Compliance with Safety Standards

Implementing safety measures can help reduce liability for employers and demonstrate compliance with safety standards to appropriate regulatory agencies.

OEMs who integrate safeguarding into their machines enjoy a ready market for their easy-to-use, pre-integrated machines.

Increased Productivity

Safeguarding machines benefits workers and manufacturers alike by reducing lost work days due to injury, increasing productivity, and improving worker morale.

Banner engineers are here to help! Let us know about your machine safeguarding needs, and our engineers can help you find the right solution for your application.

Learn about more machine guarding solutions from Banner Engineering.

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

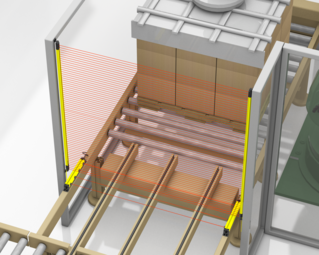

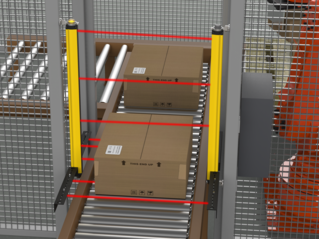

Area and Gate Guarding on Automotive Assembly Line

Integral hinge will stop conveyor once the gate is opened and the grid is muted when gate is opened.

Depalletizer Guarding with Muting

LS light curtains are intuitive, easy-to-use safety devices used for machine safeguarding. They are built to withstand challenges commonly found in manufacturing and packaging environments. LS-S models require no PC software, DIP switches, or other devices for quick, easy configuration. Highly visible alignment indicators and intuitive diagnostics simplify setup, facilitate troubleshooting, and minimize system downtime.

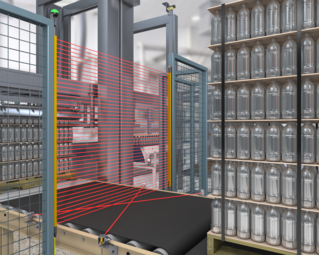

Depalletizer Guarding with Muting Pair

A company needed a way to safe-guard the area where pallets of empty bottles or cans enter into the depalletizer. Learn how Banner Engineering's XS26-2 Safety Controller with EZ-Screen safety light and LS-S safety light curtains helped maintain a continuous flow of pallets while protecting hazardous areas of a machine from workers.

Dual-operator Robotic Work Station

See how Banner’s EZ-SCREEN LS Heavy-Duty Type 4 Safety Light Curtains uses cascading to maximize safety while minimizing cabling and equipment footprints.

End-to-End Safety Sensing

The solution requires the sensor to mount snugly within a machine opening, with continual end-to-end sensing that leaves no gaps. This enables the light screen to be located a minimum distance from the machine hazard point, using minimal floor space (which reduces the reach for the operator), and eliminating snag and aesthetic issues. At 28 mm x 26 mm (1.1" x 1"), Banner's EZ-SCREEN LP safety light screen is incredibly compact and can mount in tight spaces.

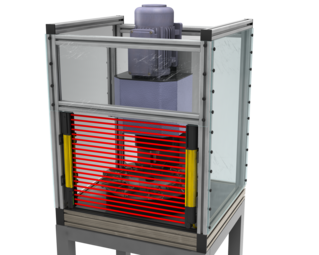

Guarding Conveyor Entry on Palletizer Machines

Safeguarding palletizer machines present many challenges to keep personnel safe and maintain efficient production. The new SGS Safety Grid with muting arm bar kit protects the dangerous robotic machinery while allowing boxes to pass through the Grids without stopping production. The muting arms can recognize if anything other than a box passes through the Grids and will trigger a machine stop on the palletizer.

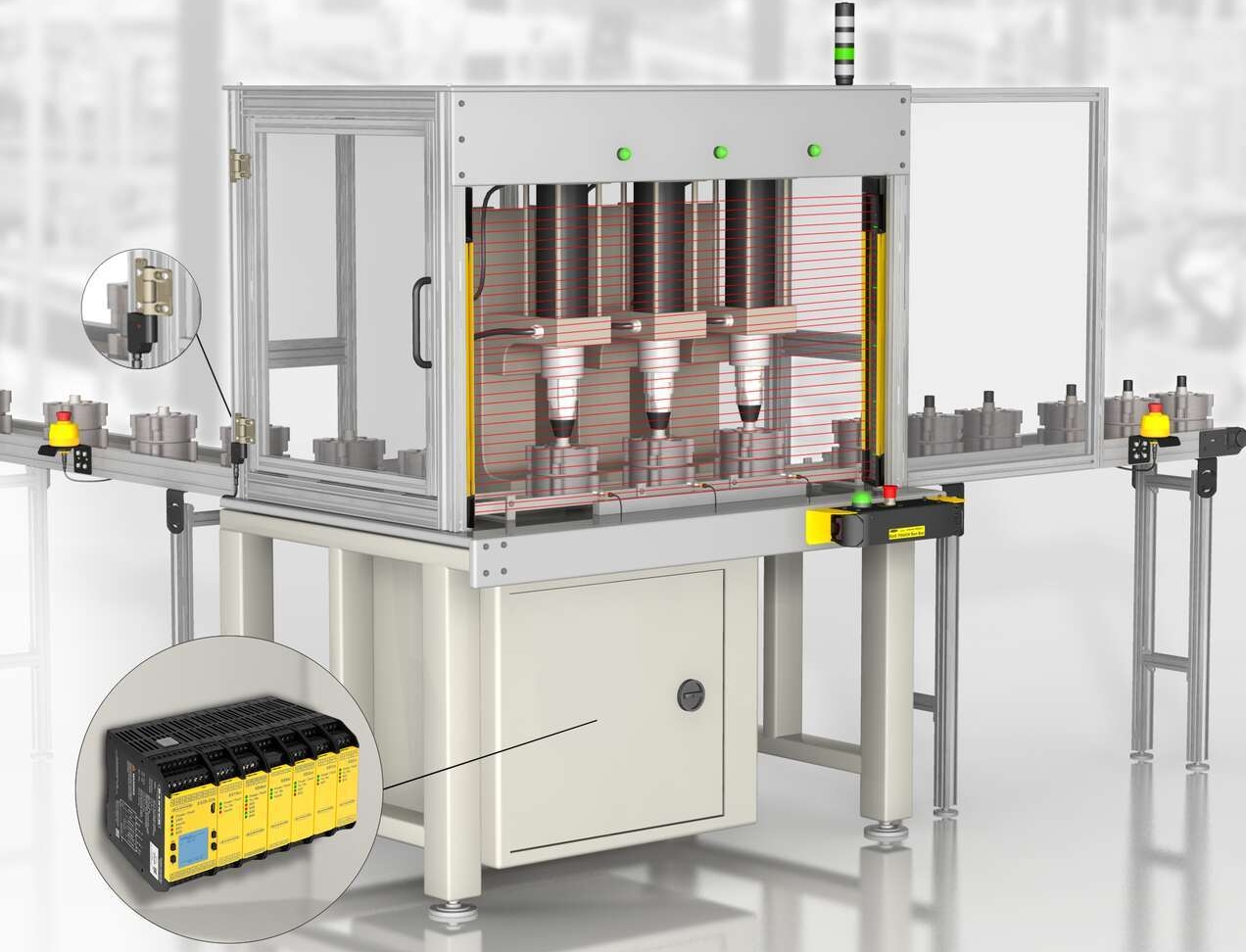

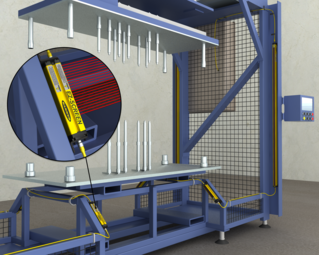

Heat Stake Machine Safeguarding

In this example, two sides of a heat stake machine require guarding because of separate operator load and unload stations. On each side of the station, two safety light screens protect workers; one with a 48" vertical light screen for area guarding and one with a 12" inclined light screen to guard the point of operation where the tool is loaded and unloaded.

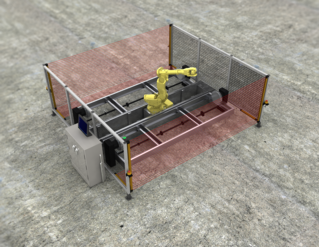

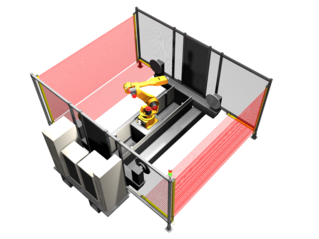

L-Configured Guarding

At both open sides of a robotic work cell, a pair of EZ-SCREEN safety light screens are linked—or cascaded—in an L-shaped configuration to guard the access point both vertically (reducing separation distance) and horizontally (providing continual sensing). Up to four pairs of EZ-SCREEN light screens can be connected.