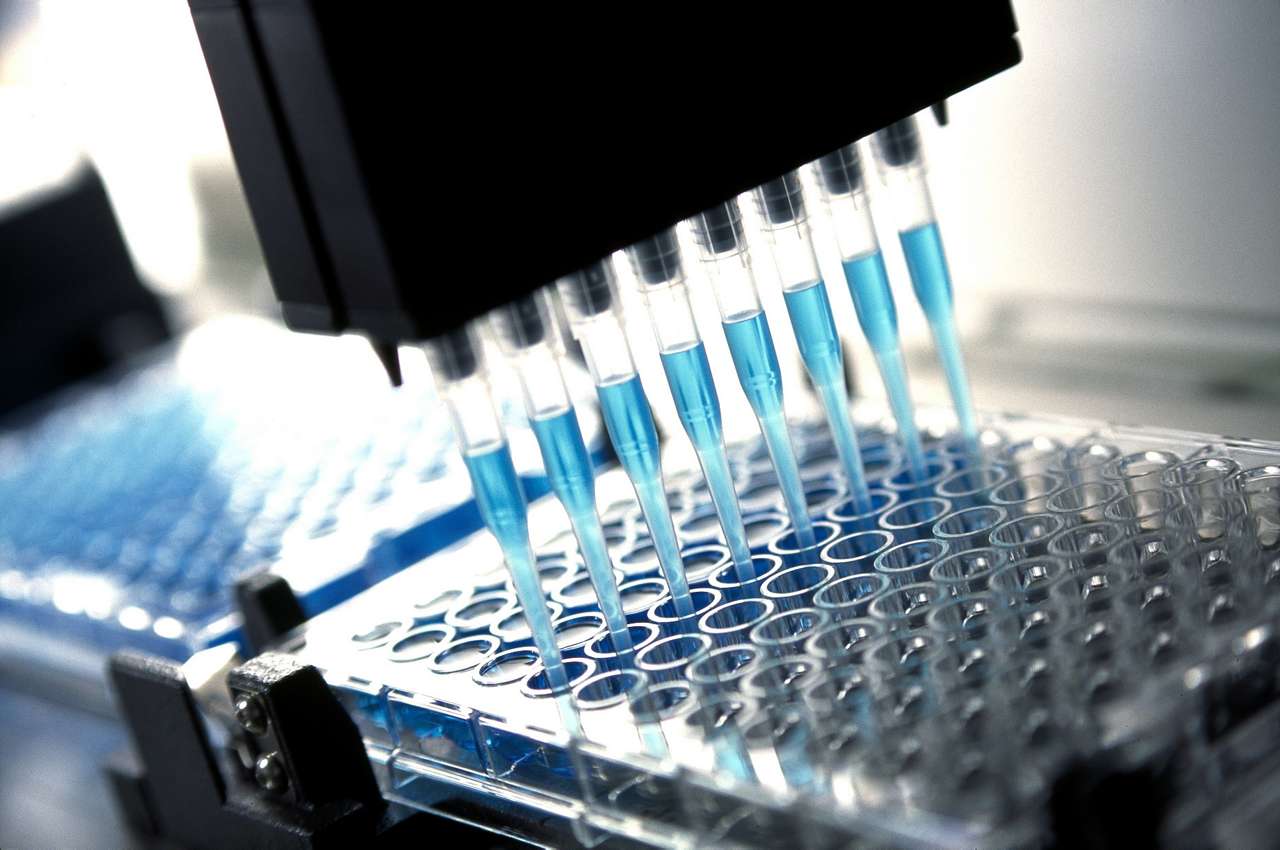

Automated Diagnostics

Companies operating in the laboratory automation, bio-storage, and automated diagnostic industry rely on Banner’s team of industry and application experts and our comprehensive offering of sensors, vision sensors, safety, and lighting products to solve challenging applications.

-

Medical Assembly

Ensuring product quality in assembly processes for medical products or kitted assemblies is critical. Banner Engineering provides products and solutions that help ensure and improve product quality as well as assembly processes and efficiency, worker experience, productivity and safety.