Hopper Storage Solutions for Food Packaging

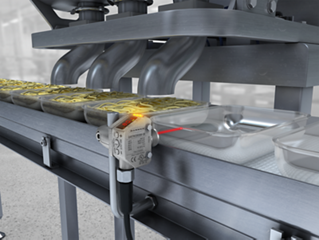

Hoppers are in-process storage solutions used for holding and dispensing food into the trays as they move down the production line. Food is stored in each hopper and is portioned out into the trays.

Each hopper holds a different element of the final product, such as noodles, sauce, meat, or vegetables, creating a multi-step system for filling the containers. Once each tray has been filled with all necessary ingredients it moves to the next station on the conveyor.

Utilizing multiple hoppers allows for better management of the food being processed. This also creates more room for potential error, which is why selecting the correct devices is of the utmost importance.

It is necessary to monitor the levels inside each hopper to ensure that product is replenished in a timely manner and to prevent empty hoppers during production. One of the more challenging aspects of level monitoring is the different types of food or sauce that are stored in each hopper. Consistency and color of the food can make them some products more difficult to detect. For instance, red targets reflect red light well which makes sauces such as marinara easy to detect. Green targets, such as pesto, reflect red light poorly, creating a challenge for accurate level monitoring. Banner Engineering’s laser technology is a reliable solution to this problem, enabling accurate detection of various colors. This is possible because of the laser sensor's ability to see light and dark targets at the same distance and the sensor's ability to intuitively adjust laser power.

It is also important to detect tray position at each hopper so that food is not dispensed without a tray present, causing a mess and wasted product. Tray color and material can cause difficulties and require versatile solutions. The hopper stations are also in a clean-in-place environment and are subjected to frequent washdowns. Banner offers a wide variety of sensors, safety products, and lighting that are rated IP69K to withstand high-pressure water.

Clear Tray Detection at Hopper Food Storage Units

Learn how the Q4X detects clear plastic trays at hopper and filling station in the food industry.

Black Plastic Tray Detection at a Hopper and Filling Station

Learn how the Q4X detects dark colored trays at hopper and filling station in the food industry.