X-Ray and Checkweigh Solutions for Food Packaging

The x-ray and checkweigher station consists of two separate machines that work together to ensure quality control. The x-ray will scan packed food as it passes to make sure that there are no foreign objects, such as bone, plastic, or metal. The checkweigher confirms the weight of each package to ensure conformity and meet weight regulations.

For both the x-ray machine and checkweigher, a sensor needs to detect the presence of each tray so that the machines are not running when product is not on the line. The sensor detects product presence – a clear or colored plastic tray – and then triggers the x-ray or checkweigher to scan the food. If any objects are discovered or the food does not meet weight requirements the tray is removed from the line. There is typically a reject sensor to count the number of failed products.

Beyond the challenge of detecting different tray materials and colors, x-rays also require visual alert aids that notify nearby operators when the x-ray machine is powered on. The TL50 LED Tower Lights are available with custom laser etching to specify which light indicates an ON status for the x-ray. The K50 is available with current monitoring to detect when the LED is burnt out, incompliance with FDA requirements for indicators on x-rays.

Washdown-rated products are also important for x-ray and checkweigh stations. Banner Engineering offers a wide variety of products that have been rated to IP69K for washdown environments.

Featured Applications

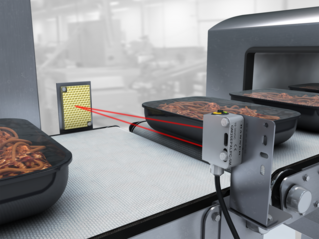

Conveyor-Triggered Checkweigh Station for Food Trays

Banner Engineering's QM26 washdown sensor detects dark plastic food trays as they approach a checkweigh machine that confirms the correct weight of the filled trays.

Checkweigh Station Indication of Pass/Fail Status

Harsh washdown environment, alert operators of fail status