Automated Quality Control

Identify Issues Early and Save Costs

Defects and errors in parts and components can negatively impact downstream processes, production efficiency, and product quality.

Consistent, reliable inspection of parts and components can help manufacturers identify potential issues early on in the manufacturing process, minimizing costly lost product and production time.

Banner’s expertise in a range of sensing technologies allows us to offer optimal quality control solutions for detecting defects, measuring components, monitoring tolerances, and verifying attributes.

Rugged, Reliable Sensors are Required

Automated quality control applications often involve inspecting challenging targets, such a clear and reflective targets, extremely dark targets against a dark background, multicolored targets with many color transitions, and targets moving at high speeds.

Depending on the application, the smallest errors can become critical failures further down the line, making precise inspection a must. In some applications, quality control inspections occur in extremely harsh environments, where sensing technology can be exposed to dust and dirt, high pressure washdown, machine vibration, and more.

Banner Engineering offers a range of rugged, reliable photoelectric, laser measurement, and vision sensors that improve your automated quality control processes--even in the most challenging applications. Keep reading to learn more, or contact us to discuss your specific application.

Reliably Inspect Every Target

Fast, reliable quality inspections are essential to ensuring consistent throughput without sacrificing quality.

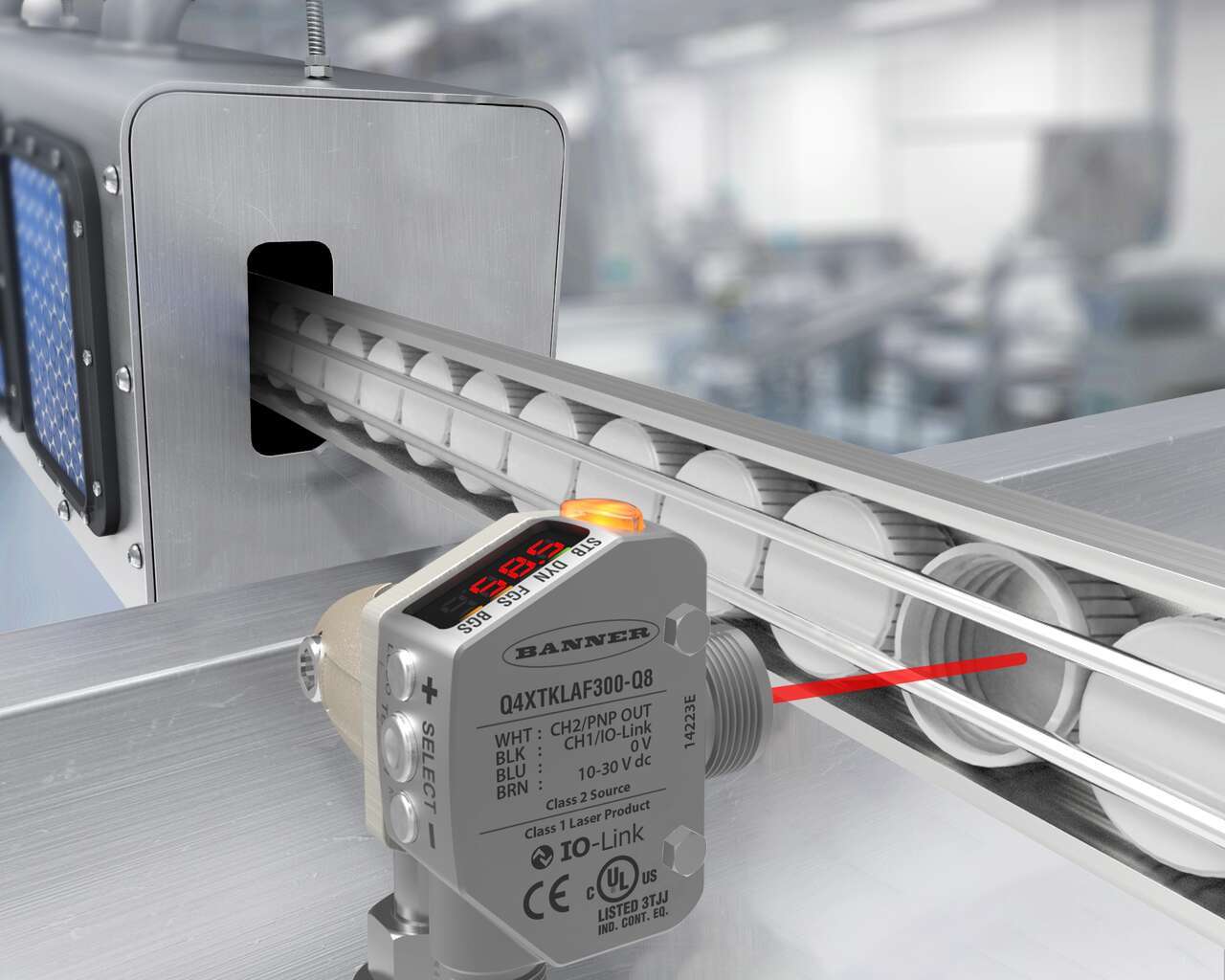

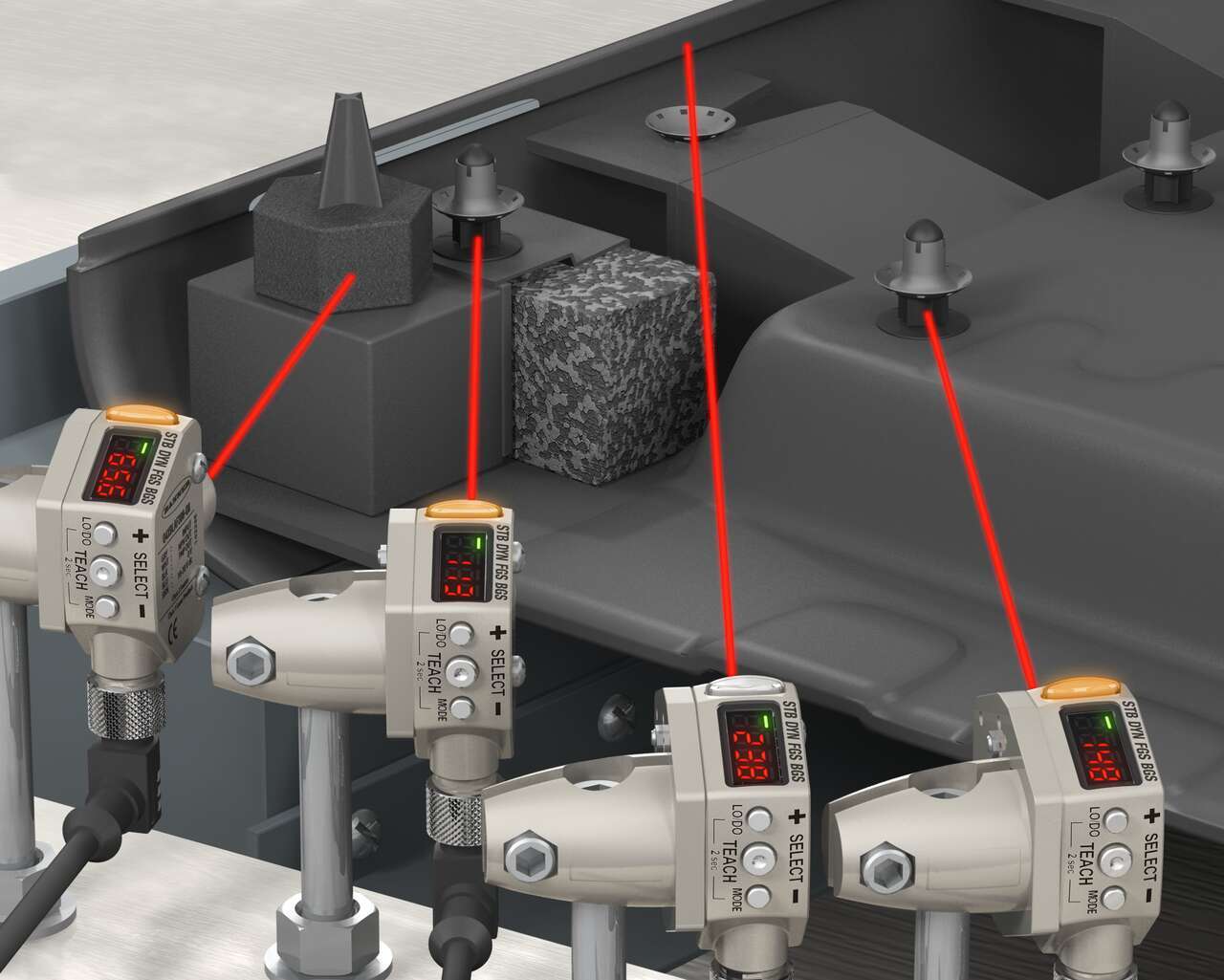

Thanks to advancements in laser measurement technology, sensors can now measure traditionally challenging targets (including clear, reflective, and low contrast targets). For example, the Q4X laser measurement sensor reliably inspects extremely dark targets on aginast an equally dark background.

in addition, thanks to dual mode which measures both distance and light intensity, smart laser measurement sensors from Banner can reliably inspect both distance-based and contrast-based conditions with a single device, which saves inventory costs.

Furthermore, with IO-Link communication, users can track sensor performance, identify trends in inspection results, and even predict when maintenance is needed so that simple problems like a dirty lens can be fixed prior to sensor failure.

Maintain Tight Tolerances

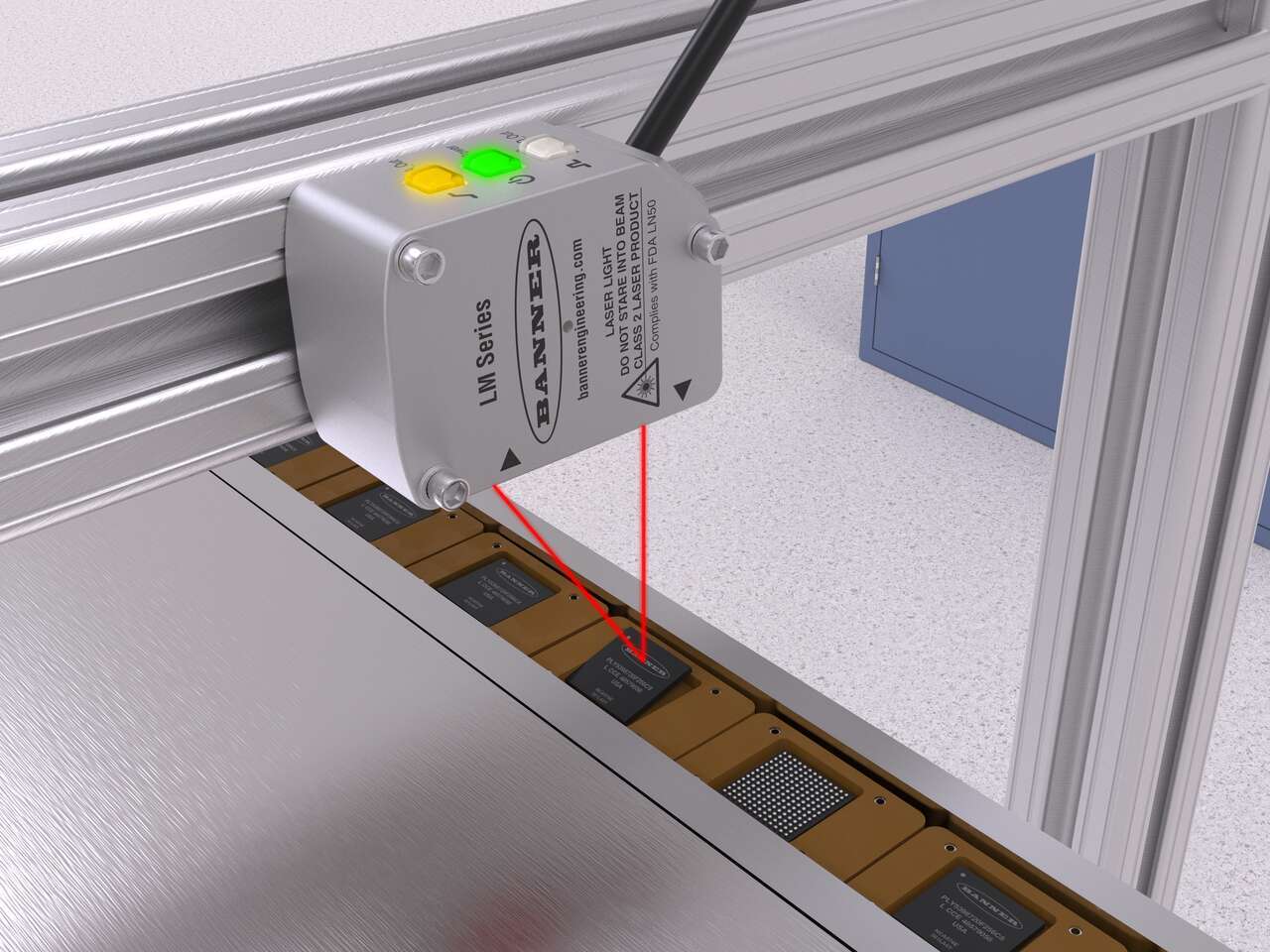

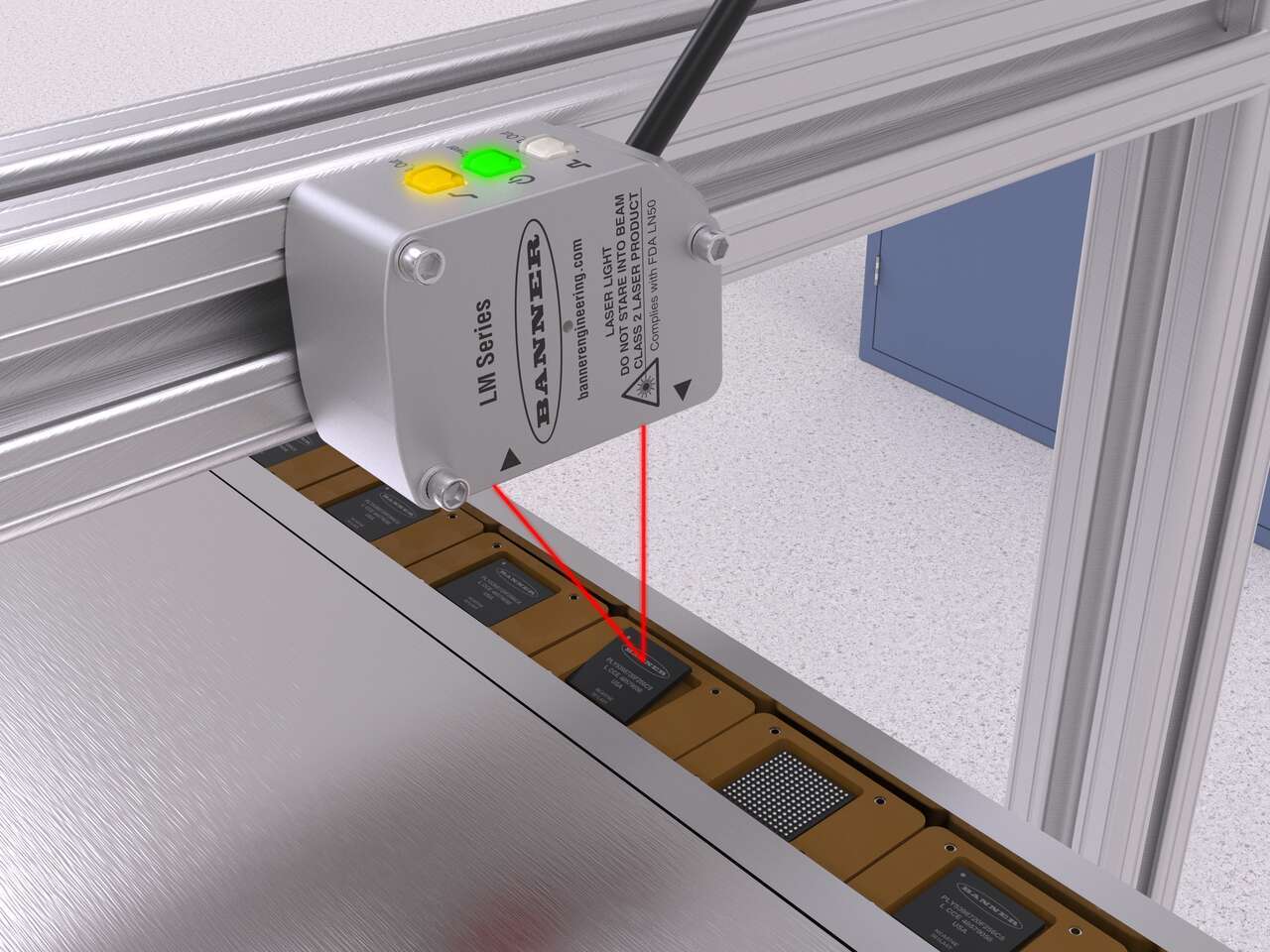

Quality control applications that require precise measurement can be some of the most challenging applications to solve. Very tight tolerance requirements demand a reliable solution that can measure parts in micrometers to detect the smallest variations in part size, thickness, orientation, placement, and more. Ensuring parts meet strict quality standards can help reduce problems downstream and reduce the risk of product recall due to imperfect parts.

Laser measurement sensors are a common solution for precise part inspections. However, real world conditions—including variations in target color and reflectivity, fluctuations in ambient temperature, and vibration from improper mounting—can make precise measurement challenging, even for laser sensors that perform well in perfect laboratory conditions.

The LM Series precision measurement sensor from Banner Engineering offers best-in-class performance with superior stability, reliability, and precision for real world targets.

Prevent Errors at the Source

Error proofing refers to preventing a process from resulting in defects by stopping mistakes at the source, rather than down the line. Preventing mistakes at the source can significantly improve productivity by keeping mistakes from becoming bigger problems downstream.

In automated processes, error proofing solutions like sensors and vision systems can be used to ensure poblems are corrected before a process can proceed.

Meanwhile, in manual processes, such as bin picking, visual warnings clearly indicate to operators when their actions are correct or incorrect using colored and/or animated lights. Light-guided assembly is an excellent example of using visual indication for error-proofing.

Laser Distance Sensor

Capteurs de distance laser robustes et polyvalents, extrêmement performants et capables de détecter des variations de distance inférieures à un millimètre.

- Plusieurs modèles disponibles : sortie logique, sortie analogique (0 à 10 V ou 4 à 20 mA), détection des objets transparents et IO-Link

- Portée de détection fiable comprise entre 25 mm et 610 mm

- Détection basée sur la distance d'un large éventail de cibles avec des couleurs, surfaces et matériaux différents

- Double mode d'apprentissage (intensité + distance) parfaitement adapté aux applications de contrôle qualité et à la détection des objets transparents sans rétro-réflecteur

- Robuste boîtier IP69K en acier inoxydable certifié par la FDA

Precision Measurement Sensor

Le capteur de mesure haute précision de la série LM offre des performances exceptionnelles et une grande stabilité au sein d'un dispositif compact, ainsi qu'une expérience utilisateur intuitive.

- Mesure précise avec une résolution de 0,004 mm

- Temps de réponse rapide de 0,5 ms et taux d’échantillonnage de 0,25 ms

- Boîtier compact adapté aux espaces confinés

- Boîtier présentant une grande stabilité thermique et montage sécurisé pour améliorer la stabilité

- Sortie logique avec IO-Link et sortie analogique 4-20 mA

- Indice de protection IP67 et acier inoxydable 316 pour résister aux produits chimiques

- Écran de capteur déporté (RSD) en option pour une configuration et une surveillance à distance

iVu Series

Vision Sensor

Les capteurs de vision iVu et iVu Color permettent de contrôler le type, les dimensions, l'orientation, la forme et la position des pièces ainsi que leur couleur ou les variations de couleur.

- Solution tout-en-un avec caméra, contrôleur, objectif et éclairage inclus

- Configuration en quelques minutes à l'aide du logiciel pour PC Vision Manager, de l'écran tactile embarqué ou de l'écran tactile déporté

- Inspection de plusieurs points avec un large choix d'outils en niveau de gris ou couleur

- Boîtier IP67 compact et robuste, disponible avec éclairage annulaire intégré en rouge, bleu, vert, blanc, infrarouge ou ultraviolet

- Objectifs interchangeables, y compris à monture en C, pour une flexibilité maximale des applications

- Protocoles EtherNet/IP™, Modbus/TCP, PROFINET®, PCCC et RS-232 série

![Éclairage à LED utilisé pour contrôler les produits pharmaceutiques liquides [Exemple de réussite]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2011/WLA-IV-Bag-Manual-Inspection---Particulates.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Zéro défaut sur un bobinoir industriel [Exemple de réussite]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/Fotolia_51604759_M.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)