Level Measurement

Accurate Level Measurement Saves Costs

Accessing accurate level data from containers, hoppers, and tanks is critical to managing inventory, securing contents, assuring quality and safety, and saving costs.

Banner solutions for measuring and monitoring fill and material levels are available in a range of sensing technologies to optimize detection for each unique target and environment.

Used in combination with our wireless products, these solutions provide accurate, real-time data from assets deployed in remote and hard-to-access areas.

Reliable level detection is critical for a wide range of applications. For example, a dependable level measurement solution can:

- Ensure material is not wasted in spills due to overfill, which saves time and costs.

- Protect equipment from damage due to underfilling

- Prevent unplanned downtime and keeps processes moving along smoothly by predicting when containers will run out and enabling them to be refilled in a timely manner.

- Ensure customers and end users receive the correct amount of product, which improves customer satisfaction.

However, level measurement can be challenging due to the wide variety of materials, the location of containers, mounting contstraints, and more.

From precise measurement solutions to wireless solutions for remote tank level monitoring, Banner Engineering offers a variety of technologies to match your level measurement application. See a few examples below, or contact us to discuss your specific application.

Measure Level of Material in a Stack

- An accurate sensor is needed to monitor the stack height of the carton blanks in the magazine to ensure the stack is not empty and prevent downtime.

- A smart sensor, like the Q4X sensor, can accommodate changes in carton size and machine speed to help reduce downtime for setup and changeovers.

- The analog output provides a real-time gauge of the stack height. This allows the cartoner machine to have several “call for parts” set points without having to manually move the sensor.

- With exceptional linearity and a four-digit display, the Q4X sensor provides real-time feedback with an analog (V or mA) or distance (mm) readout.

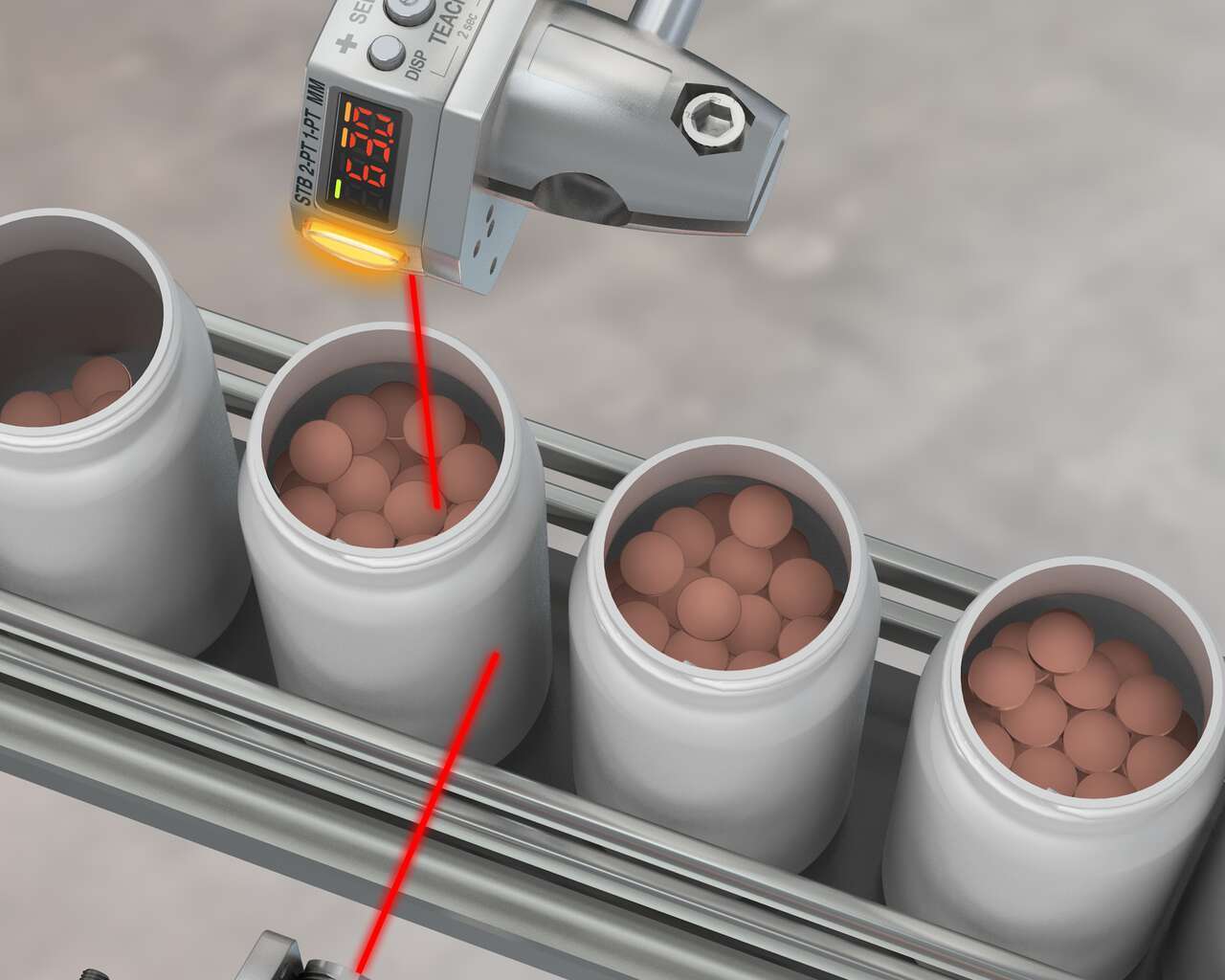

Monitor Level of Material in a Hopper

- For long-range level detection applications, an LTF Series laser measurement sensor can be installed up to 12 meters away from the target

- At this distance, the sensor will not interfere with system operations or come into contact with the equipment or process.

- The sensor features high excess gain, superior signal control and automatic adaptive laser power control for reliable detection, regardless of surface color or reflectivity.

- The exceptional linearity, repeatability and resolution of LTF series sensors ensure tremendous accuracy in measuring the distance from the sensor to the material in the hopper.

- The laser sensor can be paired with a TL50 Pro tower light to provide dynamic status indication of hopper fill level, for monitoring at a glance even from a distance.

Monitor Liquid Levels in Tanks

- Storage tanks, totes, and containers can be found in a wide variety of environments, from indoor or outdoor installations to above or below ground deployments.

- Properly monitoring and managing levels inside these tanks can help increase productivity and profitability.

- A wireless ultrasonic sensor uses sound waves to detect objects, for a non-contact level measurement solution.

- Ultrasonic sensors are also immune to target color, reflectivity, or transparency.

- Wireless communications open up additional benefits including saved time and costs, real-time remote monitoring, and adaptability to meet changing requirements.

Rugged Laser Distance Sensor

Sensores de distancia láser versátiles y robustos que ofrecen un rendimiento superior y son capaces de detectar cambios en la distancia de un milímetro.

- Salida discreta, analógica (0 to 10 V or 4 to 20 mA), para detección de objetos claros y modelos de IO-Link.

- Rango de detección confiable desde cerca de 25 mm y hasta 610 mm

- Detecta objetivos en una gran variedad de colores, materiales y superficies basado en la distancia

- El modo de enseñanza dual (intensidad + distancia) es ideal para aplicaciones de corrección de error y permite la detección de objetos claros sin necesidad de un retro reflector.

- Carcasa robusta de acero inoxidable clasificada IP69K grado FDA

Laser Measurement Sensor

La tecnología de arreglo lineal de la serie LE proporciona un gran desempeño y una gran resolución, independientemente del color o brillo de los objetivos.

- Listo para medir al momento en que sale de la caja

- Ajuste fácil e intuitivo con una pantalla de dos líneas y 8 caracteres

- El arreglo lineal proporciona exactitud y repetibilidad para objetivos desafiantes

- Láser visible para un tamaño reducido del punto y una fácil alineación

- Modelos con IO-Link disponibles

LTF Series

Long Range Laser Measurement Sensor

La serie de sensores LTF de alto rendimiento detecta objetos a una distancia recta o en ángulo, hasta a 24 metros de distancia sin importar el color, material o brillo.

- Salidas Analógicas y Discretas para aplicaciones de medición y detección

- La combinación de rango, repetibilidad y precisión lo hace el mejor de su clase, permitiendo una detección de objetivos altamente confiable y una medición de distancia exacta.

- Cuenta con una pantalla de dos líneas de 8 caracteres y con botones de programación para una fácil configuración, resolución de problemas y para visualizar la medición de distancia en tiempo real

- Una carcasa clasificación IP67, una alta inmunidad a la luz ambiental y un funcionamiento estable aún en cambios de temperatura le proporcionan un desempeño fiable en entornos difíciles.

- Opciones avanzadas, incluyendo retardos, modos de medición avanzados y evitación de interferencias

- Disponible en modelos con comunicación IO-Link que permite la configuración y monitoreo remoto y simplifica el cableado, el mantenimiento preventivo y el reemplazo del dispositivo