Counting Syringes with a Slot Sensor

Challenge

The assembly and packaging of syringes is automated starting with the use of equipment such as feeder bowls and conveyor rails. Once the parts move down the rail, reliable detection is needed in order to sense and count the parts, even as the syringes are apt to swing and vibrate through the sensing field.

Solution

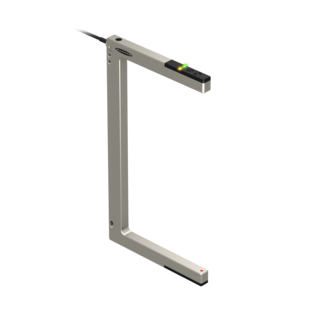

In this application, the semi-transparent syringes have been oriented in a feeder bowl (not shown) and are moving down a rail in preparation for the next stage of assembly and packaging. A Banner SLM Slot Sensor is ideal for this application because the sensor housing is equipped with an emitter and receiver on the end of each fork, creating a perfectly aligned opposed-mode sensing beam for the syringes to pass through. The SLM Slot Sensor is adjusted with a gain potentiometer with optimal sensitivity to detect translucent objects and performs flawlessly even when the moves and sways along the rail.

For ease of setup and installation, slot sensors are ideal because mounting the SLM effectively positions an emitter and receiver all at once with no physical alignment needed. The same principle is true for wiring – the SLM only needs one cable to apply power and output, saving installation time and money.