Dual Output Status Indication

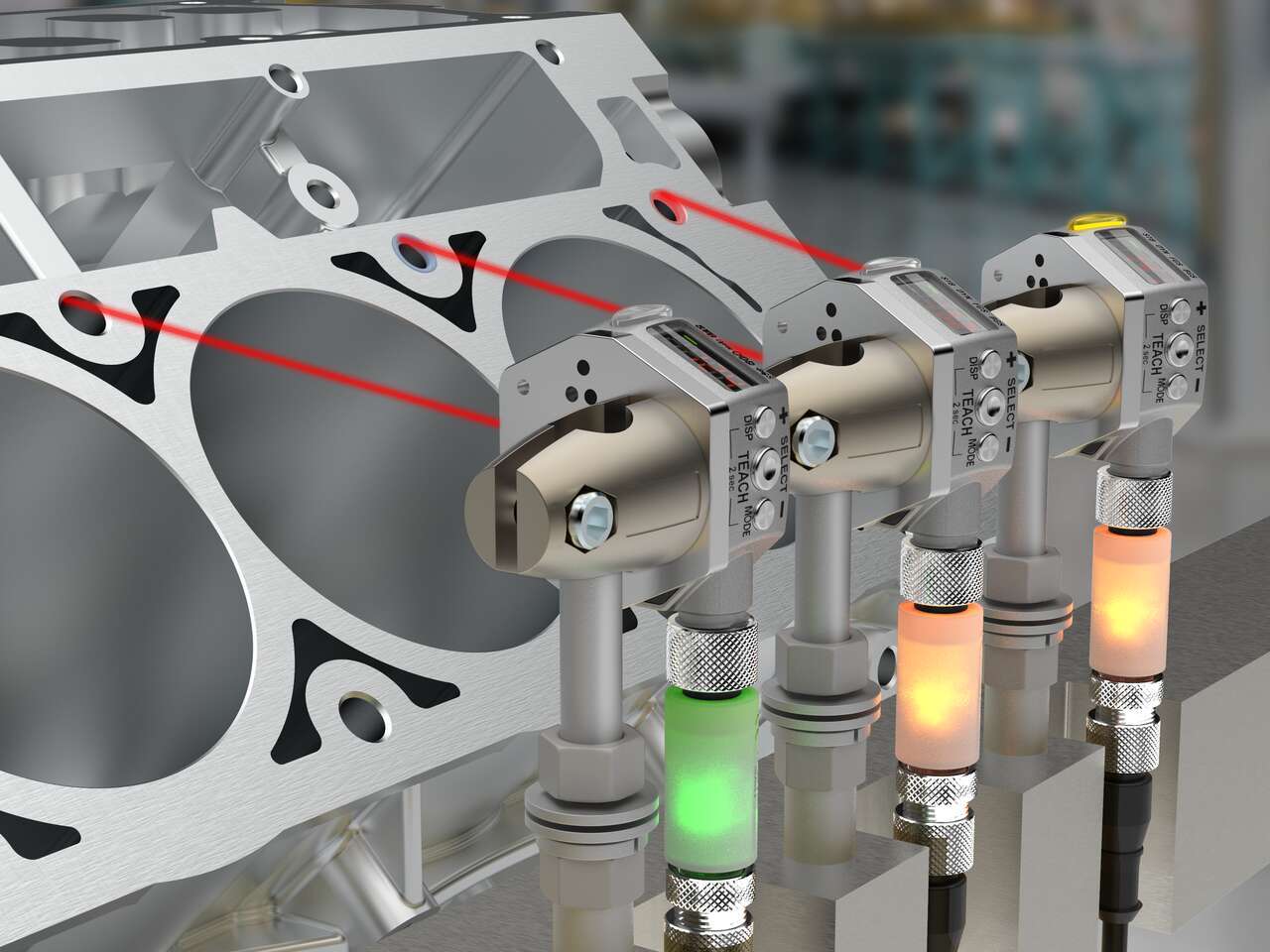

Light-Guided Verification for Automotive Manufacturing

Traditionally, laser measurement sensors only measure distance. Several Banner laser measurement sensors, such as the Q4X, can measure light intensity in addition to distance. The ability to measure light intensity and distance is what we call dual mode. Keep reading to learn how an automotive parts manufacturer recently used Q4X sensors and S15L Series In-Line Sensor Status Indicators to easily indicate dual output status on assembly lines.

In a recent lighting and indication application, an automotive manufacturer was concerned with the lack of visual confirmation given from the second output on their sensors. Because a Q4X only has one indicator, operators looking at the sensors were unable to see when the second output was active.

They wanted an easier way to tell that the assembly line was functioning in a timely, accurate manner. Additionally, it was difficult to troubleshoot the issues that arose on the assembly line, causing costly downtime.

A solution was needed to help workers identify the status of outputs and ensure proper production times.

Learn more about the benefits of the S15L Series In-Line Status Indicator

The automotive parts manufacturer equipped their sensors with an S15L, a two-color indicator light. This way, one output could use the indicator on the Q4X and the other output could use the S15L. (In this configuration, when both outputs are on, the S15L and Q4X indicator illuminate yellow. When both outputs are off, only the S15L illuminates, in green.) Output one measured distance and indicated that a rubber washer was placed on the assembly and output two, using dual mode, verified the correct color of the rubber washer. The Q4X indicator was used to verify that the washer was inserted in the assembly, and the S15L was used for quality inspection to verify that the color of the washer was correct.

The light indication system for this application used several features of the Q4X and S15L devices to enable easy visual confirmation on the assembly line:

- Bright indication to mimic sensor power and output status

- Connected directly to the Q4X for easy visual indication

- Highly visible body allows for 360 degree-visibility and simple problem identification

In addition, troubleshooting became a simpler process. Operators who couldn’t see output two on the sensors were easily able to tell that everything was functioning properly. The new solution resulted in faster throughput and less downtime.

Together, this cost-effective, simple solution enabled operators to identify problems faster, save on production costs, and improve assembly processes.

Outputs |

In-Line Indicator |

Sensor Indicator |

Both off |

Green |

Off |

Output 1 on, Output 2 off |

Yellow |

Off |

Both on |

Yellow |

Yellow |

Reduce downtime and increase efficiency

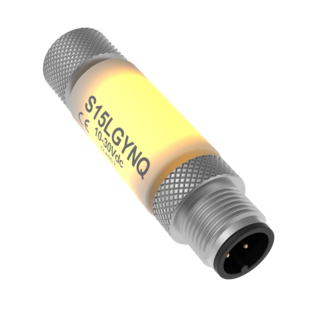

Machine downtime is costly and identifying the problem can be time-consuming. The S15L Series In-Line Sensor Status Indicator can be mounted on a sensor for 360 degree-visibility of power and status. With its highly visible body, it allows workers to identify and troubleshoot problems faster, which decreases downtime. Response time is quicker since the S15L is easily accessible, can be mounted anywhere, and is easy to use. In-line connection allows for simple problem identification.

Bright, highly visible indication

The 4 LEDs contained in the device produce two colors, green and yellow, to identify power and output status. Its low-profile design makes it ideal for bright indication in tight spaces. For example, the S15L can be placed in-line with part in place sensors that may not be visible to the operator to indicate that the sensor power is on (green) or that the part is in place and the output is active (yellow).