Multicolored Targets and Product Changeover

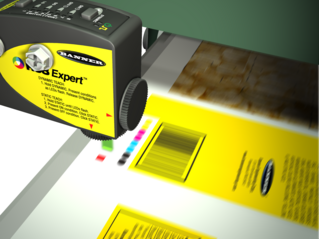

Multicolored targets are increasingly becoming the norm, especially in consumer packaged goods industries. The various types of packaging used include shiny, glossy, or other unpredictable surfaces.

For example, reflective, multicolored, and wrinkled material such as foil or film is frequently used in food and beverage packaging and can cause inconsistent sensor readings.

Multicolored targets are challenging for many sensors to consistently detect. This is because some colors, such as very dark colors, are more difficult for traditional photoelectric sensors to see because darker colors reflect back less light back to the sensor compared to lighter colors. Multicolored targets also have frequent color transitions and varying amounts of reflectivity that further impact sensing reliability.

Product changeover creates additional challenges because sensors must be able to reliably detect a variety of color combinations. To keep up with consumer demand, manufacturers require flexible sensing solutions that can detect all colors and that can be quickly updated with each new "recipe" during product changeover to keep production lines moving.

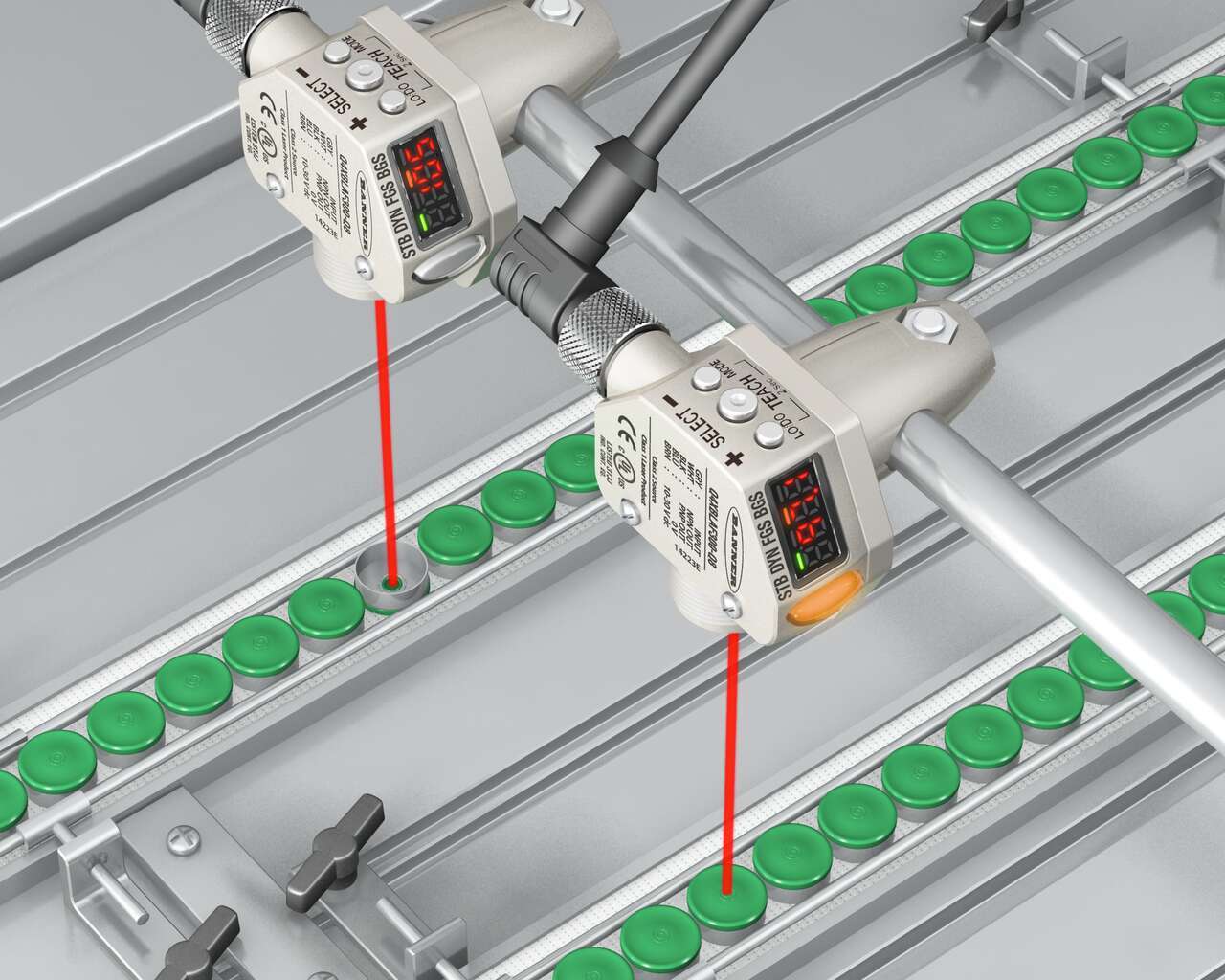

Laser distance sensors are an excellent choice for detecting multicolored packaging because cause they determine target presence or absence using distance. Laser distance sensors are unaffected by color transitions, and they can reliably detect all different varieties of packaging, regardless of color or reflectivity.

In addition, many laser distance sensors from Banner Engineering feature exceptionally high excess gain to reliably detect very dark colors, as well as automatic gain adjustment to dynamically increase or decrease sensing power depending on target reflectivity.

With IO-Link, users can easily read and change device parameters through the control system software, enabling fast configuration and commissioning that saves time and resources.

In addition, IO-Link sensors can accommodate multiple recipes that can be quickly and dynamically changed from the control system as needed—such as in the case of product changeover. For example, a line that runs products of different sizes at different times will require changes to sensors’ distance thresholds.

Manufacturers use many terms to describe sensor performance, but not all manufacturers use the same specifications, which can make it challenging to compare different models of sensors. Read the article to learn tips for choosing the right sensor for any application.

Laser Distance Sensor with IO-Link, 25-610 mm

Capteurs de distance laser robustes et polyvalents, extrêmement performants et capables de détecter des variations de distance inférieures à un millimètre.

- Plusieurs modèles disponibles : sortie logique, sortie analogique (0 à 10 V ou 4 à 20 mA), détection des objets transparents et IO-Link

- Portée de détection fiable comprise entre 25 mm et 610 mm

- Détection basée sur la distance d'un large éventail de cibles avec des couleurs, surfaces et matériaux différents

- Double mode d'apprentissage (intensité + distance) parfaitement adapté aux applications de contrôle qualité et à la détection des objets transparents sans rétro-réflecteur

- Robuste boîtier IP69K en acier inoxydable certifié par la FDA

Laser Distance Sensor with IO-Link, 9.5 cm to 2 m

Le laser à suppression d'arrière-plan Q5X est un capteur puissant, performant et économique dans un boîtier rectangulaire standard.

- Sa portée est comprise entre 9,5 cm et 2 m.

- Grâce à sa réserve de gain très élevée, le capteur peut détecter avec une grande fiabilité les objets les plus sombres (cibles noires avec < 6 % de réflexion).

- Il détecte parfaitement les cibles noires sur un fond noir, les cibles noires sur un fond métallique brillant, les objets transparents et réfléchissants, les emballages multicolores, et les cibles de toutes les couleurs.

- Un mode d'apprentissage Dual Teach mesure à la fois la distance et l'intensité lumineuse pour résoudre les applications les plus difficiles.