Work In Process (WIP) Tracking

From Raw Material to Finished Product

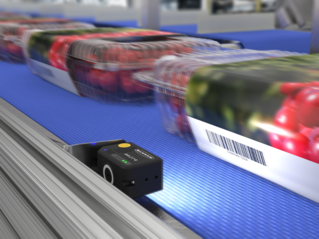

Work in Process (WIP) tracking refers to tracking each item in production throughout the entire manufacturing process to ensure efficiency, accuracy, and traceability.

In many facilities, WIP tracking is still completed by hand, using spreadsheets and manual data entry; however, automated WIP tracking not only saves times and reduces errors, but it also provides real-time visibility into the flow of materials throughout production.

The foundation for automated WIP tracking is reliable barcode reading. Keep reading to learn about code reading solutions for WIP tracking or contact us to discuss your specific application.

Visibility into Every Step of the Process

Tracking items from raw materials to finished products provides a wide variety of benefits including enabling manufacturers to:

- Know the location and status of customer orders during production to ensure on-time shipment and delivery.

- Track availability of raw materials inventory in real time to facilitate restocking and keep production levels on target.

- Accurately track scrapped or reworked parts to identify areas for process improvement.

- Track finished products back to the original materials for quick and accurate recall of defective products.

These, among other capabilities, enable manufacturers to increase profitability and remain competitive in their industries by increasing efficiency, reducing waste, and allowing for accurate, real-time identification of defects and bottlenecks.

Track Inventory and Origin of Materials

- A product's quality depends on the integrity of its parts, so tracking raw materials is critical.

- Scanning and tracking received goods and raw materials provides manufacturers with valuable data that can be used in case an issue is discovered during quality inspections or product recall.

- If a defect is identified with a particular part on a product, insight into the origin of the defective materials can help manufacturers isolate affected batches and prevent future defects.

- In addition to facilitating quality control and recalls, tracking incoming goods also enables better inventory management to ensure necessary parts are restocked in a timely manner.

Improve Efficiency and Reduce Waste

- Tracking individual components throughout product helps manufacturers improve efficiency, reduce waste, and achieve lean manufacturing goals.

- For example, manufacturers can easily determine which parts are scrapped most often and where the waste is occurring. This allows manufacturers to identify solutions to reduce waste and analyze the success of those solutions over time.

- Scanning components and products at each stage of production also enables manufacturers to track the time between each stage to identify and reduce bottlenecks in production and facilitate staffing and resource allocation.

Ensure Accurate, Timely Order Fulfillment

- Accurate and timely shipments are critical. Missed ship dates, incorrect, or incomplete orders can cause delays throughout the supply chain and decrease customer satisfaction.

- Order, shipping, and tracking information is embedded in separate 1D and 2D barcodes printed every box in a shipment. This information must be verified before the boxes are loaded onto a pallet and the shipment leaves the facility.

- As packages travel at high speeds on the line to the palletizer, an ABR 7000 barcode reader with a liquid lens autofocus verifies each barcode printed on the label.

- Algorithms programmed into the barcode reader locate each barcode, extract the data, and verify that the barcodes match the criteria established during inspection setup.

- This information is then sent over an Ethernet connection to the management system which records the data.

Imager-Based 1D and 2D Barcode Reader

Geniş yelpazedeki lensleri sayesinde birden fazla çözünürlük seçeneği sunar

- ABR 7000 Serisi, genişletilmiş okuma mesafesi ve görüş alanı, çeşitli aydınlatma ve odak uzunluğu seçenekleri (otofokus dahil) ve birden fazla okuyucuyu birbirine bağlayabilme gibi gelişmiş özellikler sunar.

- DPM ve düşük kontrastlı kodlar dahil olmak üzere en zorlu 1D ve 2D kodları okuyabilir.

- Üzerinde bulunan butonlarla veya Barcode Manager yazılımı ile hızlıca programlanabilir.

- Dahili LED ışıkları mevcuttur ve odak ayarı cihaz üzerinden kolayca yapılabilir bu sayede uygulamada maksimum esneklik sağlar.

- Fonksiyonel lens seçenekleri ile kurulum ve konfigürasyonu oldukça kolaydır.

- Ethernet, seri gibi endüstriyel haberleşme protokollerine sahiptir.

- Web server özelliği sayesinde, kontrol edilen görüntü ve kontrollerin istatiksel sonuçlarını sistemin bağlı olduğu ağ üzerindeki herhangi bir noktadan izleyebilirsiniz.

Imager-Based 1D and 2D Barcode Reader

Üstün kod okuma yeteneğine sahip iVu BCR Serisi en zorlu izlenebilirlik uygulamalarınıza kullanımı kolay çözümler sunar. Fonksiyonel barkod okuyucuların geniş yelpazede lens, ışık ve kullanıcı arayüzü seçenekleri mevcuttur.

- Okunması zor ve hasar görmüş barkodlar dahil olmak üzere 1D ve 2D barkodları okuyabilir.

- Tek bir denetim özelliğiyle birden fazla barkodu yönden bağımsız olarak okuyabilir.

- Dahili ekran, harici ekran ya da PC aracılığı ile programlayabilirsiniz.

- Ethernet, Serial ve USB gibi endüstriyel haberleşme protokolleriyle Endüstri 4.0 uygulamalarında kullanım için idealdir.

- IP67 koruma sınıfına sahip iVu Serisini endüstriyel ortamlarda güvenle kullanabilirsiniz.

- Dahili aydınlatma seçenekleri sayesinde daha iyi kontrast elde etmenize yardımcı olur.

- Standart veya C-Mount değiştirilebilir lensleri uygulamada maksimum esneklik sağlar.

TCNM Series

Laser-Based 1D Barcode Scanner

Endüstride en çok tercih edilen tüm lineer barkodların algılanmasında kullanılabilen TCNM Serisi barkod tarayıcı yüksek okuma hızına, geniş tarama derinliğine ve yüksek çözünürlüğe sahiptir.

- Endüstride en çok kullanılan lineer barkodları algılar

- Saniyede 500 ile 1000 adet tarama gerçekleştirilebilir

- Smart Teach butonu ve LED indikatörleri ile kolay kurulum ve kullanım imkanı sunar

- Özel algoritması sayesinde, hasarlı barkodları başarıyla okur

- GeniusPlus yazılımı ile konfigüre edilir

- Multi-head ağ ile birden fazla tarayıcıyı tek bir uygulamada birbirine bağlayabilirsiniz

- Sağlam, IP65 koruma sınıfına sahiptir