Roll Diameter and Tension Control

Ensure Quality and Reduce Unplanned Downtime

Maintaining the correct level of tension on web materials is critical to ensure quality and minimize material breakage, wandering, and other process issues that can lead to unplanned downtime.

Measuring roll diameter is fundamental to maintaining the correct amount of web tension. Variations in materials, material color, translucence and reflectivity, and environmental conditions can challenge a sensor’s ability to detect and measure these targets.

Banner provides a range of sensing technologies capable of accurately and consistently measuring roll diameter to ensure the correct level of web tension.

Choosing a Sensor for Roll Measurement

Accurate roll diameter measurement and monitoring controls tension by enabling dynamic adjustment of wind and unwind speeds proportional to the change in the size of the roll. This protects materials from damage due to too much or too little tension. However, monitoring roll diameter accurately can be challenging, since this application requires an extremely linear output across the entire range of the sensor.

Linearity refers to how closely a sensor’s analog output approximates a straight line across the measuring range. The more linear the sensor’s measurements, the more consistent the measurements across the full range of the sensor. That is, the more linear the sensor, the more the output shows the correct change along a line of measurement.

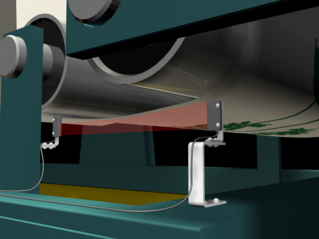

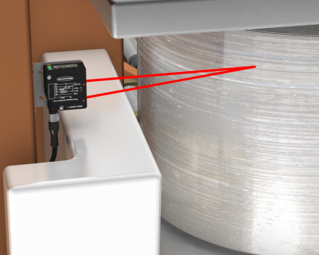

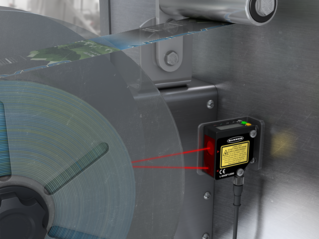

In the image to the left, the two-point teach option on the LE laser sensor is used to teach a full (4 mA) and an empty (20 mA) roll. The analog output provides a real-time gauge of the roll diameter. The more linear the sensor is, the more reliable the measurements between a full and and an empty roll. With perfect linearity, half of the roll would be gone when the sensor gives 12 mA. Sub-millimeter linearity is critical for reliable roll diameter monitor for tension control applications.

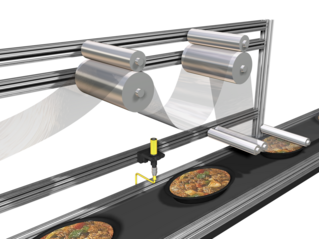

Roll Diameter Monitoring for Multicolored Labels

- In consumer packaged goods industries, labels need to be applied to the products quickly and without error to keep production levels high.

- Accurately monitoring the diameter of a roll of labels and controlling the unwinding speed helps ensure that the process runs smoothly.

- A solution is needed that can accurately report the material level on a roll in order to prevent it from running out and delaying production.

- A laser distance sensor, like the Q4X series, which is unaffected by color transitions and has an extremely linear output, can reliably monitor rolls of multicolored labels.

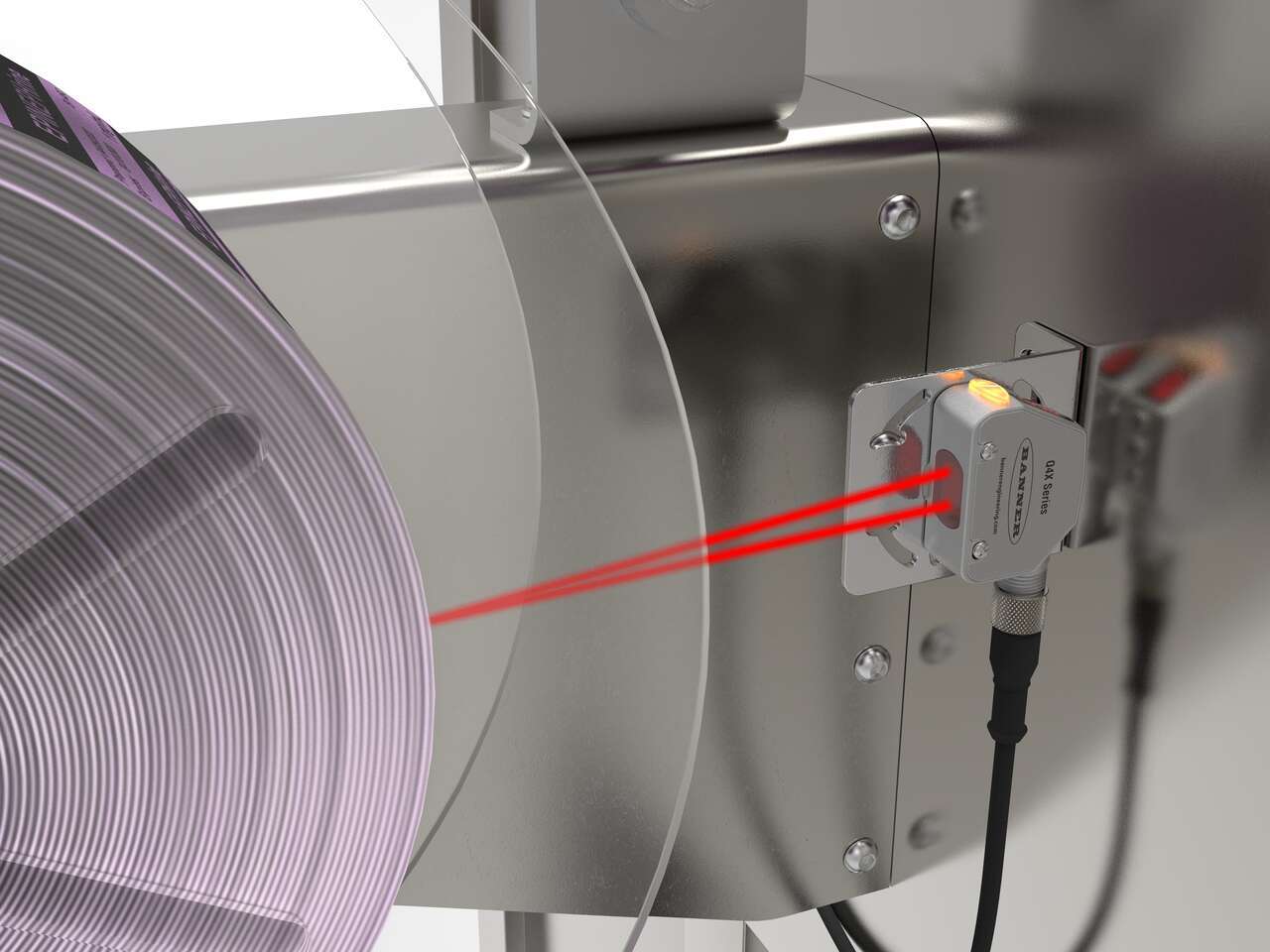

Shrink Wrap Roll Diameter Measurement

- Accurately determining the diameter of a roll of shrink wrap is essential to prevent material from running out during the shrink wrapping process and ensuring proper tensioning.

- As pallets enter the shrink wrapping station, a reliable solution must provide accurate data to alert operators if the roll of plastic wrap is running low.

- The LE Series provides accuracy and repeatability when measuring challenging targets, like clear and reflective plastic, for reliable measurement of the shrink wrap rolls.

- The analog output can be used to control wind or unwind speeds on the shrink wrap roll. The discrete output can be used to alert operators that the roll is almost empty.

Measuring Paper Rolls in a Range of Colors

- Prior to being packaged, paper table coverings of varying colors, including very dark colors, are unwound from large rolls and cut to size.

- Insufficient or excessive tension can damage the table coverings, making them unsellable. To maintain the proper level of tension, the unwind speed must increase proportionately to the shrinking size of the roll.

- The LE Series laser sensor reliably measures each roll, regardless of paper color, even extremely dark colors. The superior linearity, repeatability, and resolution of the LE550 ensure reliable and consistent roll measurement and output.

- Out of the box, the LE550 automatically scales across its entire operational range, from 100 mm to 1000 mm. The LCD display provides real-time measurement and output information and makes it easy to assign set points and output levels.

1 m Laser Displacement Sensor

La tecnología de arreglo lineal de la serie LE proporciona un gran desempeño y una gran resolución, independientemente del color o brillo de los objetivos.

- Listo para medir al momento en que sale de la caja

- Ajuste fácil e intuitivo con una pantalla de dos líneas y 8 caracteres

- El arreglo lineal proporciona exactitud y repetibilidad para objetivos desafiantes

- Láser visible para un tamaño reducido del punto y una fácil alineación

- Modelos con IO-Link disponibles

Rugged Laser Distance Sensor

Sensores de distancia láser versátiles y robustos que ofrecen un rendimiento superior y son capaces de detectar cambios en la distancia de un milímetro.

- Salida discreta, analógica (0 to 10 V or 4 to 20 mA), para detección de objetos claros y modelos de IO-Link.

- Rango de detección confiable desde cerca de 25 mm y hasta 610 mm

- Detecta objetivos en una gran variedad de colores, materiales y superficies basado en la distancia

- El modo de enseñanza dual (intensidad + distancia) es ideal para aplicaciones de corrección de error y permite la detección de objetos claros sin necesidad de un retro reflector.

- Carcasa robusta de acero inoxidable clasificada IP69K grado FDA

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)