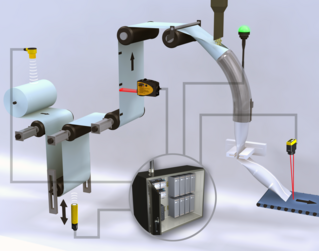

Compact, right-angle ultrasonic sensors with built-in temperature compensation. Available in analog or configurable discrete models.

- Offers choice of user-selectable NPN or PNP discrete or 0-10V dc or 4-20 mA analog output

- Available with range of 100 mm to 1 m, 200 mm to 2 m, or 300 mm to 3 m

- Delivers high-accuracy performance with built-in temperature compensation across a wide range of ambient temperatures

- Configurable discrete model allows users to select normally open (NO) or normally closed (NC) output and NPN or PNP output type

- Available with analog output for applications requiring a continuous current or voltage output

- Housed in T-style right-angle housing with 30 mm threaded nose

- Simplifies setup with push-button TEACH programming of custom sensing window

- Allows remote TEACH for added security and convenience

Downloads

Technical Literature

Product Data Files

Software

Brochures & Catalogs

Application Notes

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

Detect Installed Glass on Automobile

Detect moonroof presence from extended range

Clear Material Loop Control

Banner’s T30UX ultrasonic sensor is the perfect sensor for detecting clear material for loop control because it uses sound rather than light, which makes it more accurate and cost-effective for this specific application. Although the material is clear, it presents a solid surface for an ultrasonic sensor to bounce a sound wave. The T30UX has a more accurate transducer, a smaller dead zone and minimum distance compared to other sensors that can be used for clear material detection.

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

Loop Control of Clear Plastic

The detection of clear plastic is always a challenge. The optical beam of traditional photoelectric sensors will burn through clear material, making sensing results unreliable.

Vertical Form Fill Seal Machine Solutions

Ultrasonic Sensor: Banner’s T30UX ultrasonic sensor delivers accurate distance sensing to provide a non-contact method to measure the roll of film’s diameter. By determining the roll’s radius, the vertical form fill seal machine can calculate the amount of film that remains and can signal the operator when it is low. The material should be advancing a predetermined distance equal to the desired length of each bag or package.