High Speed Sensing Applications

Maintain High Throughput and Quality

Manufacturers must keep lines moving quickly in order to meet production goals and maximize efficiency. However, very high speed applications can be challenging for the sensors that verify part presence, inspect part quality, count parts, and more.

In material handling and logistics, maintaining efficiency without sacrificing quality and accuracy is also critical.

To ensure quality in high speed processes, facilities depend on reliable detection and measurement solutions that can keep pace.

- Many high speed applications also include extremely challenging targets, including clear, reflective, multicolored, and extremely objects.

- In some cases, the application may require extremely precise measurement of challenging targets at very high speeds.

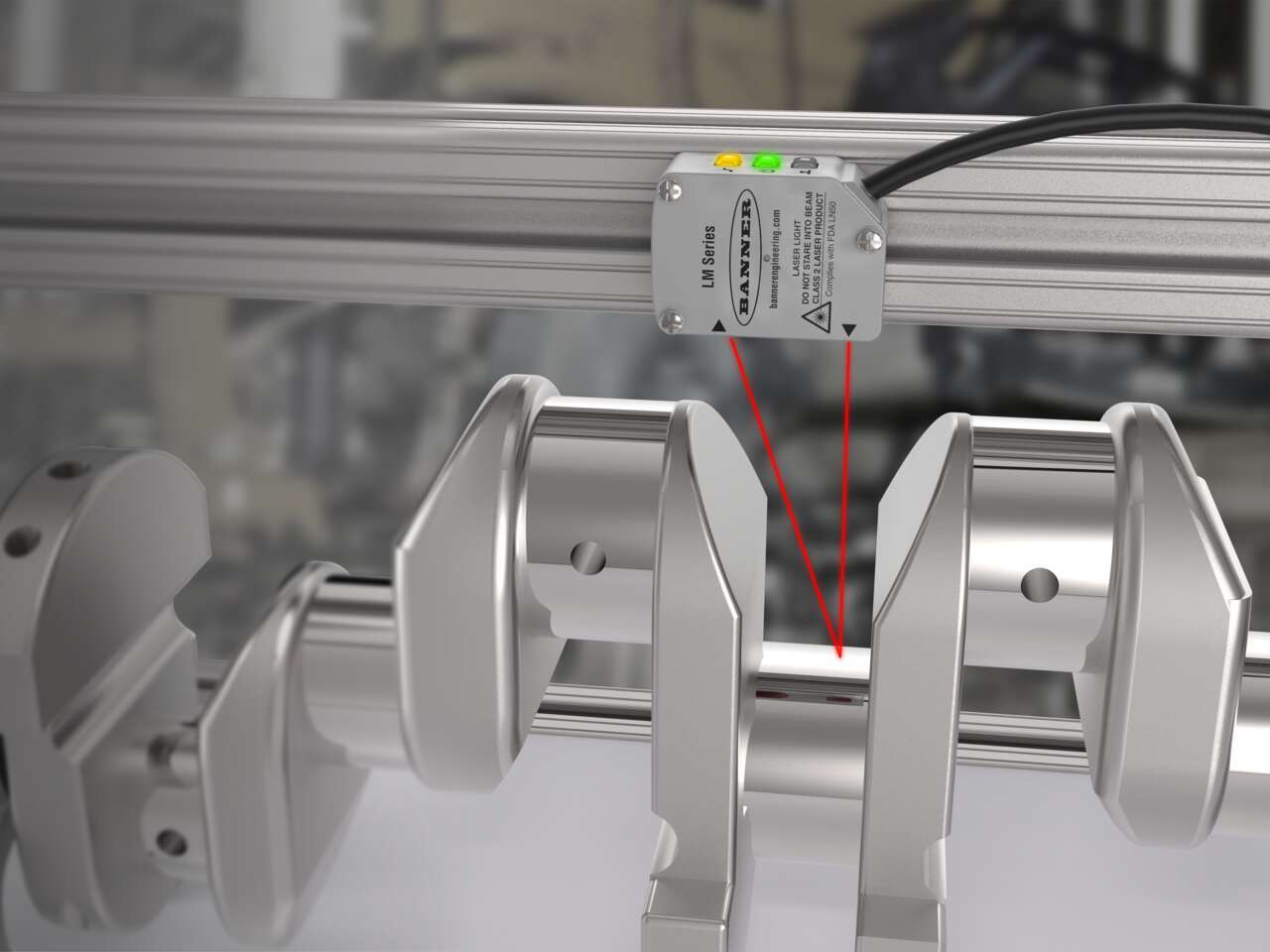

- For example, in automotive manufacturing, crankshaft runout measurements must be monitored continuously to ensure that they meet tolerance requirements. The reflective surface of the crankshaft and the high speed and precision of the application can be challenging for sensors to measure reliably. Learn how the LM Sensor solves this challenge.

- Banner offers a variety of sensing solutions for the most difficult high speed applications. See example solutions below or contact us to discuss your application.

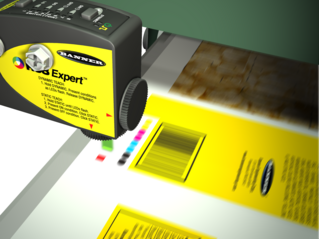

Packaging Industry

- Primary packaging has many high-speed processes, and it is important to verify correct packaging, which can be done by detecting registration marks.

- White registration marks on dark backgrounds, such as blue, can be challenging to detect at high speeds since many sensors are not able to maximize contrast for reliable detection of the mark and not the background.

- Banner Engineering's Q3X versatile, rugged laser contrast sensor is ideal for detecting registration marks. With a range up to 300 mm, the Q3X has a tight laser spot able to detect a small white registration mark reliably.

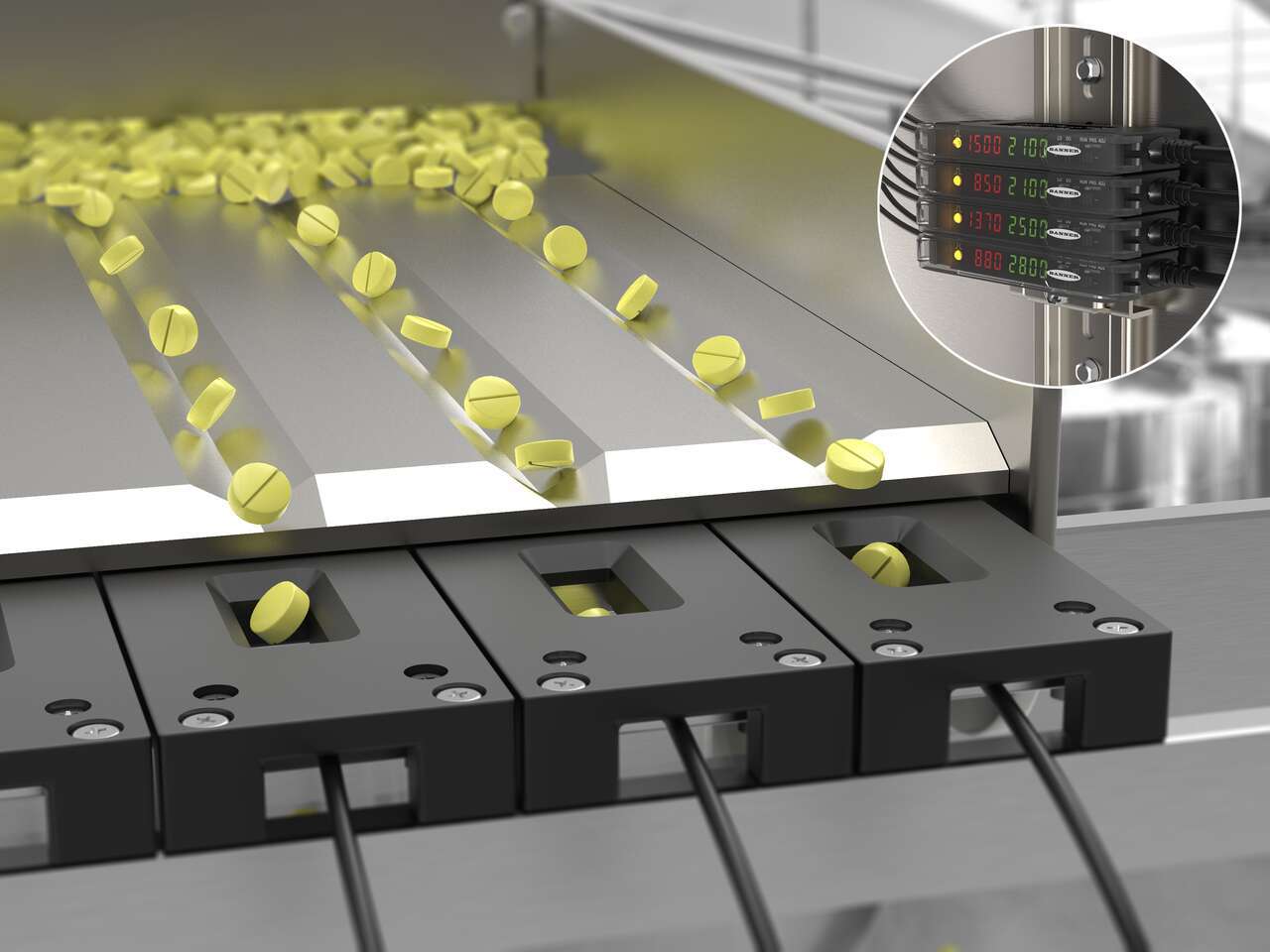

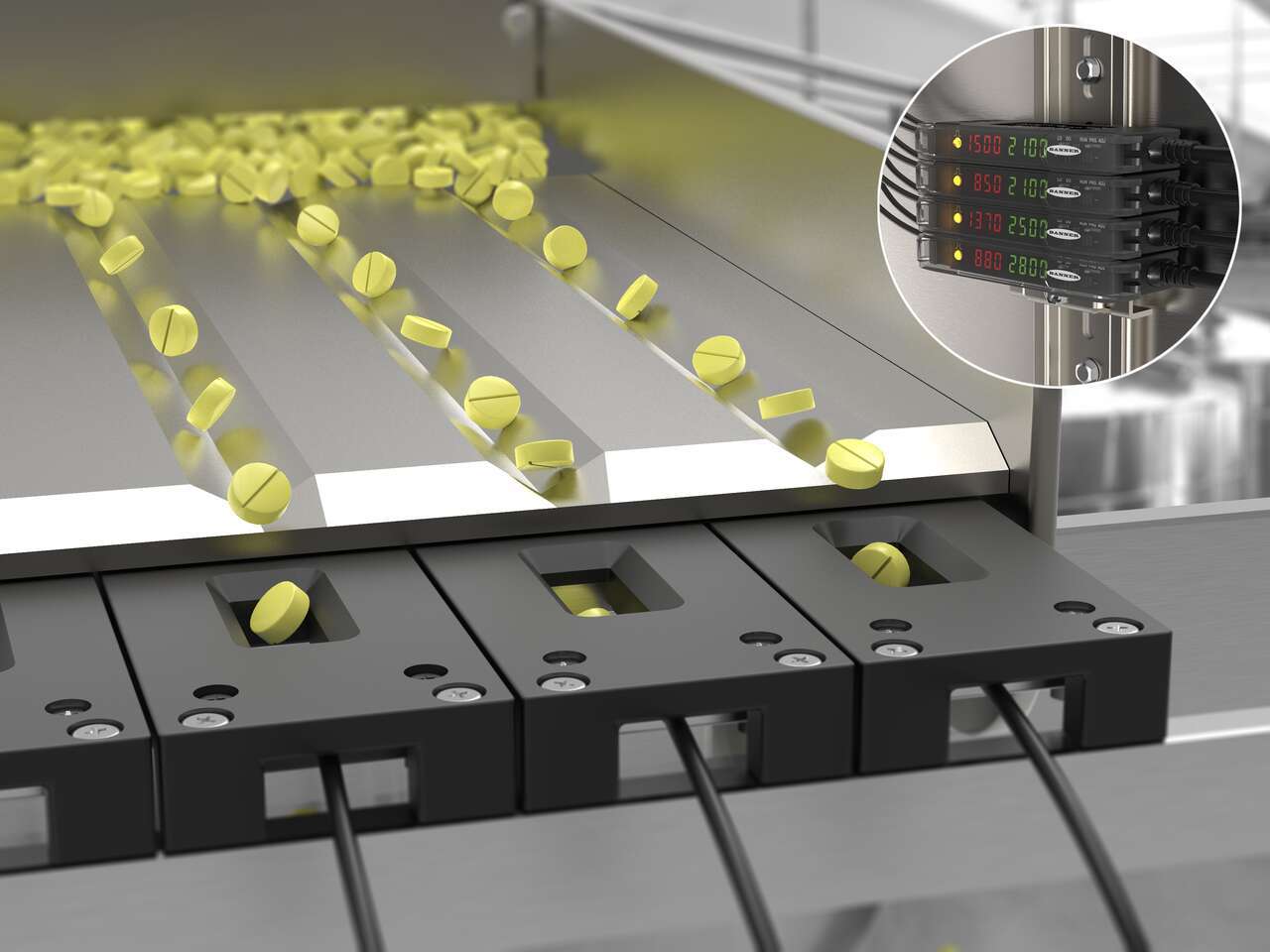

Pharmaceutical Industry

- In pharmaceutical packaging, products such as tablets, capsules and gel caps need to be accurately counted to achieve the proper number of tablets in each bottle.

- Pharmaceutical and medical industries use a dispensing mechanism to ensure the tablets separate from one another and don’t fall into the bottle side-by-side or simultaneously.

- All of this is done very quickly, creating the need for a high-speed, small-object counting sensor that can ensure tablets are accurately dispensed.

- The DF-G2 fiber optic amplifier is designed for high speed applications and can achieve 10 microsecond response time with 5 microsecond repeatability.

Material Handling Industry

- Sorting parcels and packages prior to delivery is an essential step in shipping and handling.

- Order fulfillment applications rely on accurate automated sorting to keep costs down, maximize efficiency, and accommodate large volumes of packages during peak shipping seasons.

- To reduce the risk of error, an automated profiling solution is necessary to scan packages to ensure accurate—and fast—sortation.

- LE Series laser measurement sensors are an ideal solution to this applicaiton due their fast 5-10 millisecond response speed and ability to reliably detect any target, regardless of size, color or reflectivity.

High Speed Fiber Optic Amplifier

Diseñado para lograr el rango de respuesta más rápido del mundo, el amplificador DF-G2 de fibra óptica puede lograr un tiempo de respuesta de 10 microsegundos con repetibilidad 5 microsegundos.

- Los modelos con IO-Link permiten el monitoreo y la configuración remotos

- La mejor velocidad de respuesta en su clase de 10 us, 15 us, 50us, 250 us, 500 us, y 1000 us

- Dos pantallas digitales de fácil lectura que muestran el nivel de señal y el límite al mismo tiempo

- Su sencilla interfaz garantiza una fácil instalación y programación del sensor a través de pantallas y teclas/interruptores o entrada remota para cable de programación TEACH

- Los métodos expertos de TEACH y SET aseguran una óptima ganancia y límite para todas las aplicaciones, especialmente en altas velocidades o bajo contraste.

- La electrónica térmicamente estable acorta el tiempo de puesta en marcha y mantiene la estabilidad de la señal durante la operación

Laser Measurement Sensor

La tecnología de arreglo lineal de la serie LE proporciona un gran desempeño y una gran resolución, independientemente del color o brillo de los objetivos.

- Listo para medir al momento en que sale de la caja

- Ajuste fácil e intuitivo con una pantalla de dos líneas y 8 caracteres

- El arreglo lineal proporciona exactitud y repetibilidad para objetivos desafiantes

- Láser visible para un tamaño reducido del punto y una fácil alineación

- Modelos con IO-Link disponibles