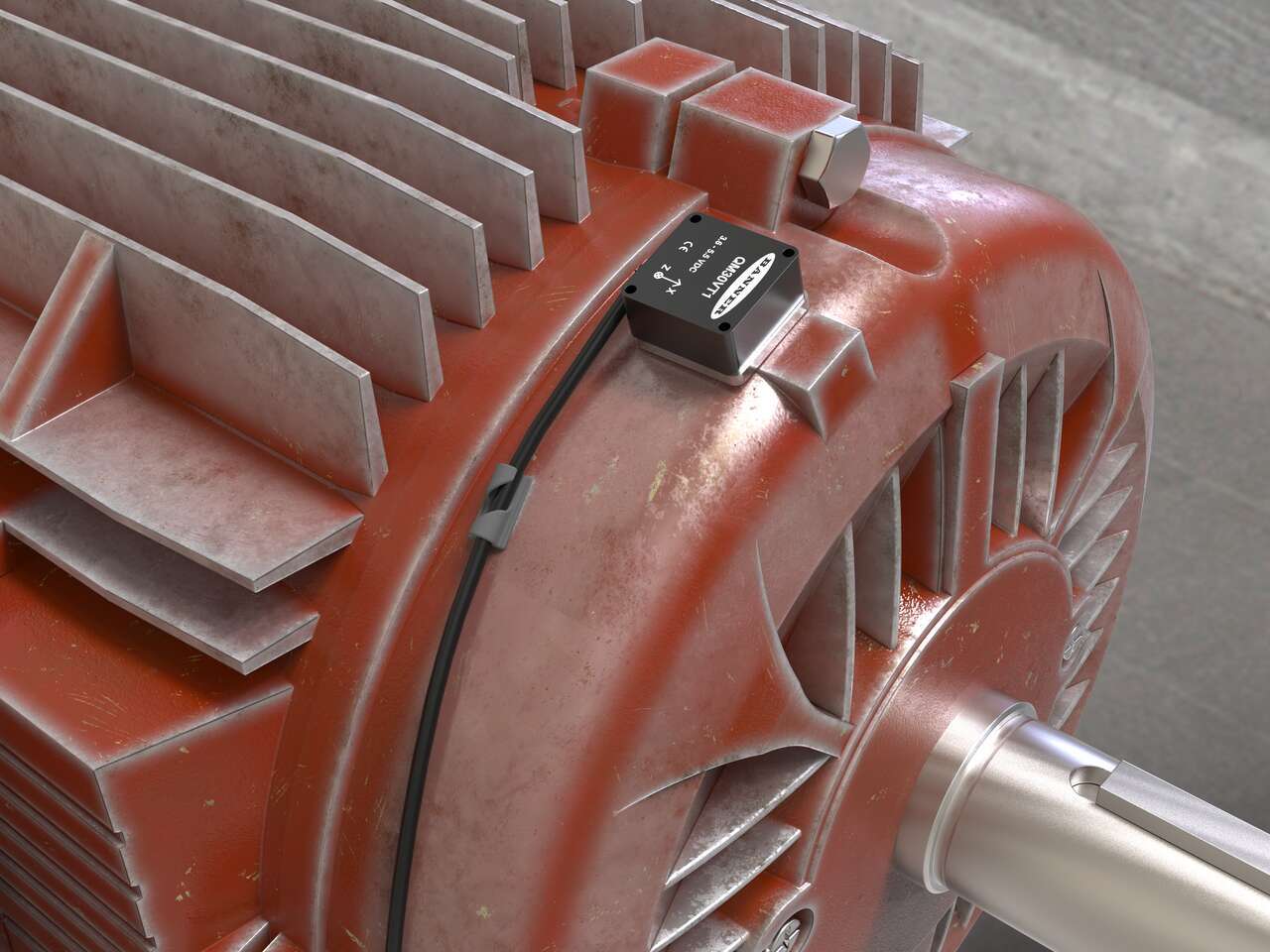

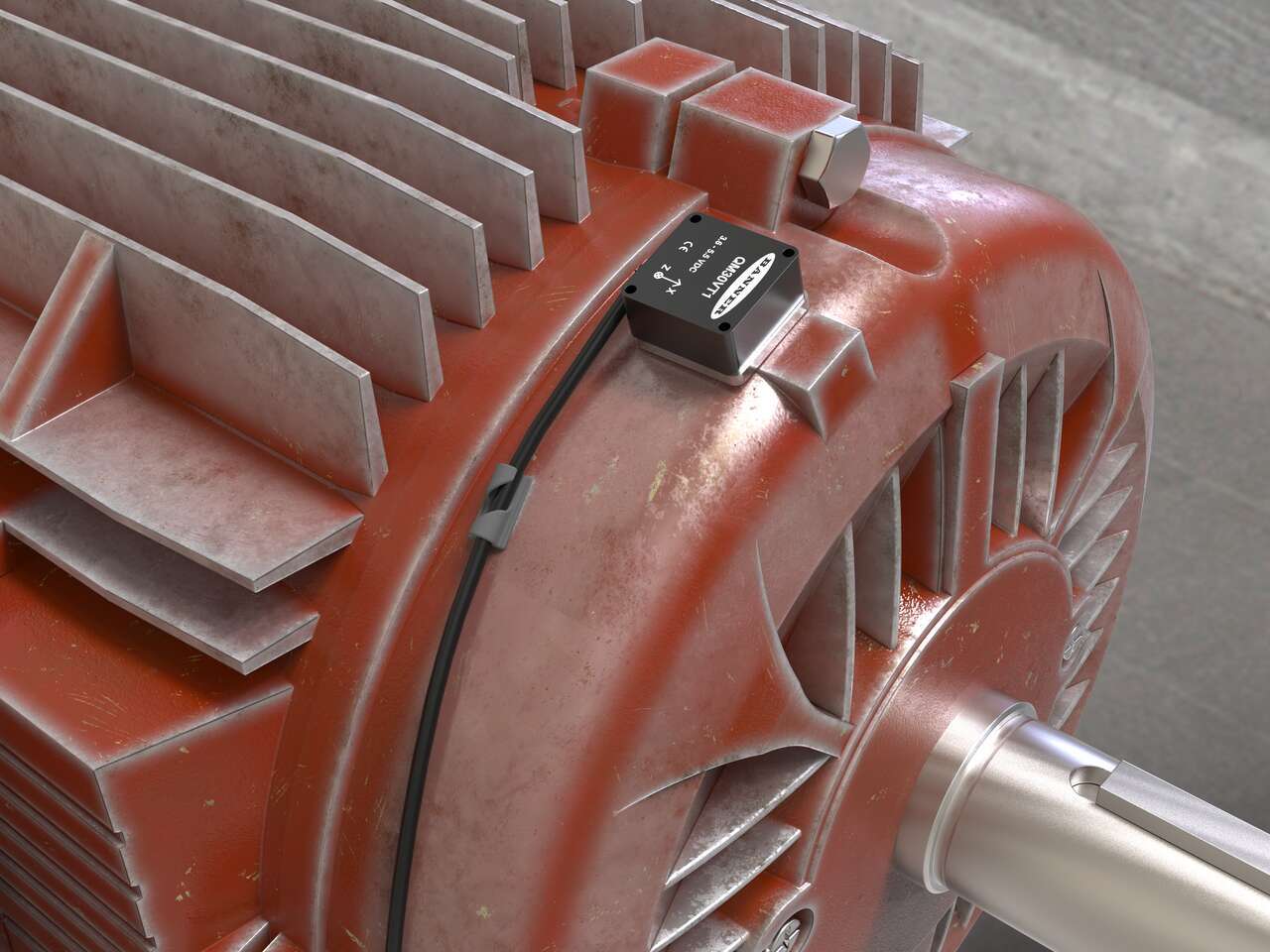

How To Guide: QM30VT Mounting Orientation

In this video, learn how to install the QM30VT Vibration & Temperature Sensor with the proper orientation for accurate condition monitoring.

QM30VT sensors have a low-profile design and rigid metal construction that reduces resonant interference and increases surface contact, enabling exceptional levels of accuracy in measuring RMS velocity and temperature. They are able to detect even slight increases in machine vibration and temperature for early identification of potential problems.

QM30VT 2-Axis Vibration Sensors

Applications

Wireless products enable predictive maintenance in the port industry. Motors and gearboxes on cranes are prone to high vibration and temperature which can cause them to degrade. Predictive maintenance allows employees to interfere and solve problems before they completely fail and cause unplanned downtime and lost profit.

Learn how the installation of Banner wireless vibration sensors and data from the DXM wireless gateway prevented unplanned downtime in this application.

Remote monitoring enables increased visibility into the performance and efficiency of machines, processes, and people.

Wireless products enable predictive maintenance in the port industry. Motors and gearboxes on cranes are prone to high vibration and temperature which can cause them to degrade. Predictive maintenance allows employees to interfere and solve problems before they completely fail and cause unplanned downtime and lost profit.

Learn how the installation of Banner wireless vibration sensors and data from the DXM wireless gateway prevented unplanned downtime in this application.

Remote monitoring enables increased visibility into the performance and efficiency of machines, processes, and people.

We noticed you didn’t finish your online checkout. We're dedicated to providing the best shopping experience possible and would love to hear if you faced any challenges. Let us know how we can make your experience even better.

In this video, learn how to install the QM30VT Vibration & Temperature Sensor with the proper orientation for accurate condition monitoring.

Monitor machine health utilizing predictive maintenance by continuously monitoring for vibration and temperature changes.

Our application engineers are here to help with expert guidance and support. Send us your inquiry, and we’ll get back to you as soon as possible. We’re here to make sure you get the answers you need.