Safety of a Plastic Film Heat Sealer

Application: Prevent heat sealer from operating if a door is open

Challenges: Multiple pinch points present on machine

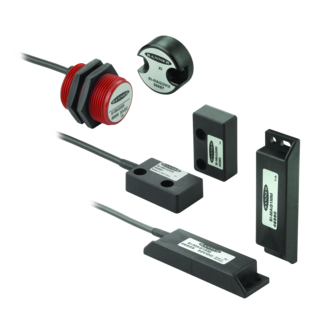

Solution: Banner Engineering’s SI-MAG series magnet switches

Benefits: Compact housing and sealed components

Heat sealers secure plastic film to food trays after the trays have been filled. It is not unusual for heat sealers to have points where an operator’s hand or arm could get pinched between machine parts or material. If left unguarded, these pinch points could potentially cause serious harm to operators while the machine is running. A safety solution reduces the risk of injury by shutting down the machine when the doors are open. Due to the limited mounting space within the heat sealer machine, a compact solution is required.

Small Safety Switch with Sealed Components

By adding Banner Engineering’s SI-MAG series magnet style switches to the heat sealer, injuries can prevented. Installing these switches onto the heat sealer doors will detect when someone opens the door and signal the machine to stop running.

SI-MAG switches work well on food production lines because they are rated IP67 with sealed components which makes them resistant to the wet environment and debris that are typically associated with the food industry. They are available in coded magnet to minimize risk of intentional defeat. The switches are also available in three different housing styles with a compact size, making them easy to conceal once installed on the heat sealer.