-

Company

-

Banner Blog

-

What is IIoT?

What is IIoT?

Hardware Devices Are a Vital Part of Data-Driven Industrial Intelligence

The Industrial Internet of Things (IIoT) is defined as the sensors, machines, instruments, and autonomous devices that are networked together to collect real-time data for industrial applications. For automated and semi-automated factory manufacturing, IIoT provides key insights to increase productivity, improve efficiencies, and reduce costs. This collected device data can be analyzed in cloud or edge-computing platforms, allowing users to take actions with directly measurable value:

- optimize production

- increase operational efficiency

- reallocate resources

- execute predictive maintenance

- reduce energy consumption

- improve error-proofing

- minimize downtime

- manage costs

IIoT forms part of a complete technology ecosystem, benefiting factory automation, assembly lines, logistics, shipping and distribution, and other key elements of today’s manufacturing. In essence, it is a subset of the Internet of Things (IoT)—referring to physical devices and digital tools built to communicate with each other online—but focused specifically on industry and the business advantages that can be achieved.

IIoT networks rely on online connections, cloud servers, and software, but the hardware components of these systems should not be overlooked. Fortunately, Banner Engineering makes it possible to not only design customized IIoT-capable automation systems, but also upgrade existing manufacturing infrastructure for comprehensive IIoT implementation.

Why Is IIoT Important?

IIoT is a key component of Industry 4.0, or the Fourth Industrial Revolution. This is a concept for modern manufacturing that harnesses the power of networked systems and data analytics, which enables companies to make strategic, insight-driven business decisions. In essence, IIoT is what turns factories into “smart” factories. Captured data can be used to accelerate and scale existing operations, or even redefine business models to better serve customers and outdo competitors. The term also implies a certain urgency: if companies are too slow in adopting IIoT technology, they might find themselves left behind in the competitive global marketplace.

Meanwhile, a company that constantly gathers and interprets data from its equipment can realize a distinct competitive advantage. It can monitor the speeds of automated processes to identify issues such production bottlenecks, make corresponding adjustments, and fine-tune machine performance to eliminate inefficiencies and improve throughput. Data makes it easier to manage quantities of raw materials—a necessity especially in a time of disrupted supply chains—and it can be used to determine more cost-effective logistics for packaging and distributing finished goods.

The benefits of IIoT integration range from enhancements to advanced technology to commonsense time-savings. For example, robots equipped with sensors can collect information about themselves and their environment, and then transmit that data. But also, tools or parts from inventory lists can be tracked online to diminish the time that operators would normally spend searching for them.1

“According to Oxford Economics data, the Industrial Internet of Things (IIoT) can impact industries that account for 62% of GDP in the G20 countries,” notes the Spanish multinational electric utility company Iberdrola. “The application of IIoT in industry promises to become the biggest driver of productivity and innovation in the next decade.”2 And sure enough, companies worldwide are taking IIoT technology seriously and investing heavily in implementation. Manufacturing, transport, and energy applications saw a global investment of over 300 billion dollars in 2019, which is expected to double by 2025.3

Download the Guide

Download the 3 Ways IIoT Will Impact Your Operations PDF to learn about the three key ways that IIoT tools will impact manufacturing operations by harnessing data.

- Make Equipment Data Visible to All Who Need It

- Pinpoint Reliability Issues and Eliminate Downtime with Predictive Maintenance

- Track Throughput Metrics to Optimize Productivity and Increase Profitability

Using IIoT for Smarter Machine Maintenance

One other compelling argument for incorporating IIoT technology is that it enables companies to go beyond traditional scheduled preventative maintenance and instead practice informed predictive maintenance. By attaching machine sensors to monitor factors including vibration and temperature, factory operators can capture indications that a crucial mechanism, such as a motor, might be showing signs of impending burnout or failure. If a breakdown were to occur at the wrong moment, it could cause a catastrophic loss of production time and expected revenue. Sensor data identifying parts that require imminent maintenance is profoundly valuable insight, because it gives the company an opportunity to schedule repair or replacement of those parts before they fail.

The financial impact of predictive maintenance is quantifiable. McKinsey Global Institute reports the following:

We estimate that predictive maintenance could reduce maintenance costs of factory equipment by 10 to 40 percent. … Additionally, better predictive maintenance using IoT can reduce equipment downtime by up to 50 percent and reduce equipment capital investment by 3 to 5 percent by extending the useful life of machinery. In manufacturing, these savings have a potential economic impact of nearly $630 billion per year in 2025.4

What Kind of Factory Data Can Be Captured?

Sensors are now so ubiquitous in manufacturing automation that it is difficult to imagine a factory that doesn’t incorporate them. Most factories use many different types of sensors for counting product quantities, timing steps in an automated process, or ensuring optimal manufacturing conditions, but by their very nature, the electronic signals that sensors already transmit can be collected for insightful data analytics. Even a basic binary pulse from a sensor is a potential data source that can be monitored to streamline operations. The frequency of how often a photoelectric beam is interrupted (for instance by products on a conveyor) can be captured and recorded to calculate operating speeds, which can then be adjusted to maximize productivity as part of a greater production process.

The kinds of data that sensors can capture are practically unlimited. They can record quantities, volumes, distances, weights, sizes, shapes, colors, positioning, temperatures, thermal activity, vibration, reflectivity, curvature, surface variations, material composition, response to sound waves, proximity to physical obstacles, visual or auditory information, texture patterns, steps in a programmed sequence, and almost anything else. Any value that a sensor can observe can be a data point, and any data point can be measured over time.

In this way, the entire philosophy of IIoT is part of the trend of “Big Data” analytics for making insight-driven business decisions. Put simply, the more data that manufacturers collect from their installed sensors, the more they understand about their own systems’ capabilities. They can leverage this “actionable” data about to refine processes at any level of production. And those refinements can lead to leaner, more productive results, enabling a distinct fulfillment advantage over competitors.

Facts and Myths about the Cost of Implementing IIoT

While optimizing production to embrace IIoT is a significant task that requires clear direction and organization-wide buy-in, it is not as cost-prohibitive as one might initially assume.

McKinsey identifies some of business leaders’ common misunderstandings about IIoT.5 Among them is the idea that IIoT is only an online dashboard and the idea that it requires “greenfield” sites. First, while IIoT applications require some sort of online capability to capture and present industrial data, they also require hardware, including sensors and controller connections. Secondly, while it is certainly a good idea to plan to include IIoT capabilities in brand-new factory sites, it is not only possible but also affordable to implement IIoT in existing (“brownfield”) sites.

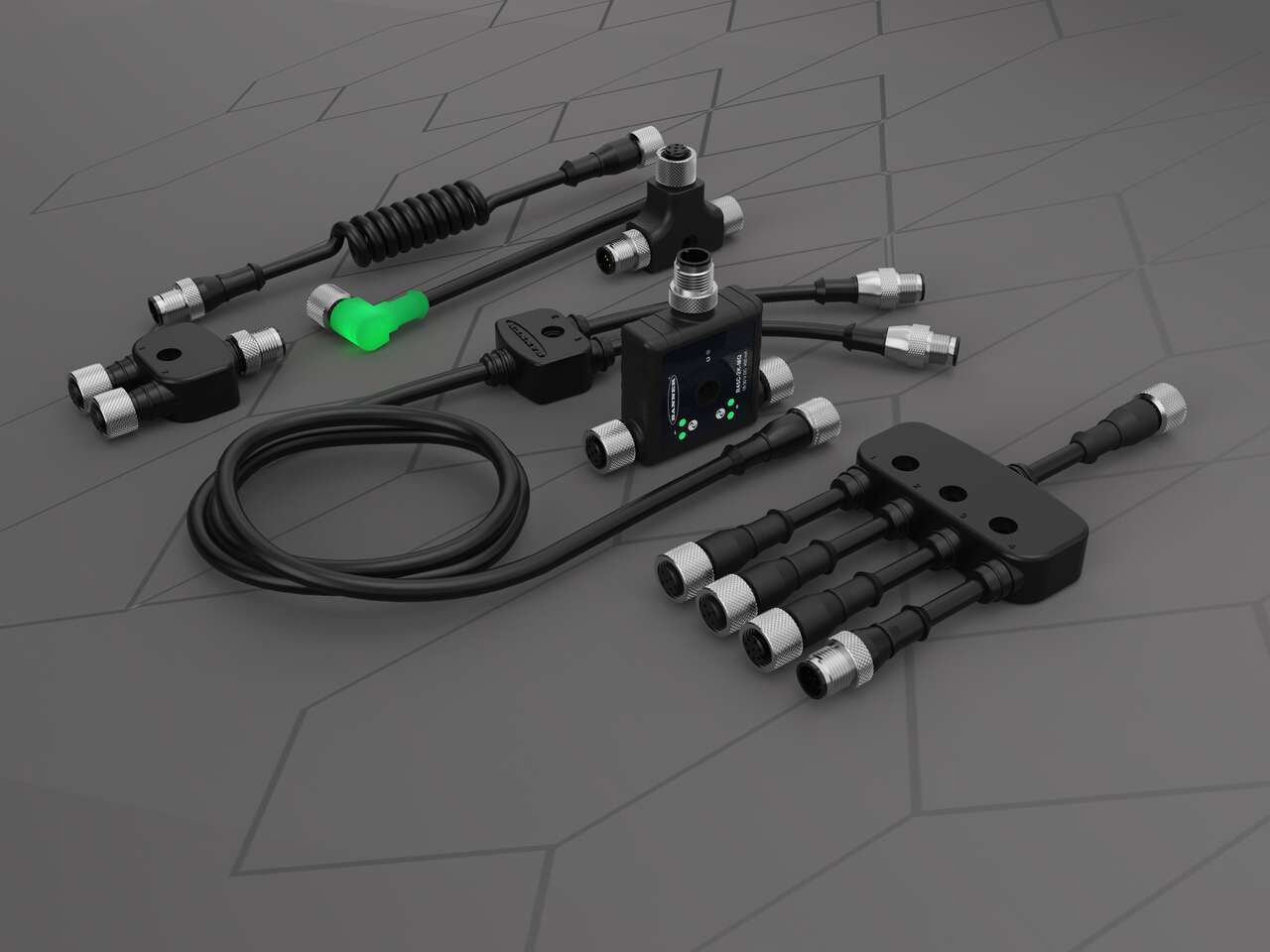

In fact, Banner’s Snap Signal product line makes it possible to add IIoT data collection to an established factory’s existing equipment, from any brand. In essence, IIoT can be implemented as an overlay network using T-junctions, splitter cables, and converters to capture signals from the sensor infrastructure already in place.

IIoT Relies upon Hardware

Discussions about the impressive potential of IIoT and Industry 4.0 frequently tout software, cloud computing, and artificial intelligence, but details about IIoT hardware are frequently neglected. This is unfortunate, because hardware technology is a crucial element of IIoT systems, and the developments in industrial automation hardware are revolutionary in their own right.

Realizing the benefits of IIoT requires hardware devices installed directly where the work is being performed, such as sensors to monitor factory machines. These sensors need to be connected to a central controller that consolidates all the machine signals that need to be monitored. Finally, manufacturers need an interface or online platform to view and interpret the collected data.

Banner Engineering has been a leading supplier of industrial technology for more than fifty years, providing innovative sensors, lighting, safety equipment, and networking devices for manufacturers worldwide. We are equally committed to outfitting companies with the most advanced IIoT smart-factory solutions.

Getting Started with IIoT

How does a manufacturer implement IIoT for industrial automation? This easy and straightforward process does require some careful planning, but Banner experts are standing by to help customers figure out where and how to install sensors, hubs, and controllers throughout their future or current production facilities.

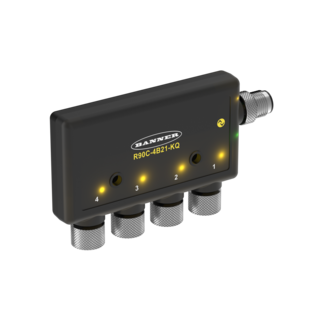

The Snap Signal family of products enables users to split off from an installed sensor output, copy the signal, and transmit it over industry standard M12 cabling. It is a brand-agnostic “overlay” network that can integrate with manufacturers’ existing sensors and equipment, easily converting signal formats, and its modular design makes it possible to start small and scale up as factory operations expand and develop. Installing a controller, such as a Banner DXMR90, makes it possible to combine simultaneously running branched signals from multiple sensors, potentially for all monitored machines throughout a factory, and convert those signals to Ethernet data.

All this factory information can be monitored onscreen in an HMI or an industrial PC, but users can explore it in greater detail in online computer software, including cloud platforms such as Banner’s highly customizable Cloud Data Services or Amazon AWS. It’s even possible to send data to the cloud wirelessly and securely over long distances using cellular connections or an edge device like the DXM1200 Wireless Controller.

IIoT Products Available Right Now

Banner is already facilitating cutting-edge IIoT solutions for manufacturers worldwide. Our ever-growing product inventory includes several devices that can be easily combined and incorporated into any industrial environment.

In Conclusion

IIoT and Industry 4.0 represent a major shift in manufacturing, and factories that delay evolving will likely face major competitive challenges in the future. Fortunately, adapting manufacturing to collect insightful machine data does not have to be overwhelming or cost prohibitive.

Whether you are revitalizing your existing facility or designing new factory processes from the ground up, Banner is here to support you. We continue to engineer device solutions that enable you to transform your traditional manufacturing operation to a leaner and more productive IIoT-enabled smart factory. All with an approach that is agile, scalable, and practical.

Frequently Asked Questions

What is Industry 4.0?

Also known as the Fourth Industrial Revolution, Industry 4.0 represents the twenty-first-century movement toward networked interconnectivity and “smart” automation technology in manufacturing and other industrial settings. The term “Industry 4.0” was coined in Germany in 2011, as a step beyond the preceding industrial revolutions:

The First Industrial Revolution refers to the transition from work done by hand to work performed with machines using steam and waterpower, generally during the late eighteenth and early nineteenth centuries.

The Second Industrial Revolution occurred when business operations took advantage of electricity and extensive railroad and telegraph lines, from the late nineteenth to the early twentieth centuries.

The Third Industrial Revolution, also known as the Digital Revolution, involved replacing traditional mechanical and analog electronic processes with computer hardware and software in the second half of the twentieth century.

As such, the Fourth Industrial Revolution represents another leap forward, through the use of IoT, IIoT, cloud computing, machine learning, artificial intelligence, and related technology.

What is an IIoT Platform?

One example of an IIoT platform is Banner’s Snap Signal product line. As an overlay solution, Snap Signal products include a variety of adapters, filters, and converters to connect existing sensors to centralized hubs and controllers, which can then communicate real-time factory data with PLCs, HMIs, or online cloud dashboards. Snap Signal is IIoT made easy.

How will Industry 4.0 further improve productivity?

Manufacturers that embrace IIoT technology are able to collect, manage, and respond to factory-wide sensor data in real-time. They can see where bottlenecks or slowdowns are occurring and make necessary adjustments to those areas to improve overall throughput. IIoT also enables factories to transition from static production lines to manufacturing “cells,” offering enough flexibility to provide mass customization. Automated data collection from sensors at every stage of factory operations helps to reduce and prevent human errors and product defects, saving time and costs from returns or recalls.

A 2020 study from MPI Group notes that, of the manufacturing leaders that have implemented Industry 4.0 in their operations, most report significant positive results. They share that the IIoT has or will:

- Increase productivity (88%)

- Increase profitability (74%)

- Improve product quality (48%)

- Increase customer satisfaction (43%)

- Improve machine reliability/up time (42%)

- Increase worker safety (41%)6

What is a “smart factory” under Industry 4.0?

A smart factory is a manufacturing facility that captures data about its automated processes and sends that information to operators for analytics and insight-driven decision-making. Much like how smart phones are constantly sending and receiving telemetry data over cellular networks and WiFi, a smart factory constantly transmits machine data as long as it remains online. Factories that leverage this connectivity can be more productive, nimble, and profitable than traditional factories relying on purely mechanical and digital technology.

References

- Andy Chang, “Your IIoT Questions, Answered,” IndustryWeek, May 14, 2019. https://www.industryweek.com/technology-and-iiot/article/22027595/your-iiot-questions-answered.

- “What is IIoT? Discover the Industrial Internet of Things,” Iberdrola. https://www.iberdrola.com/innovation/what-is-iiot.

- Ibid.

- James Manyika et al., “The Internet of Things: Mapping the Value Beyond the Hype,” McKinsey Global Institute, June 1, 2015 (p. 70). https://www.mckinsey.com/business-functions/mckinsey-digital/our-insights/the-internet-of-things-the-value-of-digitizing-the-physical-world.

- Mads Lauritzen et al., “Industrial IoT Generates Real Value—If Businesses Overcome Six Myths,” McKinsey & Company, June 2, 2020. https://www.mckinsey.com/business-functions/operations/our-insights/industrial-iot-generates-real-value-if-businesses-overcome-six-myths.

- Richard Howells, “How Industry 4.0 Boosts Productivity and Profitability in Intelligent Factories,” Forbes, July 1, 2020. https://www.forbes.com/sites/sap/2020/07/01/how-industry-40-boosts-productivity-and-profitability-in-intelligent-factories/?sh=67988fb848ec.