Tank Level Monitoring

Predictive Maintenance for Tanks

Storage tanks, totes, and containers can be found in a wide variety of environments, from indoor or outdoor installations to above or below ground deployments.

Properly monitoring and managing levels inside these tanks can help owners and asset managers increase productivity and profitability.

Keep reading to learn more about the benefits of a wireless solution for tank level monitoring.

There are many technologies to choose from that vary in terms of accuracy, reliability, and costs. Visual inspections and measuring sticks may be relatively inexpensive, but they are labor-intensive and prone to error because they rely on manual reporting methods.

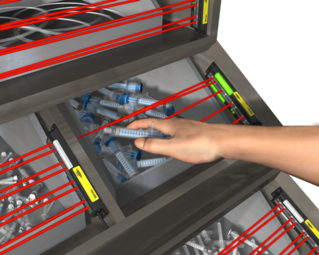

More accurate tools, like floats and submersible pressure transducers, are not dependent on human labor to measure levels, which can simplify processes and minimize the risk of error. However, in some applications, a non-contact solution is preferable (for example, when measuring the level of caustic liquids).

A wireless ultrasonic sensor is a great choice for applications where a non-contact solution is needed. These sensors use sound waves to detect objects, so they do not need to come into contact with the materials they are measuring. They are also immune to target color, reflectivity, or transparency. Wireless communications open up additional benefits including saved time and costs, real-time remote monitoring, and adaptability to meet changing requirements.

Quick Commissioning Without Costly Cable Runs

The infrastructure changes required in a wireless system are minimal, far easier, and less costly to implement than a wired system.

In a basic setup, a wireless node is connected to a measuring device, like a wireless ultrasonic sensor, and installed on the container. Each node in the network is bound to a wireless gateway or controller with an integrated gateway. Next a site survey is conducted to verify the connection between the deployed nodes and the gateway.

The system is then configured, and inspection parameters and alarm thresholds are set. A system like this can monitor many containers and can be set up in a fraction of the time and at a much lower cost than a wired system.

Improve Efficiency with Real-Time Alerts

With connected devices, asset managers can easily access tank level data in real time. improving both efficiency and productivity. For example, with real time monitoring of remote containers, managers can strategically plan visits based on actual need instead of sending staff to a site based on forecasted expectations of container levels. This saves time and costs while ensuring that tanks are full and processes are running smoothly.

In addition, automated alerts can be setup to notify staff of potential issues, minimizing emergencies when a tank runs dry or overflows. A real-time remote monitoring system can alert personnel via text or email if tank levels are outside of the established thresholds, and it allows them to respond to these conditions before they become critical.

Maintain the Flexibility to Make Changes Quickly

Business needs can change over time and companies may need to add or move containers at a site to keep up with new demands. Wireless networks are versatile, scalable, and adapt easily to changing requirements. They are also flexible enough to monitor both fixed and portable assets.

With a wireless system, containers can be moved as often as needed without altering the system or disconnecting the measuring device, which means containers can be monitored even while in transit. New nodes from new containers can be integrated into the existing network, or a new network can be deployed to accommodate a new group of tanks without the time and labor commitments of altering a wired network.

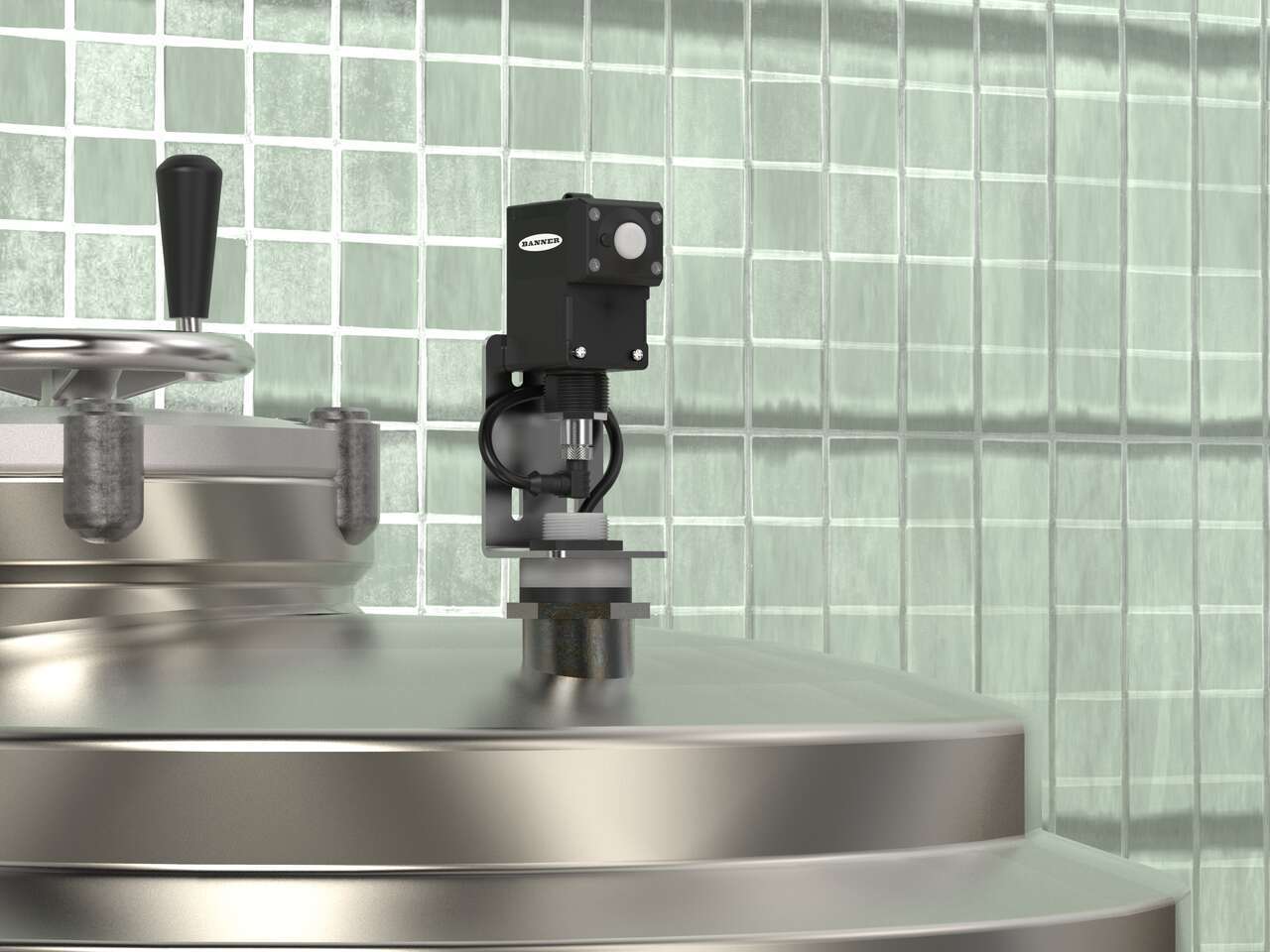

Wireless Ultrasonic Sensor for Tank Monitoring

Mobil veya uzaktaki tankları izlemek için ekonomik ve kullanımı kolay bir çözüm sunan K50U serisi, kablosuz node veya Multihop Modbus Radyo ile birlikte tak-çalıştır olarak kullanılması için tasarlanmıştır.

- 300 - 3000 mm aralığında algılama yapan modelleri geniş yelpazedeki uygulamalarda seviye ölçmek ve izlemek için idealdir.

- 100 - 1000 mm aralığında algılama yapan daha kısa menzilli modelleri kısıtlı alanlarda bulunan küçük tanklarda daha yüksek ölçüm hassasiyeti sunar.

- Dahili sıcaklık kompanzasyonu

- Zorlu algılama şartlarına uygun olarak IP67 korumalı dayanıklı tasarıma sahptir

Wireless Controller for IIoT Applications

DXM100, Ethernet bağlantısına sahiptir ve Endüstri 4.0 uygulamaları için ideal bir endüstriyel kablosuz gateway çözümüdür.

- Yerel kablosuz ağ için ISM radyoları 900 MHz ve 2,4 GHz frekanslarında mevcuttur.

- Modbus RTU'yu Modbus TCP/IP veya Ethernet I/P'ye dönüştürür.

- Lojik kontrolörü, eylem kuralları ve metin dili yöntemleri kullanılarak programlanabilir.

- Veri günlüğü tutulması için mikro SD kart sunar.

- Uyarıları E-posta ve SMS ile gönderebilir.

- GSM bağlantısı mevcuttur.