1

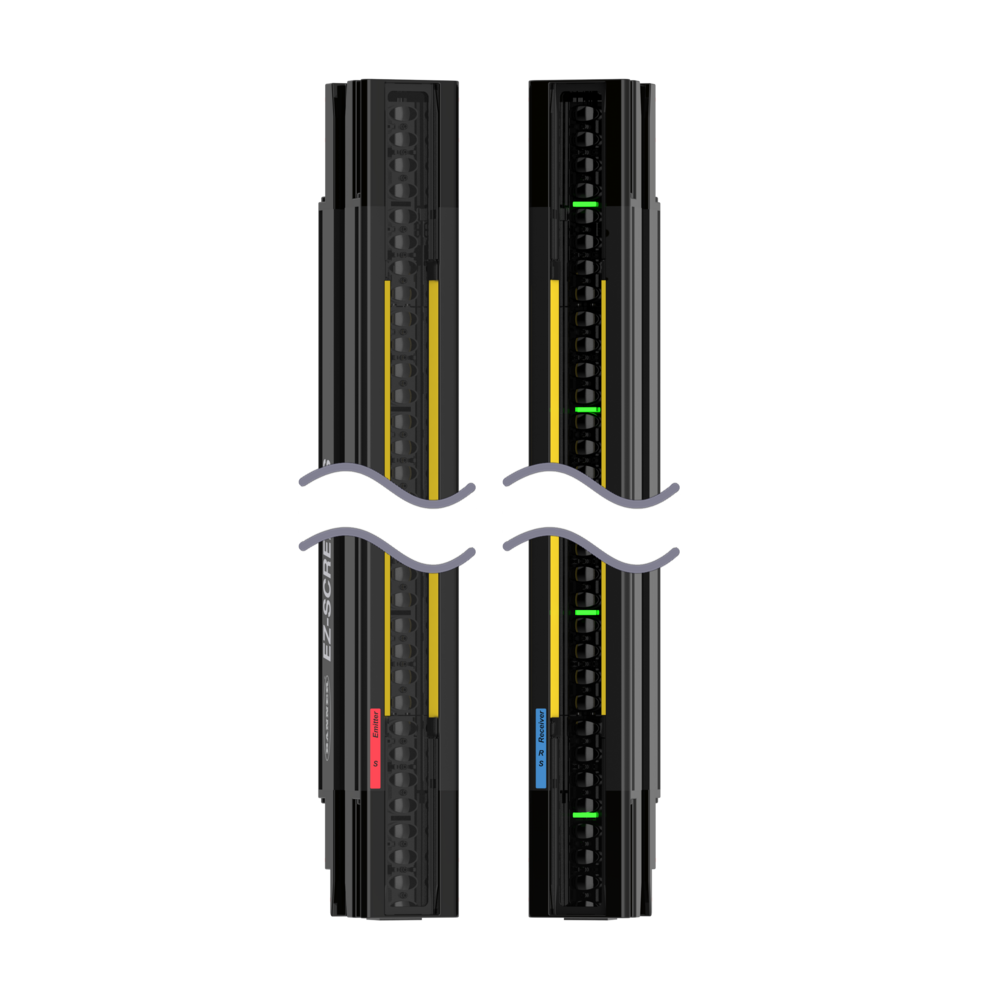

Safeguarding of a Power Press

Banner Engineering’s EZ-SCREEN LS is extremely robust with heavy duty extruded aluminum IP65/67 rated housing, metal endcaps and a recessed window to protect it from collisions related to stock removal and incidental impact.

Learn More

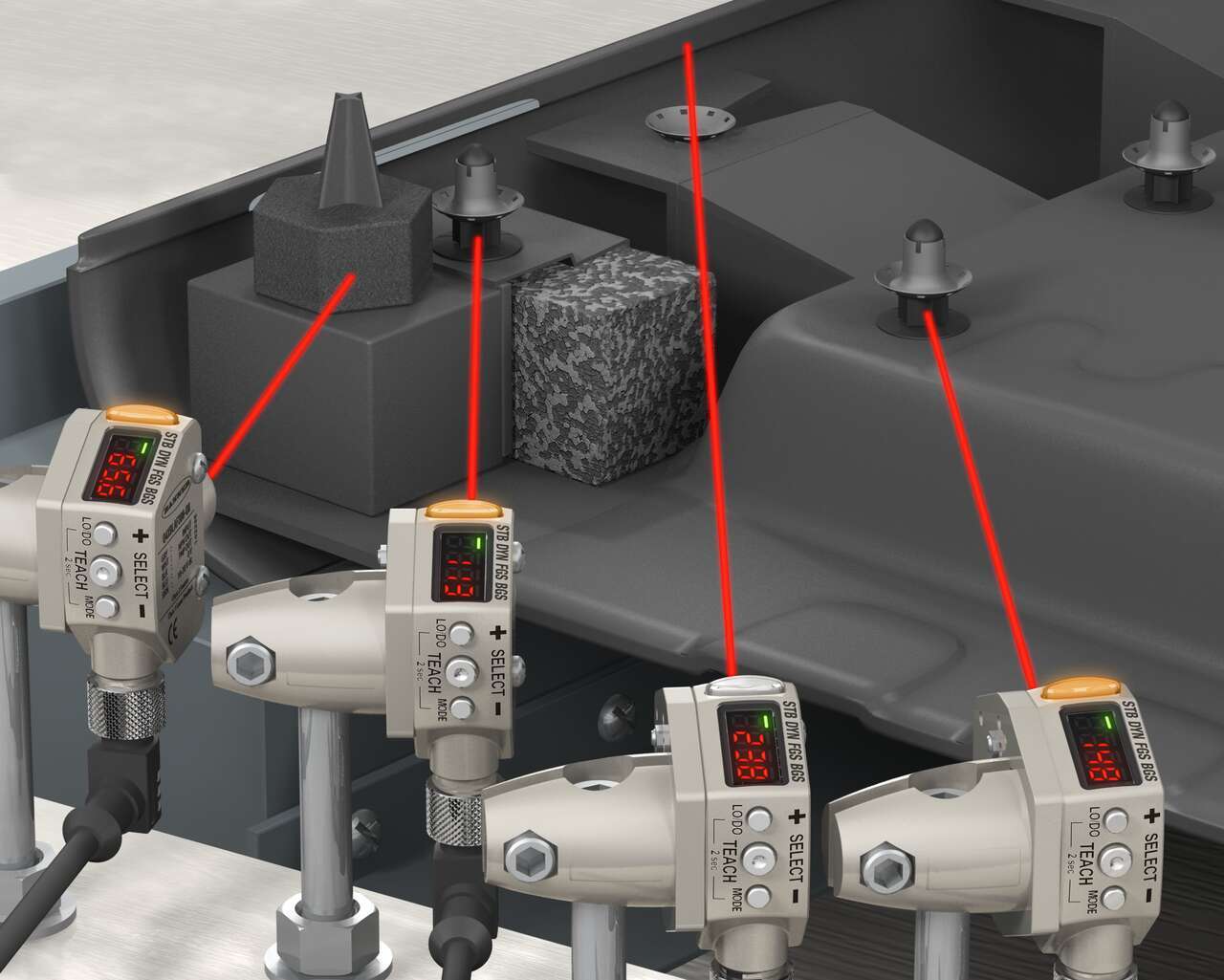

2

Multiple Point Inspection on Stamped Metal Parts

To verify the expected number of holes exists on a small metal part, the iVu Plus TG Image Sensor with Multipoint Inspections can be configured for multiple regions of interest (ROIs) to ensure holes exist and were punched in the correct place. When set up for area inspection, the iVu will scan multiple points on the stamped part to verify the presence or absence of a feature or features of interest.

Learn More

3

Detection of Surface Imperfections with Green LED Lighting

Learn how green LED task lights enhance visibility of surface imperfections on manufacturing materials.

Learn More

4

Sheet Metal Thickness Measurement

Precise and consistent sensing while material moves down a conveyor measuring thickness at micron levels.

Learn More

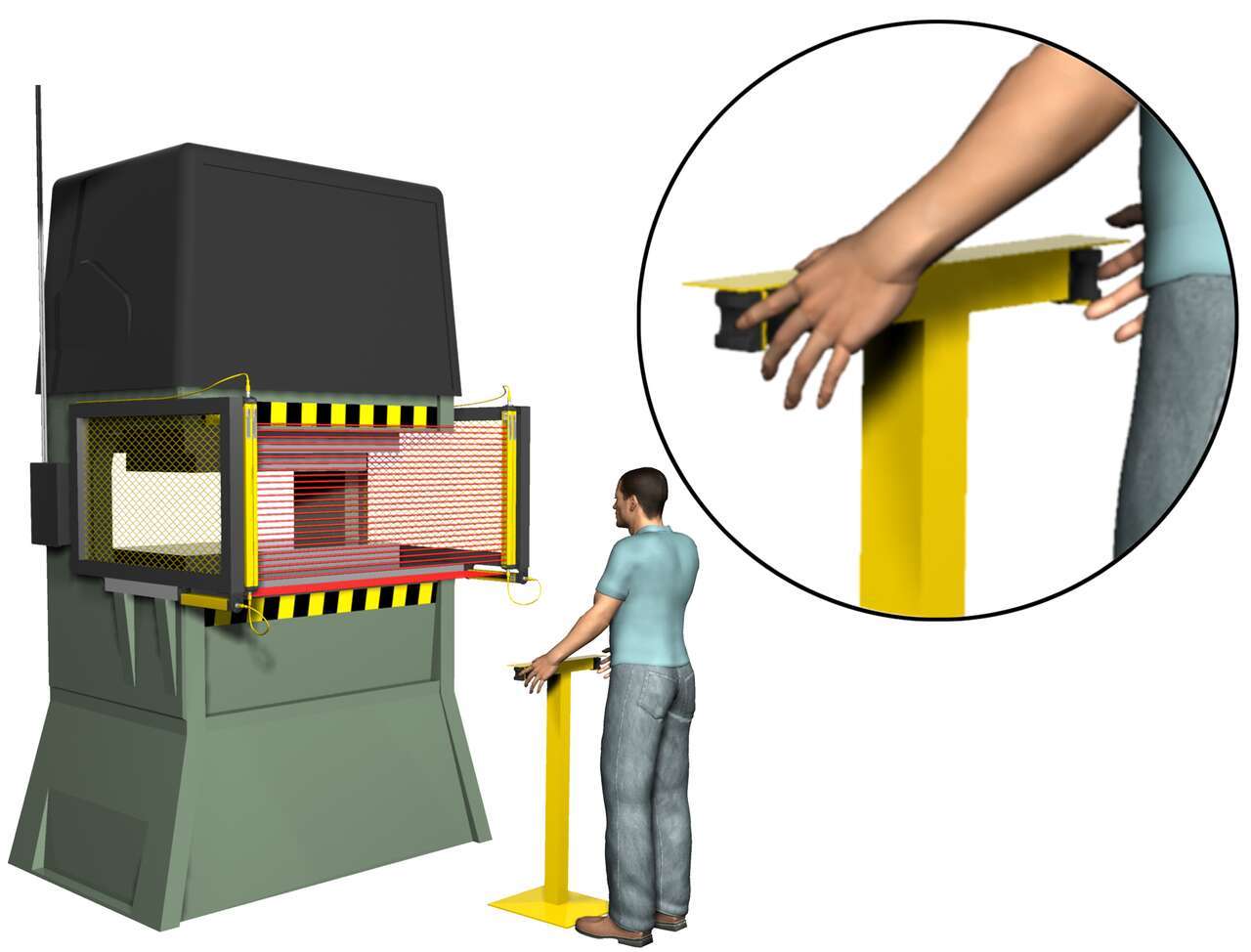

5

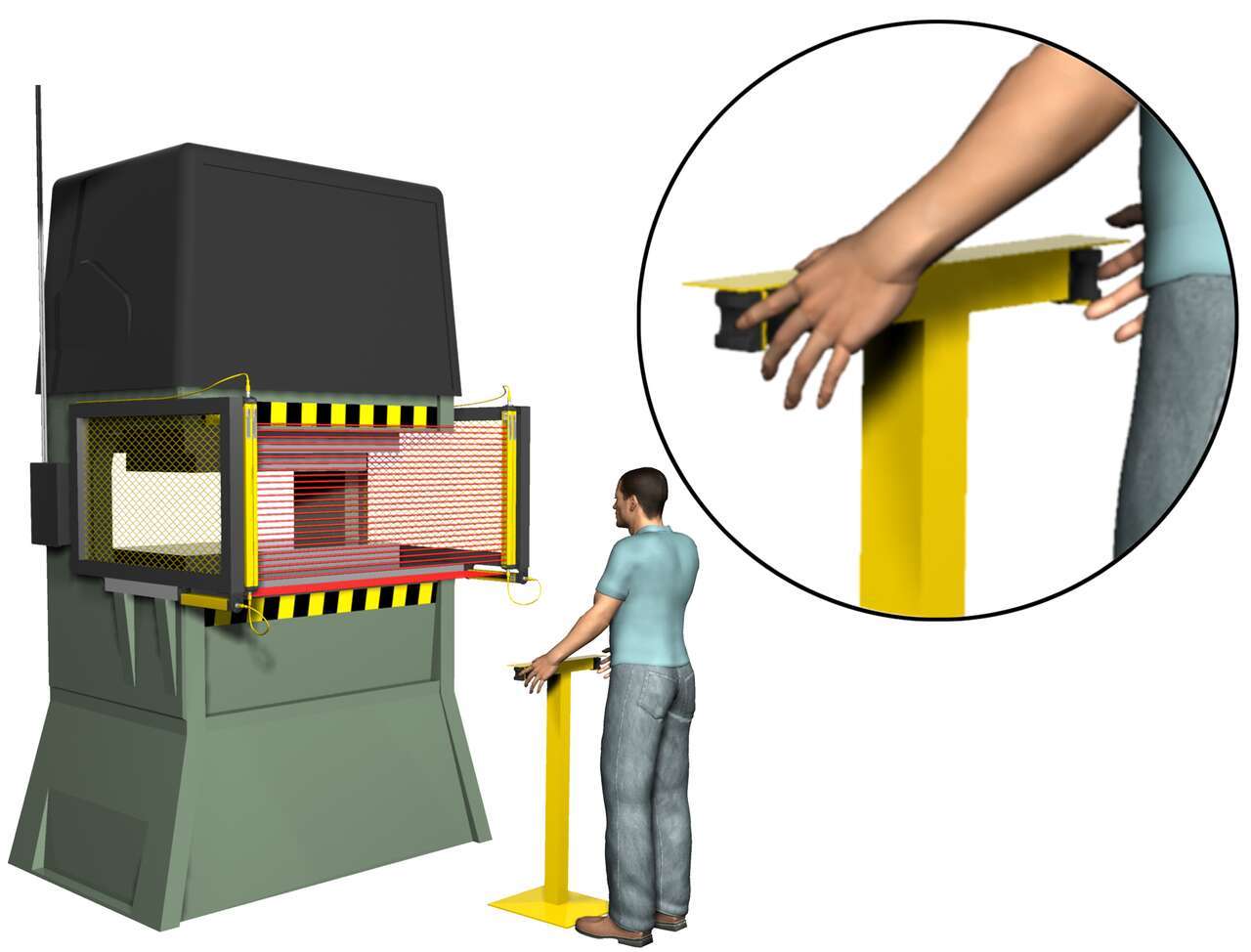

Two-Hand Control Monitoring

A two-hand control safeguarding system will prevent the operator from approaching the machine while a hazard is present. The machine cycle will begin only when the operator touches both Self-Checking Touch Buttons (STBs) within half a second of each other and will continue operation only as long as both hand controls are actuated, thereby assuring that the operator will remain at the control station while the machine is in use.

Learn More

6

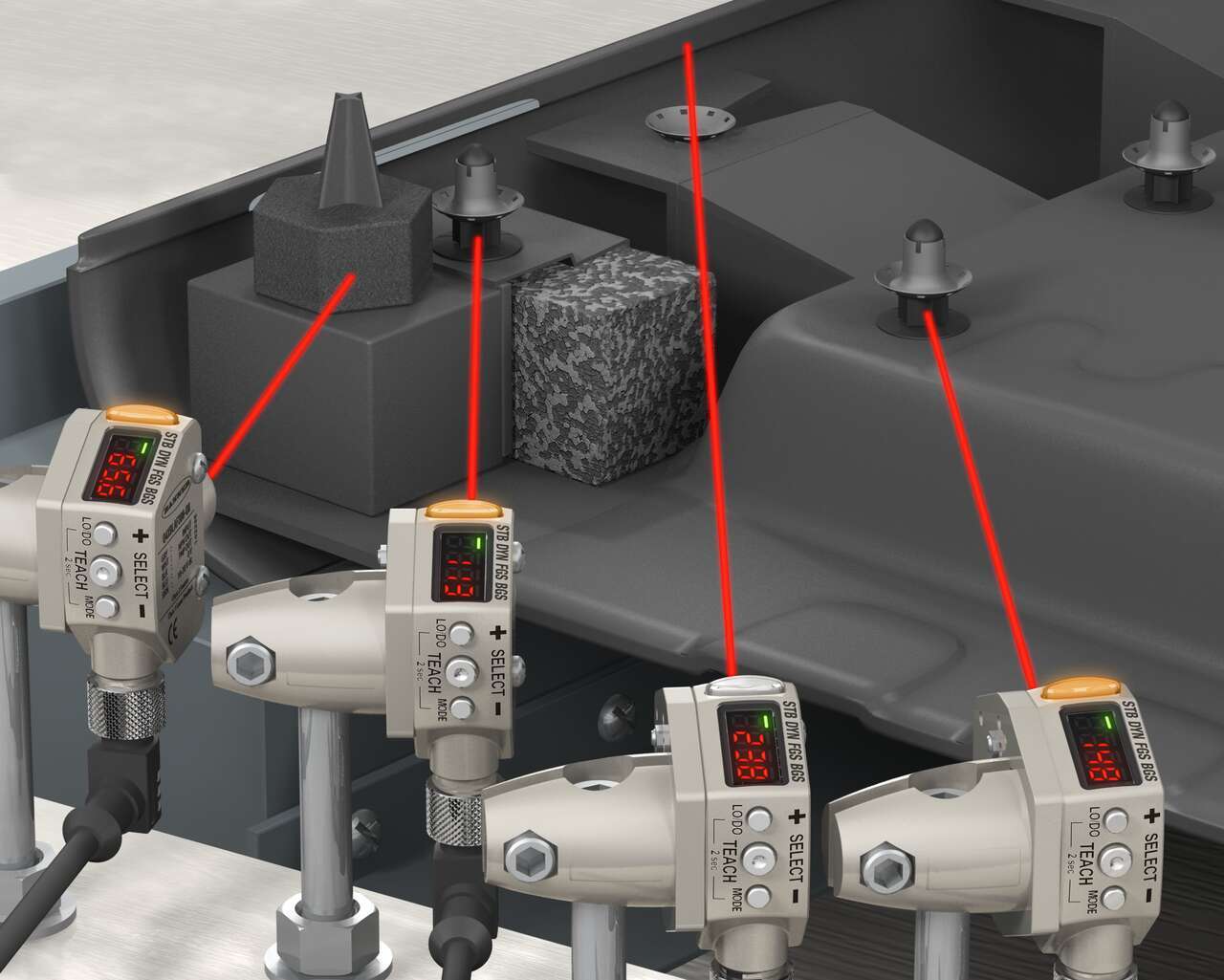

Detecting Black Parts on Black Door Panel

Since door panels are often dark colors such as black or gray, and the foam used to eliminate rattles and provide stiffness is generally black, it can be difficult for standard sensors to differentiate between foam presence and absence due to poor contrast.

Learn More

7

Reading DPM Codes on Automotive Components

Direct part mark (DPM) codes can be small, complex, and difficult to distinguish from the material they are etched into. The ABR 7000 barcode reader is available in models specifically designed to solve challenging low-contrast and DPM applications like this.

Learn More

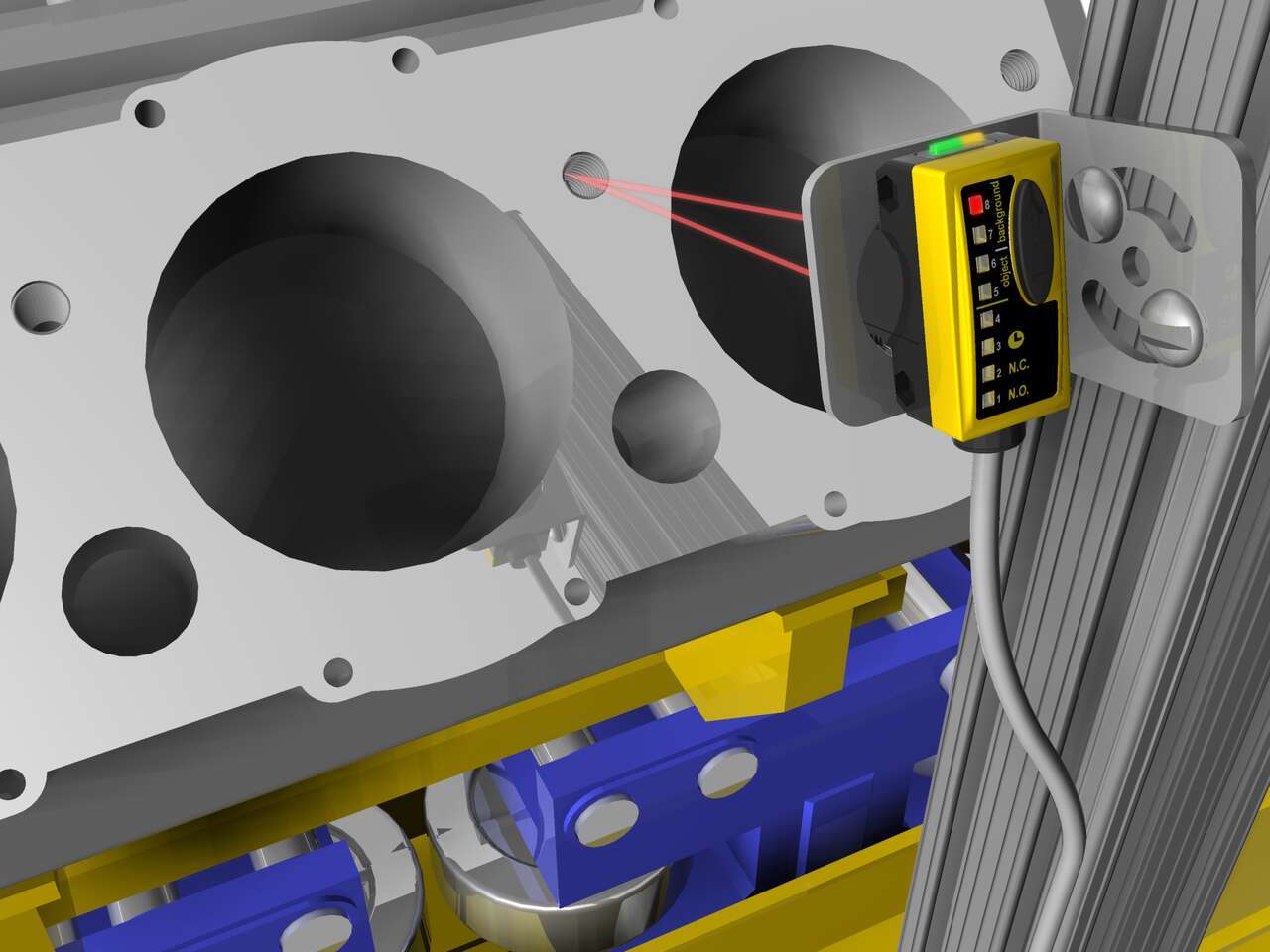

8

Ensuring Part Presence and Position on Car Doors from Afar

High excess gain enables the sensor to detect items from an angle and it has very high accuracy, so even slight variations in target position will be detected.

Learn More

9

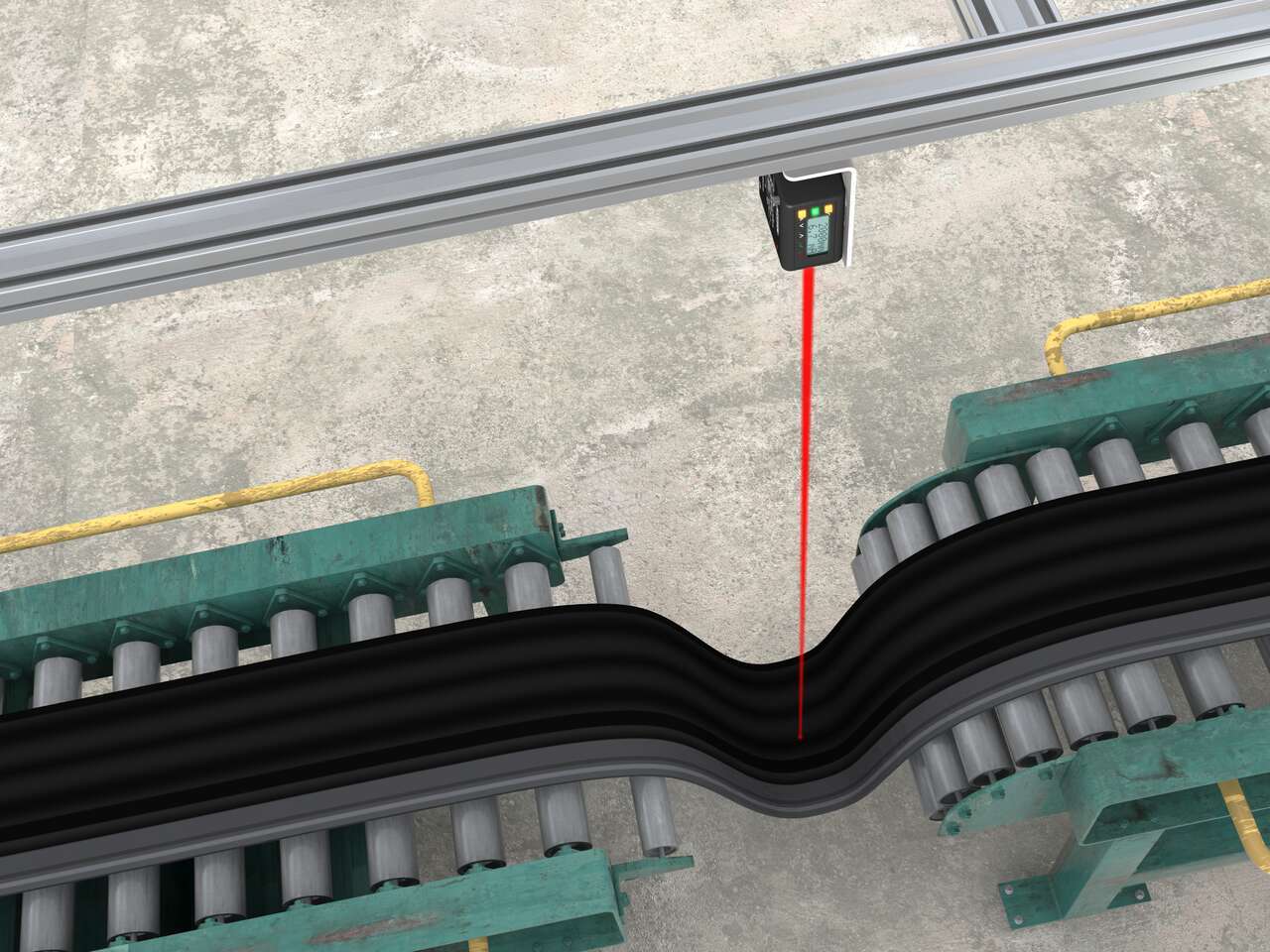

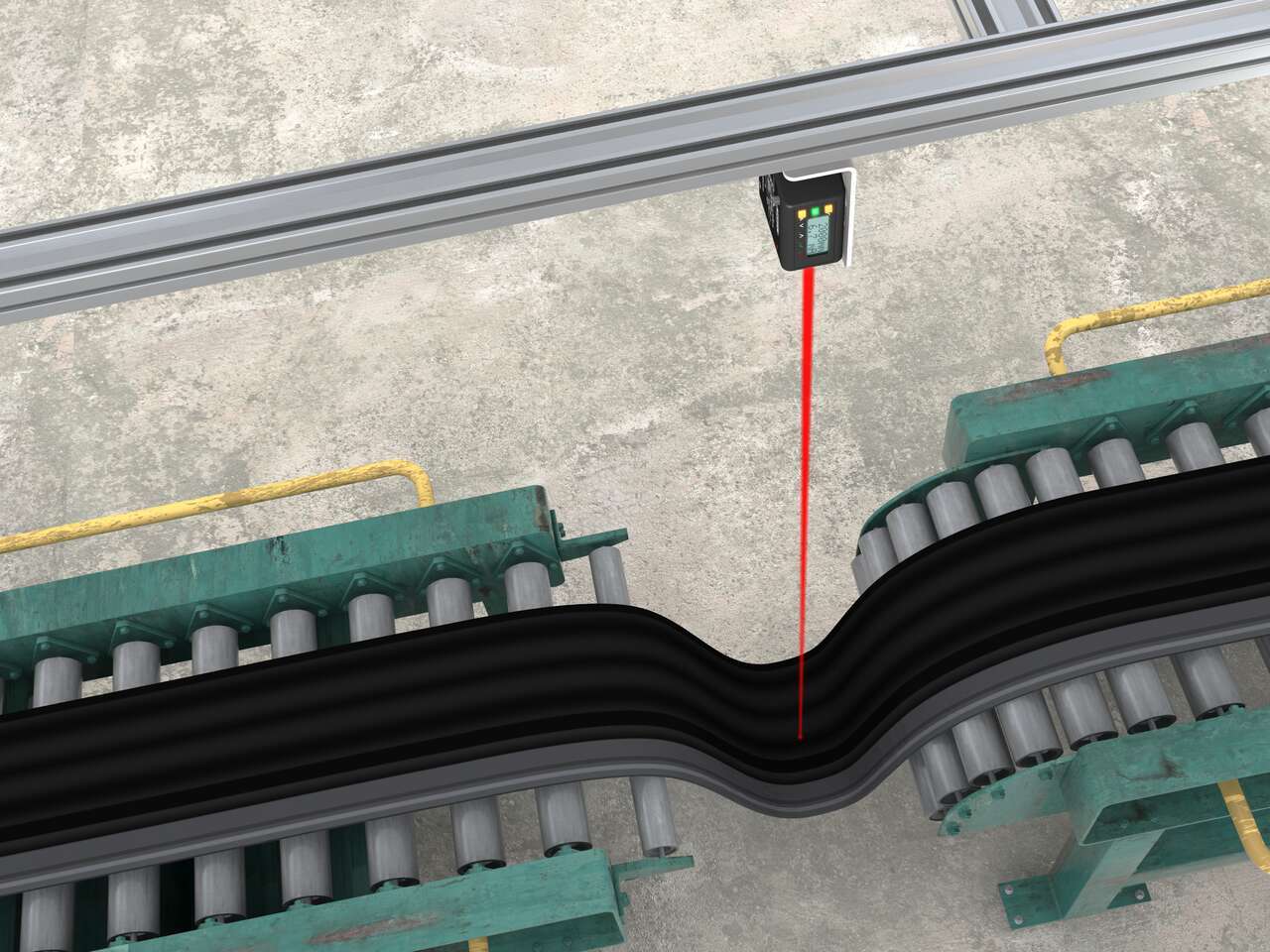

Tire Production: Loop Control for Shiny Black Tread Rubber

Loops must be closely monitored and machine speed adjusted to maintain proper tension on the material.

Learn More

10

LED Lights Illuminate Control Cabinet

Operators access machine systems through the control cabinet and need Intense illumination of the cabinet facilitates for maintenance and management.

Learn More

11

Sensors to Measure Movement Range

During assembly, inspections are conducted to measure seat height adjustment, forward and rearward movement, and upright and recline motion.

Learn More

12

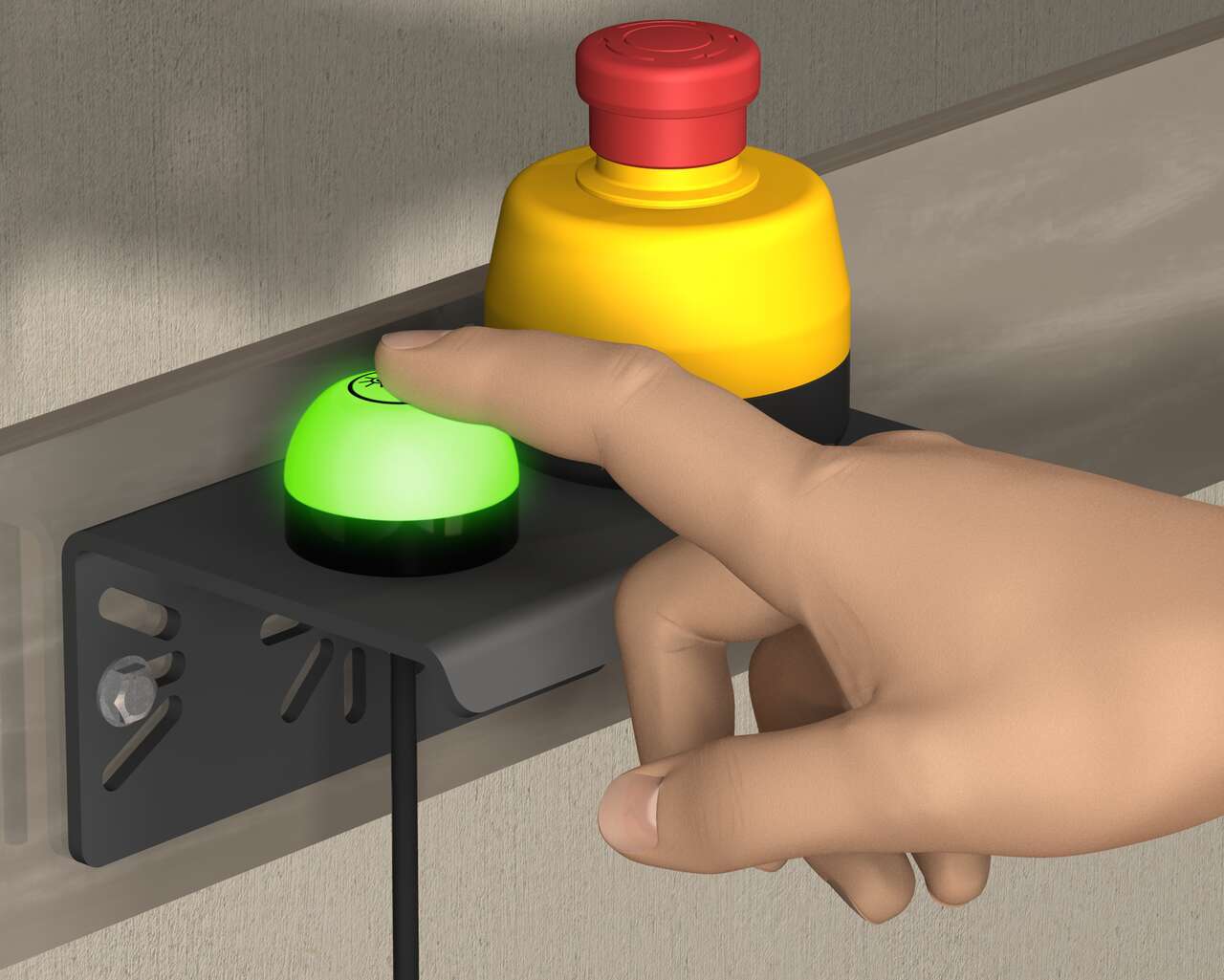

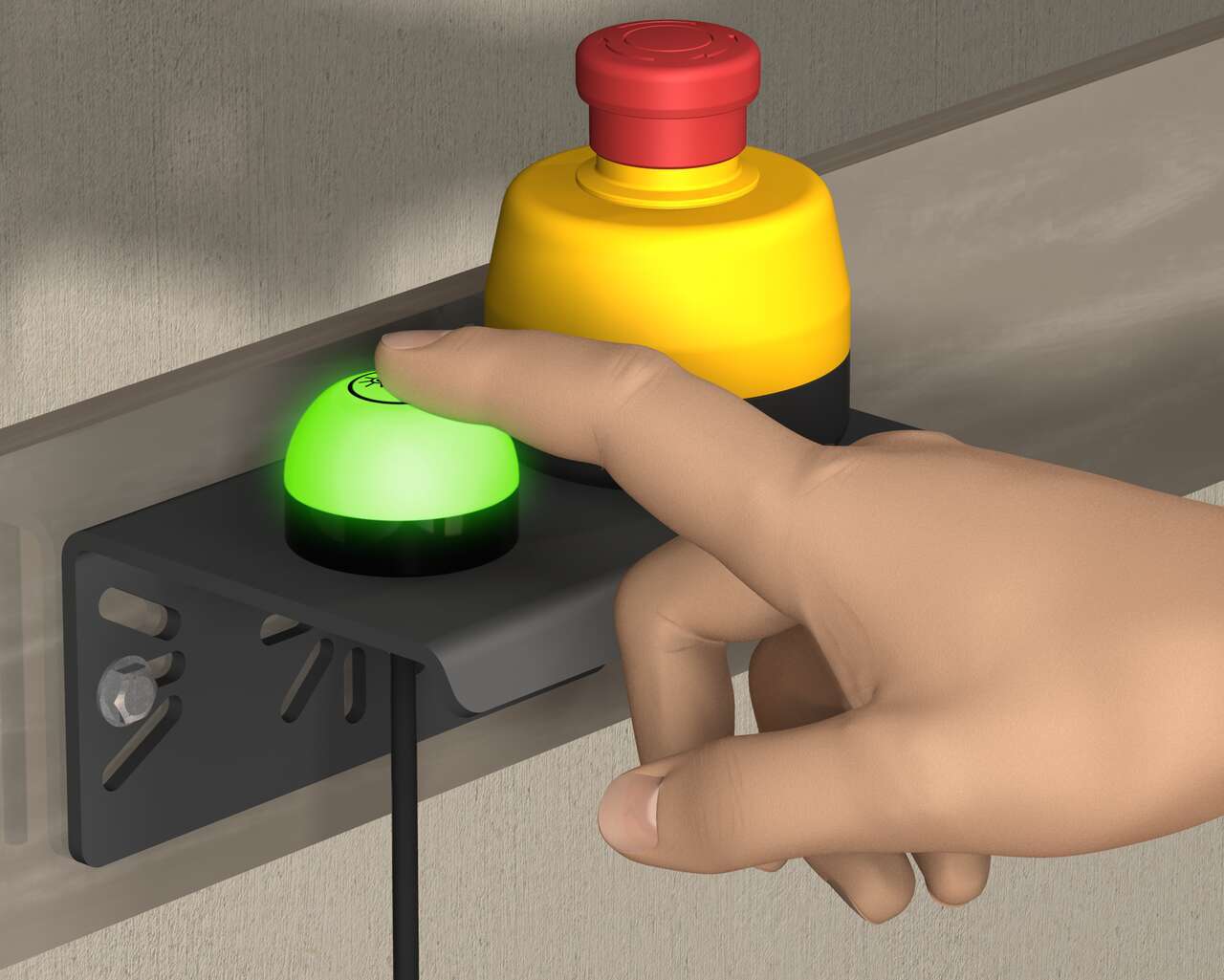

Emergency Stop Indication

With the all-in-one enclosure, the emergency stop pushbutton combined with the K50 Touch lighted indicator communicates simple status indication in emergency conditions.

Learn More

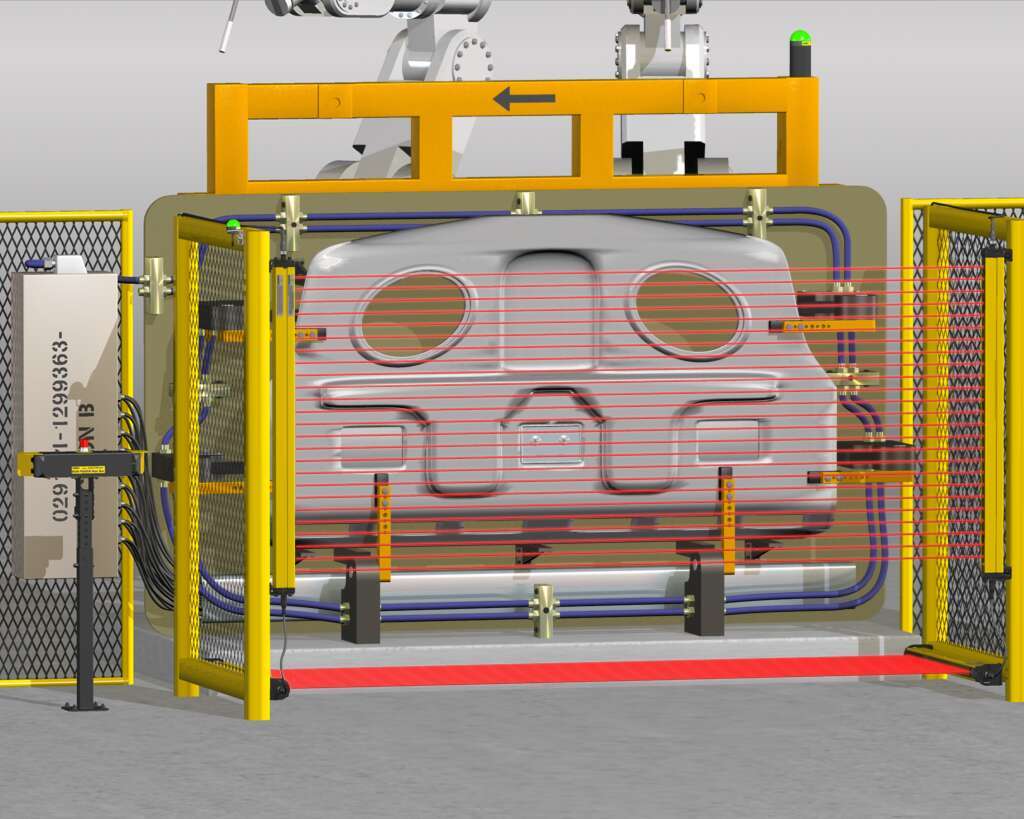

Banner’s EZ-SCREEN® series safety light curtain system is a well established solution for the harsh requirements of welding equipment. With the ability to cascade (series connect) multiple segments together, configurations such as this horizontal/ vertical pair are easily implemented with standard hardware (no master/slave models).

Learn More

14

Detecting a Line of Adhesive on a Vehicle Door Panel

A VE Series Smart Camera, configured to use the bead tool, inspects each door panel for the presence and consistency of adhesive. The camera has a wide field of view and a 2 MP imager capable of detecting even slight inconsistencies in the amount of adhesive applied.

Learn More

15

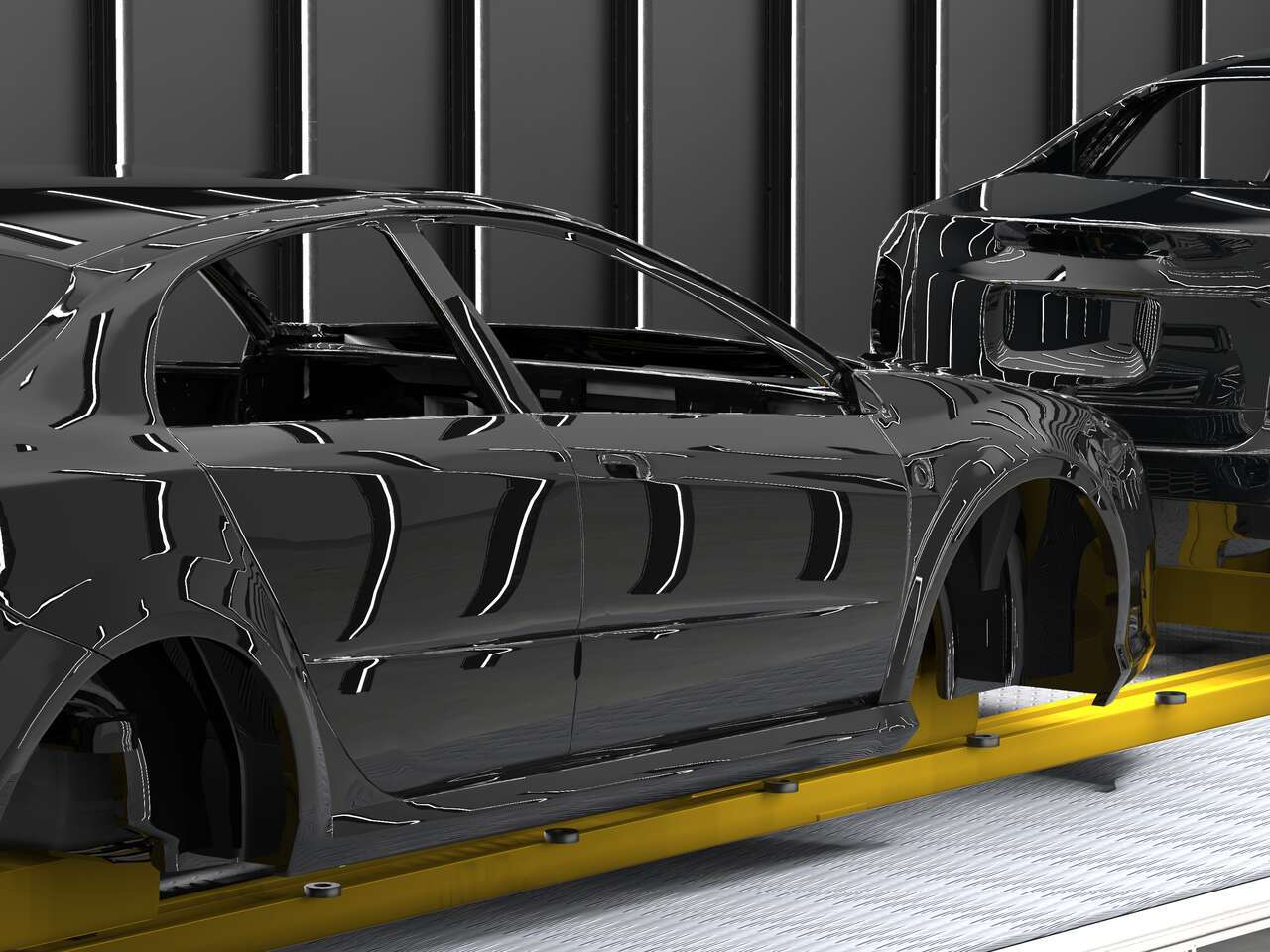

Area and Gate Guarding on Automotive Assembly Line

.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

Integral hinge will stop conveyor once the gate is opened and the grid is muted when gate is opened.

Learn More

16

Predictive Maintenance and Condition Monitoring

Predictive maintenance enables users to more accurately anticipate when machine maintenance will be needed based on real-time data from the machines themselves.

Learn More

17

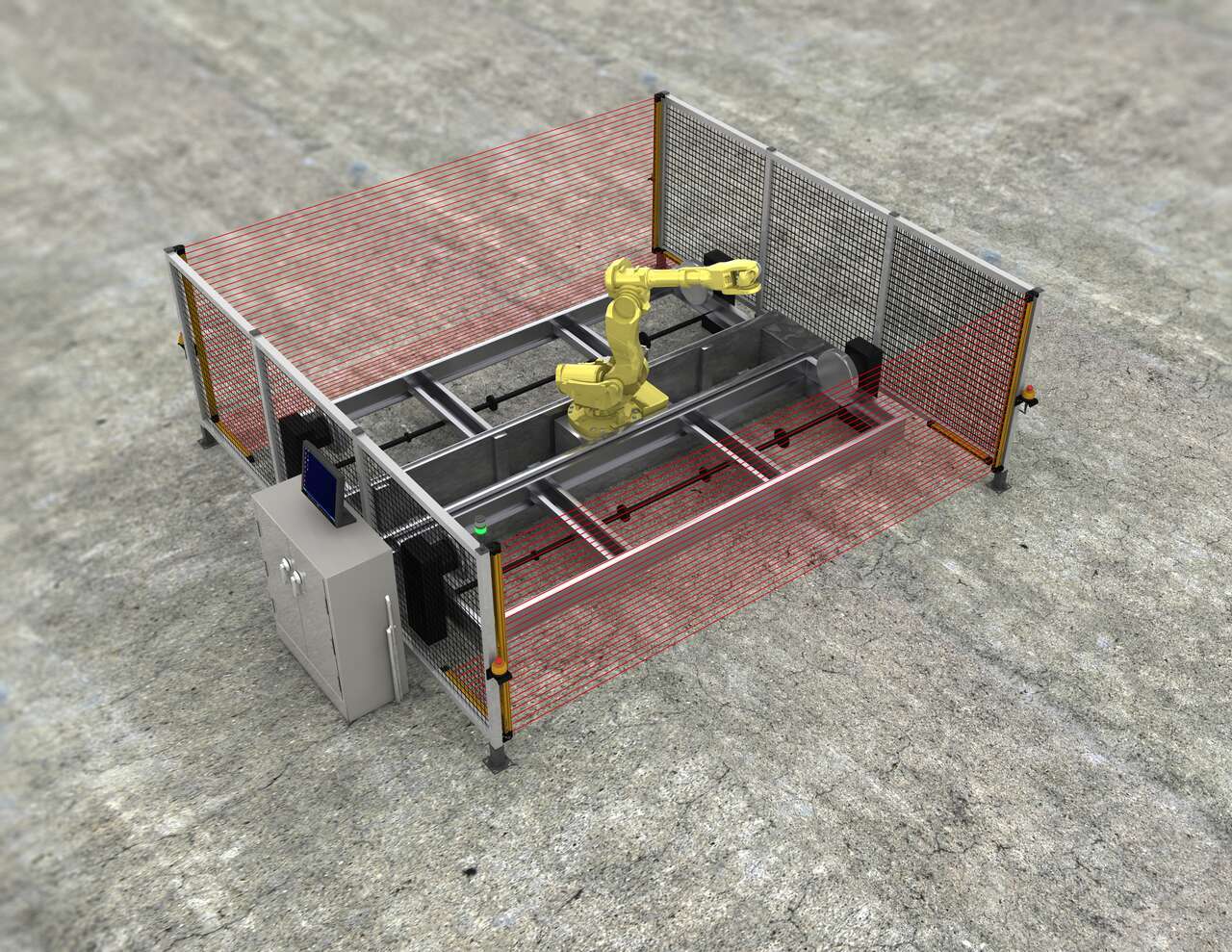

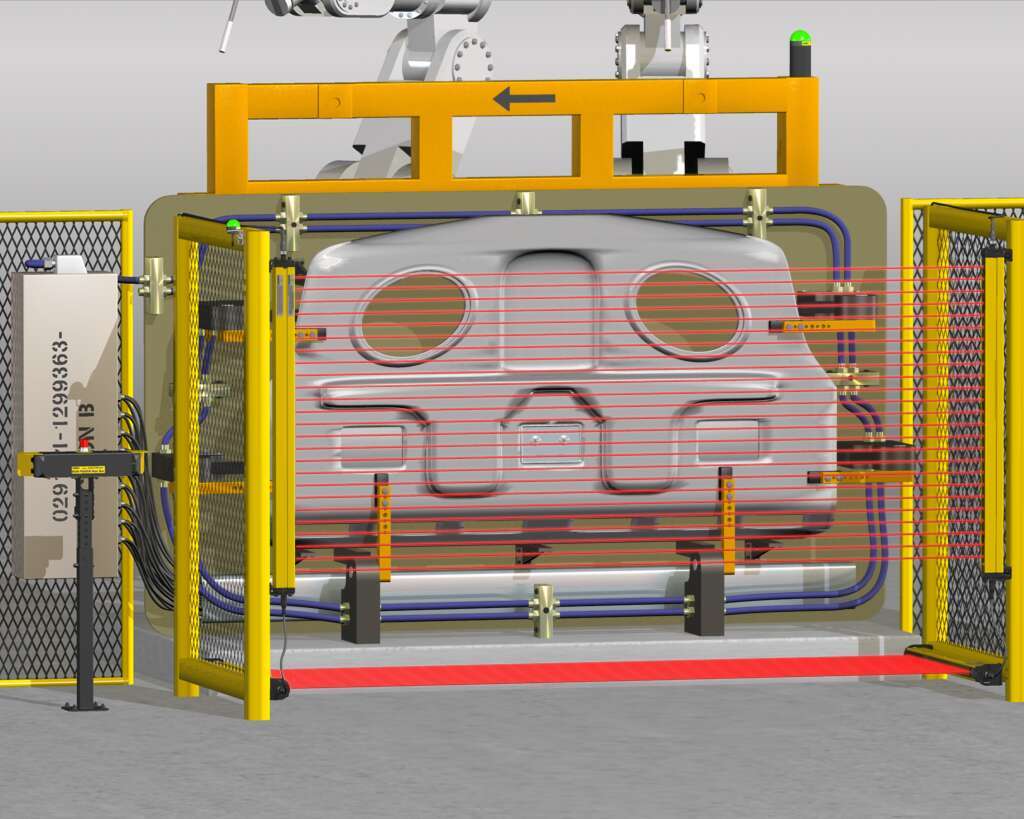

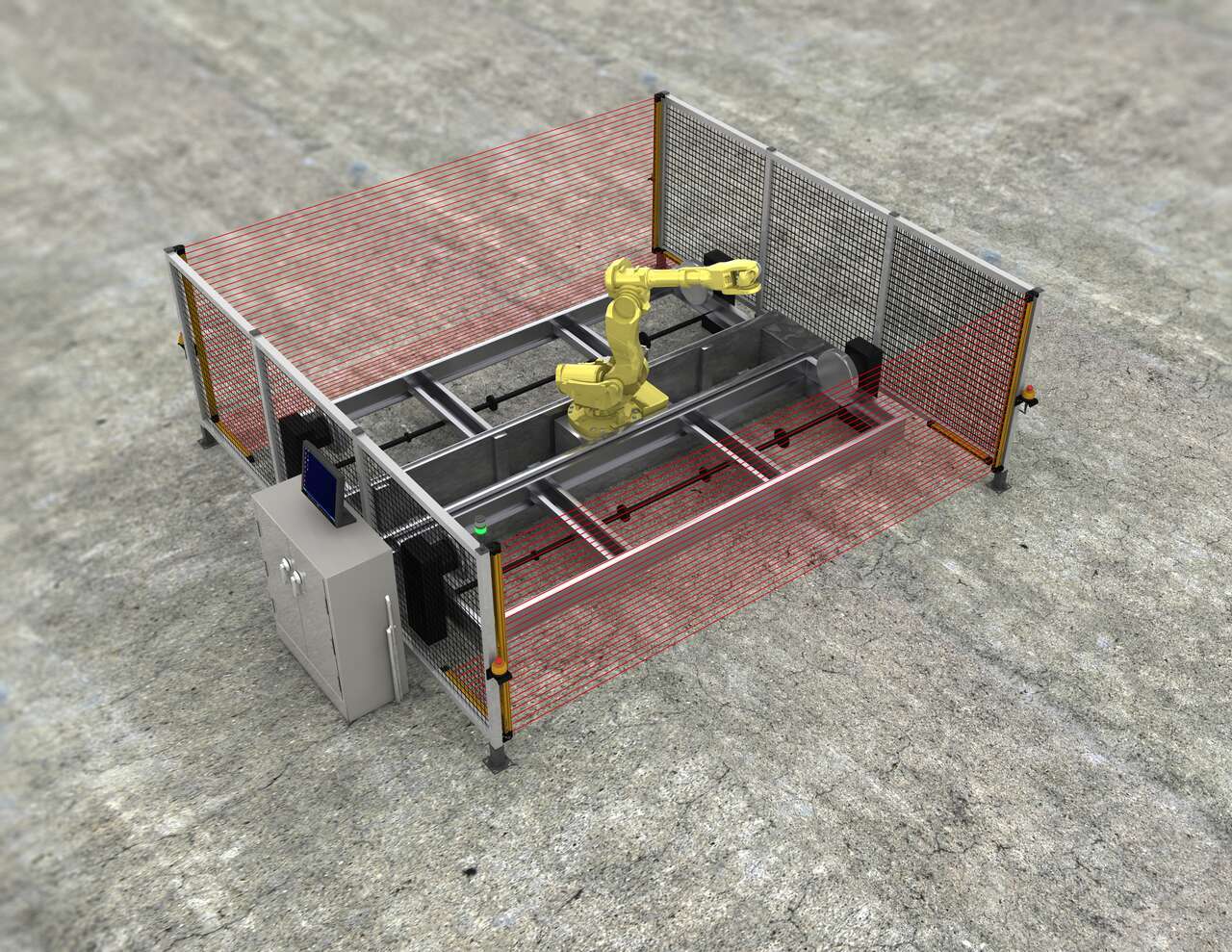

Dual-operator Robotic Work Station

See how Banner’s EZ-SCREEN LS Heavy-Duty Type 4 Safety Light Curtains uses cascading to maximize safety while minimizing cabling and equipment footprints.

Learn More

18

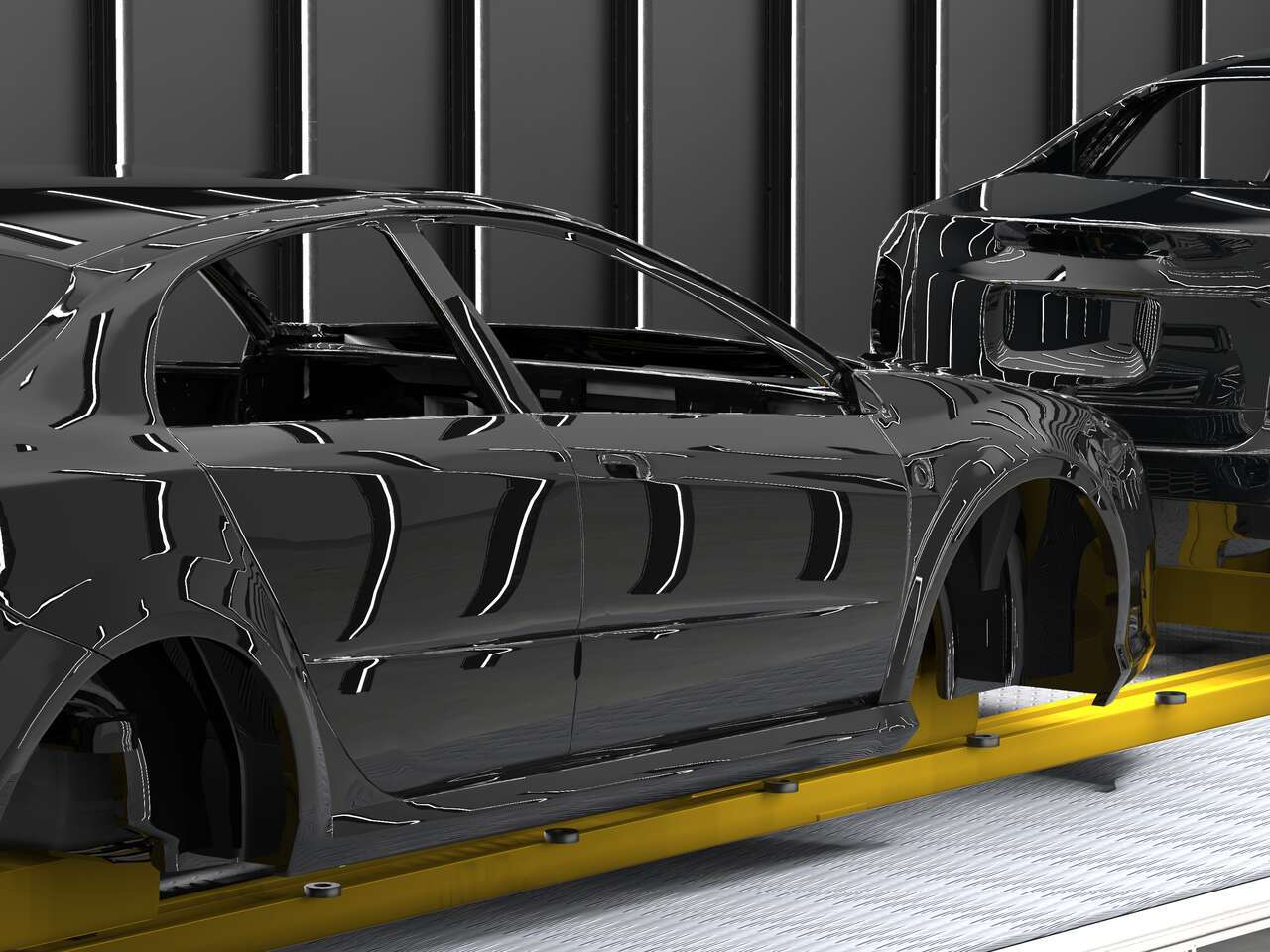

Paint Tunnel Inspection in Motor Vehicle Manufacturing

Inspection with high quality illumination, identifies vehicles needing additional work to ensure the highest quality paint finish.

Learn More

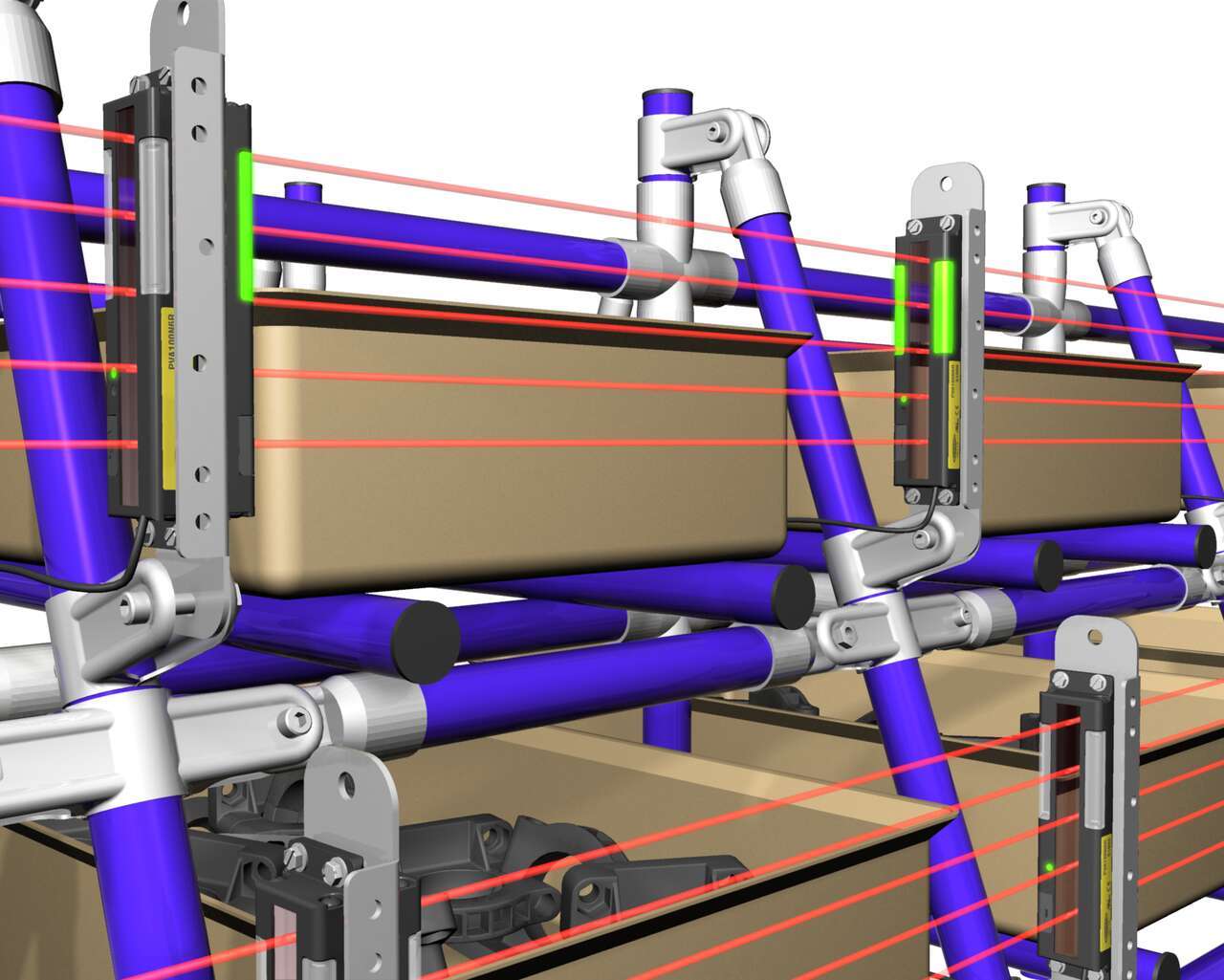

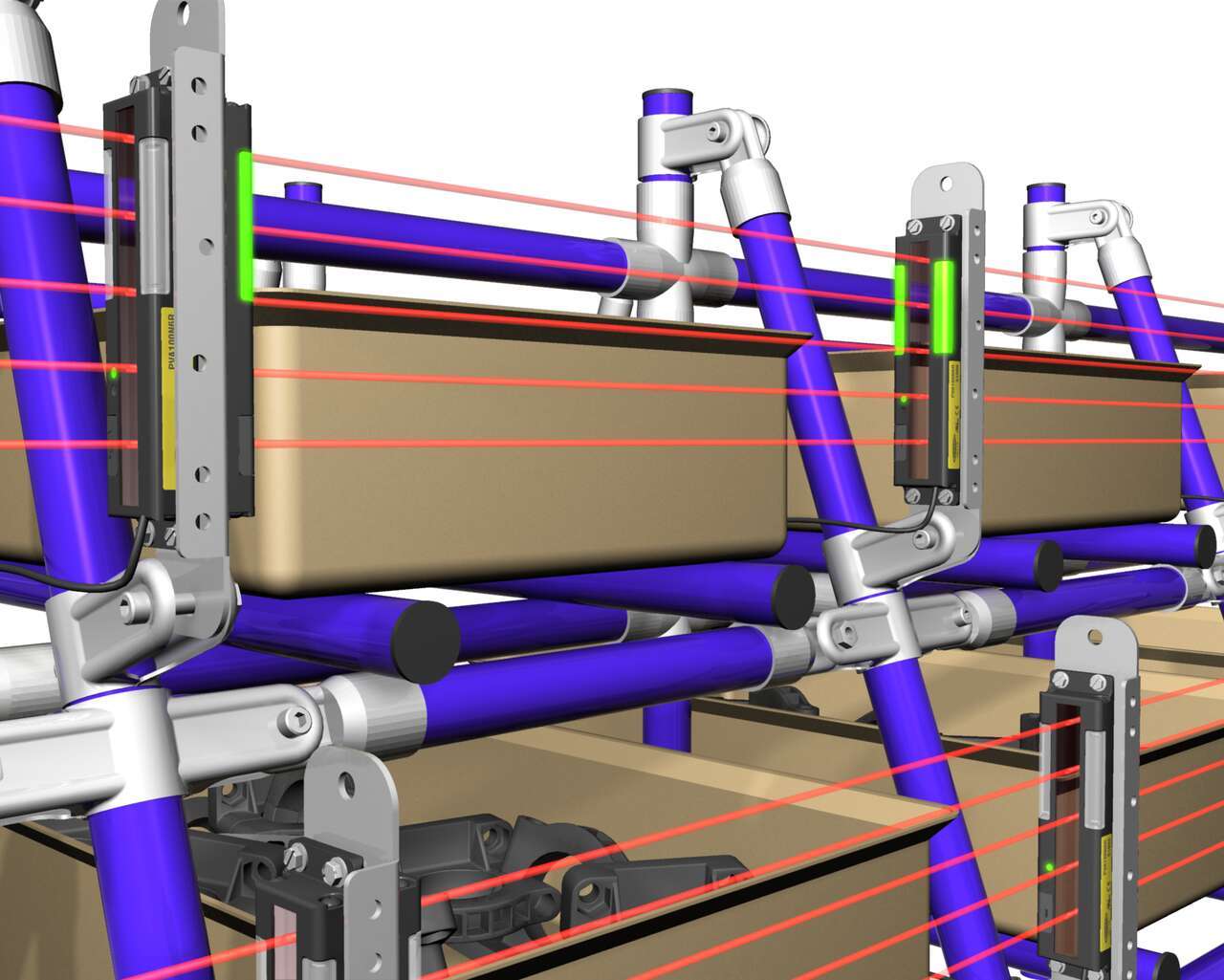

The EZ-LIGHT PVA pick-to-light sensors provide a reliable error-proofing solution for various operation systems. The light indicate to assemblers which items to pick and in which order to pick them.

Learn More

20

Assembly Timer Indication at Automotive Assembly Station

The TL50 Pro tower light helps assemblers meet expected cycle times and support overall takt time requirements.

Learn More

21

Call for Parts, Service, or Pallet Pickup

Increase production efficiency by developing a wireless call-for-parts, service, and Andon system that allows for up to 35 work stations to call out to 12 forklifts/Hi-Los using the EZ-Light K70 Touch to wireless Direct Select operator interface.

Learn More

22

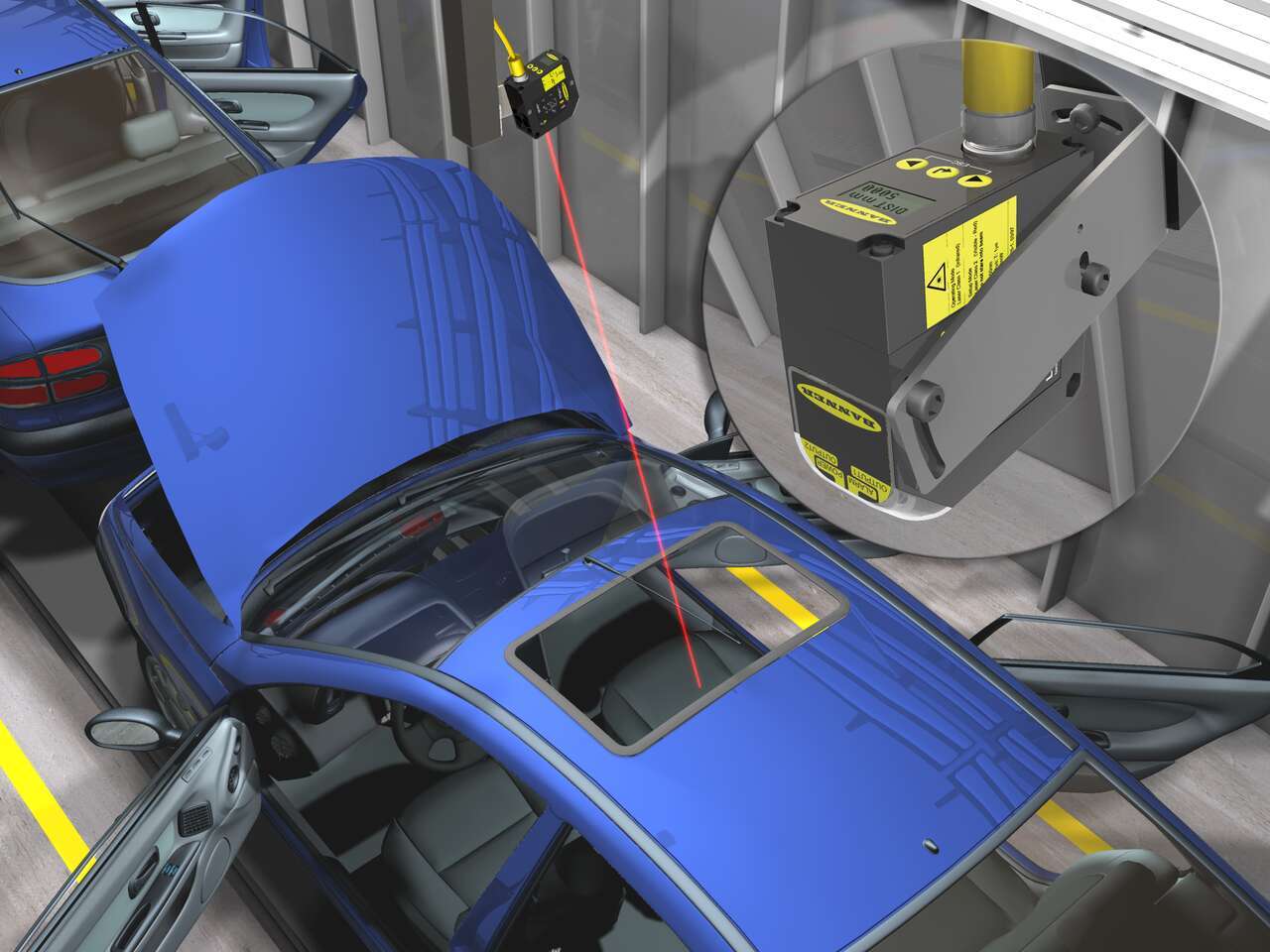

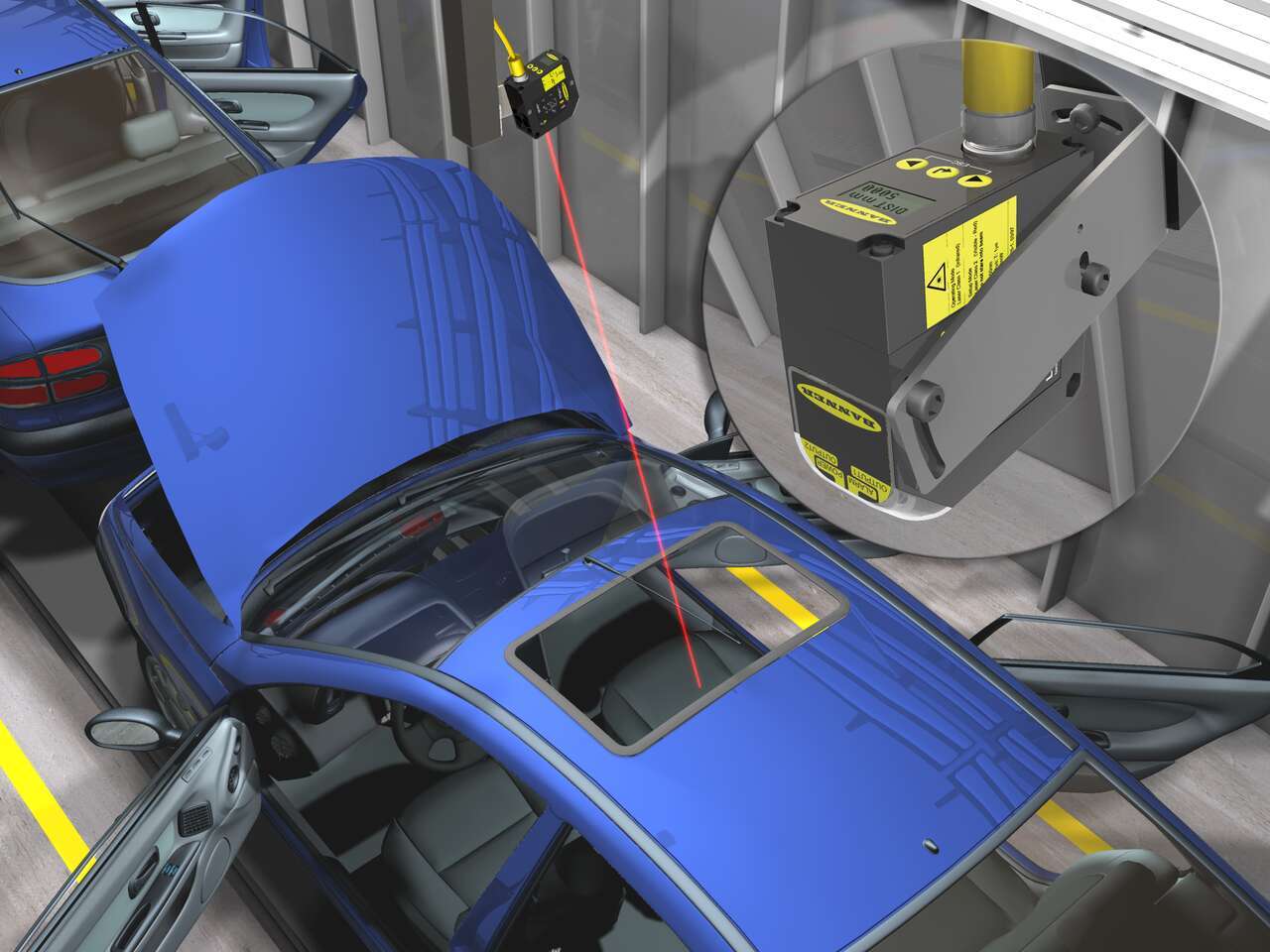

Long-Range Inspection in Automotive Assembly

As vehicles move forward on an automotive assembly line, an L-GAGE LT7 time-of-flight laser sensor is directed inside the sun roof to verify that the car seat has been installed and is in the correct position.

Learn More

23

Detect Installed Glass on Automobile

.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

Sensor solutions to detect the presence of a moonroof on an automobile assembly line where extended range capabilities are required.

Learn More

24

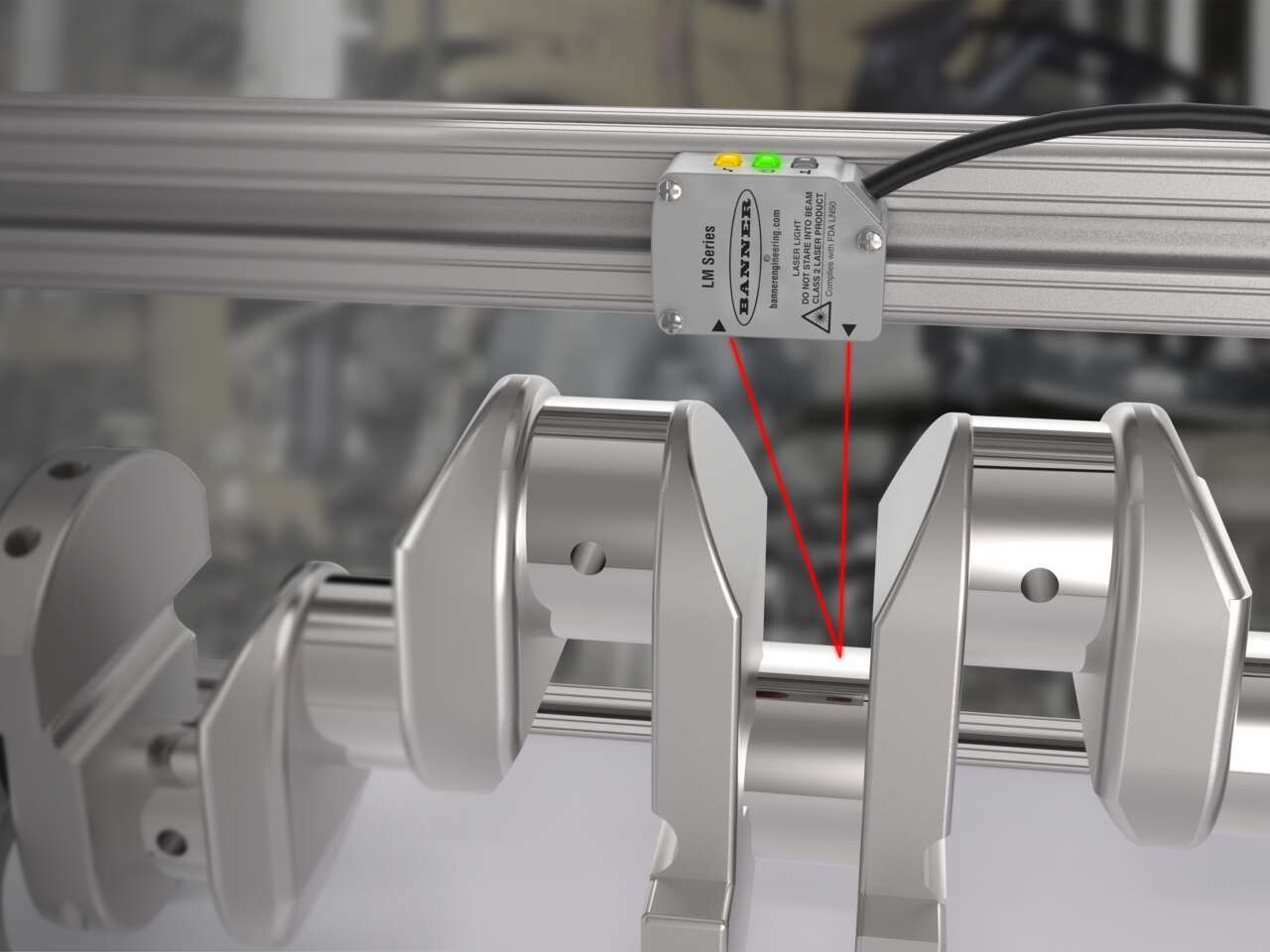

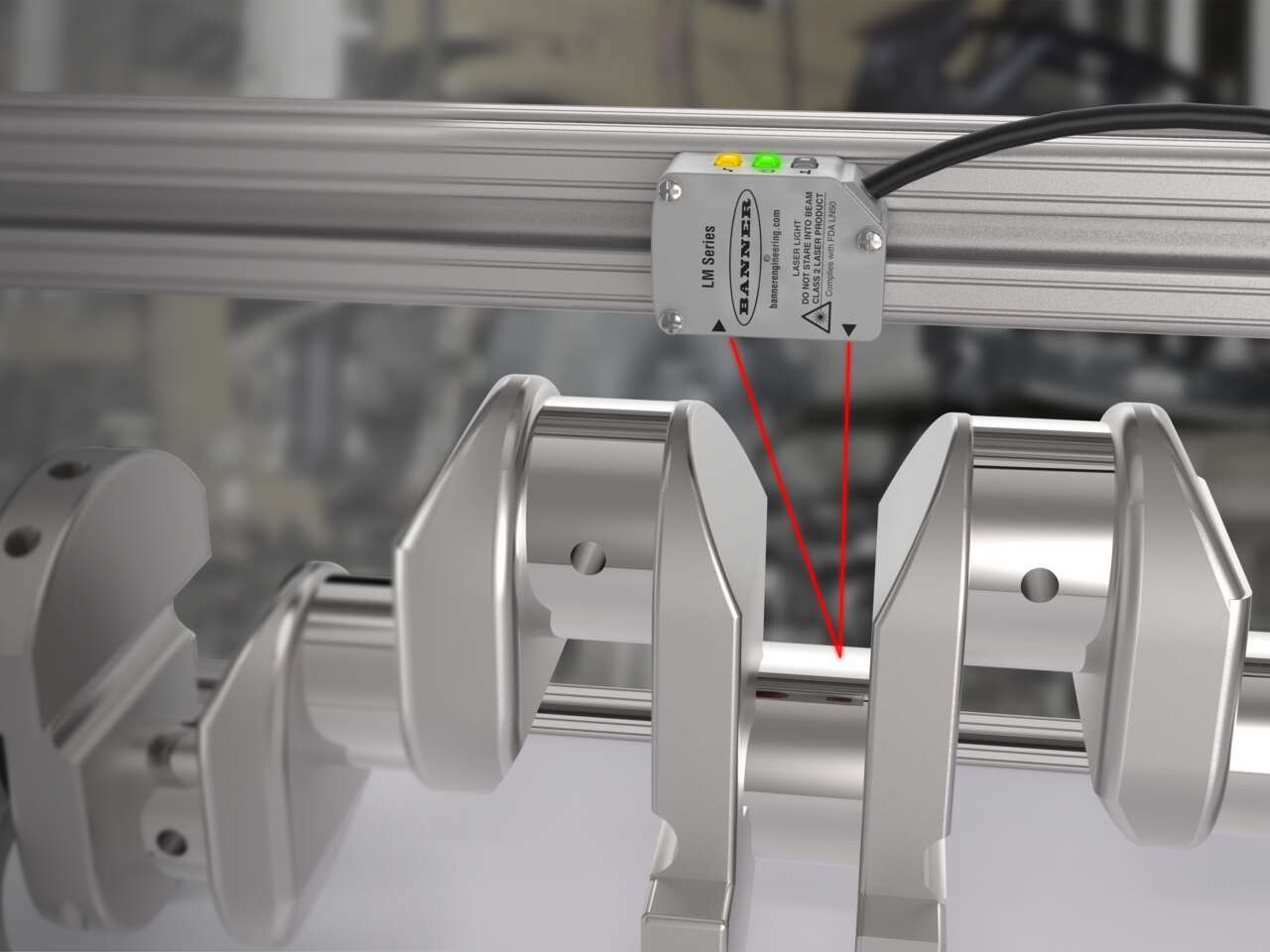

Precise Crankshaft Runout Measurement

Crankshaft runout measurements must be monitored continuously to ensure that they meet tolerance requirements. Learn how LM Series laser measurement sensors solve this difficult application.

Learn More

25

Overall Equipment Effectiveness (OEE) Solutions

Remote monitoring capabilities provide data for OEE calculations, making it easier for manufacturers to identify and remedy causes of waste within their facilities.

Learn More

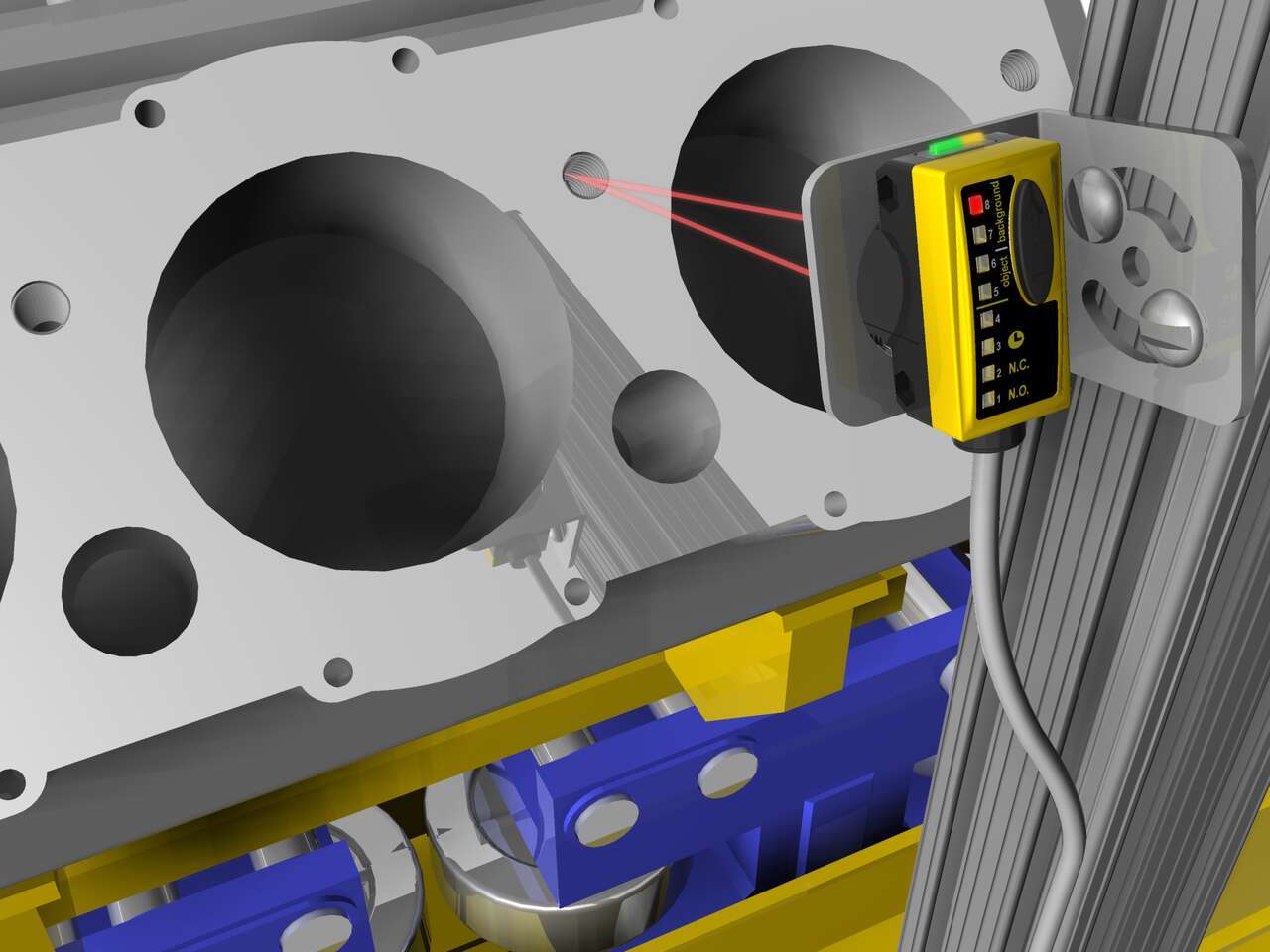

The WORLD-BEAM QS30's narrow laser beam can prevent these mistakes from happening it is necessary to verify, from a distance, that bolt threads have been cut into holes in a manifold.

Learn More

.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

.jpg/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)