Machine Guarding at the Point of Operation

Guard Hazards Where Work is Performed

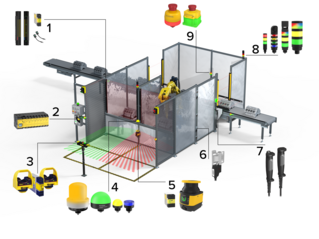

The point of operation on a machine is where the work is performed. Guarding the point of operation is critical to protecting personnel from accident or injury as well as preventing equipment damage.

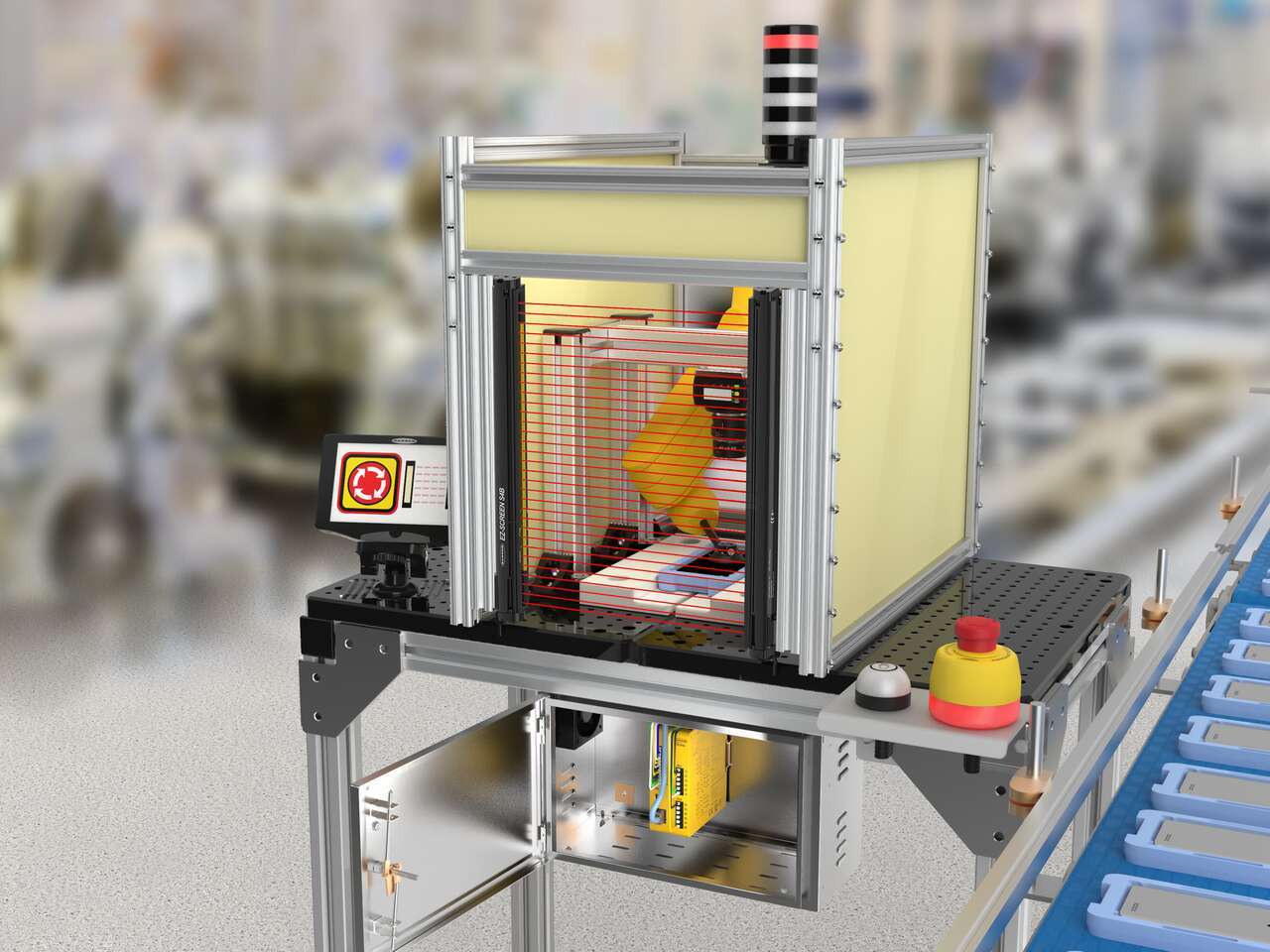

In many point of operation applications, operators must work in very close proximity to the hazard. Hard guards can be impractical in these applications, as they can reduce ergonomics and productivity of operators. Optical sensing technologies, like safety light curtains, protect the point of operation while allowing operators to interact with the machine more seamlessly.

Safety light curtains typically consist of an emitter and receiver—where the emitter sends beams of light to the receiver—creating a sensing screen that guards machine hazards The light curtain can detect when an individual or object interrupts any beam in the screen and can trigger a halt to the hazardous motion.

Safety light curtains can be rated Type 2 or Type 4 depending on the level of risk they protect against, and they come in a variety of resolutions (distance between beams) to detect an arm, hand, or finger. The specific resolution required will depend on your application, how far away the light curtain is placed from the hazard, and how quickly the hazardous motion can be halted based on a minimum safety distance calculation.

Please note: The information on this page is meant for educational purposes only and is accurate as of the time of publication. Always consult a safety expert about your specific application before implementing any machine safety measures.

End-To-End Sensing Ensures No Gaps in Protection

When using a safety light curtain for point of operation applications, it is critical to ensure that there are no gaps where a finger or hand could go around the protective beam of light undetected.

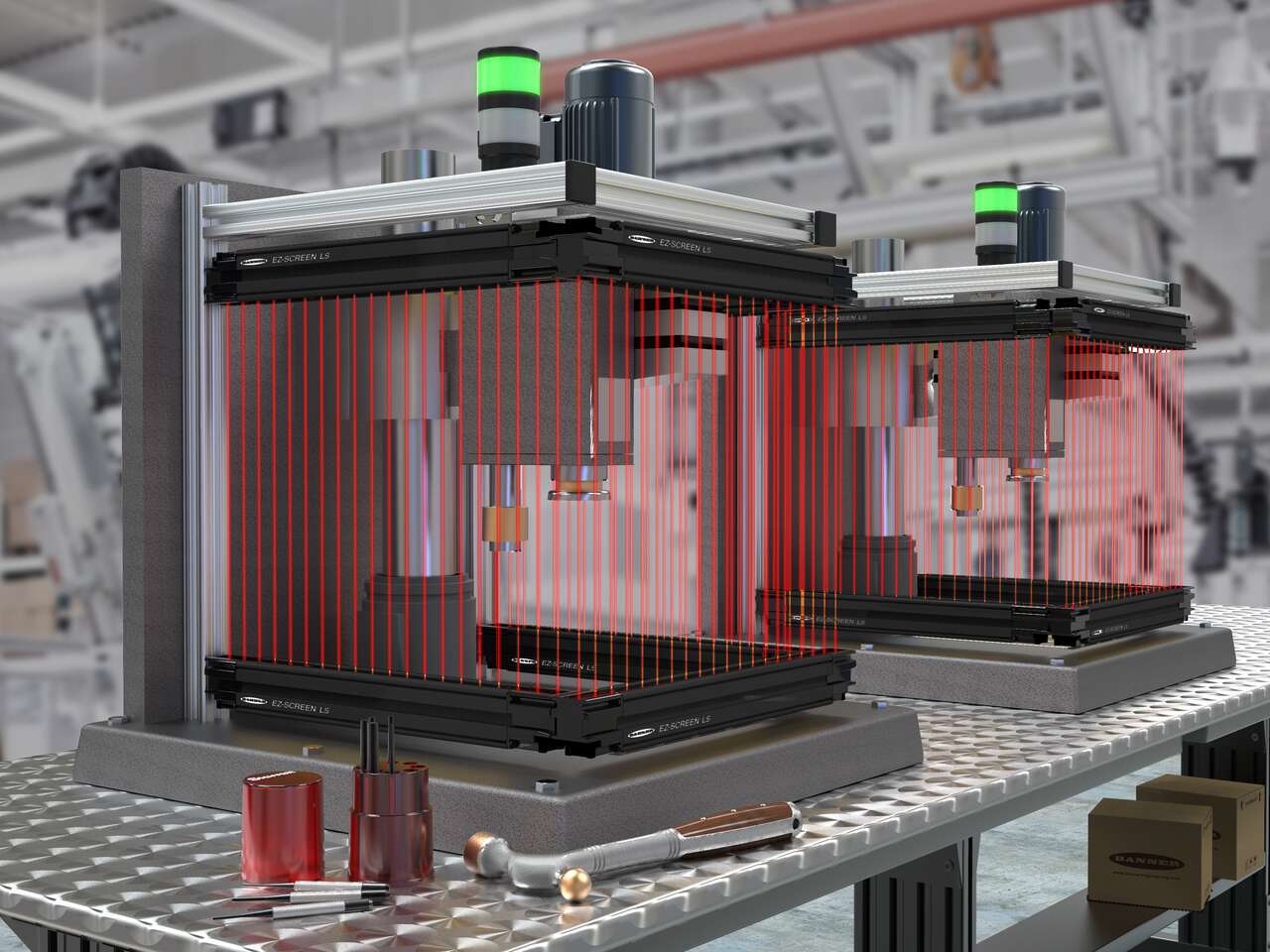

Many safety light curtains now feature end-to-end sensing, which means that the protective beams of light extend across the entire length of the light curtain. In the image to the left, you can see that the beams go all the way to the end of the light curtain, which means there are no gaps even when light curtains are cascaded together in various configurations.

If there are blind zones or other gaps, these must be taken into consideration when designing the safety system. A risk assessment is an important first step in any safety project to ensure that considerations like these are accounted for and addressed before implementation.

Ergonomic Safety for Even the Tightest Spaces

Optical safety devices often save space and improve operator ergonomics compared to doors and other hard guards. Safety light curtains facilitate a more seamless operator interaction with the machine, which can help improve productivity.

Near the point of operation, space is often limited. While safety light curtains are available in a wide range of protective heights, they can also be extremely compact and low profile for even the tightest spaces.

Rugged Design Ensures Safety in All Environments

Industrial environments can be punishing for safety devices. When choosing an industrial safety device, consider the surrounding environment to ensure that the ruggedness of the device meets your application requirements. For example, features like heavy-duty aluminum housing and a recessed lens protect safety light curtains from damage due to impact.

In addition, in food processing applications, light curtains mounted close to the process must endure frequent high pressure, high temperature washdown to adhere to food safety standards. Many light curtains can be equipped with IP69K-rated protective enclosures to ensure reliable operation in these harsh conditions.

Easy-to-Use, Full-Featured Safety Light Curtain

Les barrières immatérielles de sécurité LS sont des dispositifs de sécurité intuitifs et simples à utiliser, conçus pour assurer la protection des machines. Leur conception robuste leur permet de résister aux conditions difficiles des chaînes de fabrication et de conditionnement.

- Modèles aux fonctionnalités complètes et diverses options pour répondre aux exigences de nombreuses applications

- Boîtier en aluminium très robuste et fenêtre encastrée pour éviter tout dommage dans les environnements difficiles

- Détection de bout en bout

- Indicateurs d'alignement et de diagnostic très visibles

- Résolution de 14, 23 et 40 mm (capacité de détection)

- Disponible en 23 longueurs (de 280 à 1820 mm, par incrément de 70 mm)

- Indice de protection IP65/IP67 et modèles IP69K disponibles

Full-Featured, Low Profile Safety Light Curtain

Le profil compact à faible encombrement du système LP convient parfaitement aux machines plus petites tout en étant suffisamment robuste pour répondre aux exigences des grandes presses mécaniques.

- Détection en continu pour éviter les angles mort

- Résolution de 14 ou 25 mm, zones de détection de 270 à 1 810 mm

- Profil compact et nombreuses options de montage pour un large éventail d'applications de sécurité machine

- Le système dépasse les exigences de fiabilité des commandes OSHA/ANSI et possède une certification cULus NIPF et CE de type 4, catégorie 4PLe et SIL

Compact Light Curtain for Simple Applications

Les systèmes SLC4 sont nos barrières immatérielles de sécurité les plus petites et compactes. Elles sont conçues pour protéger les points d'accès et postes de commandes sur des machines de production plus petites ou d'autres équipements similaires.

- Hauteur protégée définie entre 160 et 320 mm

- Portée de détection de 10 cm à 2 m

- Modèles disponibles avec une résolution de 14 mm (détection d'un doigt) ou de 24 mm (détection de la main)

- Boîtier interne robuste en aluminium avec boîtier externe en polycarbonate IP65

- Fonctionnalités de base avec démarrage/redémarrage automatique (réarmement automatique)

- Conception de détection de bout en bout (sans angle mort)