Machine Guarding at the Point of Operation

Guard Hazards Where Work is Performed

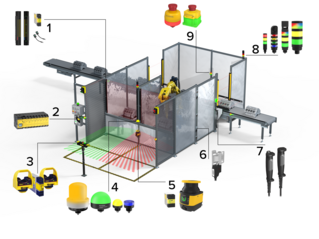

The point of operation on a machine is where the work is performed. Guarding the point of operation is critical to protecting personnel from accident or injury as well as preventing equipment damage.

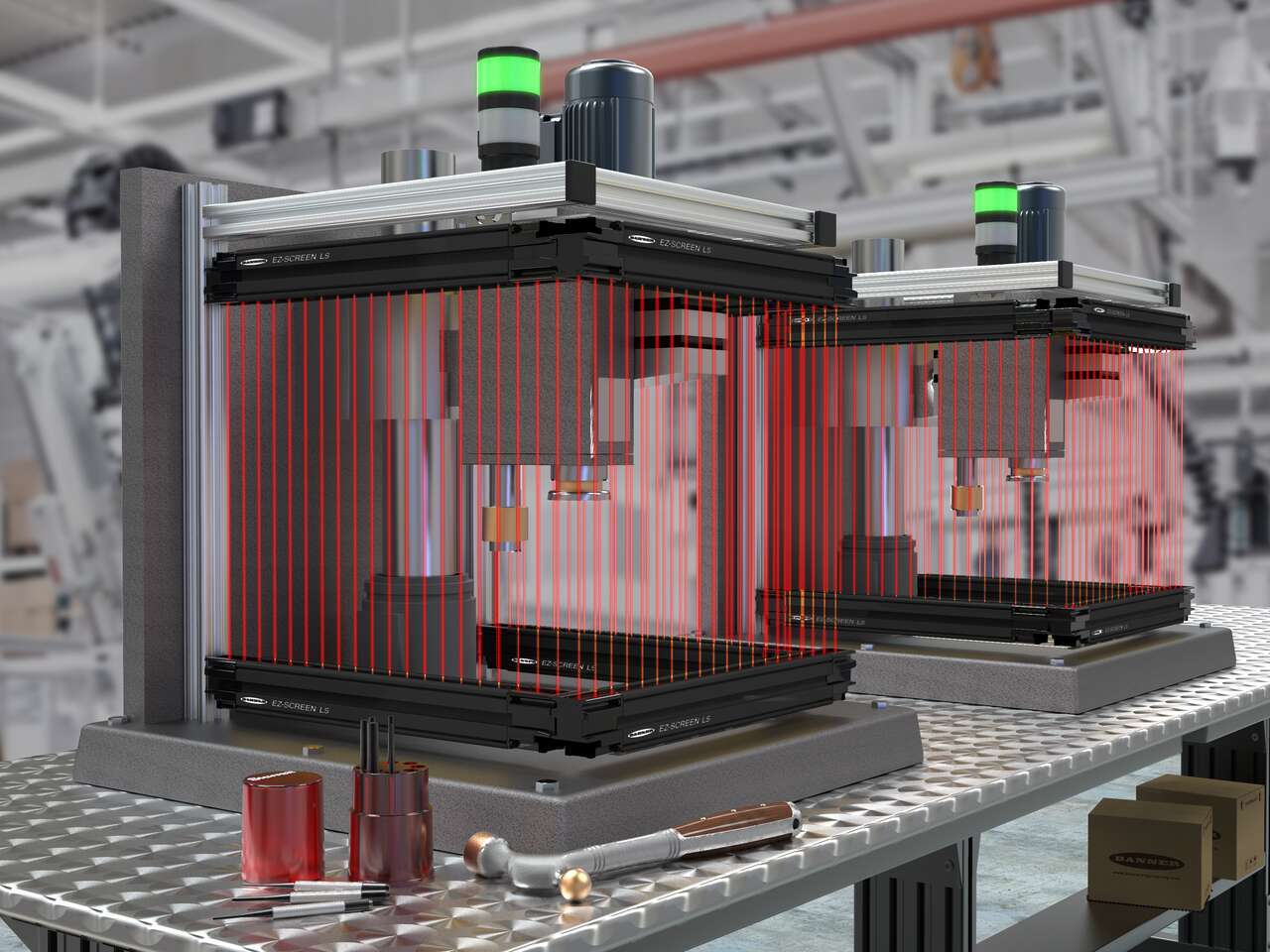

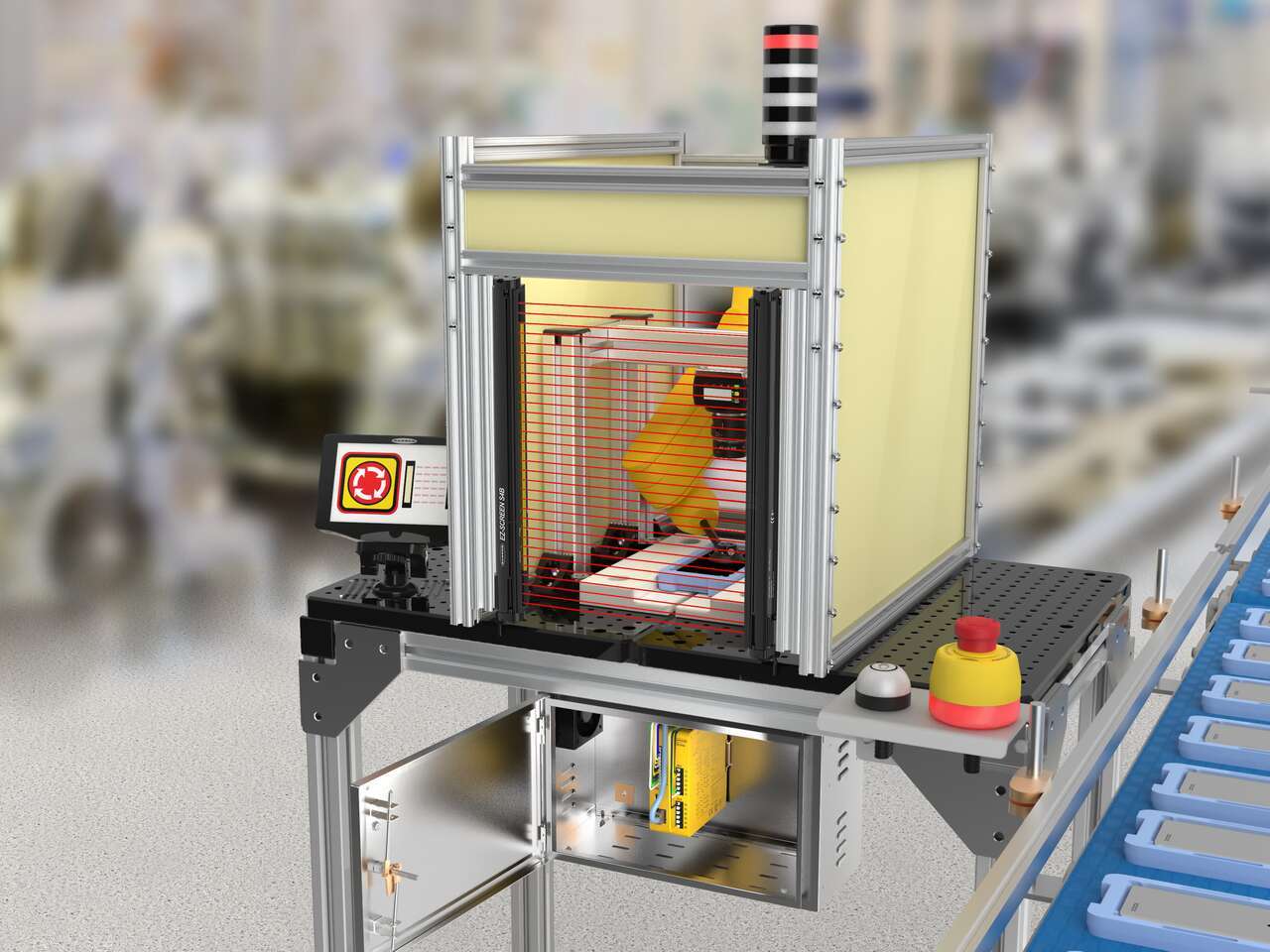

In many point of operation applications, operators must work in very close proximity to the hazard. Hard guards can be impractical in these applications, as they can reduce ergonomics and productivity of operators. Optical sensing technologies, like safety light curtains, protect the point of operation while allowing operators to interact with the machine more seamlessly.

Safety light curtains typically consist of an emitter and receiver—where the emitter sends beams of light to the receiver—creating a sensing screen that guards machine hazards The light curtain can detect when an individual or object interrupts any beam in the screen and can trigger a halt to the hazardous motion.

Safety light curtains can be rated Type 2 or Type 4 depending on the level of risk they protect against, and they come in a variety of resolutions (distance between beams) to detect an arm, hand, or finger. The specific resolution required will depend on your application, how far away the light curtain is placed from the hazard, and how quickly the hazardous motion can be halted based on a minimum safety distance calculation.

Please note: The information on this page is meant for educational purposes only and is accurate as of the time of publication. Always consult a safety expert about your specific application before implementing any machine safety measures.

End-To-End Sensing Ensures No Gaps in Protection

When using a safety light curtain for point of operation applications, it is critical to ensure that there are no gaps where a finger or hand could go around the protective beam of light undetected.

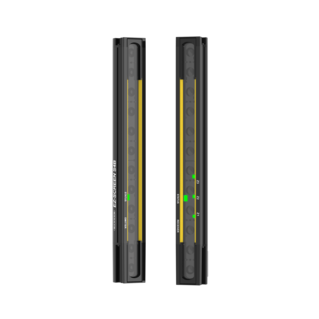

Many safety light curtains now feature end-to-end sensing, which means that the protective beams of light extend across the entire length of the light curtain. In the image to the left, you can see that the beams go all the way to the end of the light curtain, which means there are no gaps even when light curtains are cascaded together in various configurations.

If there are blind zones or other gaps, these must be taken into consideration when designing the safety system. A risk assessment is an important first step in any safety project to ensure that considerations like these are accounted for and addressed before implementation.

Ergonomic Safety for Even the Tightest Spaces

Optical safety devices often save space and improve operator ergonomics compared to doors and other hard guards. Safety light curtains facilitate a more seamless operator interaction with the machine, which can help improve productivity.

Near the point of operation, space is often limited. While safety light curtains are available in a wide range of protective heights, they can also be extremely compact and low profile for even the tightest spaces.

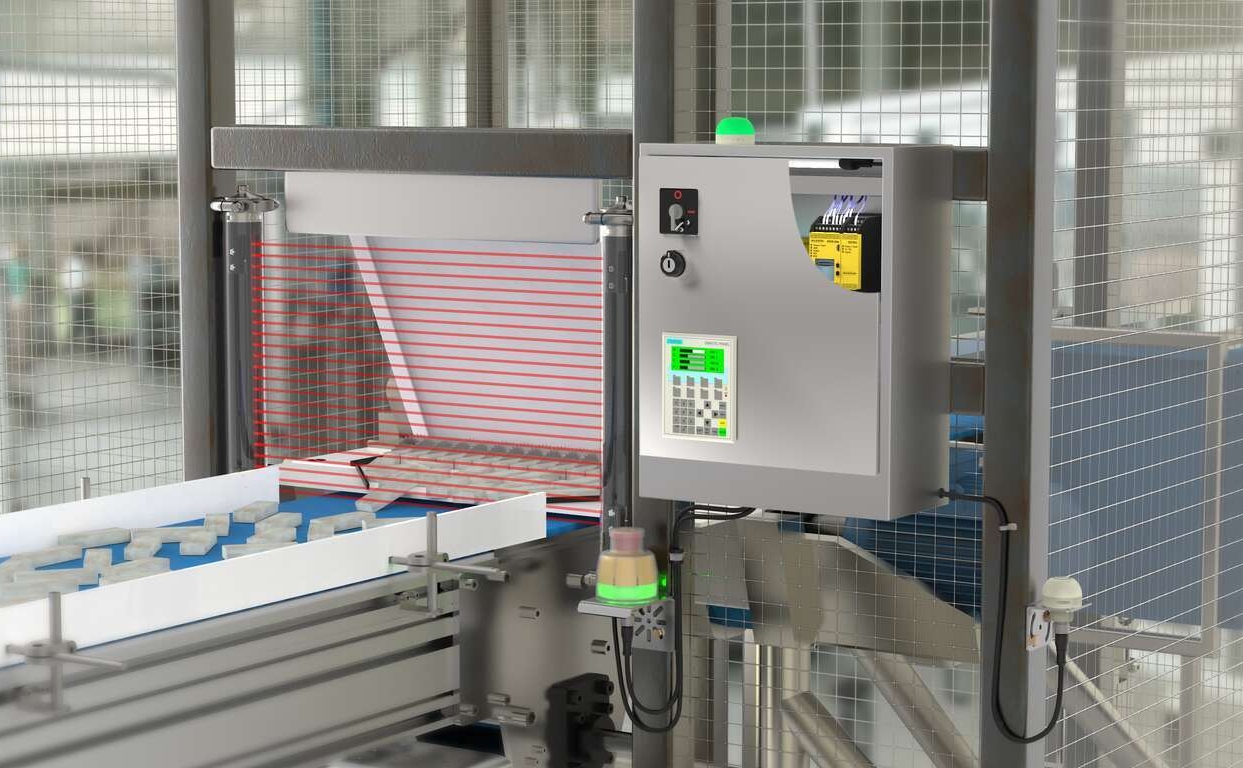

Rugged Design Ensures Safety in All Environments

Industrial environments can be punishing for safety devices. When choosing an industrial safety device, consider the surrounding environment to ensure that the ruggedness of the device meets your application requirements. For example, features like heavy-duty aluminum housing and a recessed lens protect safety light curtains from damage due to impact.

In addition, in food processing applications, light curtains mounted close to the process must endure frequent high pressure, high temperature washdown to adhere to food safety standards. Many light curtains can be equipped with IP69K-rated protective enclosures to ensure reliable operation in these harsh conditions.

Easy-to-Use, Full-Featured Safety Light Curtain

LS emniyet ışık bariyerleri, makinaları emniyetli hale getirmek için kullanılan, sezgisel ve kullanımı kolay emniyet cihazlarıdır. Üretim ve paketleme tesislerindeki en zorlu ortam şartlarına dayanıklıdır.

- Çeşitli uygulamalardaki ihtiyaçları karşılayabilir

- Zorlu ortamlarda hasar görmesini önlemek için alüminyum gövdeye ve güçlendirilmiş ön cama sahiptir

- Ölü bölgesiz algılama yapar

- Hizalama indikatörleri mevcuttur

- 14, 23 ve 40 mm çözünürlük sunar

- 70 mm çözünürlüğe sahip bariyerlerin 280 ile 1820 mm arasında uzunluk seçenekleri mevcuttur

- IP65/IP67 koruma sınıfına sahiptir

Full-Featured, Low Profile Safety Light Curtain

LP'nin yerden tasarruf sağlayan, kompakt gövdesi daha küçük makinalar için ideal olmakla birlikte, daha güçlü preslerin ihtiyaçlarını karşılayacak kadar da dayanıklıdır.

- Uçtan uca algılama yapabilen ölü bölgesiz tasarıma sahiptir

- 14 mm veya 25 mm'lik çözünürlükteki modellerin algılama mesafeleri, 270 ila 1810 mm arasında değişir

- Kompakt profili ve birden fazla montaj seçeneği sayesinde, LP Serisi Emniyet Işık Bariyerleri geniş bir yelpazede makina güvenlik uygulamaları için idealdir

- OSHA/ANSI Control Reliability gereksinimlerini karşılar; cULus NIPF sertifikasına, Kategori 4, Kategori 4PLe ve SIL 3 için CE sertifikasına sahiptir.

Compact Light Curtain for Simple Applications

SLC4 Serisi emniyet ışık bariyerlerimiz, daha küçük üretim makinalarında veya benzeri ekipmanlardaki erişim ve çalışma noktalarında koruma sağlamak için tasarlanmıştır.

- 160 mm ila 320 mm arası algılama bölgesine sahiptir

- 0.1 m ila 2 m arasında algılama yapar

- 14 mm (parmak koruma) ya da 24 mm (el koruma) çözünürlüğe sahip modeller mevcuttur

- IP65 koruma sınıfına sahip koruma kılıfı içerisinde sağlam alüminyum iç gövdeye sahiptir

- Otomatik start/restart fonksiyonu bulunur

- Uçtan uca algılama yapar (ölü bölgesiz)

![Washdown Cover for Emergency Stop Buttons [Video]](/content/dam/banner-engineering/projects/video-thumbnails/E-Stop_Cover_Video_Thumbnail-new.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)