Kitting and Sequencing

Build Kits and Assemblies Quickly and Accurately

Kitting involves assembling separate but related items into a single unit or kit that is packaged together.

In Just In Time (JIT) manufacturing, sequencing refers to delivering kits of materials to the next station exactly when they are needed to ensure maximum efficiency.

For example, in automotive manufacturing, kits of parts are delivered to the next stage of production at exactly the time that a kit is needed. Assembling kits in this way is also known as "offline kitting."

Pick-to-light solutions help ensure kits are assembled accurately at a fast pace and can be delivered to the next stage of production at the right time.

Ensuring Quality in Kit Building is Essential

Kitting and sequencing applications can be challenging because kits and other assemblies are often made of many different components. Each kit must be assembled correctly to ensure that end users, or assemblers at the next stage of production, receive a complete kit.

Due to the number of items, and the variety of kits that may be assembled at a station, it can be easy for assemblers to lose track of what has already been put in the kit. For example, they may accidentally leave out items or add duplicate items, which increases costs and makes parts inventory management a challenge.

Manually verifying that each kit is complete, and does not contain duplicates, is time-consuming and prone to error. Therefore, it is necessary a solution that can streamline assembly tasks and verify accuracy.

Just In Time sequencing applications depend on a fast, accurate kit building to ensure that kits arrive at the next station at the right time and contain all of the necessary parts.

Ensure Quality Even in Large, Complex Assemblies

- At stations where multiple different kits are assembled, specific colors can be assigned for each kit. Pick-to-light devices illuminate with the corresponding color, such as blue, alerting the operator to pick items from all the bins with blue lights.

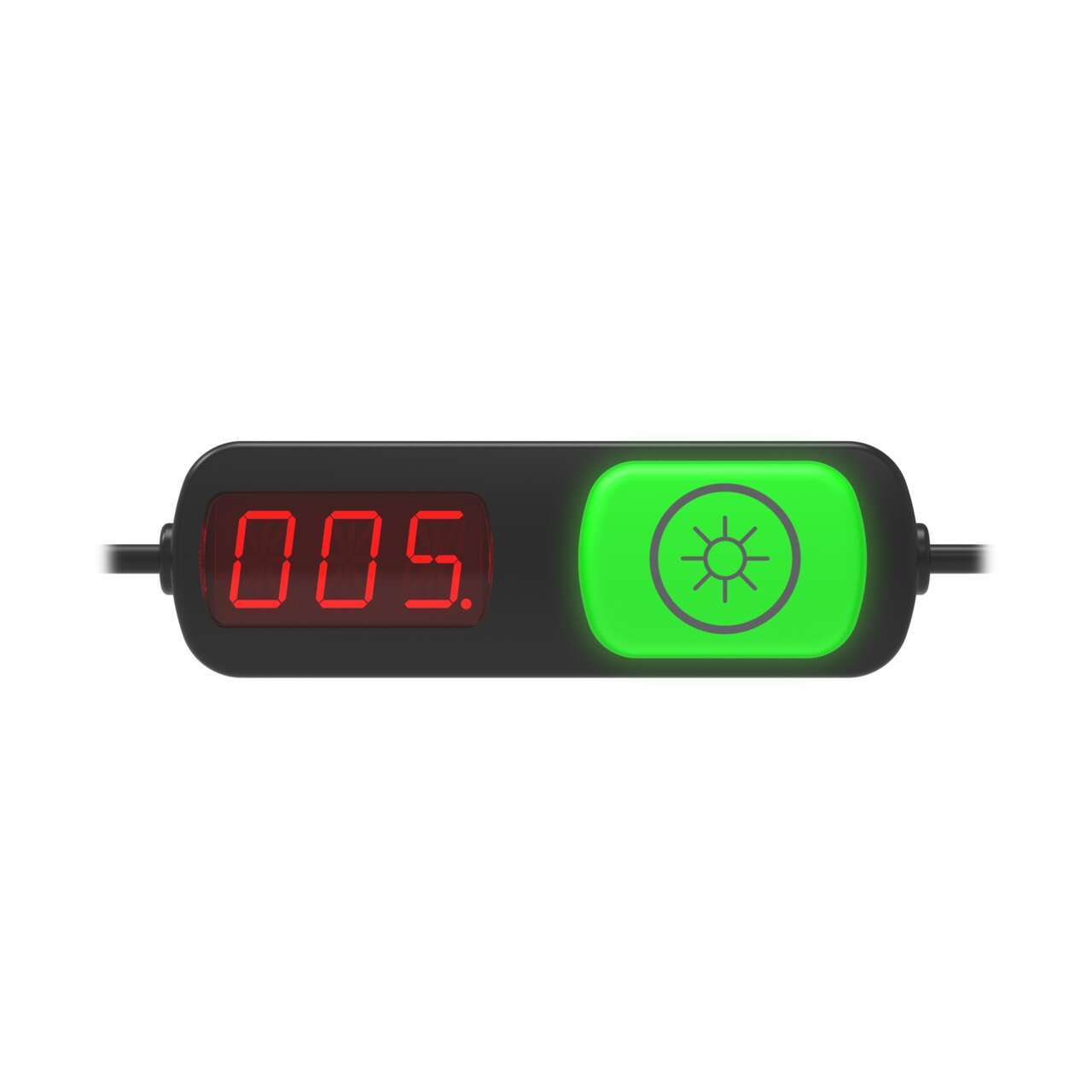

- Devices with an alphanumeric display indicate the quantity of each item to pick.

- After an operator has transferred the items from each pick bin to the color-matched kit bin, they press the blue touch button to signal that they are finished, and the light turns off.

- The process is repeated with additional colors, and once all the lights are off, that round of kit is complete.

Check Pick Accuracy in Real Time

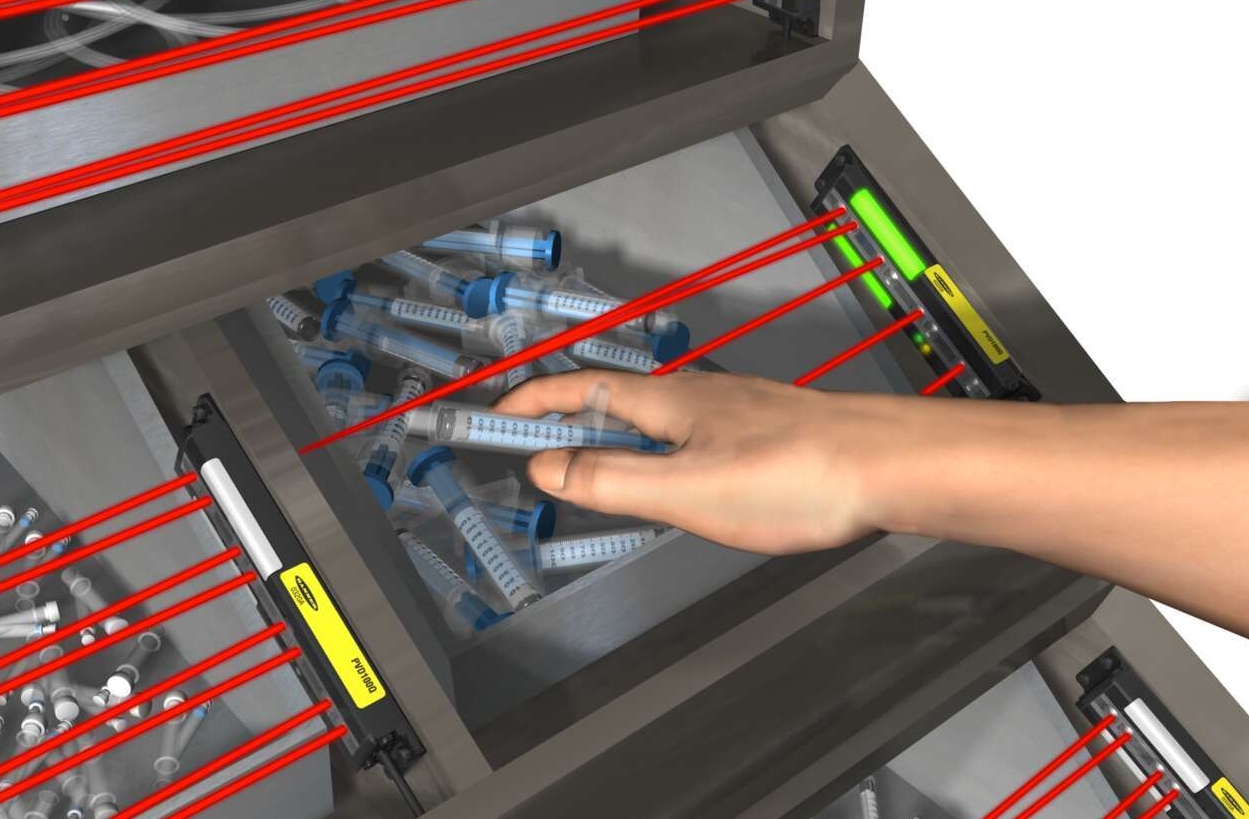

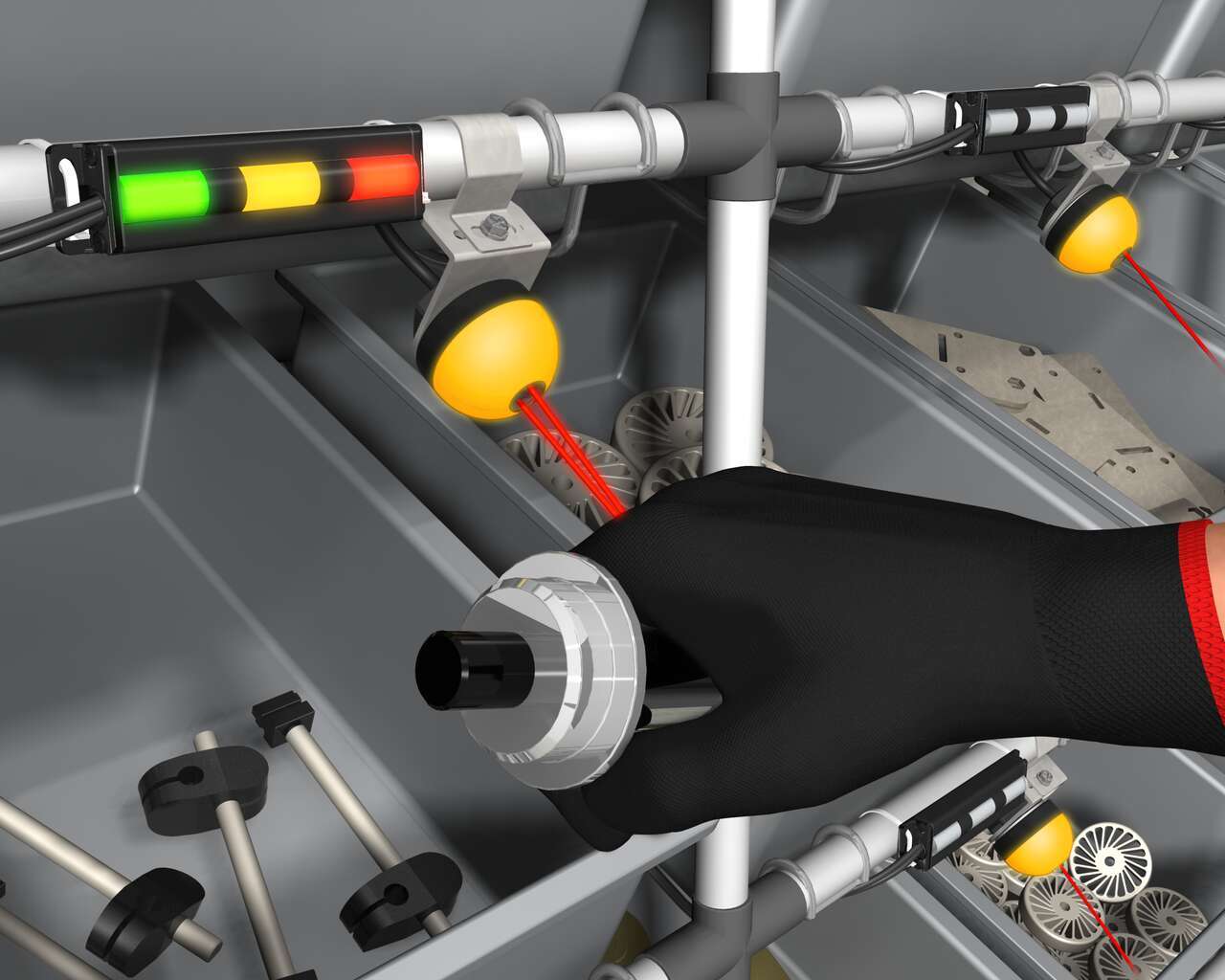

- Pick-to-light devices with optical sensing capabilities can be used to check picks for accuracy in real time.

- These devices detect when a hand reaches into a bin and breaks the sensing beam or array.

- When picks are executed correctly, yellow LEDs confirm that the operator picked from the right bin.

- If the operator reaches into the wrong bin (for example, to pick the wrong item or pick a piece out of order), a light turns red indicating an error.

Reduce Wasted Time and Save Costs

- Light-guided solutions speed up onboarding time for new employees, as well as training on new product assembly. Different colors of lights are easy to interpret quickly with minimal training.

- Pick-to-light solutions reduce time wasted re-reading instructions, as well as checking and re-checking work.

- By verifying parts at each step, pick-to-light solutions can reduce errors during the assembly process and save time during quality inspections downstream.

- Improving efficiency at both assembly and inspection stages reduces overhead costs and increases profitability.

Pick-to-Light Devices

La gamme de boutons tactiles K50 Pro combine un témoin lumineux et une fonction de commutation transistorisée activée par simple effleurement. Elle convient idéalement aux opérations de prélèvement en casier et de lean manufacturing. Les boutons tactiles K50 Pro allient la technologie tactile et la robustesse, avec en plus la polyvalence des LED RVB multicolores. Les boutons tactiles K50 Pro sont compatibles avec le logiciel Pro Editor qui permet de les personnaliser facilement.

- Voyants LED très lumineux associés à des fonctions de commutation à activation tactile

- Modèles compatibles programmables grâce au logiciel Pro Editor et au câble convertisseur Pro de Banner pour personnaliser les couleurs et les animations

- Construction robuste de classe IP67 et IP69K pour les environnements de lavage haute pression

- Conception ergonomique qui ne nécessite aucune pression physique pour fonctionner, et élimine la fatigue de la main et du poignet

- Choix idéal pour les applications d'aide au choix et d'appel de pièces dans divers secteurs et environnements, de l'agroalimentaire au secteur automobile

- Jusqu'à 14 couleurs possibles dans un même appareil (rouge, vert, bleu, jaune, magenta, orange, violet, blanc, cyan, ambre, vert citron, vert printemps, bleu ciel et rose)

- Modèles IO-Link offrant toutes les fonctionnalités Pro gérées dynamiquement par l'appareil maître, plus contrôle individuel des LED pour une personnalisation complète des états

Pick to Light Devices

De dimensions plus petites que la série K50, le système d'aide au choix de la série K30 combine un voyant lumineux et une fonction de commutation transistorisée activée par simple effleurement tactile.

- Conception ergonomique qui ne nécessite aucune pression physique pour fonctionner, ce qui élimine la fatigue de la main et du poignet

- Fonctionnement tactile simple avec le doigt

- Actionnement facile à mains nues ou avec des gants de travail

- Construction robuste et entièrement encapsulée de classe IP69K pour les environnements washdown à haute pression

- Convient parfaitement pour les applications d'aide au choix ou d'appel de pièces dans diverses industries

- Modèles à 1 ou 2 couleurs pour satisfaire les besoins de multiples applications