Food: Primary Packaging

Primary Food Packaging

Banner offers products and solutions designed specifically to perform reliably in harsh conditions and withstand the environmental challenges common to primary packaging areas in the food processing industry.

We offer a broad range of IP67, 68 and 69k and stainless steel food grade components, as well as optional chemical-resistant housings that withstand routine clean-in-place (CIP) procedures. Banner sensors, LED lights and indicators are easy to use and deploy, support production demands and facilitate product changeover, simplify and streamline processes, improve efficiency and enhance worker experience.

Primary Packing Food Applications

View Applications by Machine Type

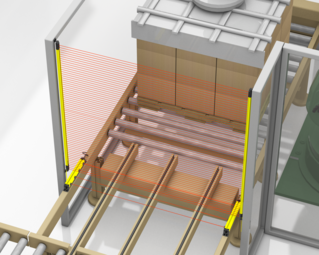

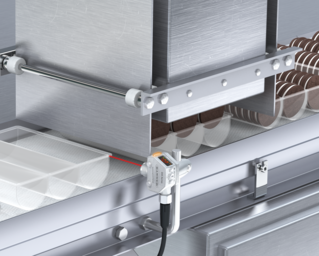

Denester

Enhance food packaging with Banner's tray denesting solutions using Q4X and QS18 Expert™ Sensors for efficient clear container handling.

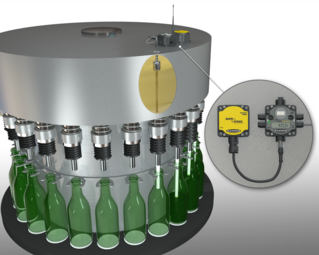

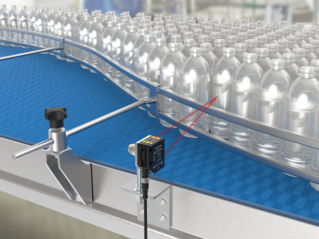

Hopper

Banner's hopper storage solutions for food packaging use level monitoring and laser sensors for consistent resupply and error reduction in various conditions.

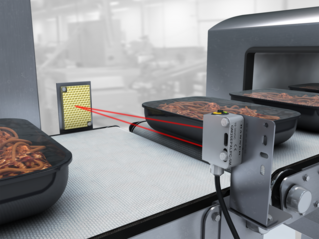

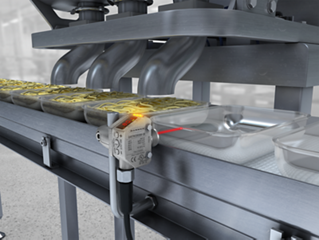

Heat Sealer

Banner's heat sealing solutions for food packaging feature clear object detection and LED lighting to ensure efficient and waste-reducing sealing of food trays.

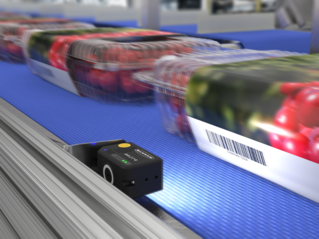

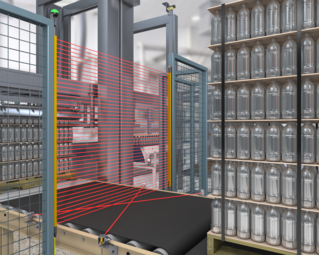

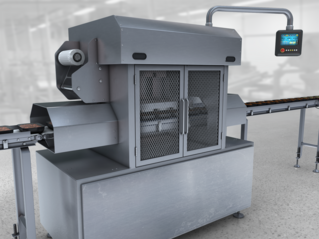

X-Ray & Checkweigher

Banner's X-Ray and Checkweigh solutions for food packaging feature sensors for quality control and LED tower lights, FDA compliant and suitable for washdowns.