All Semiconductor Solutions

-

Monitoring Environmental Conditions

Monitoring Environmental Conditions

A semiconductor fab needs to monitor temperature, relative humidity, and oxygen levels at multiple points within their processing plant, along a 2 kilometer long process piping system. They require a solution that monitors temperature, relative humidity, and oxygen levels, provides a location for the monitoring points, and collects all data to a central point and interfaces with their SCADA system. The solution needs to create an efficient, safe work environment for all employees. With over 2 kilometers of underground tunnel piping systems, installing cable to each monitoring location is cost prohibitive.

-

Environmental Monitoring inside a Machine Control Panel

Environmental Monitoring inside a Machine Control Panel

Identify small problems before they become major issues that impact machine performance and uptime.

-

Easy-to-See Status Indication in Close Proximity to Staff

Easy-to-See Status Indication in Close Proximity to Staff

To optimize efficiency and output, the progress of multiple FOUPs in single wafer deposition machine must be closely monitored. Staff work in close proximity to these machines and prolonged exposure to bright light from tower lights can cause eye strain, leading to physical and mental fatigue. Keep reading to learn how TL30 Basic tower lights solve this application.

-

Monitor Leaks in Your Critical Applications

Monitor Leaks in Your Critical Applications

Monitor leaks in your critical applications and receive real time alerts when they occur.

-

Machine Safeguarding in an ESD-Sensitive Environment

Machine Safeguarding in an ESD-Sensitive Environment

In this application, machine operators require access to the wafer carrier station. The EZ-SCREEN ESD safety light curtain system is configured to safeguard the process and operator using emitters, receivers and mirrors to enclose three sides of the station. Safety light curtains allow quicker, easier access than physical barriers while preventing machine movement if the operator reaches into the hazardous zone.

-

Safety Control on Small Machines

Safety Control on Small Machines

An SC10 Series safety controller replaces the functionality of three safety relays with one compact, cost-effective device offering intuitive operation and advanced capabilities.

-

Amber Illumination Suitable for Photosensitive Materials

Amber Illumination Suitable for Photosensitive Materials

Illumination during photolithography processes is challenging because white light contains a percentage of blue wavelengths, which negatively affect photosensitive materials. The WLS15 strip lights switch between two colors for safe use during photolithography.

-

Semiconductor Process Tool Illumination

Semiconductor Process Tool Illumination

Banner’s WLS27 are rugged LED strip lights specifically developed to provide brilliant, even illumination in challenging environments and compact spaces. They have a space-saving, aerodynamic design, are fully encapsulated in a protective shell, and come in a broad range of illumination color options. Machine designers can install WLS27 LED strip lights wherever they are best suited to illuminate a work area without making costly or time consuming modifications to the lights.

-

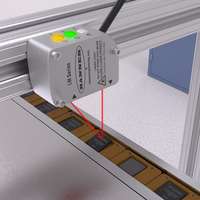

Detecting Integrated Circuit Chip Presence and Orientation

Detecting Integrated Circuit Chip Presence and Orientation

A precise measurement solution is required to ensure that integrated circuit (IC) chips are present and oriented correctly in nests. Learn how the LM laser measurement sensor solves this application.

-

Wafer Center Detection with DF-G2

Wafer Center Detection with DF-G2

By pairing Banner’s DF-G2 with four opposed mode PLIS-1 fiber optics, operators can ensure that a wafer is placed correctly on the end effecter of a robotic arm, ensuring that no damage is done when passing it into the chamber.

-

Lead Frame Detection in a Magazine

Lead Frame Detection in a Magazine

In the process of die bonding and wire bonding, lead frames are conveyed in a tall vertical cassette. To increase throughput, the cassettes are inspected to determine if a lead frame is present in each slot. Because the lead frame can be as thin as 0.1 mm, it can be difficult to sense. The VS1 convergent sensor easily senses this thin profile, as well as non-reflective plastic ball grid arrays (PBGA).

-

Wafer Mapping in a Cassette

Wafer Mapping in a Cassette

PicoDot sensors are positioned to sense the edge of the same wafer at the same time. If only one sensor detects a wafer edge, that wafer is most likely inserted at an angle, or cross slotted.

-

Wafer Mapping with Bargraph Display

Wafer Mapping with Bargraph Display

The fibers of the D10 Expert sensor move along the stack of wafers in the cassette, mapping which slots are occupied and which are empty. The bargraph displays the sensor's status.

-

Bond Wire Break Detection with a Fiber Optic Pair

Bond Wire Break Detection with a Fiber Optic Pair

A semiconductor company requested a sensor to detect breakage of very fine wire during assembly to eliminate unscheduled downtime.

-

Integrated Circuit Lead Frame Detection with a D10

Integrated Circuit Lead Frame Detection with a D10

The lead frame of an integrated circuit moves on a U-shaped channel toward the cassette that holds multiple frames. The D10 Expert Analog/Discrete sensor detects the leading and trailing edge, to signal to the cassette that the lead frame is approaching. The sensor operates in the opposed mode, because large differences in reflectivity of frame materials make diffuse sensing impossible.

-

Sensing in a High-Speed Chip Shooter

Sensing in a High-Speed Chip Shooter

The bussable power feature of the D10 Expert allows for up to 16 sensors to be wired together and powered through one power supply, reducing the amount of wiring required and making it possible to use multiple sensors without needing multiple connection points. Space can be further conserved by mounting the sensors together on a DIN rail, utilizing fiber optics to monitor multiple inspection points in a confined space.

.jpg/jcr:content/renditions/cq5dam.web.200.200.jpeg)