Tüm Otomotiv Çözümleri

-

Temperature Sensor Detects Defrost Wires [Success Story]

Temperature Sensor Detects Defrost Wires [Success Story]

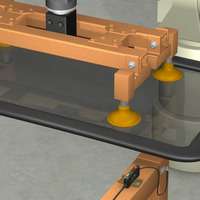

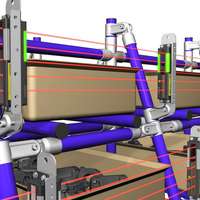

An automotive manufacturer was rejecting a supplier’s shipment of rear window assemblies due to faulty defroster grids. The supplier’s existing test procedure measured current draw across the entire heating system to detect an overall failure, but it could not detect the subtle impact of a single heating wire being broken. The window supplier partnered with a Michigan-based machine automation company to create a better test fixture—one that can verify each defrost wire heats to specification prior to shipping.

-

Motor Temperature Monitoring and Control with a Wireless Network

Motor Temperature Monitoring and Control with a Wireless Network

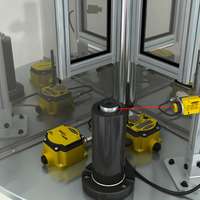

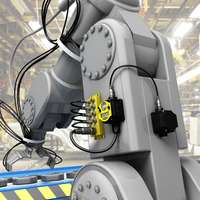

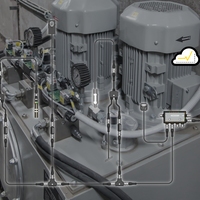

Instead of installing I/O transmission cabling, use a 10 to 30V dc powered SureCross Node and a Banner T-GAGE temperature sensor. When using host control systems, the SureCross Gateway transmits the temperature to the plant control room using a digital output related to temperature setpoints within the sensor. The motor is powered down or up based on these temperatures. When using a Gateway Pro as the wireless master device, the data ca be logged and alerts sent out to notify maintenance personnel when a motor is performing outside expected parameters.

-

Equipment Monitoring from a Supervisor's Station

Equipment Monitoring from a Supervisor's Station

• Provide at-a-glance machine status indication • Send machine status information to a wide range of devices • Alert staff and supervisors of critical conditions via text message or email

-

Restocking Assembly Stations for a Continuous Workflow

Restocking Assembly Stations for a Continuous Workflow

• Restock assembly stations before components run out without overstocking • Provide real-time communication between assemblers and the forklift operators who supply them • Monitor delivery efficiency

-

Call for Pickup from an Assembly Station to an AGV

Call for Pickup from an Assembly Station to an AGV

• Remove completed pallets from assembly stations quickly • Enable direct communication from assembly stations to AGVs • Improve process efficiency using turnaround time data to

-

Warning Indication where Obstructions Limit Visibility

Warning Indication where Obstructions Limit Visibility

• Provide high-visibility warning indication • Minimize risk to staff in high-traffic forklift area • Facilitate the flow of traffic through an area with visual obstructions

-

Remote Monitoring to Optimize Overall Equipment Effectiveness

Remote Monitoring to Optimize Overall Equipment Effectiveness

• Provide instant visual communication across a busy plant floor • Collect machine status and other data to calculate Overall Equipment Effectiveness (OEE) • Alert staff to critical conditions via text message or email

-

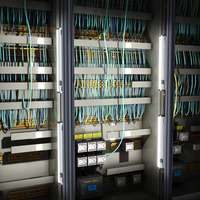

Environmental Monitoring inside a Machine Control Panel

Environmental Monitoring inside a Machine Control Panel

• Identify small problems before they become major issues that impact machine performance and uptime • Access environmental data from a remote location • Notify operators of critical conditions via text message or email

-

Status Indication on Driverless Vehicles [Success Story]

Status Indication on Driverless Vehicles [Success Story]

The K50L domed 50 mm indicator light works well for status indication on autonomous shuttle buses. The buses operate on short distances in outdoor environments that exposed the bus technology to a variety of weather conditions. The rugged K50L indicators are rated IP67 and IP69K to withstand water ingress in the harsh environment.

-

Multicolor Indicators and Illuminated Touch Buttons Simplify Machine Panels

Multicolor Indicators and Illuminated Touch Buttons Simplify Machine Panels

S22 Pro Series touch buttons and indicators simplify control panel design and improve operator experience and performance. Pro Editor software expands the built-in display capabilities available with the S22 Pro Series, enabling custom displays.

-

Assembly Timer at Busy Work Station

Assembly Timer at Busy Work Station

K50 Pro touch buttons with IO-Link communication display takt time within workers' sightlines so that the assembly pace stays on track and meets production goals.

-

Hidrolik Güç Ünitelerini İzleyin

Hidrolik Güç Ünitelerini İzleyin

Hidrolik güç ünitelerinin ve diğer hidrolik makinelerin basıncını, akımını, yağ sıcaklığını ve motor vibrasyon/sıcaklığını kolayca izleyebilirsiniz. Snap Signal ürünlerimizle sensörlerinizi birbirine bağlayarak topladığınız verileri Modbus’a dönüştürebilir ve bu sayede sisteminizin çalışma durumunu eş zamanlı olarak izleyebilirsiniz.

-

Monitor Leaks in Your Critical Applications

Monitor Leaks in Your Critical Applications

Monitor leaks in your critical applications and receive real time alerts when they occur.

-

Bir Araç Kapı Paneli Üzerinde Yapıştırıcı Algılanması

Bir Araç Kapı Paneli Üzerinde Yapıştırıcı Algılanması

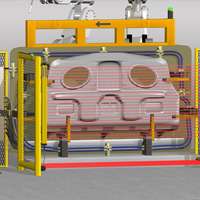

Yapıştırıcıyı algılamak üzere yapılandırılmış bir VE Serisi Akıllı Kamera, her bir kapı paneli üzerindeki yapışkanın varlığını ve durumunu inceler. Kameranın geniş bir görüş açısı vardır ve uygulanan yapışkan miktarındaki hatayı algılayabilecek 2 MP çözünürlükte bir imager'a sahiptir.

-

Siyah Kapı Paneli Üzerindeki Siyah Parçaların Tespiti

Siyah Kapı Paneli Üzerindeki Siyah Parçaların Tespiti

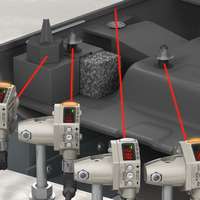

Banner'ın Q4X Serisi lazer mesafe ölçüm sensörü, yükseklik farkı olsa bile siyah zemin üzerindeki siyah hedefi algılamak gibi zorlu uygulamalar için idealdir. Sınıfının en kuvvetli lazer ışığına sahip Q4X, renkten ve parlaklıktan bağımsız şekilde sadece yükseklik farklarını algılayarak varlık/yokluk kontrolü yapar.

-

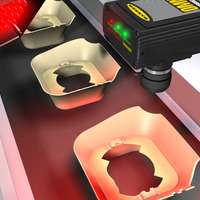

Damgalı Metal Parçalarında Birden Fazla Noktada Denetim Yapma

Damgalı Metal Parçalarında Birden Fazla Noktada Denetim Yapma

Küçük bir metal parçada beklenen sayıda deliğin mevcut olduğunu doğrulamak için, Multipoint Denetim özelliğine sahip iVu Plus TG Serisi Vision Sensörü, deliklerin mevcut ve doğru yerde olmasını sağlamak amacıyla birden fazla bölgeyi (ROI) denetleyecek şekilde konfigüre edilebilir. iVu, Area (Alan) denetimi için ayarlandığında, Delikli bir nesnedeki, deliklerin varlığını ve ölçüsünü denetler.

-

Diş Açılıp Açılmadığının Kontrolü

Diş Açılıp Açılmadığının Kontrolü

Standart sensörler genellikle dişlerin varlığını tespit etmekte güçlük çeker. WORLD-BEAM QS30 Serisi ince lazer ışık demeti sayesinde yaklaşık 800 mm mesafeden manifold üzerindeki dişlerin açılıp açılmadığını algılayabilir.

-

Açılmış Deliklerin Denetimi

Açılmış Deliklerin Denetimi

Bu uygulamada, Area inspection (Alan denetimi) için yapılandırılmış iVu Serisi sensör kullanılır. Delikler açıldığında, sensör tüm delikleri değerlendirerek mevcut olduklarını ve büyüklüklerinin doğruluğunu denetler. Eğer problem varsa sensör ürün hattına bir hata outputu gönderir ve parça reddedilir.

-

Rulman Denetimi

Rulman Denetimi

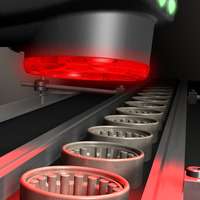

Bu çözümde, Match (karşılaştırma) denetimi için yapılandırılmış bir iVu Serisi sensör, rulman içeren komponentlerdeki tüm rulmanların mevcut olup olmadığını denetler. Eğer sensör eksik rulman saptarsa, sensör üretim hattına bir hata outputu gönderir ve komponent hattan ayırılır.

-

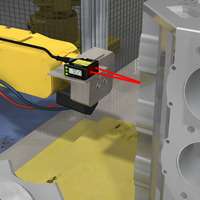

Motor Gövdesindeki Parçanın Yerinde Olup Olmadığının Algılanması

Motor Gövdesindeki Parçanın Yerinde Olup Olmadığının Algılanması

Banner’ın LE550 lazer sensörü, parçaların yerlerinde olup olmadıklarının algılanması için idealdir. Sensör, uzun mesafelerden küçük parçaların yerlerinde olup olmadıklarının doğrulanması gereken uygulamalar üzerinde oldukça hassas şekilde çalışır. LE550 dijital output ile 3 mm'de kalınlık için ölçüm yapar; tutma klipsinin mevcut olduğunu ve motor gövdesinin doğru yerde olduğunu kontrol eder.

-

Kaynak Ucu Kontrolü

Kaynak Ucu Kontrolü

R55F Serisi sensör, bir kaynak makinası üzerindeki uçların olması gereken özelliklere uygun olup olmadığını kontrol eder. Zorlu ortamda ısıya direnç sağlamak için cam fiberler kullanır.

-

Parça Varlığının Doğrulanması

Parça Varlığının Doğrulanması

WORLD-BEAM QS18 ayarlanabilir alan arka fon bastırmalı sensör, 7,5 cm'lik tarama mesafesi gerektiren bu uygulama için mükemmel bir seçimdir. Yüksek kazanç özellikleri, ayarlanabilir eşik değeri ve görülebilir kırmızı ışığı ile zorlu çevre koşullarında uzun kullanım ömrü sunar.

-

Otomotiv Montajında Uzun Menzilli Denetim

Otomotiv Montajında Uzun Menzilli Denetim

Otomotiv montaj hattında araçlar ilerledikçe, L-GAGE LT7 Serisi uzun menzilli lazer sensörü, oto koltuğunun montajının yapıldığını ve doğru konumda olduğunu kontrol eder. 250 m'ye kadar olan son derece uzun menzilli, çift dijital output'a sahip (PNP) reflektörlü modelleri otomobil endüstrisinde çok yönlü bir sensör olarak kullanılmaktadır.

-

Otomotivde Kaynak Somunu Denetimi

Otomotivde Kaynak Somunu Denetimi

Robot bir bileşene birden fazla kaynak somunu yerleştirdikten sonra operatör bu parçayı, iki adet PresencePLUS P4 OMNI vision sensörü kurulan bir denetim istasyonuna koyar. Düzgün yerleştirilmemiş kaynak somunları baş aşağı, yana yatmış, hatta kaynak somunu eksik olabilir. PresencePLUS P4 OMNI, kaynak somunlarının mevcut, yana yatmamış olduğunuve doğru yerleştirildiğini kontrol eder. Vision kamerası parçaların hareketini kompanze eder ve uzun bir mesafeden denetim yapabilir.

-

Otomotiv Sigorta Kutusu Denetimi

Otomotiv Sigorta Kutusu Denetimi

PresencePLUS COLOR Pro vision sensörü, sigorta kutusundaki renklerle kodlandırılmış sigortaları denetleyerek doğru konumda olup olmadıklarını kontrol eder.

-

Otomotiv Borusunun Denetimi

Otomotiv Borusunun Denetimi

Otomotiv borusuna mass-airflow (maf) testi yapıldıktan sonra, PresencePLUS Pro borunun açık bir ucu üzerine konumlandırılır. PresencePLUS Pro, borunun içerisindeki sıcaklık sensörünün yerinde ve hasarsız olup olmadığını kontrol eder.

-

Plastik Enjeksiyon Eksik Atış Algılama

Plastik Enjeksiyon Eksik Atış Algılama

Bir üretim hattının üzerine monte edilen yüksek çözünürlüklü PresencePLUS P4 OMNI 1.3, kalıplandıktan sonra direksiyon bileşenlerinin denetimini yapar. P4 OMNI, fazla miktarda malzeme olan veya az miktarda malzeme bulunan alanları kontrol eder.

-

Otomotiv Kapı Kollarında Renk Denetimi

Otomotiv Kapı Kollarında Renk Denetimi

PresencePLUS P4 Serisi COLOR OMNI vision sensörü, montajı yapılan araçlar için yanlış renkli olan iç kapı kollarını algılar. Özel braketlerle monte edilmiş olan on-axis ışık, göz alan parıltıyı önlemek için homojen aydınlatma sağlar.

-

Otomobil Üzerinde Takılı Camı Algılama

Otomobil Üzerinde Takılı Camı Algılama

Bir otomobil montaj hattında bir açılır tavanın varlığını algılamak için uzun menzilli sensörlere ihtiyaç vardır.

-

Kontrol Panosunu Aydınlatan LED Işıklar

Kontrol Panosunu Aydınlatan LED Işıklar

Bir ekipman üreticisi, otomotiv endüstrisi için test ve ölçüm makinaları imal etmektedir. Operatörler kontrol panosu üzerinden makina sistemlerine eriştiklerinden dolayı pano içinin yoğun bir şekilde aydınlatılması, makinenin bakımını ve yönetimini kolaylaştırır. Daha önce firmada, bu görev için birden fazla AC güçle beslenen floresan aydınlatma armatürü kullanılıyordu.

-

LED'lerle Üstün Işık Dağılımı [Başarı Hikayesi]

LED'lerle Üstün Işık Dağılımı [Başarı Hikayesi]

American Hofmann Corporation, çalışma alanlarını, muhafaza ve kontrol panolarını aydınlatmak için floresan ışık armatürlerin yerine WLB32 Serisi endüstriyel LED aydınlatmayı seçti. WLB32 Serisi LED aydınlatma, daha iyi ışık dağılımının yanı sıra montaj kolaylığı sunması, şirketin kararındaki en önemli etkenlerdi.

-

Operatör Yönlendirme Çözümü [Başarı Hikayesi]

Operatör Yönlendirme Çözümü [Başarı Hikayesi]

Bir Henshaw müşterisi, otomotiv endüstrisi için transmisyon ve güç aktarma organları üretmektedir. Şirket, transmisyon supap gövdelerinin montajındaki hatalar nedeniyle verimlilik kaybı yaşadığından dolayı Henshaw'dan hataları azaltacak ve montaj işlemini iyileştirecek bir sistem geliştirmesini talep etmişitir.

-

Run Bar ile Operatör Rehberliği [Başarı Hikayesi]

Run Bar ile Operatör Rehberliği [Başarı Hikayesi]

Önde gelen bir makina üreticisi, batarya hücresi montajı için tasarlanmış iş istasyonlarını üretmektedir. İş istasyonlarının katma değeri oluşturan bileşenlerinden biri, operatör rehberlik cihazıdır ve üç görevi yerine getirir: Montaj işlemlerinin başlatılması ve durdurulması, toplanacak ve montajı yapılacak parçaların indikasyonu ve acil durumlarda hat operasyonunun tamamen durdurulması. OEM firmasının bu cihazları kendi başına inşa etmesi ve monte etmesi çok pahalı hale geldiğinden, Banner'dan her şey dahil bir çözüm üretmesini istediler. Önde gelen ikinci katman pil tedarikçisinin OEM firmasına, müşterisinin zaman çizelgesi gereksinimlerini karşılamak adına bir çözüm sunması gerekiyordu.

-

Motor Gövdesinin Konumlandırması

Motor Gövdesinin Konumlandırması

Banner’ın L-GAGE LH Lazer Mesafe Sensörü, bir parçanın tam olarak konumlandırılmasının kritik öneme sahip olduğu uygulamalar için idealdir. L-GAGE LH Serisi, koyu renkli hedefleri sürekli olarak mikron seviyelerinde denetler. Banner’ın lazer mesafe sensörü, motor gövdelerinin konumlandırılması dahil olmak üzere, konumlandırma uygulamalarında oldukça hassas çalışır. Sensör neredeyse her türlü yüzeyde ölçüm yapabilir; bunların arasında motor gövdelerinin imalatında sıkça kullanılan, dökme demir veya alüminyum alaşımlar da vardır.

-

Eldivenlerle Takım Hazırlama

Eldivenlerle Takım Hazırlama

Banner’ın K50 Serisi sabit arka fon bastırmalı indikatörü, takım hazırlama sürecinde eldiven kullanan operatörlerin bile doğru parçaları seçmesini sağlar. Bunun ardından operatöre doğru parçayı seçtiğini bildirmek için ışığını yeşilden sarıya çevirir. Üreticinin tercihine bağlı olarak farklı renkler seçil98ebilir. K50'nin siyah eldiven algılama yeteneği özellikle yalın imalat süreçleri için önemlidir, çünkü çalışanlar bu süreçlerde genellikle koyu renk eldivenler giyerler.

-

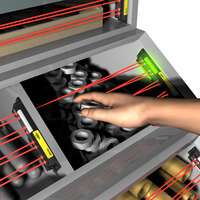

Otomotiv Montajında Parça Çıkarma Doğrulaması

Otomotiv Montajında Parça Çıkarma Doğrulaması

Bir otomotiv montaj fabrikasında bazı parçaları geçici olarak birleştirmek için "bomba pimleri" olarak adlandırılan pimler kullanılır. "Bomba pimlerinin" çıkartıldığından emin olmak için denetim istasyonunda, EZ-LIGHT PVA pick-to-light sensör monte edilmiş bir konteyner bulunur.

-

Motor Bloğunda Plastik Conta Tespiti

Motor Bloğunda Plastik Conta Tespiti

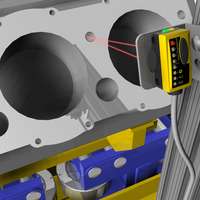

Banner Q4X lazer sensörü çok küçük yükseklik farkları ve siyah üzerinde siyah ya da parlak yüzeylerin var/yok kontrolü için ideal bir çözümdür. Aluminyum motor bloğu üzerinde contaların bulunması zorunludur; Q4X 1 mm kadar küçük bir farklılık algıladığında, plastik contanın olmadığına veya birden çok conta olduğuna ilişkin bir sinyal göndererek operatörü uyaracaktır. Birden çok contanın varlığı ön fon bastırmalı modda Q4X'in pencere öğretme yöntemi sayesinde algılanabilir.

-

Küçük Kutular İçin Parça Seçme İndikatörü

Küçük Kutular İçin Parça Seçme İndikatörü

Montaj işleminde hata riskini azaltmak için, 400 mm menzile sahip tek parçalı bir EZ-LIGHT PVD pick-to-light sensör ile birlikte doğru montaj sırasıyla programlanmış bir proses kontrolörü arayüz oluşturmaktadır. Kontrolör, montaj operatörüne hangi parçayı seçeceğini göstermek için PVD'nin ışıklarını doğru sırayla yakarken PVD, montaj operatörünün elinin kutuya girdiğini ve çıktığını tespit eder. Kontrolör de, toplama sırasına göre bir sonraki kutuya ilişkin sinyali PVD'ye ileterek yanmasını sağlar.

-

Uzun Kutular için Pick-to-Light Uygulaması

Uzun Kutular için Pick-to-Light Uygulaması

EZ-LIGHT PVA Serisi pick-to-light sensörleri çeşitli sistemlere hata giderme çözümü sunar. Üzerinde bulunan ışık, montajcılara hangi malzemeyi seçeceğini ve hangi sırayla seçeceğini gösterir.

-

İzlenebilirliği Sağlamak için UV Barkodların Kullanımı [Başarı Hikayeleri]

İzlenebilirliği Sağlamak için UV Barkodların Kullanımı [Başarı Hikayeleri]

Bir oto güneşlik üreticisi, markanın montajcısına göndermeden önce her bir güneşliğin güvenlik etiketinin üzerinde Data Matrix UV barkodlarının basılı olduğunu kontrol etmesi gerekiyordu. Müşteri, görünmez 2D Data Matrix barkodu izlenebilir olması ve hata tespiti yapılması amacıyla okumak; bu verileri Ethernet IP üzerinden PLC'ye göndermek için Banner ile iletişime geçti.

-

QR Kod Okumak için Vision Sensörünün Kullanımı [Başarı Hikayeleri]

QR Kod Okumak için Vision Sensörünün Kullanımı [Başarı Hikayeleri]

Montaj öncesinde, motor ve transmisyon üniteleri montaj hattında eleştirilirler. Elinde barkod okuyucu bulunan bir çalışan da her transmisyon ünitesinin QR kodunu tarar. Kodlar küçüktür, minimum kullanılmayan bölgeye sahiptirler. Ayrıca barkod okuyucularının menzili de oldukça sınırlıdır. Bu etkenler bir araya geldiğinde, QR kodlarını tarama işlemi zor hale gelir, montaj prosesine süre ekleyerek iş gücü kaynaklarını meşgul eder.

-

Detect Installed Glass on Automobile

Detect Installed Glass on Automobile

Sensor solutions to detect the presence of a moonroof on an automobile assembly line where extended range capabilities are required.

-

Manual Load Weld Cell

Manual Load Weld Cell

Banner EZ-SCREEN® serisi emniyet ışık bariyeri sistemi, kaynak ekipmanlarındaki zorlu gereksinimleri karşılamak için yapılandırılmış bir çözümdür. Birden çok parçayı birbirine kaskatlama (seri bağlama) özelliği ile, yatay/dikey çift benzeri konfigürasyonlar standart donanımla (master/slave model olmadan) kolayca kurulabilir.

-

Perimeter Guarding on a Tube Bending Machine

Perimeter Guarding on a Tube Bending Machine

Geniş aralıklı ızgara platform yapılı SGS emniyet ışık bariyeri, çalışma alanı çevresini ekonomik bir şekilde korur. Izgaranın tehlikeden uzaklığı, bir kişinin veya cismin ızgaradan geçmesi durumunda hareketin durdurulması için gereken süreyi sağlayacak kadardır.

-

Area and Gate Guarding on Automotive Assembly Line

Area and Gate Guarding on Automotive Assembly Line

Bir konveyör üzerinde ilerleyen araç, SGS Serisi Emniyet Izgara Sistemi tarafından korunan tehlikeli bir alana girer. Araç yaklaşırken SGS Izgara geçici olarak susturularak, konveyörün durdurulmasına gerek kalmadan aracın geçmesine izin verir. Izgara sistemi susturulduğunda, bir çalışanın kilitlemeli koruma üzerinden tehlikeli alana girmeye kalkışması riski vardır. Bu durumda çalışan kendisini tehlikeye sokar ve hareketli araç tarafından çarpılma riski ortaya çıkar.

-

Makina İzleme/Toplam Ekipman Etkinliği

Makina İzleme/Toplam Ekipman Etkinliği

• Yerel indikasyonun ötesindeki verilere erişin • Hızlı tepki vermek için gerekli bilgileri toplayın • Daha önce kullanılamayan verilere dayanan iyileştirmeleri gerçekleştirin

-

Parça, Servis veya Palet Çağırma

Parça, Servis veya Palet Çağırma

• Parça, servis veya alım çağrısı yapmak için kablosuz sistem kullanarak verimliliği artırın • 6 adet forklift 18 adet çalışma istasyona bağlanabilir • Kritik meseleleri iş akışını bozmadan hızla çözün

-

Yönetici İstasyonundan Ekipman İzleme

Yönetici İstasyonundan Ekipman İzleme

• Makinanın durumu hakkında anında bilgi verir • Makinanın durumu hakkında farklı sistemlere bilgi gönderir • Kritik koşulları SMS veya e-posta ile çalışanları ve yöneticileri bilgilendirir

-

Montaj İstasyonu Stoklarını İş Akışı Sağlayacak Şekilde Besleme

Montaj İstasyonu Stoklarını İş Akışı Sağlayacak Şekilde Besleme

• Parçaların tükenmemesi için montaj istasyonlarına ekleme yapın • Montaj elemanları ile onlara parça tedarik eden forklift operatörleri arasında eş zamanlı haberleşme sağlayın • Teslimat verimliliğini izleyin

-

Montaj İstasyonundan Otomatik Yönlendirilmeli Araç (AGV) Çağırma

Montaj İstasyonundan Otomatik Yönlendirilmeli Araç (AGV) Çağırma

• Tamamlanmış paletleri montaj istasyonlarından hızla çıkarın. • Montaj istasyonları ile Otomatik Yönlendirmeli Araçlar (AGV) arasında doğrudan iletişimi imkanlı hale getirin • Çalışma döngüsü verilerini kullanarak süreç verimliliğini artırın.

-

Görünürlüğü Sınırlayan Alanlarda Uyarı Işığının Kullanımı

Görünürlüğü Sınırlayan Alanlarda Uyarı Işığının Kullanımı

• Yüksek görünürlükte sahip uyarı sağlayın • Yoğun forklift trafiği olan alanlardaki riskleri en aza indirin • Görünürlüğü sınırlayan alanda trafik akışını kolaylaştırın

-

Genel Ekipman Etkinliğinin Optimizasyonunu Uzaktan İzleme

Genel Ekipman Etkinliğinin Optimizasyonunu Uzaktan İzleme

• Yoğun fabrika üretim alanında anlık görsel haberleşme sağlar. • Genel Ekipman Etkinliğini (OEE) hesaplamak için makine durumu verilerini ve diğer verileri toplar • Kritik koşulları SMS veya e-posta ile çalışanlara bildirir

-

Bir Makina Kontrol Panelinin İçerisinde Çevresel İzleme

Bir Makina Kontrol Panelinin İçerisinde Çevresel İzleme

• Küçük sorunları, makina performansını ve çalışma süresini etkileyen büyük sorunlara dönüşmeden saptamak • Uzak bir konumdan çevresel verilere erişmek • Kritik koşulları SMS veya e-posta ile operatörlere bildirmek

-

Kestirimci Bakım İçin Motor Durumu İzleme

Kestirimci Bakım İçin Motor Durumu İzleme

• Makine sorunlarını ciddi hasar veya plansız duruşlara neden olmadan önce saptamak. • Sistemdeki değişikliklerin SMS veya e-posta ile çalışanlara bildirilmesi • Tek bakışta makine durumu hakkında indikasyon sağlama

-

Küçük Konnektörlerin Denetimi [Başarı Hikayesi]

Küçük Konnektörlerin Denetimi [Başarı Hikayesi]

Bir otomotiv tedarik şirketinin ürettiği koltuk sistemlerinin yapısında ve tasarımında, konforu ve güvenliği artıran özellikler mevcuttur. Koltukların alt tarafında yer alan ağırlık sensörleri sayesinde bir koltukta oturan kişinin büyüklüğü ve konumu tespit edilir. Bu bilgiler, bir kaza olması durumunda hava yastıklarının kullanılıp kullanılmayacağını veya nasıl kullanılacağını etkiler.

-

Sac Metal Kalınlığı Ölçümü

Sac Metal Kalınlığı Ölçümü

LH Serisi lazer sensörler, yüksek doğrulukta ve mikron seviyelerde kalınlık ölçümü için mükemmel bir çözümdür. L-GAGE LH Serisi, bu seviyelerde koyu renkli hedefleri sürekli gözlemleyebilir. LH'ın 1024 piksel CMOS lineer görüntüleyicisi, 1-10 mikron arasında değişen mikrometre düzeyinde çözünürlüğe sahiptir ve bu sayede, sacın kalınlığını hızlı ve doğru bir şekilde ölçebilir.

-

Hareket Mesafesini Ölçen Sensörler

Hareket Mesafesini Ölçen Sensörler

Montaj sırasında, koltuk yüksekliği ayarını, ileri ve geri, dik ve yatma hareketlerini ölçen denetimler gerçekleştirilmelidir. Her denetim için iki sensör kullanıldığından dolayı, koltuklara kolay erişilebilmesi ve serbest dolaşımlarının sağlanması için sensörler konveyör hattından uzağa yerleştirilmelidir. Denetleme sırasında maksimum aralık, koltuk ve sensör arası 1 metre olmalıdır.

-

Cam Rezistans Tellerinin Sıcaklık Sensörü İle Algılanması [Başarı Hikayeleri]

Cam Rezistans Tellerinin Sıcaklık Sensörü İle Algılanması [Başarı Hikayeleri]

Bir otomotiv üreticisi, cam rezistans ızgaralarının arızalı olması nedeniyle bir tedarikçinin arka cam sevkıyatını kabul etmedi. Tedarikçinin mevcut test prosedürü, genel bir arızayı algılamak için tüm ısıtma sisteminin akımını ölçtü, ancak kırılan tek bir ısıtma kablosunun ince etkisini tespit edemedi. Cam tedarikçisi firma, her bir cam rezistans telinin sevkıyat öncesinde şartnameye uygun şekilde ısınabildiğini kontrol ederek, daha iyi bir test düzeneği oluşturmak amacıyla Michigan merkezli bir makina otomasyon şirketi ile birlikte çalıştı.

-

UV Barcodes for Traceability

UV Barcodes for Traceability

Before shipping to the brand assembler, a supplier of auto visors needs to verify that Data Matrix UV barcodes have been printed on each visor’s safety label. The customer turned to Banner to read invisible 2D Data Matrix barcode and send data via Ethernet IP to a PLC for traceability/error proofing.

-

Vision Sensor to Read QR Codes

Vision Sensor to Read QR Codes

iVu Plus BCR Gen 2 with 25 mm Micro Lens replaces hand held barcode readers to collect data from dense, difficult-to-read QR codes on vehicle transmissions. A WL50S high-intensity LED spot light illuminates the target area.

-

Reading DPM Codes on Automotive Components

Reading DPM Codes on Automotive Components

Direct part mark (DPM) codes can be small, complex, and difficult to distinguish from the material they are etched into. The ABR 7000 barcode reader is available in models specifically designed to solve challenging low-contrast and DPM applications like this.

-

Operator Guidance Solution

Operator Guidance Solution

A Henshaw customer manufactures drivetrain and powertrain systems for the automotive industry. The company had experienced productivity losses due to errors in the assembly of transmission valve bodies. Henshaw was tasked with developing a system that would reduce errors and improve the assembly process.

-

Kitting Operation with Gloves

Kitting Operation with Gloves

Banner’s fixed-field K50 indicator detects gloved hands , sensing when operators select the correct parts during the kitting process. The K50 indicator’s logic function is then able to notify the operator that he/she picked correctly by changing from green to yellow—additional colors can be selected to suite to the manufacturer’s preference. The K50’s ability to detect black gloves is especially important for lean manufacturing processes where workers typically wear dark gloves.

-

Part Pick Indication for Small Bins

Part Pick Indication for Small Bins

To reduce the risk of error in an assembly operation, a one-piece EZ-LIGHT PVD pick-to-light sensor with a 400 mm range is interfaced with a process controller programmed with the correct assembly sequence. The controller makes the PVDs light up in the correct order, to show the assembler which part to pick. After the PVD detects that the assembler's hand has entered and left the bin, the controller signals the PVD of the next bin in the pick sequence to light up.

-

Long Bin Pick-to-Light

Long Bin Pick-to-Light

The EZ-LIGHT PVA pick-to-light sensors provide a reliable error-proofing solution for various operation systems. The light indicate to assemblers which items to pick and in which order to pick them.

-

Multiproduct Light-Guided Assembly Station

Multiproduct Light-Guided Assembly Station

PTL110 pick-to-light devices on a multiproduct assembly station are a highly effective way to prevent errors and speed up build time. The optical sensors on PTL devices detect hands as they pass by, confirming that a pick was made.

-

Light-Guided Kit Building at Large Station

Light-Guided Kit Building at Large Station

Manual kit building at large stations can be time-consuming and subject to human error, especially if storage racks are difficult to navigate. The PTL110 series pick-to-lights are scalable for large systems and highly versatile to complete numerous tasks.

-

Pano Aydınlatması İçin LED Işıkların Kullanımı

Pano Aydınlatması İçin LED Işıkların Kullanımı

Otomotiv endüstrisi için test ve ölçüm makinaları imal eden ekipman üreticisi pano içini yoğun şekilde aydınlatarak, pano üzerinden makina sistemlerine erişen operatörlerin makina yönetimlerini ve bakımlarını kolaylıkla yapmalarını sağlamak istemektedir. Bu uygulama için AC güçle beslenen birden fazla floresan kullanmaktadır.

-

Superior Light Distribution with LEDs [Success Story]

Superior Light Distribution with LEDs [Success Story]

American Hoffmann Corporation chose WLB32 LED light bars to illuminate work areas, enclosures and control cabinets, replacing fluorescent light fixtures. The superior light distribution offered by the WLB32 LED lights lights, as well as the ease of installation were key factors in the company's decision.

-

Yüzey Kusurlarının Yeşil Renkli LED Aydınlatma İle Tespit Edilmesi

Yüzey Kusurlarının Yeşil Renkli LED Aydınlatma İle Tespit Edilmesi

Yeşil renkli LED çalışma ışıkları ile imalat malzemeleri üzerindeki yüzey kusurlarını kolayca tespit edebilirsiniz.

-

LED Işıklar İle Kalite Kontrol Uygulamalarınızı İyileştirin

LED Işıklar İle Kalite Kontrol Uygulamalarınızı İyileştirin

Otomotiv endüstrisindeki parçaların denetimi için yoğun renklere sahip ama gözü rahatsız etmeyen bir ışığın kullanılması gereklidir. Bu sayede çalışanların üretkenliğin arttırılması sağlanır.

-

Konveyörler İçin Yüksek Kalitede LED Aydınlatma

Konveyörler İçin Yüksek Kalitede LED Aydınlatma

İmalat alanında yüksek yoğunluğa sahip ve parlak ışıkların kullanımı çok önemlidir. Konveyör üzerinde aydınlatma sağlamak için birden fazla ışığın birbirine bağlanarak hat üzerine kolaylıkla monte edilebileceği çözümlerin geliştirilmesi gerekir.

-

Kule Işığının Montaj İstasyonunda Zamanlayıcı Olarak Kullanımı

Kule Işığının Montaj İstasyonunda Zamanlayıcı Olarak Kullanımı

Otomotiv üretiminde üretim hedeflerine ulaşmak için verimliliği arttırmak çok önemlidir. Montaj istasyonlarında yaşanan herhangi bir gecikme üretimin sonraki safhalarını da etkilediğinden maliyetli kayıplara neden olur. Gecikmelerden kaynaklanan kayıpların önüne geçmek için TL50 Pro Serisini takt zamanını montaj çalışanlarına gösterecek şekilde zamanlayıcı olarak kullanabilirsiniz.

-

Dual Output Durum İndikasyonu Çözümleri

Dual Output Durum İndikasyonu Çözümleri

S15L Serisi sensör durum indikatörünün sunduğu iki farklı renk ile sensörün besleme ve output durumunu gösterebilirsiniz. Parlak ışık sağlayan tasarımı ile 4-5 pinli kablolar için ekonomik çözümler sunar.

-

Küçük Konnektörlerin Denetimi [Başarı Hikayesi]

Küçük Konnektörlerin Denetimi [Başarı Hikayesi]

Bir otomotiv tedarik firmasının ürettiği koltuk sistemlerinin yapısında ve tasarımında, konforu ve güvenliği artıran özellikler mevcuttur. Koltukların alt tarafında yer alan ağırlık sensörleri sayesinde, koltukta oturan kişinin büyüklüğü ve konumu tespit edilir. Bu bilgiler, bir kaza olması durumunda hava yastıklarının kullanılıp kullanılmayacağını veya nasıl kullanılacağını etkiler.

-

Sac Metal Kalınlığı Ölçümü

Sac Metal Kalınlığı Ölçümü

LH Serisi lazer sensörler, yüksek doğrulukta ve mikron seviyelerde kalınlık ölçümü için mükemmel çözümler sunar. Koyu renkli hedefleri kararlı şekilde algılayabilir. LH'ın 1024 piksel CMOS lineer görüntüleyicisi, 1-10 mikron arasında değişen mikrometre düzeyinde çözünürlüğe sahiptir ve bu sayede sacın kalınlığını hızlı ve doğru şekilde ölçebilir.

-

Hareket Mesafesini Ölçen Sensörler

Hareket Mesafesini Ölçen Sensörler

Montaj sırasında, koltuk yüksekliği ayarını, ileri ve geri, dik ve yatma hareketlerini ölçmek için kontroller yapılır. Her denetim için iki sensör kullanıldığından, koltukların serbest şekilde hareket etmesini sağlamak ve koltuklara kolaylıkla erişmek için sensörler konveyör hattından uzağa monte edilmelidir. Ayrıca, koltukla sensör arasındaki maksimum mesafe 1 metre olmalıdır.

-

Krank Mili Yatağı Ölçümü

Krank Mili Yatağı Ölçümü

Krank mili yatağının belirlenen tolerans aralığında olup olmadığını LM Serisi ile kontrol edebilirsiniz.

-

Run Bar Provides Operator Guidance

Run Bar Provides Operator Guidance

A leading machine manufacturer builds workstations designed for accurate, timely and cost-effective battery cell assembly. A value added component of the workstations is an operator guidance device that does three jobs: enables assembly processes to start and stop, indicates parts to be picked and installed, and completely stops line operation if emergencies occur. When it became too costly for the OEM to construct and mount these devices themselves, they turned to Banner to craft an all-inclusive solution. To honor the time line requirements of their customer—a major tier two battery supplier—the OEM needed the solution in eight weeks.

-

Engine Block Positioning

Engine Block Positioning

Banner’s L-GAGE LH Laser Displacement Sensor is ideal for applications where exact positioning of a part is crucial. The L-GAGE LH Series consistently looks at dark targets on micron levels. Banner’s laser displacement sensor is extremely accurate for precise positioning applications, including engine block positioning. The sensor can take measurements on virtually any surface, such as cast iron or aluminum alloys, which are often used for the manufacturing of engine blocks.

-

Part Removal Verification in Automotive Assembly

Part Removal Verification in Automotive Assembly

In an automotive assembly plant, temporary pins—called grenade pins—are used to attach some parts temporarily. To make sure the grenade pins are removed, the inspection station includes a container for the pins that is equipped with an EZ-LIGHT PVA pick-to-light sensor.

-

Rubber Washer Detection on Engine Block

Rubber Washer Detection on Engine Block

Banner’s Q4X versatile laser sensor is ideal for presence/absence detection even in challenging applications with small height changes such as confirming a small black target is present on a shiny metal part. The washers should be present in the cast aluminum engine block, and if the Q4X detects a slight height difference, even as small as 1 mm, it will send a signal to alert operators a rubber washer is missing or there are multiple washers present. The Q4X can detect duplicate rubber washers with its unique windowing capability while in foreground suppression mode.

-

Detecting a Line of Adhesive on a Vehicle Door Panel

Detecting a Line of Adhesive on a Vehicle Door Panel

A VE Series Smart Camera, configured to use the bead tool, inspects each door panel for the presence and consistency of adhesive. The camera has a wide field of view and a 2 MP imager capable of detecting even slight inconsistencies in the amount of adhesive applied.

-

Detecting Black Parts on Black Door Panel

Detecting Black Parts on Black Door Panel

Banner’s Q4X problem-solving triangulation-based laser sensor has no difficulty detecting dark targets on dark backgrounds when there is a height difference. The Q4X provides a reliable sensing solution with best in class excess gain and makes pass/fail judgments based on distance rather than color or reflectivity.

-

Multiple Point Inspection on Stamped Metal Parts

Multiple Point Inspection on Stamped Metal Parts

To verify the expected number of holes exists on a small metal part, the iVu Plus TG Image Sensor with Multipoint Inspections can be configured for multiple regions of interest (ROIs) to ensure holes exist and were punched in the correct place. When set up for area inspection, the iVu will scan multiple points on the stamped part to verify the presence or absence of a feature or features of interest.

-

Thread Hole Detection

Thread Hole Detection

Conventional sensors can often have difficulty detecting the presence of threads. The WORLD-BEAM QS30's narrow laser beam can detect whether a hole in the manifold is threaded from a distance of up to 800 mm.

-

Drilled Holes Inspection

Drilled Holes Inspection

This application uses an iVu Series sensor configured for an Area inspection. When holes are punched, the sensor evaluates all the holes to make sure that they are present and correctly sized. If any are not, the sensor sends a fail output to the line where the part is rejected.

-

Bearing Inspection

Bearing Inspection

The solution involves using an iVu Series sensor configured for a Match inspection to ensure that all the bearings are present for each component that includes the bearing assembly. If the sensor detects one or more missing bearings, it sends a fail output to the line, and the component is rejected.

-

Engine Block Part-In-Place Detection

Engine Block Part-In-Place Detection

Banner’s LE550 laser sensor is ideal for part-in-place verification processes. It is reliable, and extremely accurate for small part-in-place verification from long distances. The LE550 measures for 3 mm thickness using the digital output, ensuring that the retaining clip is present and the engine block is in the correct place.

-

Automotive Welding Tip Inspection

Automotive Welding Tip Inspection

The R55F high color resolution sensor checks whether the tips on a welder are within specifications, so the part being manufactured also is within specifications. In this harsh environment, the color contrast sensor uses glass fibers, for enhanced durability and heat resistance.

-

Part-in-Place Verification

Part-in-Place Verification

The WORLD-BEAM QS18 adjustable field background suppression sensor is an excellent choice for this part-in-place application, requiring a three-inch scanning distance. With the combination of high-gain characteristics, sharp adjustable cutoff and a forgiving visible red light beam this sensor ensures longevity in this harsh environment.

-

Long-Range Inspection in Automotive Assembly

Long-Range Inspection in Automotive Assembly

As vehicles move forward on an automotive assembly line, an L-GAGE LT7 time-of-flight laser sensor is directed inside the sun roof to verify that the car seat has been installed and is in the correct position. It is offered in retroreflective models with two discrete outputs (PNP) for extremely long ranges up to 250 m, making it a versatile sensor in the automotive industry.

-

Automotive Weld Nut Inspection

Automotive Weld Nut Inspection

After a robot inserts multiple weld nuts in an automotive component, a worker places the part onto an inspection station equipped with two PresencePLUS P4 OMNI vision sensors. Improperly inserted weld nuts could be missing, upside down, or tipped to one side. The PresencePLUS P4 OMNI inspects to see that the weld nuts are present, correctly oriented and not leaning.The vision camera compensates for part-to-part movement and can inspect from a long distance.

-

Automotive Fuse Box Inspection

Automotive Fuse Box Inspection

A PresencePLUS COLOR Pro vision sensor inspects color-coded fuses in a fuse box to verify that each fuse is in the correct location.

-

Automotive Duct Inspection

Automotive Duct Inspection

After a vacuum mass-airflow test of an automotive duct, a shuttle moves the PresencePLUS Pro into position above an open end of the duct. The PresencePLUS Pro verifies that a temperature sensor is still in place inside the duct and is undamaged.

-

Plastic Injection Short Shot Detection

Plastic Injection Short Shot Detection

A high-resolution PresencePLUS P4 OMNI 1.3 mounted above a production line inspects steering wheel components after they are molded. The P4 OMNI looks for areas with excess material or too little material.

-

Automotive Handle Color Inspection

Automotive Handle Color Inspection

A PresencePLUS P4 COLOR OMNI vision sensor detects interior door handles that are the wrong color for the vehicles being assembled. An on-axis light, attached with specialized brackets, provides even, diffused illumination to reduce glare.

-

Zero Defect Standard on Industrial Winder [Success Story]

Zero Defect Standard on Industrial Winder [Success Story]

A successful manufacturer of specialty industrial yarns makes fiberglass and glass thread products for applications in the automotive, aerospace, military and composite materials industries. To help maintain their high standards and minimize costly product returns, they established a goal of zero product defects. To meet this goal, the company needed an automated thread inspection system.

-

Part Color Inspection on a Vehicle Door Panel

Part Color Inspection on a Vehicle Door Panel

An iVu Color Sensor identifies RGB values of individual pieces of trim on vehicle door panels and communicates this information over an industrial Ethernet connection to a PLC.

-

Oto Koltuğu Kontrolü

Oto Koltuğu Kontrolü

The Q5X verifies the presence of dark components on a dark background--as well as vehicle seats and components of varying colors.

-

Metal Presleme Uygulamalarında Parça Kontrolü

Metal Presleme Uygulamalarında Parça Kontrolü

The Q5X sensor verifies the presence and position of reflective targets in a harsh environment.

-

Reliably Detect Adhesive Tape on Pouch Batteries

Reliably Detect Adhesive Tape on Pouch Batteries

When manufacturing pouch batteries for electric vehicles, adhesive tape material is used to complete the outer film packaging. The tape’s presence must be confirmed with optical-based sensors for quality assurance purposes. Keep reading to learn how the QCM50 color sensor solves this application.

-

Alışveriş Merkezinde Otopark Yönlendirme [Başarı Hikayesi]

Alışveriş Merkezinde Otopark Yönlendirme [Başarı Hikayesi]

Geniş alana sahip alışveriş merkezinde kablosuz sensörleri kullanarak araç trafiğini azaltabilirsiniz.

-

Electric Vehicle Detection at Charging Stations

Electric Vehicle Detection at Charging Stations

Banner Engineering’s K50R radar sensor offers an ideal solution for electric vehicle detection at recharge stations. When cars park at a charging station, the radar sensor immediately detects the vehicle’s presence. If separate monitoring indicates that the car is not plugged into the charge station, a signal is sent to a central location, alerting authorities to ticket or remove the vehicle if necessary.

-

Bank Drive-Thru Automobile Detection

Bank Drive-Thru Automobile Detection

Banner Engineering's K50R short-range radar sensor can be used to detect vehicles at bank teller drive-thru windows. It is designed to operate in any outdoor weather conditions.

-

Detecting Parking Spot Availability

Detecting Parking Spot Availability

Banner Engineering's weather-resistant K50R short-range radar sensors can be placed above parking spaces in a large, multi-level parking structure to monitor parking availability and help drivers to find open parking spaces more easily.

-

Yeşil Renkli LED Aydınlatma ile Yüzeydeki Kusurların Algılanması

Yeşil Renkli LED Aydınlatma ile Yüzeydeki Kusurların Algılanması

Yeşil renkli LED çalışma ışıklarının, imalat malzemeleri üzerindeki yüzey kusurlarının görünürlüğünü nasıl artırdığına göz atın.

-

Yüksek Kalitede LED Işıklar İle Daha Kaliteli Denetim

Yüksek Kalitede LED Işıklar İle Daha Kaliteli Denetim

Otomotiv endüstrisindeki parçaların denetimi için yoğun ama gözü rahatsız etmeyen bir ışığın kullanılması gereklidir. Daha güçlü aydınlatma çalışanların üretkenliğini artırır ve göz yorulmasını azaltır.

-

Katman Yönü Denetimi

Katman Yönü Denetimi

Operatör, lastik üretimi için lastik yapım makinasını çalıştırmadan önce PresencePLUS P4 OMNI 1.3 vision sensörü, zıt yönlü parçaların katmanlarda dönüşümlü şekilde yerleştirildiğini kontrol eder. Aynı yöne sahip iki parça üstüste katman oluşturduysa, üretilen lastik üretim işlemi boyunca ilerleyip denge testinde başarısız olur ve hurdaya atılır.

-

Konveyör Aydınlatması İçin Yüksek Kalitede LED Aydınlatma

Konveyör Aydınlatması İçin Yüksek Kalitede LED Aydınlatma

İmalat alanı için yüksek yoğunluklu, çok parlak bir aydınlatma bulmak zor olabilir. Bir konveyör üzerindeki alanları aydınlatmak için birden çok ışık ve ışıkları birbirine bağlamak için basit bir montaj çözümü gerekir.

-

Kalıptan Reddedilen Parçaları Algılama [Başarı Hikayesi]

Kalıptan Reddedilen Parçaları Algılama [Başarı Hikayesi]

Bir üreticinin tesisinde operatörler pres kalıbına metal parçaları yerleştirme ve çıkarma işlemlerini manuel olarak yapıyorlar. Tamamlanan parçalar metal bir kanal üzerinden bir kutuya gönderiliyor. Kalıpların çarpışmasını önlemek için müşterinin ihtiyaç duyduğu sensörün, kanal içerisinde değişik parçaları algılayabilmesi ve kontrol sistemine bir sinyal göndermesi gerekir. Böylece presin serbest olduğu bilgisi ile operatör yeni bir parça yerleştirebilir. Kanal kenarları ve kanal sonu gibi hat üzerinde hareketli parçaların takılabileceği noktalara sensörler monte edilmemelidir.

-

Communication in a Busy Manufacturing Site [Success Story]

Communication in a Busy Manufacturing Site [Success Story]

Fırın içerisinden geçen ürünlerin sayısı arttıkça, boşaltılması gereken öğelerin akışını idare etmek giderek zorlaşır. Sınıflandırma alanındaki tıkanma artar. ve ürünler yanlış yönlendirilebilir, hatta hasar görebilirler. Parçaların akışının durdurulması, boşaltma operatörünün hataları düzeltmesine ve toplama istasyonunu boşaltmasına imkan sağlar. Ancak boşaltma ve yükleme alanları arasındaki mesafe ile çevredeki makinelerin yarattığı ortam, operatörler arasındaki iletişimi zorlaştırır.

-

Pencere Tonu Doğrulama

Pencere Tonu Doğrulama

Banner DF-G1 ışık alıcı sensör, camın içinden ne kadar ışığın geçtiğine bağlı olarak renkli veya renksiz camları ayırt eder. DF-G1 fiber sensör, sahip olduğu buton ile konveyör boyunca kolayca ayarlanabilir. Sezgisel arayüzü, anında sensör geri bildirimine olanak tanır.

-

Işık Alıcısı Işıkların Geniş Spektrumunu Algılar

Işık Alıcısı Işıkların Geniş Spektrumunu Algılar

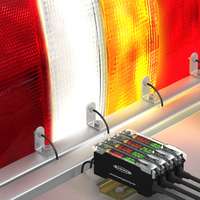

Banner’ın DF-G1 Serisi fiber optik ışık alıcısı, ışıkların doğru olarak çalıştığının kontrolünü sağlamak için, doğrudan test ekipmanına yerleştirilmek üzere geliştirilmiş, uygun maliyetli bir üründür. Diğer DF-G1 modellerinin sahip olduğu aynı kullanıcı dostu ekran ve programlama arayüzüne sahip olan ışık alıcısı, var/yok denetimleri için montaj ve test ekipmanları kontrol sistemleriyle entegre edilebilir ve arayüz üzerinden birlikte çalışılabilir.

-

Optik Dokunmatik Buton (OTB) ile Acil Stop Operatör İstasyonu

Optik Dokunmatik Buton (OTB) ile Acil Stop Operatör İstasyonu

Hepsi bir arada ünite şeklinde OTB ile birleştirilen acil stop butonu, üretim hatları için kablolama veya ek muhafaza gerektirmeyen basitleştirilmiş bir operatör istasyonu çözümüdür. Banner'ın 30 mm montajlı Acil Stop butonları bu tür uygulamalar için idealdir. Işıklandırılmış tabanı, acil stop gereksinimleriyle uyumlu şekilde aktif edildiğinde sarıdan, yanıp sönen kırmızıya geçer. Acil stop butonunun OTB'ye yakın olması, işçilerin hızlı ve kolay bir şekilde etkinleştirebilmelerini sağlar

-

Üretim Hatlarında Verimliliği Artırmak

Üretim Hatlarında Verimliliği Artırmak

DX70 çiftlerine, kule ışıkları ve switch kutuları takılarak, üreticiler kablosuz bildirim ağı oluşturabilir ve fabrika tabanında iletişim kurabilir. Operatörler switch'leri kullanarak üretim hattına bir yöneticiyi veya teknisyeni çağırabilir, hatta parça veya sarf malzemesi talebinde bulunabilirler. Kule ışık sisteminin kullanılması sayesinde görevlilerin, teknisyenlerin veya yöneticilerin her bir üretim hattını sürekli kontrol etme gereği azalır.

-

Parlak Ortam Işığında Görünür İndikasyon

Parlak Ortam Işığında Görünür İndikasyon

Parlak ve uzun ömürlü LED indikatör ışıkları sayesinde pano arkasında pencere bulunsa dahi gün boyunca yüksek seviyede görünür indikasyon sağlanır. Banner’ın EZ-LIGHT K50 Gün ışığında görünür ışığı, pek çok uygulamada durum indikasyonu belitmek için mükemmeldir. Çünkü gün ışığında görünür ışık, uzun ömürlü, enerji verimliliği sağlayan LED'lerle oldukça dayanıklıdır ve her koşulda yüksek seviyede görünür indikasyon sunar.

-

Dönen Ekipmanları İzleme

Dönen Ekipmanları İzleme

Bazı otomotiv üretim proseslerinde, parçaların çeşitli otomatik ve manuel çalışma istasyonlarına endekslenmesi için döner tablalar kullanılır. Çoğu durumda, endekslemeden önce parçaların varlığını, doğru yerleştirildiğini veya doğru şekilde işlendiğini doğrulamak için sensörlerin kullanılması gerekir. Geçmişte, sensör gücü ve sinyallerinin kontrol sistemine bağlanması için slip ring'leri kullanılması, çözümün genellikle maliyetli ve güvenilmez olduğu kanıtlanmıştır. Verimliliği artırırken daha fazla sensör sinyalinin işlenmesine olanak sağlayan alternatif bir çözüm gerekmektedir.

-

Lastik Üretiminde Kalıp Koruma

Lastik Üretiminde Kalıp Koruma

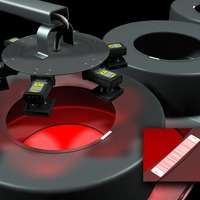

Eğer lastik presi, yanlış boyutta damgasız veya yeşil bir lastiğe diş basmak isterse, presteki kalıplar, pahalı hasarlar alabilir. Her bir lastiğin doğru prese yönlendirilmesi için, Banner’ın PresencePLUS P4 BCR 1.3 vision sensörleri, lastik göbeğin iç kısmına yakın bir etiketin üzerindeki barkodda yer alan tanımlayıcıya göre yeşil lastikleri ayırır. Bu uygulamada, bir konveyörde ilerleyen yeşil lastikler, üzerine altı BCR 1.3 vision sensörünün monte edildiği bir fikstürün altından geçer.

-

Duruş Sürelerini Azaltan Kablosuz Sistemler

Duruş Sürelerini Azaltan Kablosuz Sistemler

Paslanmaz çelik ve özel alaşımlar üreten bir firma, metal döküm endüstrisine kütük demir ve külçe tedarik ediyor. Üretim sırasında, magnezyum kütüklerini işlemek için eklemli robot kolları kullanılmaktadır ve robotların uç elemanları üzerinde bulunan sensörler, tutucuların durum bilgilerini bir kontrol panosuna iletirler. Robot üzerindeki sensörler robotik kablolar aracılığıyla kontrol panosuna bağlandığı için zorlu ortam şartları ve robotun hareketleri, kablolar için kopma tehlikesi oluşturmaktadır. Kesintiler oldukça sık yaşanıyordu, onarım ve değiştirme işlemlerini yapmak için sistemin durdurulması gerekiyordu. Bu sebeple de üretimde verimlilik azaldığı için maliyetler artıyordu.

-

Adding Run, Stop, and Bypass Capabilities on a Robotic Work Cell

Adding Run, Stop, and Bypass Capabilities on a Robotic Work Cell

Using a 2 or 3-position OS80 key operated selector switch, the operator can bring the robot to a controlled stop, enter the cell, and then quickly resume operations once work in the cell is complete.

![Temperature Sensor Detects Defrost Wires [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2012/T-GAGE-Defrost-Wire-Inspection.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![Status Indication on Driverless Vehicles [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_189577689.jpeg/jcr:content/renditions/cq5dam.web.200.200.jpeg)

.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)

.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![LED'lerle Üstün Işık Dağılımı [Başarı Hikayesi]](/content/dam/banner-engineering/photography/product-photography/wlb32/hofmann_enclosure.png/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![Operatör Yönlendirme Çözümü [Başarı Hikayesi]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/PVD_QS30LE_OTB_K50L_Bin-Pick-for-Transmission-Plate.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![Run Bar ile Operatör Rehberliği [Başarı Hikayesi]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/IMAG0198_edited.jpg/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![İzlenebilirliği Sağlamak için UV Barkodların Kullanımı [Başarı Hikayeleri]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/UVBarcode_2_small.jpg/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![QR Kod Okumak için Vision Sensörünün Kullanımı [Başarı Hikayeleri]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/iVu-Plus-BCR-Label-Verification---Transmissions.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)

.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![Küçük Konnektörlerin Denetimi [Başarı Hikayesi]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/LE550-Vehicle-Seat-Weight-Sensor-Connector.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![Superior Light Distribution with LEDs [Success Story]](/content/dam/banner-engineering/photography/application-photos/miscellaneous/hofmann_enclosures_wlb32.jpg/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![Zero Defect Standard on Industrial Winder [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/Fotolia_51604759_M.jpg/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![Alışveriş Merkezinde Otopark Yönlendirme [Başarı Hikayesi]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/kiosks_alt.jpg/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![Kalıptan Reddedilen Parçaları Algılama [Başarı Hikayesi]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2012/PVD-Part-Out.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![Communication in a Busy Manufacturing Site [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/K50-Touch-and-TL50---Industrial-Oven_For-Andrew.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)