DXM Serisi

Endüstriyel Kablosuz Gateway

Ethernet bağlantısına sahip olan DXM100, Endüstri 4.0 uygulamaları için ideal bir endüstriyel kablosuz gateway çözümüdür. DX80 Gateway özellikli (haberleşme protokolü dönüştürücü olarak kullanılabilir) ve Multihop Data Radio olarak kullanılan modelleri bulunan DXM100, lokal kablosuz ağları internet veya ana sistemlere bağlar.

- DXM1200 modelleri zorlu ortamlarda kullanım için IP67 koruma sınıfına sahiptir.

- DXM1200E modelleri ulaşılması zor kablosuz cihazlar için antene ideal konuma genişletme yeteneği sağlar.

- 900 MHz veya 2.4 GHz ISM Radio seçeneği sunar.

- Modbus RTU'yu Modbus TCP/IP veya Ethernet I/P'ye dönüştürür.

- Lojik kontrolörü, eylem kuralları ve metin dili yöntemleri kullanılarak programlanabilir.

- Veri günlüğü tutulması için mikro SD kart sunar.

- Uyarıları E-posta ve SMS ile gönderebilir.

- Lokal I/O seçenekleri: İzoleli dijital input'lar, universal input'lar, SPDT (Form C) röle output'ları, NMOS output'ları ve analog output'lar.

- 12 ile 30 V DC, 12 V DC güneş paneli veya batarya ile beslenir.

- RS-232, RS-485 ve Ethernet iletişim portları, ayrıca bir adet USB konfigürasyon portu mevcuttur.

- I/O bilgileri için LCD ekrana ek olarak, kullanıcı tarafından programlanabilir LED'lere sahiptir.

- GSM bağlantısı mevcuttur (opsiyoneldir).

Downloads

Technical Literature

DXM General Information

Teknik Literatür - DXM700

Teknik Literatür - DXM1000

Teknik Literatür - DXM1200

Teknik Literatür - DXM100

Teknik Literatür - DXM150

Solutions Guides

Software

Yazılım

PLC Support Files

PLC Destek Dosyaları

Product Data Files

Ürün Veri Dosyaları

Marketing Literature

Broşürler ve Kataloglar

Technical Notes

Additional Technical Notes available in the Wireless Reference Library.

Application Notes

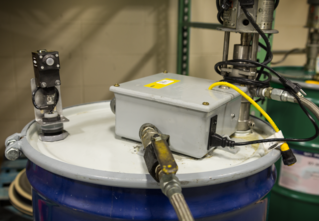

Taşınabilir Varillerde Sıvı Dolum Seviyesi İzleme

K50U kablosuz ultrasonik sensör, temassız seviye izleme çözümü sunacak şekilde özel olarak tasarlanmıştır. Varildeki epoksi seviyelerini izleyerek, yeniden doldurma sırasında potansiyel taşmalar sorun haline gelmeden önce çalışanlarınıza uyarı verebilirsiniz.

![Predictive Maintenance of Rotating Parts on Conveyor [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_111970609.jpeg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

Predictive Maintenance of Rotating Parts on Conveyor [Success Story]

Wireless monitoring of rotating parts on coal conveyors throughout a large port allows operators to utilize predictive maintenance to prevent failure and save money while reducing downtime.

![Predictive Maintenance of Motors and Gearboxes on Large Cranes [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/bigstock-In-A-Port-49071524.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

Predictive Maintenance of Motors and Gearboxes on Large Cranes [Success Story]

Wireless products enable predictive maintenance in the port industry. Motors and gearboxes on cranes are prone to high vibration and temperature which can cause them to degrade. Predictive maintenance allows employees to interfere and solve problems before they completely fail and cause unplanned downtime and lost profit.

![Vibration Monitoring a Main Air Handler [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/predictive-maint/qm30vt-motor-vibration-detection.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

Vibration Monitoring a Main Air Handler [Success Story]

Learn how the installation of Banner wireless vibration sensors and data from the DXM wireless gateway prevented unplanned downtime in this application.

Condition Monitoring for Predictive and Preventative Maintenance

Identify machine problems before they cause serious damage or unplanned downtime.

Equipment Monitoring from a Supervisor's Station

Provide at-a-glance machine status indication and send machine status information to a wide range of devices.

Improve Overall Equipment Effectiveness by Monitoring Production Input and Output

Monitoring production inputs and outputs provides machine operators and managers with critical data about their processes and equipment and can help them identify and resolve problems on the production line more quickly.

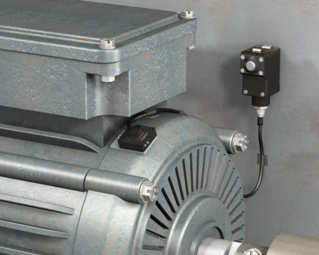

Kestirimci Bakım

Kestirimci bakım, izlenen ekipmanlardan veri alınarak, arıza gerçekleşmeden bakımın doğru ve yeterli bir biçimde yapılmasına imkan tanır.

Remote Monitoring

Remote monitoring enables increased visibility into the performance and efficiency of machines, processes, and people.

Vibration Monitoring for Predictive Maintenance

Banner’s wireless vibration and temperature sensor measures RMS velocity, in inches per second or millimeters per second, and temperature. Mounting it as close as possible to the bearings enables you to monitor the machine’s health by detecting increases in vibration and temperature. It is easy to mount using the standard bracket, the magnetic bracket or two sided thermal transfer mounting tape.

Call for Pickup from an Assembly Station to an AGV

Remove completed pallets from assembly stations quickly.

Call for Parts, Service, or Pallet Pickup

Increase efficiency using a wireless call-for-parts/service/pickup system

Machine Monitoring/Overall Equipment Effectiveness

Remotely monitor your assets and gain access to previously unavailable data.

Inbound and Outbound Status Indication at Loading Dock

In a recent material handling application, facility managers needed to find a solution that would alert them to the status of trailer capacity at loading dock doors in real-time.

Increasing Productivity with Pick-to-Light System

Learn how In the Ditch™, an Idaho-based manufacturer of award-winning products for the towing industry, was able to make substantial improvements to the efficiency and accuracy of their picking processes by implementing a complete pick-to-light system from Banner Engineering.

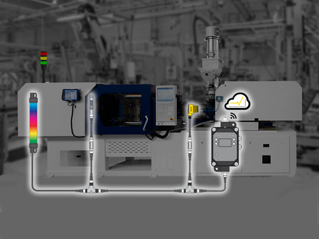

Kalıplama Makinasındaki Üretkenliği Arttırın

Snap Signal ile eski enjeksiyon kalıplama makinanıza Endüstri 4.0 yeteneğini kazandırabilirsiniz.

Videos

Drive Thru Vehicle Detection

Wireless vehicle detection at a quick serve restaurant drive-thru ensures speed of service and efficiency.

How-To Guide: DXM Controller with Ignition SCADA

Learn how to connect the Banner DXM Gateway series with the Ignition SCADA software.

![Wireless Call for Parts, Services, and Pick-Up Solution [Video]](/content/dam/banner-engineering/3d-renders/product-group/multi_division/call-for-parts/Wireless-Call-for-Parts-Group-off.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

Wireless Call for Parts, Services, and Pick-Up Solution

Learn how to improve communication and maintain a steady workflow with Banner Engineering's wireless call for parts solution.

Wireless Vibration Monitoring and Predictive Maintenance Solutions

Monitor machine health utilizing predictive maintenance by continuously monitoring for vibration and temperature changes.

Industrial Internet of Things (IIoT) Solutions

IIoT solutions from Banner Engineering provide companies with greater visibility into their operations by enabling access to critical performance and production data, making it easy to solve problems, identify trends, and make better, data driven decisions.

![Calculate OEE with a Wireless Solution [Video]](/content/dam/banner-engineering/projects/video-thumbnails/OEE_to_improve_productivity-new.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

Calculate OEE with a Wireless Solution

Calculating Overall Equipment Effectiveness (OEE) can help you improve efficiency and productivity. With a wireless system, you can track uptime, validate throughput, monitor quality, and optimize your operation.