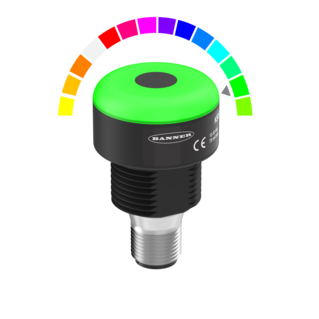

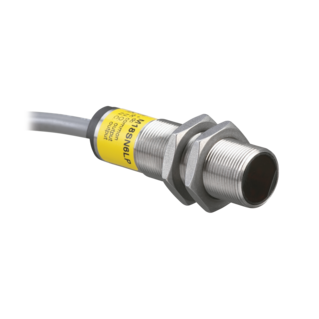

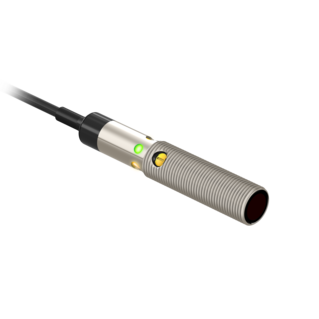

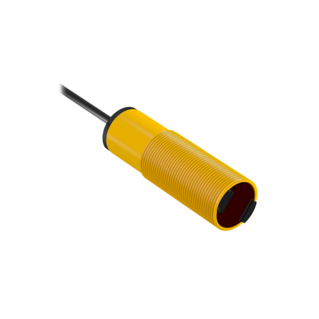

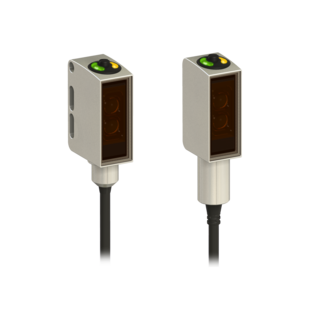

Sensores Fotoeléctricos

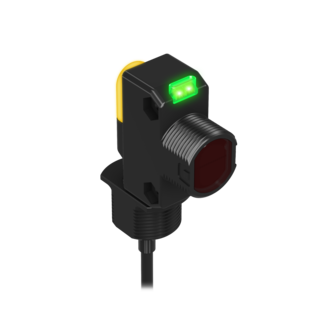

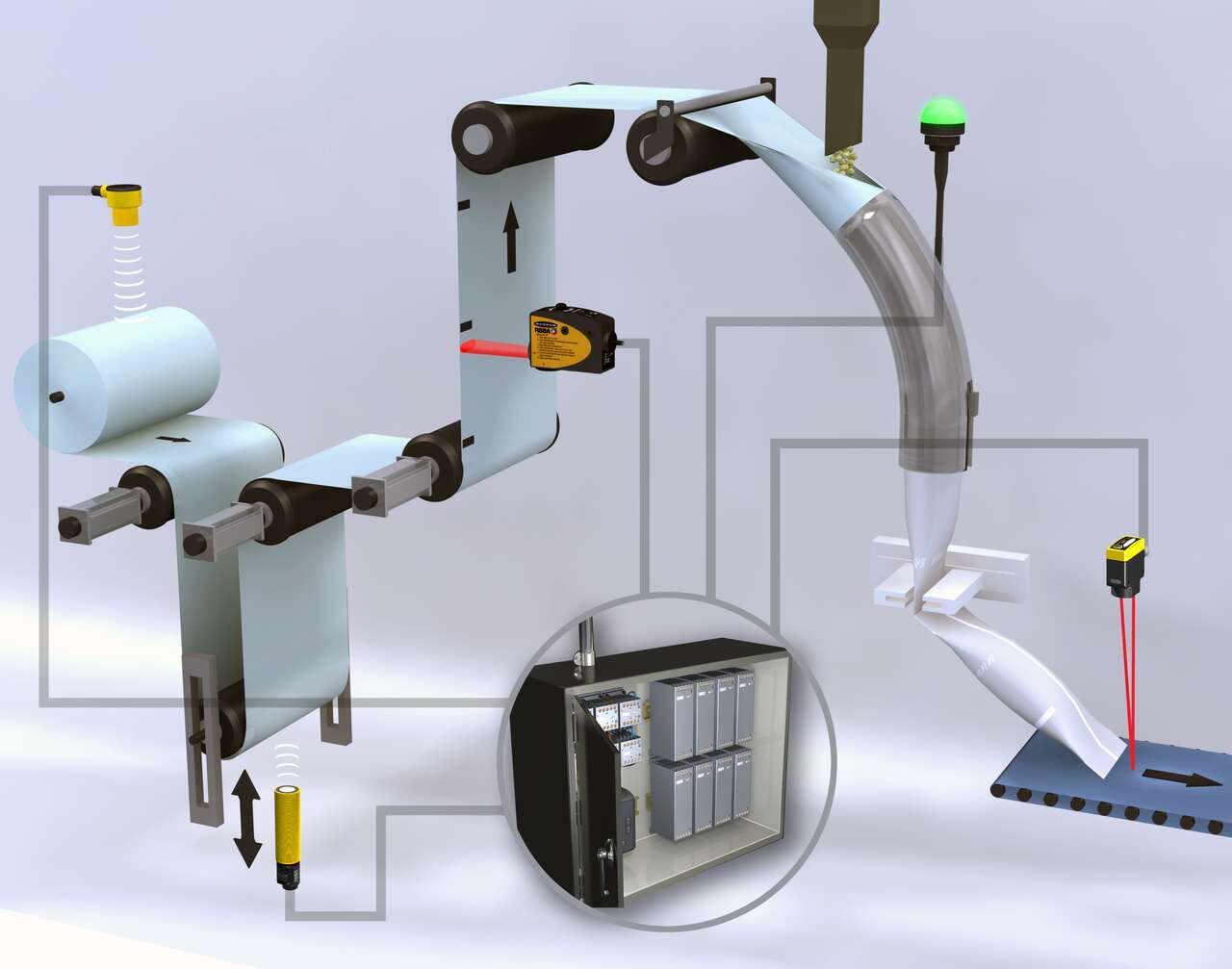

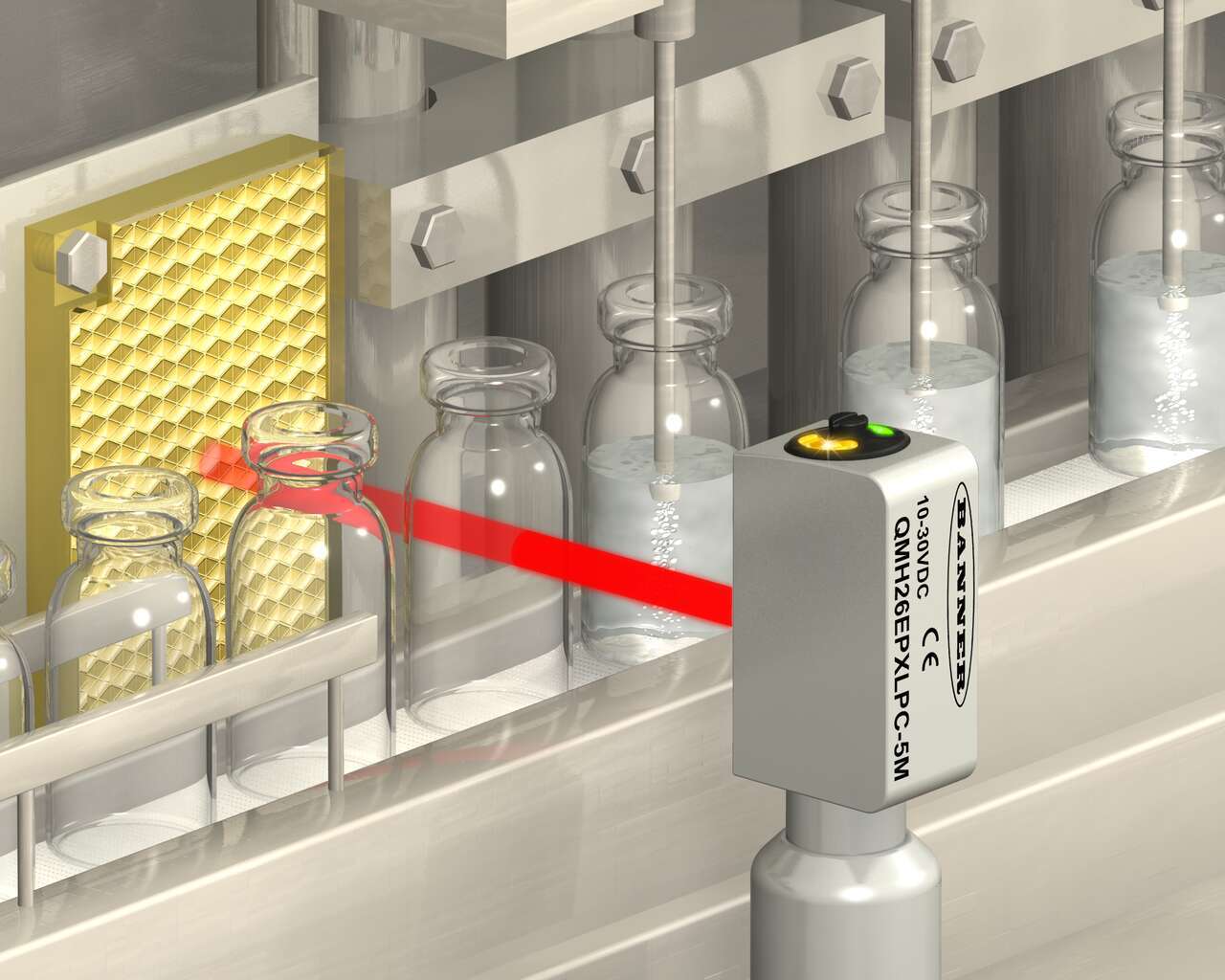

Los sensores fotoeléctricos emiten un haz de luz que detecta la presencia o ausencia de elementos y equipos o cambios en las condiciones de la superficie.

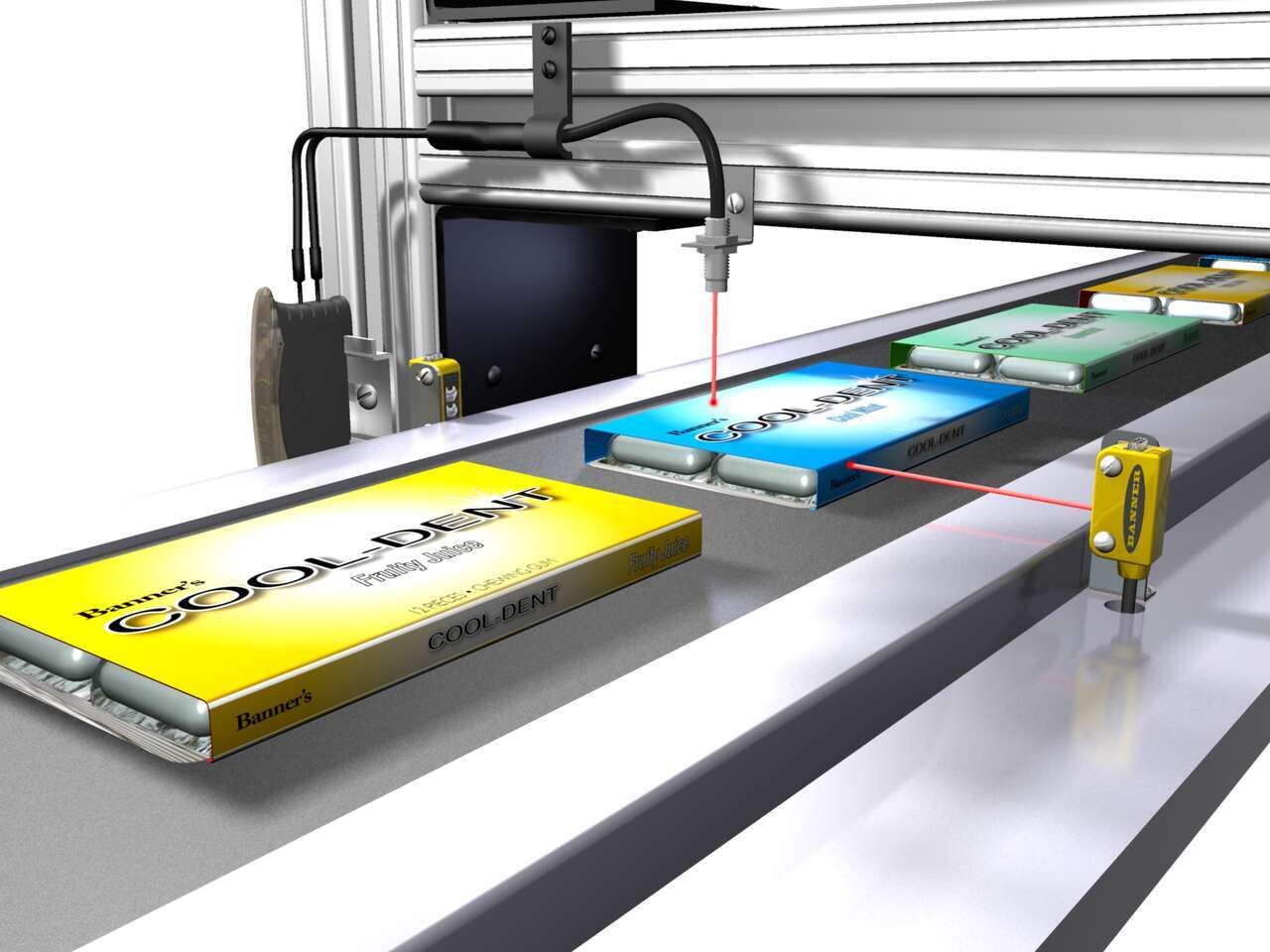

Cuando el haz de luz emitido por un sensor fotoeléctrico es interrumpido o reflejado por el objeto, el cambio en los patrones de luz es medido por un receptor y se reconoce el objeto o superficie objetivo. Los sensores fotoeléctricos son muy comunes en los campos de la fabricación industrial, como el manejo de materiales, el envasado, alimentos y bebidas, grado médico y muchos otros.

Según el estilo seleccionado, se pueden usar con o sin reflector, ser autónomos, de largo alcance, resistentes o compactos. Hay muchas opciones de alojamiento y montaje diferentes para ofrecer un ajuste correcto que cumpla con las demandas de cada aplicación. Realizan una amplia variedad de tareas y algunas de ellas incluso pueden utilizarse en entornos hostiles.

Los sensores fotoeléctricos, emiten un haz de luz que se utiliza para detectar la presencia o ausencia de elementos y equipos o cambios en las condiciones de la superficie. Cuando la luz emitida es interrumpida o reflejada por el objeto, un receptor mide el cambio en los patrones de luz y reconoce el objeto o la superficie objetivo. Los sensores fotoeléctricos son muy comunes en los campos de la fabricación industrial, como el manejo de materiales, el envasado, alimentos y bebidas, grado médico y muchos otros.

Según el estilo seleccionado, se pueden usar con o sin reflector, ser autónomos, de largo alcance, resistentes o compactos. Hay muchas opciones de alojamiento y montaje diferentes para ofrecer un ajuste correcto que cumpla con las demandas de cada aplicación. Realizan una amplia variedad de tareas y algunas de ellas incluso pueden utilizarse en entornos hostiles.

| Series Image | Series Name | Opposed Range (m) | Non-polarized Retroreflective Range (m) | Polarized Retroreflective Range (m) | Laser Polarized Retroreflective Range (m) | Diffuse Range (mm) | Fixed-Field Range (mm) | Adjustable-Field Range (mm) | Type of Emitter | Housing Material | IP Rating | Response Time (μs) | Operating Temperature | IO-Link | Clear Object Detection |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

QS18 | 20 | 6.5 | 3.5 | 10 | 600 | 200 | 350 | LED and Laser | Plastic | IP67 | 600–800 | -20 to +70 °C | ✅ YES | ✅ YES |

|

Q20-2 | — | — | 5 | — | — | — | 3000 | LED and Laser | Plastic | IP67 | 600 | -25 to +70 °C | ✅ YES | ✅ YES |

|

Q20 | 20 | 6 | 4 | — | 1500 | 150 | 400 | LED | Plastic | IP67 | 850–1000 | -20 to +60 °C | ✅ YES | 🚫 NO |

|

QS30 | 60 | 12 | 8 | 18 | 1400 | 600 | 600 | LED and Laser | Plastic | IP67 | 2000–5000 | -20 to +70 °C | 🚫 NO | ✅ YES |

|

T18-2 | 25 | — | 6 | — | 750 | 200 | — | LED | Plastic | IP67, IP68, IP69K | 1500–2000 | -40 to +70 °C | 🚫 NO | 🚫 NO |

|

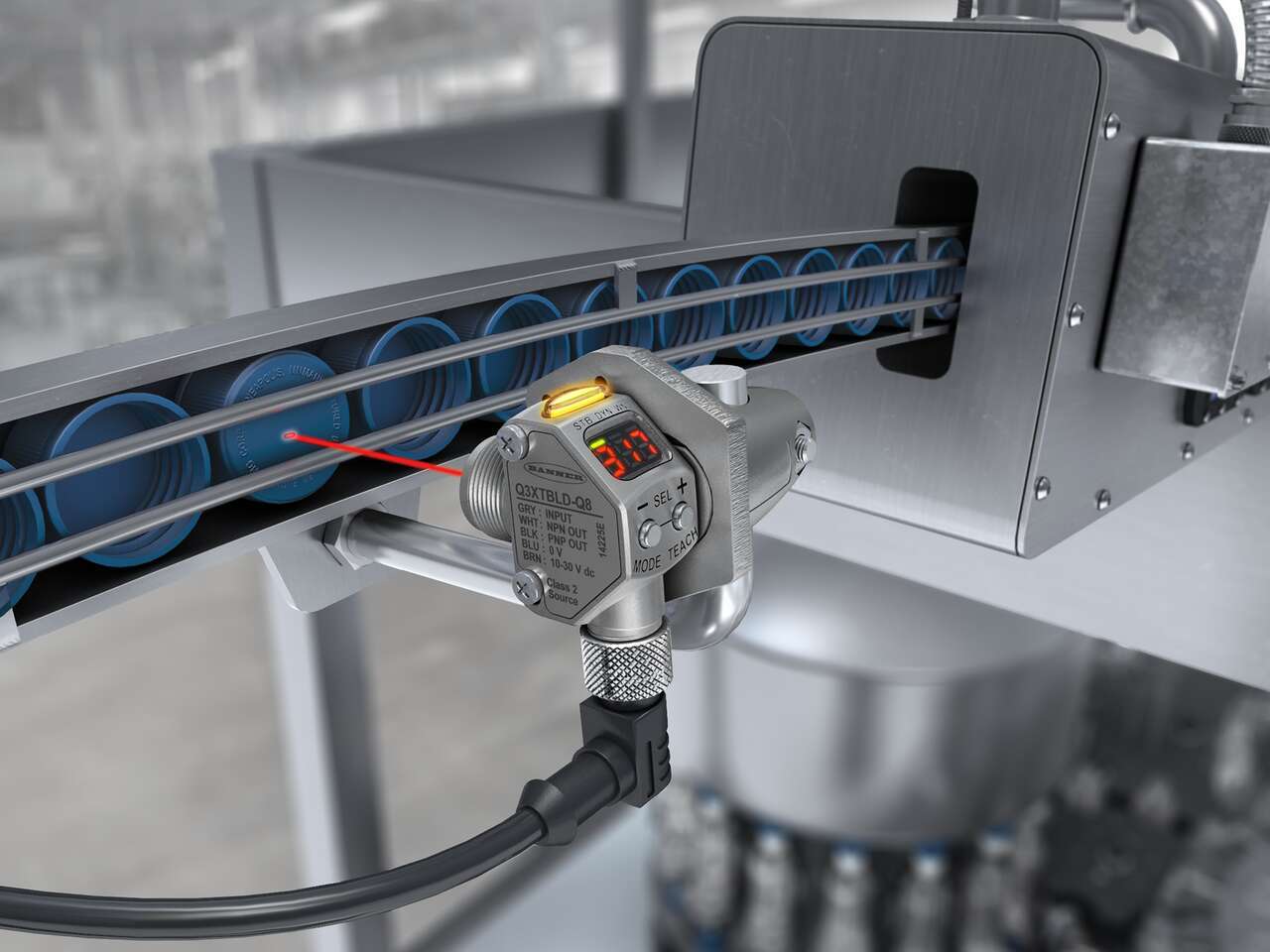

Q3X | — | — | — | — | 300 | 200 | — | Laser | Metal | IP67, IP68, IP69K | 250 | -10 to +50 °C | 🚫 NO | 🚫 NO |

|

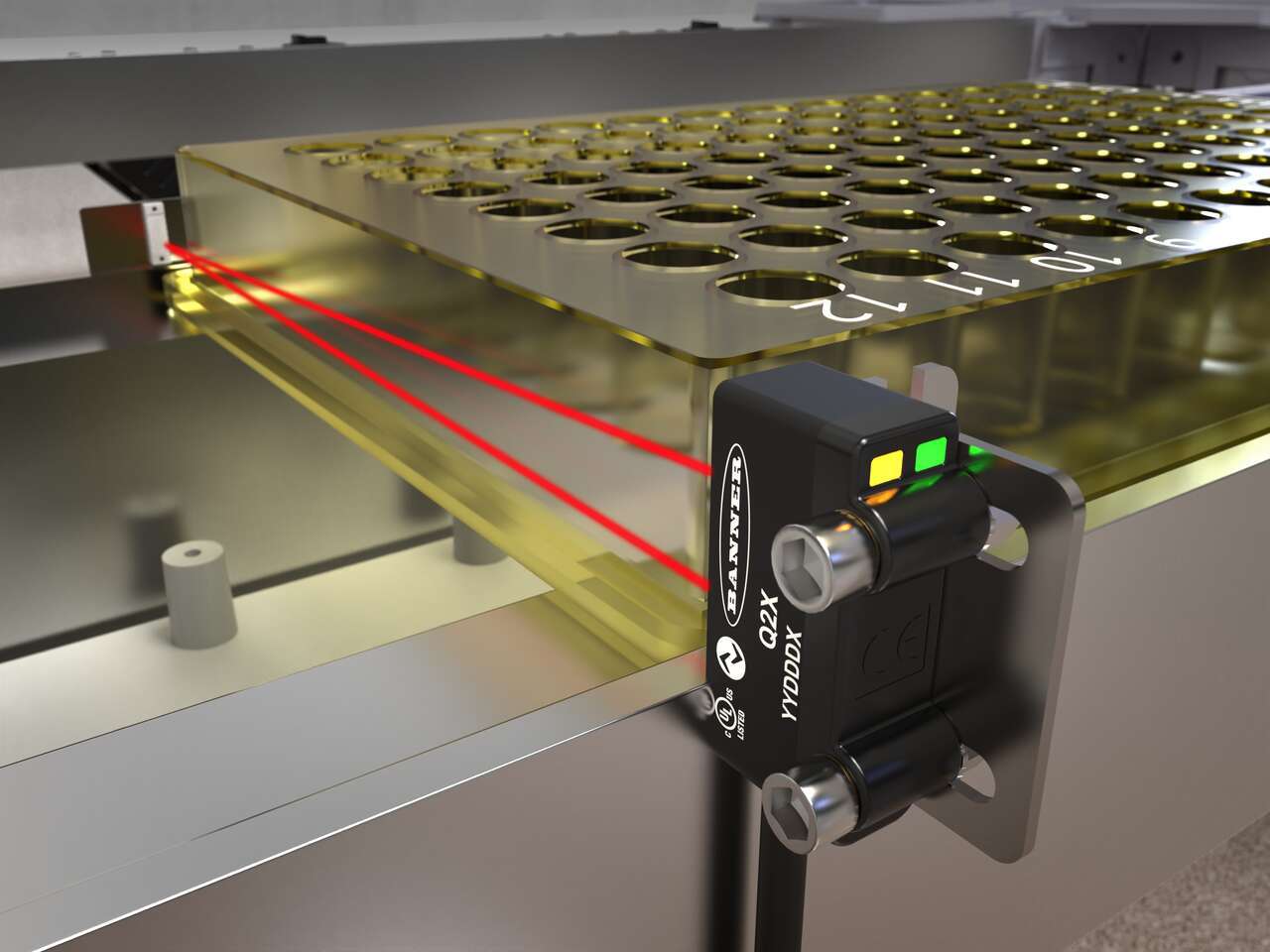

Q2X | 3 | — | 3.3 | — | — | 50 | 3000 | LED and Laser | Plastic | IP67 | 600–100,000 | -25 to +50 °C | ✅ YES | ✅ YES |

The Sensor Selection Guide briefly explains Banner's array of sensing technologies, and helpful flowcharts make it easy to find the right sensor for any application.

Los sensores fotoeléctricos pueden detectar la presencia o ausencia de objetos o cambios en las condiciones de la superficie de un objetivo. Emiten un haz de luz que es detectado por un elemento receptor. Cuando un objeto interrumpe o refleja la luz emitida, una salida conmuta, enviando una señal electrónica. Se pueden detectar la mayoría de los materiales objetivo, incluidos aquellos que son brillantes, oscuros, transparentes o multicolores. Los sensores fotoeléctricos son muy comunes en campos de fabricación industrial, como manejo de materiales, empaque, alimentos y bebidas, medicina y muchos otros.

Los sensores fotoeléctricos pueden ser de largo alcance, resistentes y compactos, y están disponibles en varios rangos de detección. Algunos requieren emisores y receptores separados, otros incluyen un emisor y un receptor en una sola carcasa (con o sin reflector) y algunos sensores son capaces de diferenciar objetivos de fondos. Estos diversos métodos de detección se conocen como modos de detección. Hay muchas opciones de alojamiento y montaje diferentes para ofrecer un ajuste correcto que cumpla con las demandas de cada aplicación. Realizan una amplia variedad de tareas, pueden tener una respuesta muy rápida y algunos incluso pueden utilizarse en entornos hostiles.

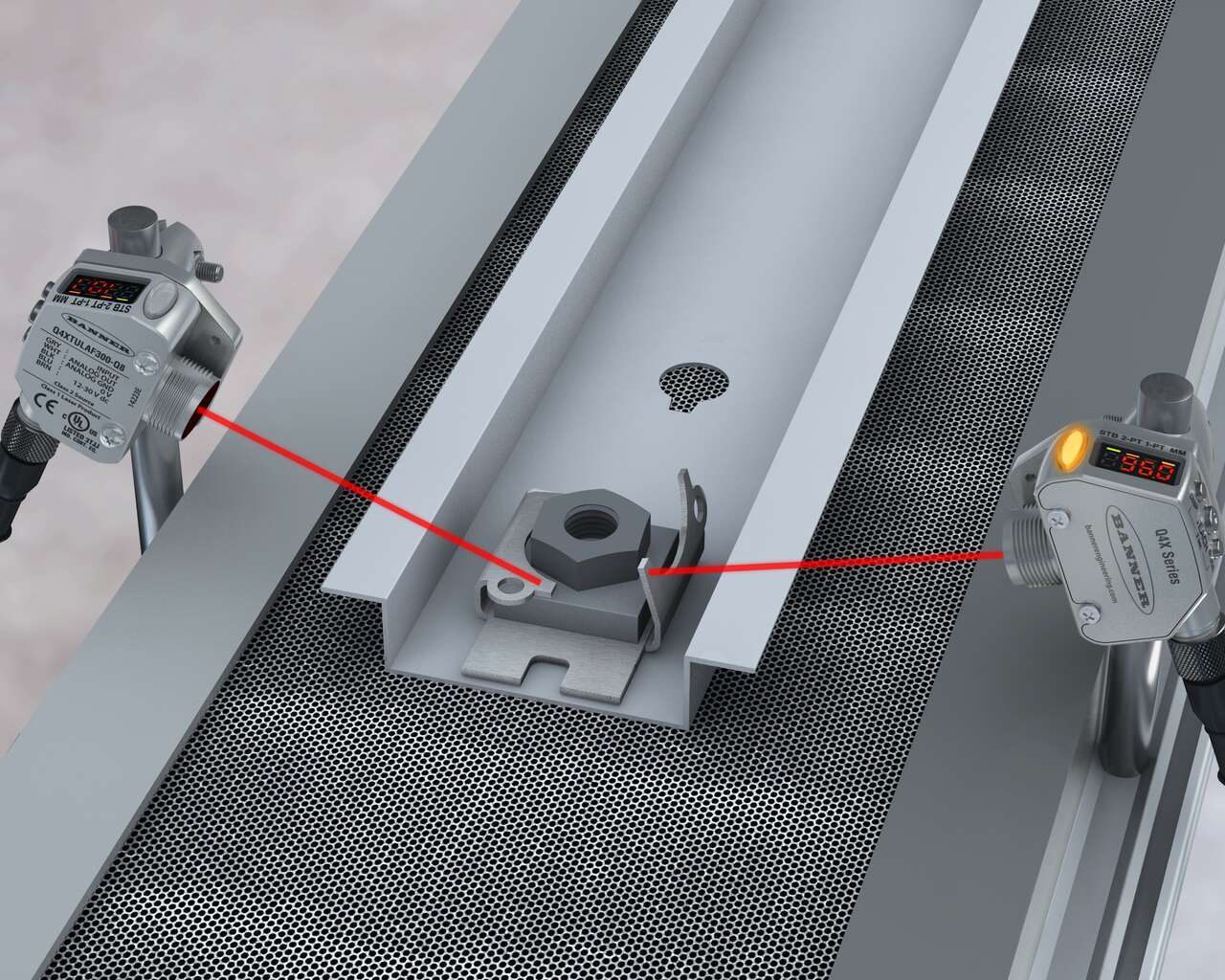

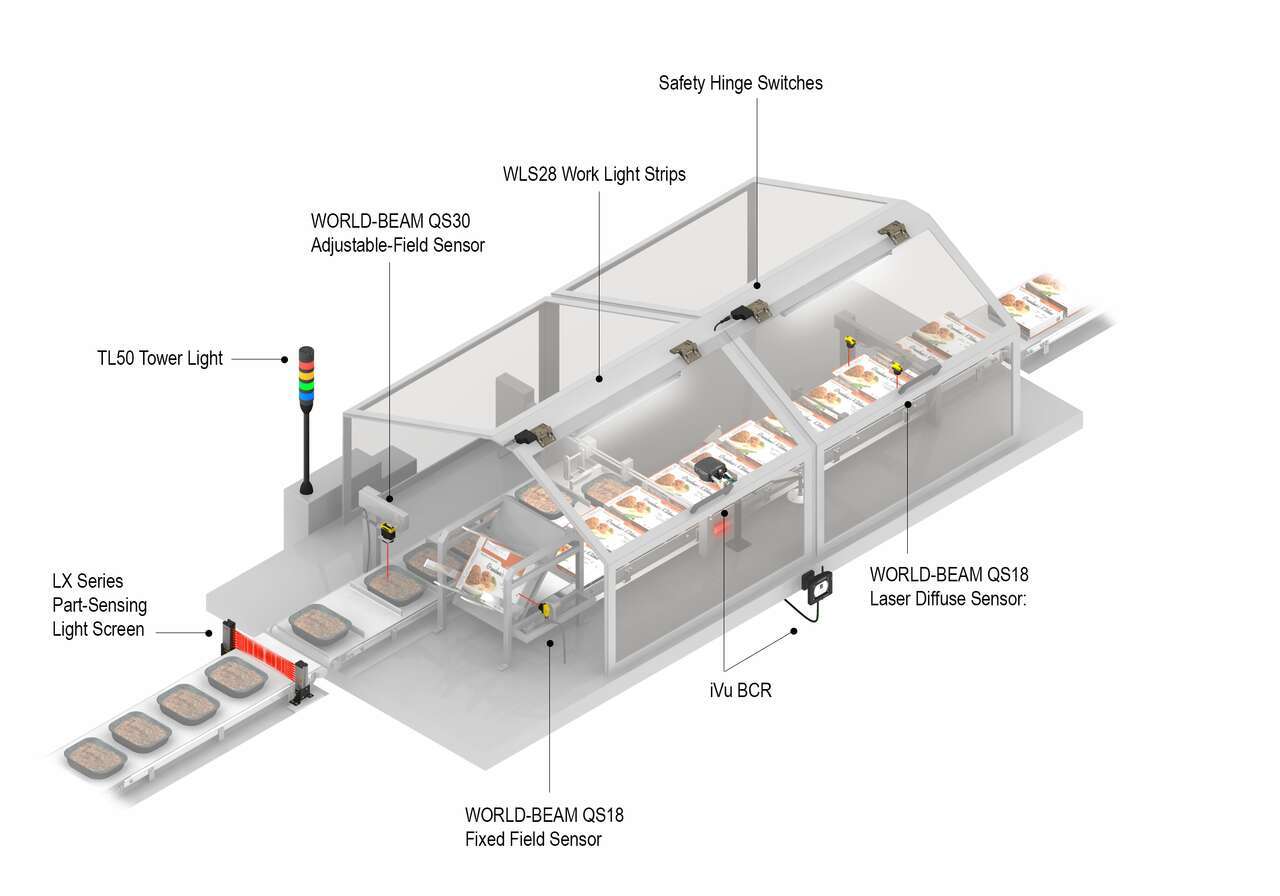

Diferentes aplicaciones requieren diferentes enfoques de detección. Para satisfacer estas diversas necesidades de aplicación, Banner ofrece múltiples modos de detección, incluidos opuesto, retrorreflectivo, difuso y supresión de fondo. El rango en el que se produce la detección, la composición física del objeto que se detecta y el entorno en el que operan los sensores pueden afectar la elección del modo de detección.

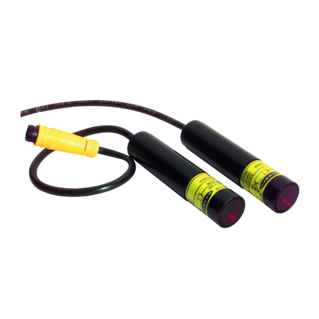

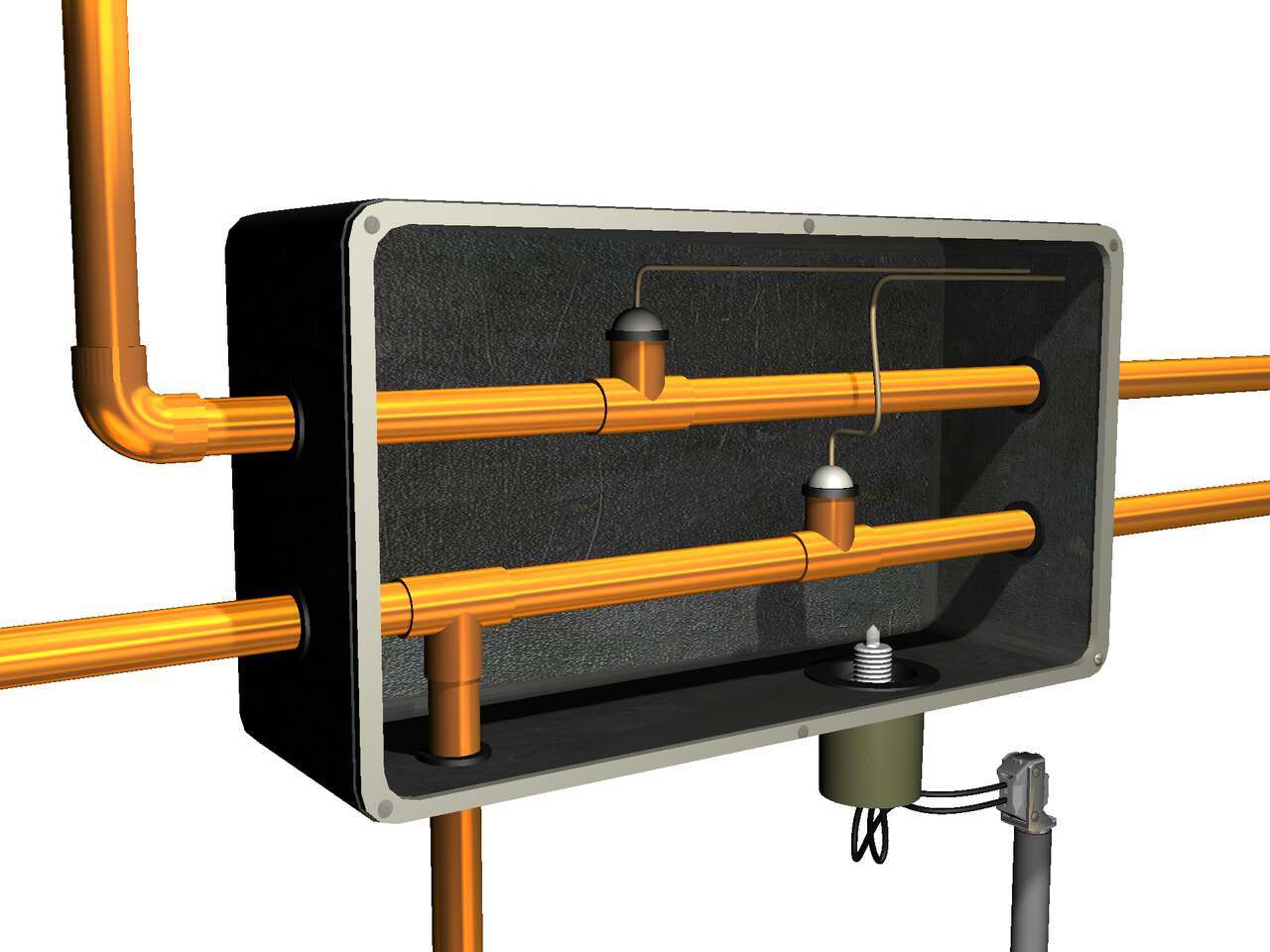

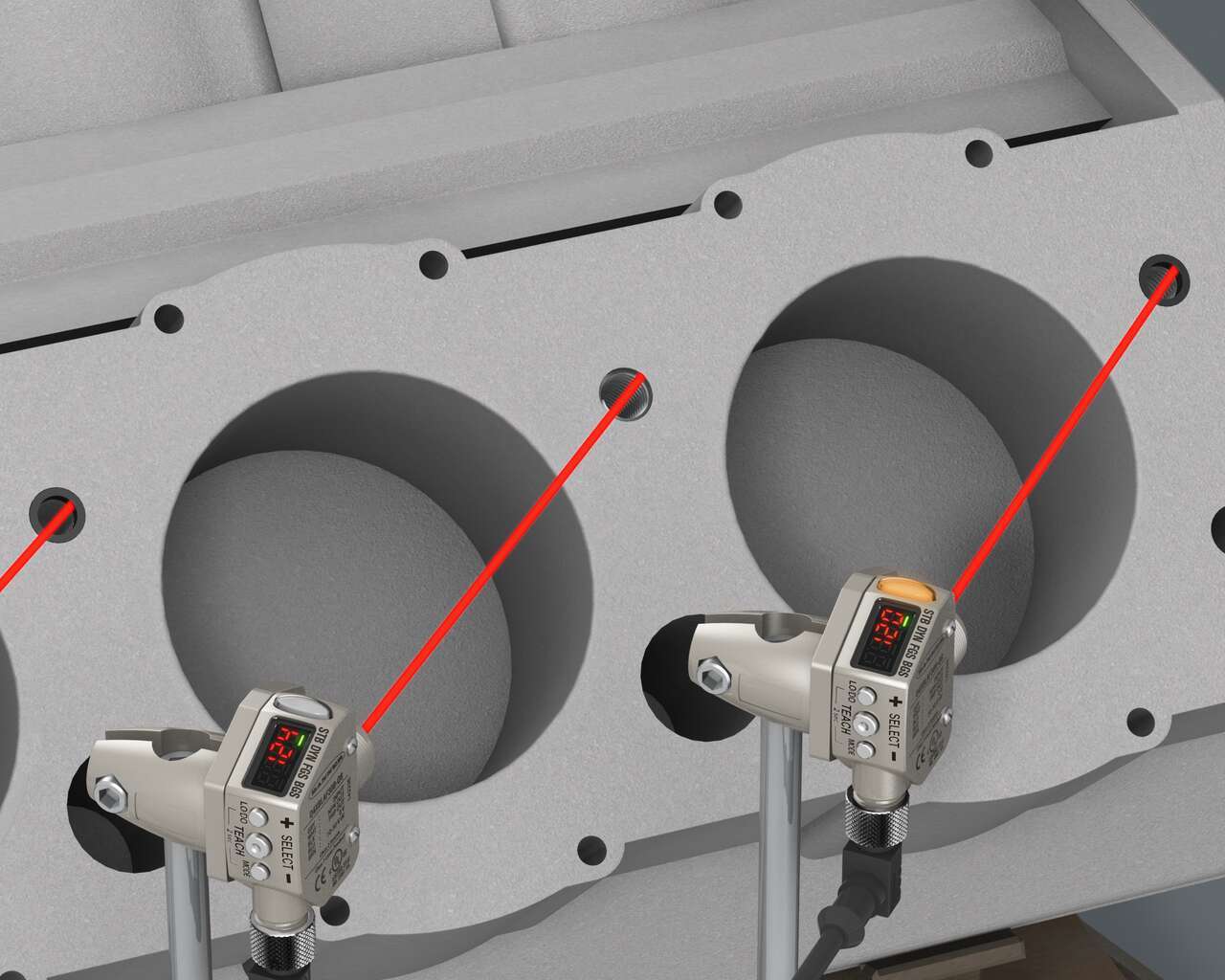

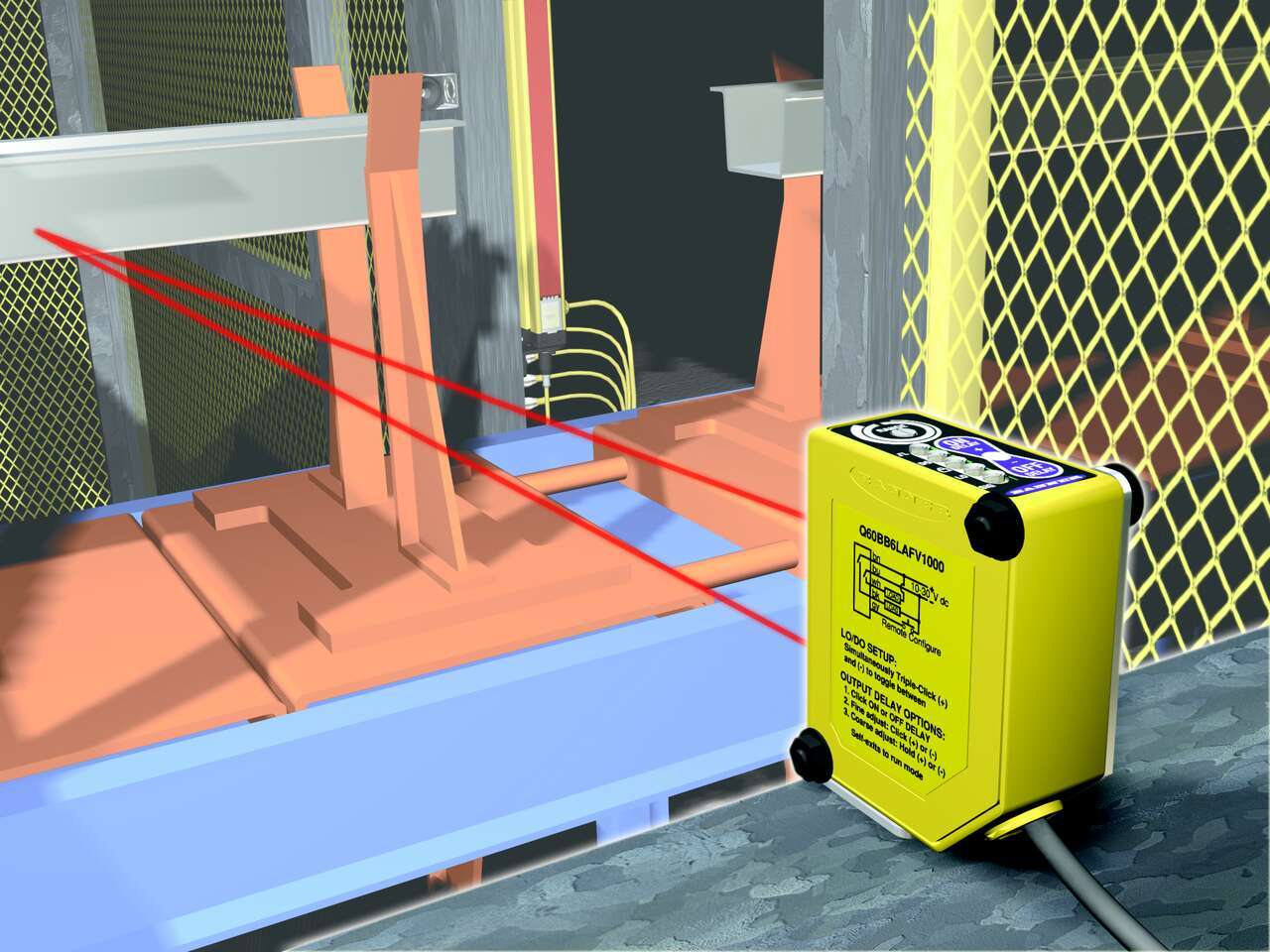

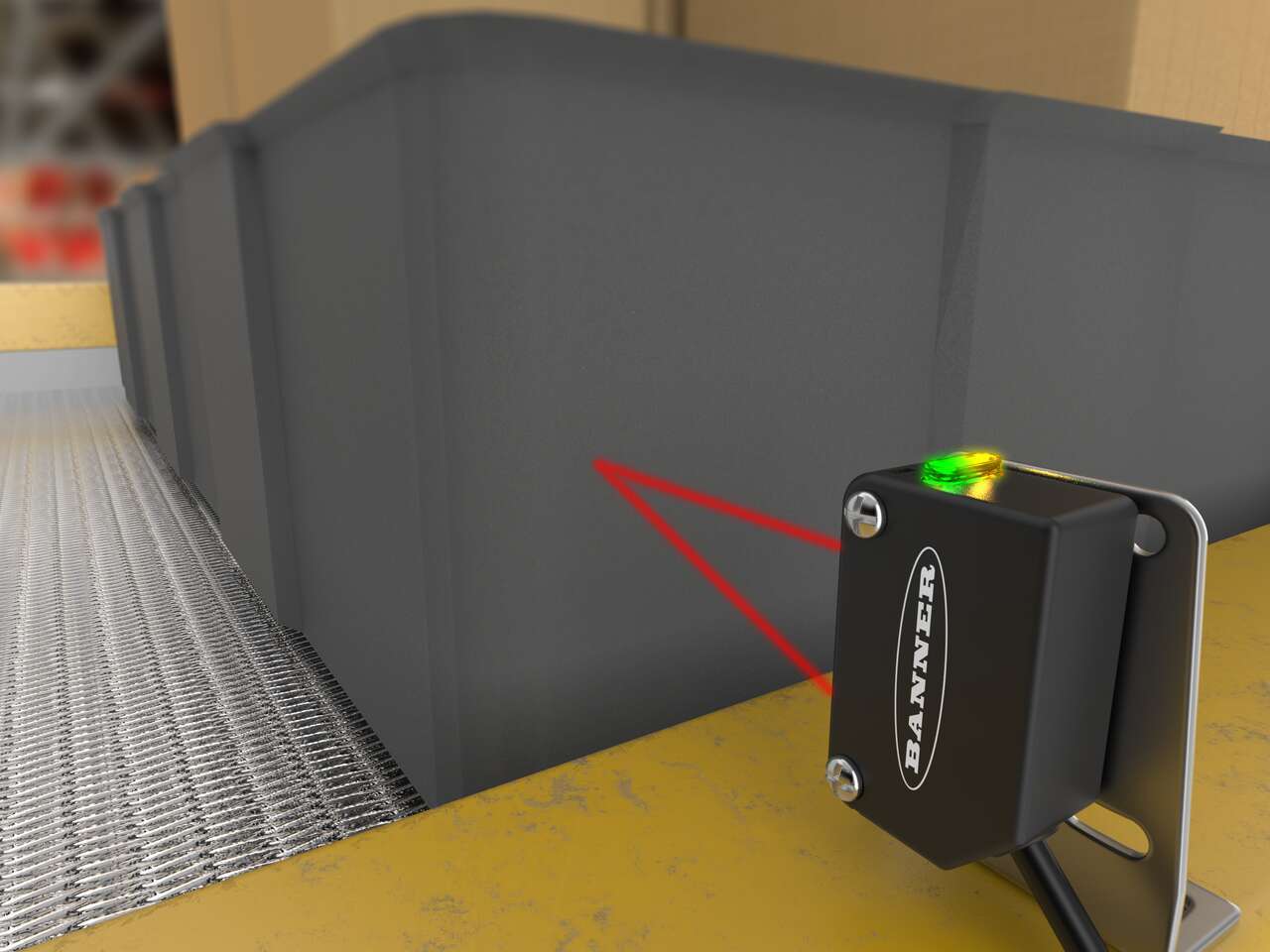

En la detección de modo opuesto, el emisor y el receptor del sensor están alojados en dos unidades separadas. El emisor se coloca frente al receptor, de modo que el haz de luz va directamente del emisor al receptor. Un objeto se detecta cuando "rompe" o interrumpe la parte activa del haz de luz, conocido como haz efectivo. Dependiendo de la aplicación, la detección de modo opuesto proporciona la mayor confiabilidad siempre que se pueda implementar. Esto se debe a que la luz pasa directamente del emisor al receptor. Luego, cuando un objeto interrumpe el haz, la salida cambiará.

- La detección en modo opuesto ofrece el mayor nivel de ganancia excedente (energía de detección)

- Rango de Detección de Largo Alcance

- Más robusta para entornos hostiles

- Detección precisa de posición

- Detección de piezas pequeñas mediante aperturas de lentes

- Impermeable a la reflectividad de la superficie (el color o acabado del objeto)

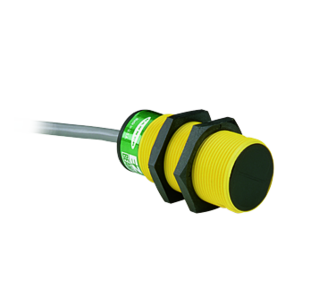

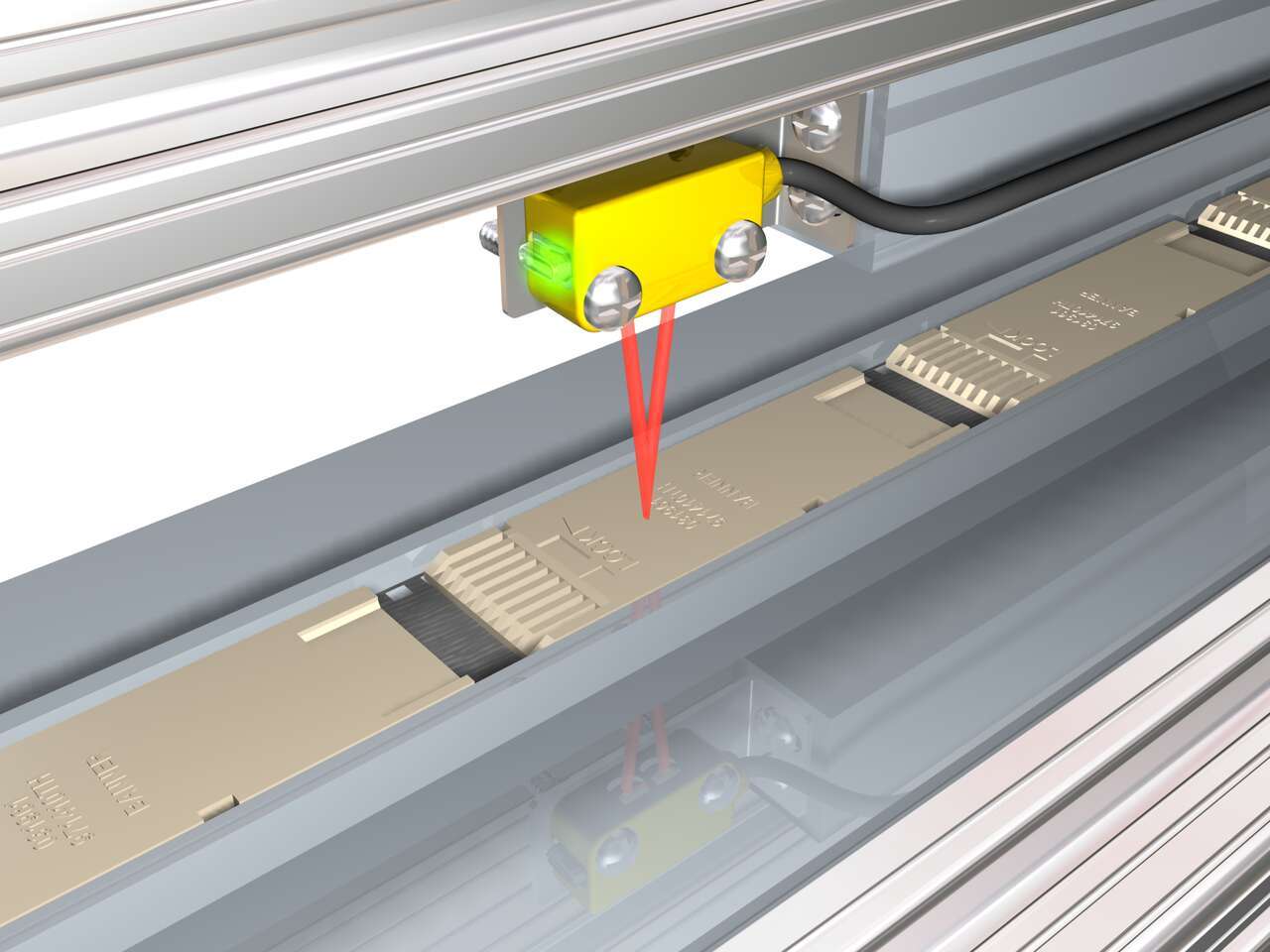

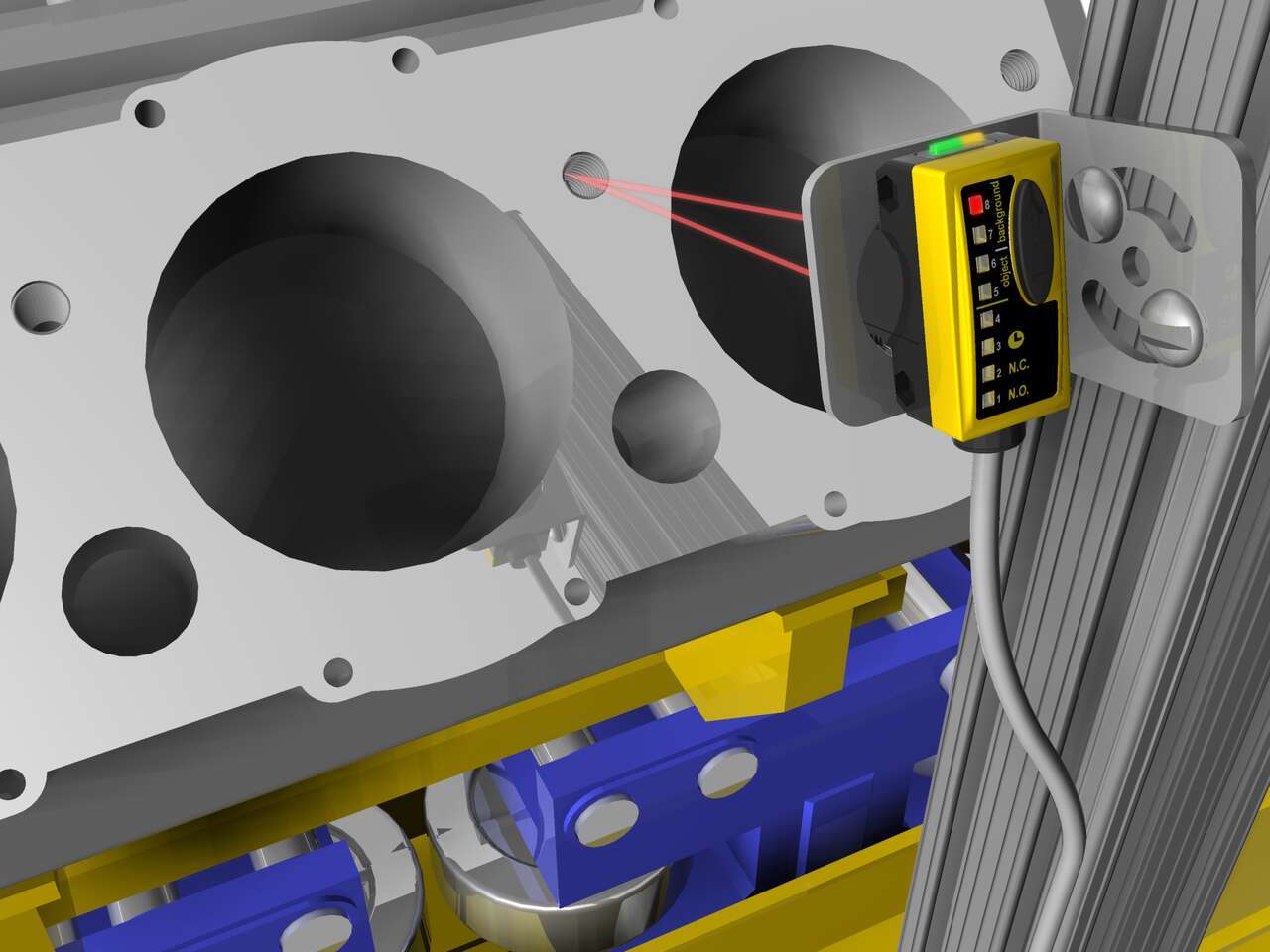

Un sensor retrorreflectante contiene los elementos emisor y receptor en la misma carcasa. Utiliza un reflector para hacer rebotar la luz emitida hacia el receptor. Similar a un sensor de modo opuesto, detecta objetos cuando interrumpen o "rompen" el haz efectivo. Dado que la detección retrorreflectiva es un modo de interrupción del haz, generalmente no depende de la reflectividad del objeto a detectar.

Sin embargo, puede ser engañado por objetos brillantes. Para esos objetivos, se debe utilizar un sensor retrorreflectivo polarizado para evitar la aproximación. La aproximación es cuando un objeto con una superficie brillante devuelve suficiente luz al sensor para imitar el haz fotoeléctrico que regresa del reflector y hace que el objeto no sea detectado. En un sensor retrorreflectivo polarizado, el emisor envía ondas de luz a través de un filtro que las alinea en el mismo plano. Estas ondas de luz rebotan en el reflector y regresan a un filtro polarizado verticalmente en el receptor. Cuando esta luz polarizada alcanza un objetivo brillante, la luz se refleja de regreso al sensor en el mismo plano en el que fue emitida y es bloqueada por el filtro, lo que indica un haz interrumpido. Sin embargo, cuando la luz polarizada llega al reflector, se dispersa en luz no polarizada con ondas de luz en los planos horizontal y vertical. Parte de esta luz pasará a través del filtro del receptor y el sensor detectará el reflector y sabrá que el haz no se interrumpe.

Un sensor de modo retrorreflectivo ofrece una alternativa conveniente al modo opuesto cuando el espacio es limitado o si las conexiones eléctricas solo son posibles en un lado de la instalación. Los sensores de modo retrorreflectante ofrecen rangos relativamente largos.

- Segundo modo de exceso de ganancia más alto

- Modelo polarizado disponible para evitar que el haz se desvíe de objetos brillantes.

- Óptica coaxial disponible para objetos claros y precisión.

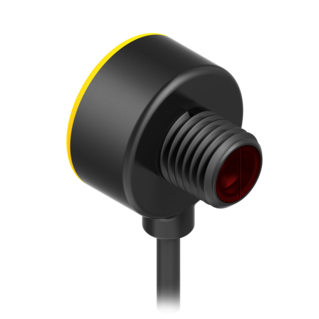

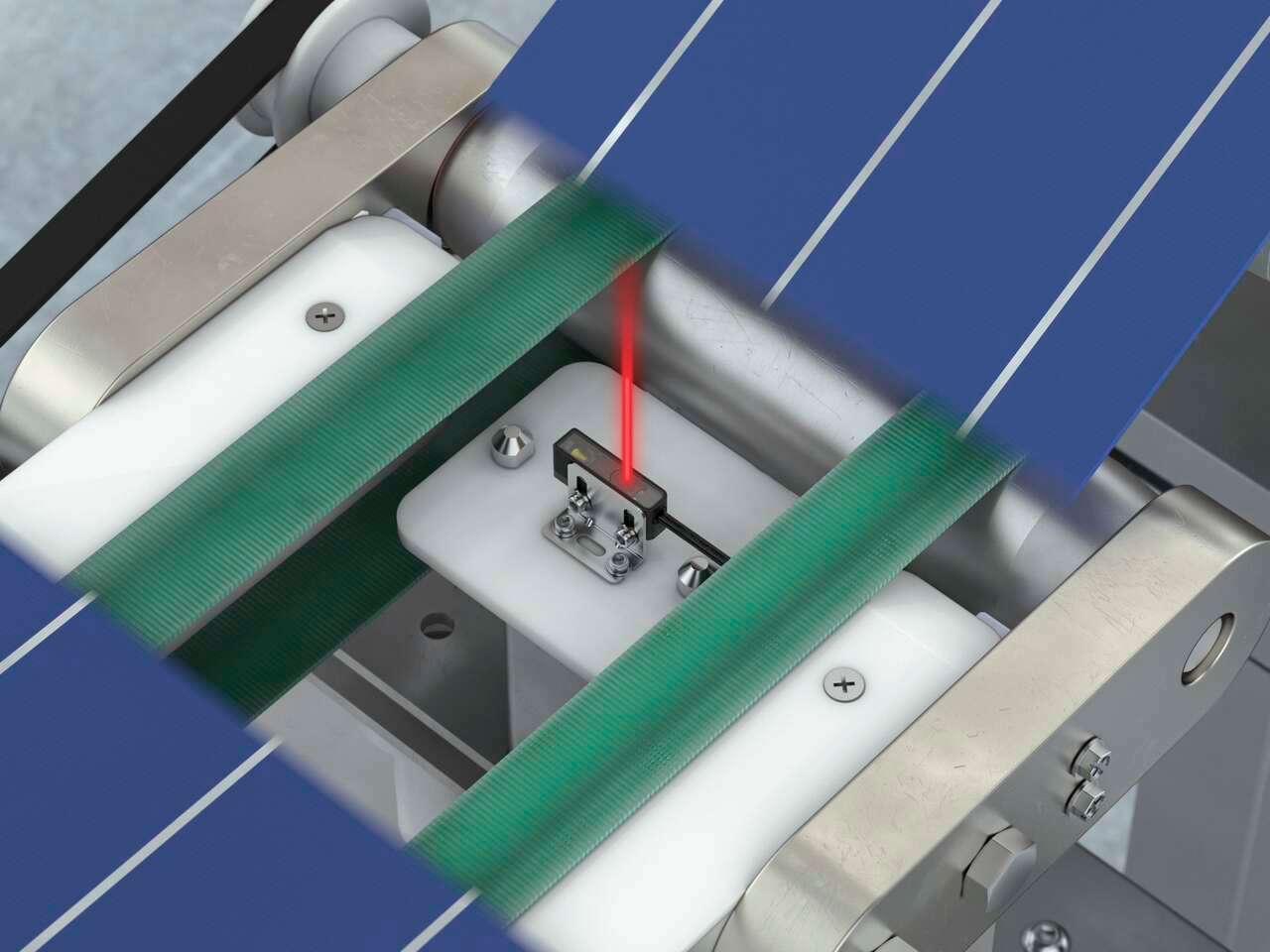

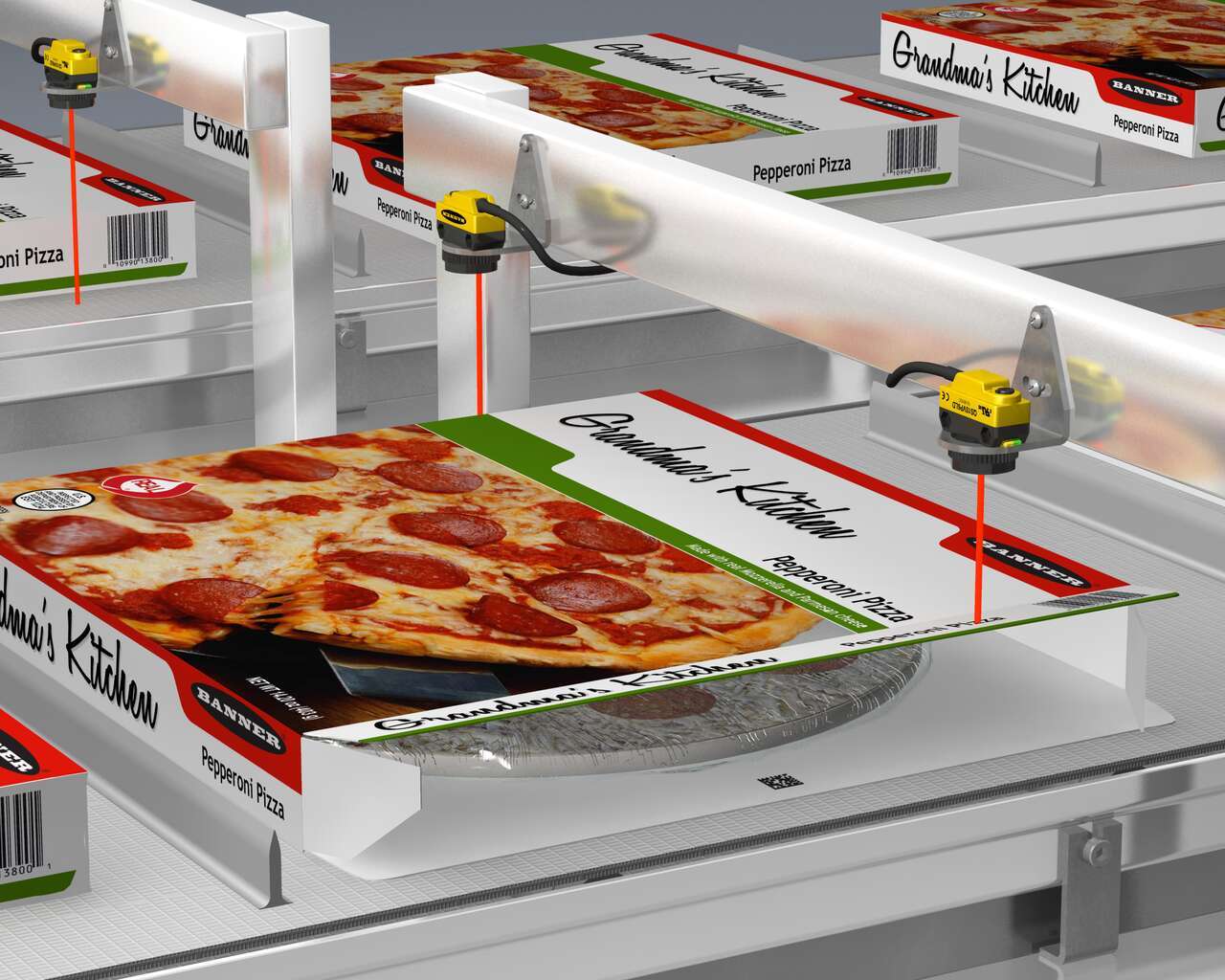

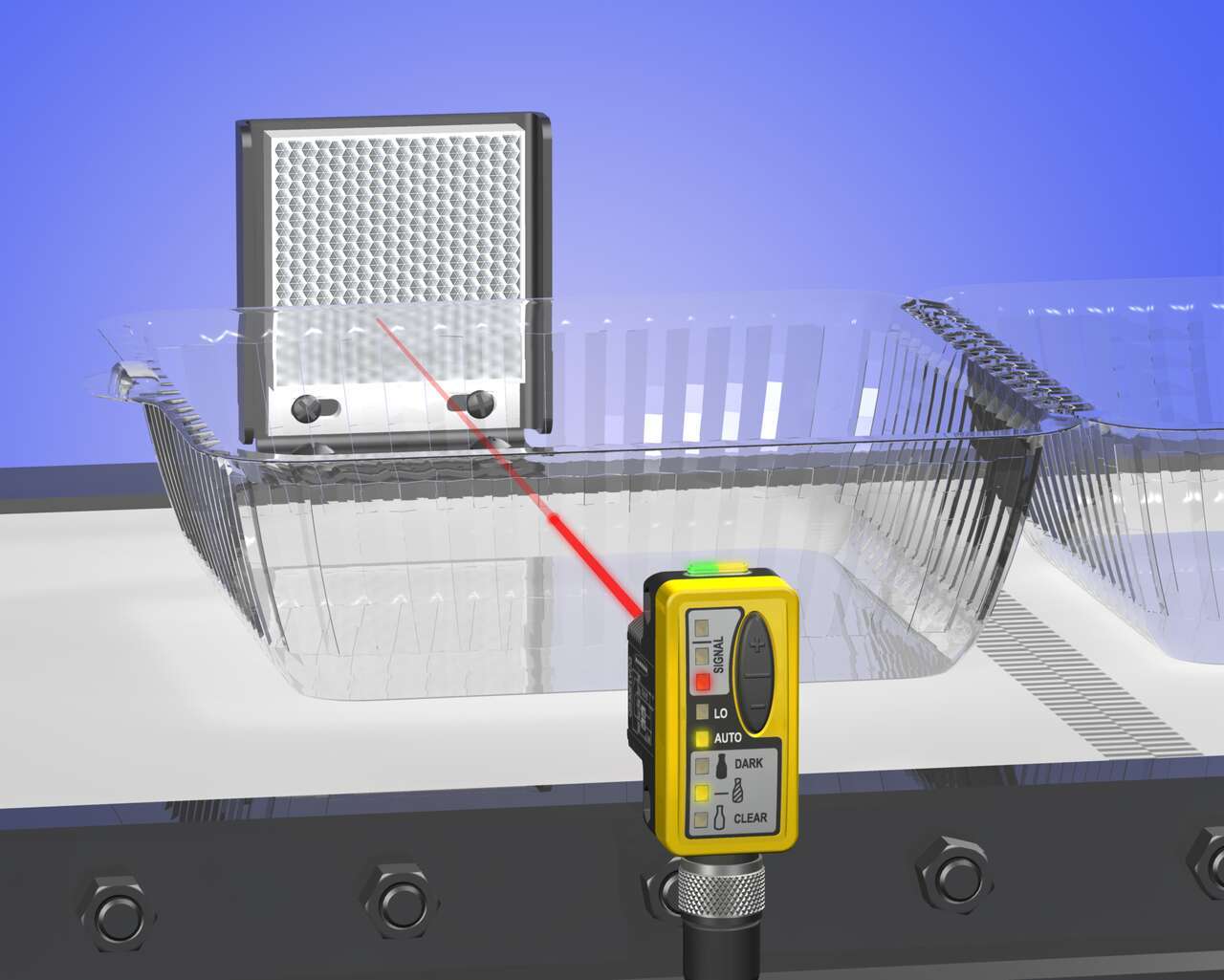

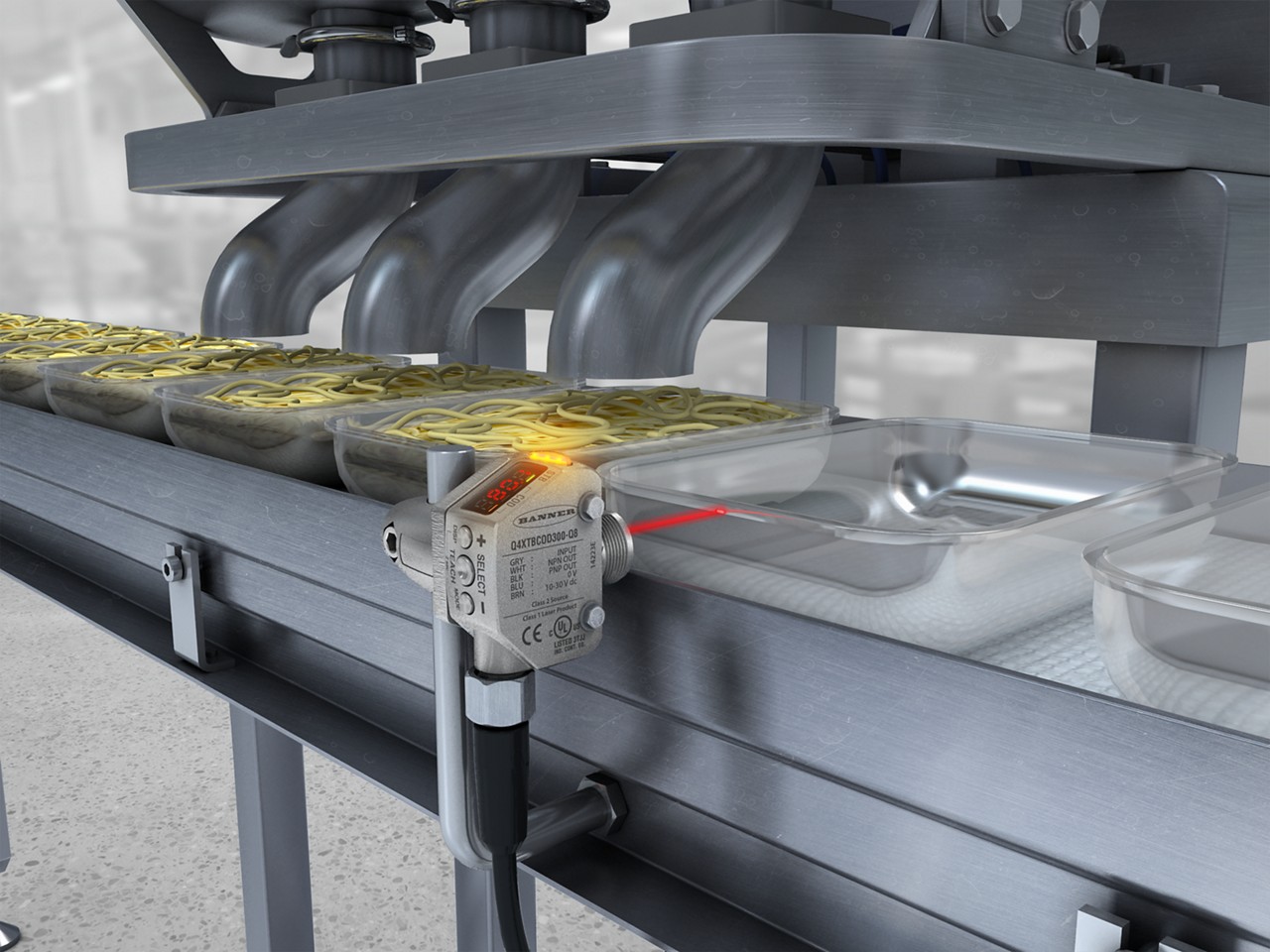

Los sensores de modo difuso contienen el emisor y el receptor en la misma carcasa, pero no utilizan un reflector. En cambio, detectan un objeto cuando la luz emitida se refleja en un objetivo y regresa al sensor. Con un sensor de modo difuso, el objeto se detecta cuando "emite" el haz; es decir, el objeto refleja la energía luminosa transmitida hacia el sensor. Se ven significativamente afectados por la reflectividad de los objetivos, lo que puede acortar drásticamente su alcance. Estos sensores no deben utilizarse en aplicaciones con piezas muy pequeñas que necesitan ser detectadas, en aplicaciones de conteo de piezas o donde haya un fondo reflectante cerca del objeto a detectar. Los sensores de modo difuso son muy convenientes y se usan a menudo cuando los sensores de modo opuesto o retrorreflectante no son prácticos.

- Bajo esfuerzo de instalación

- No requiere reflector

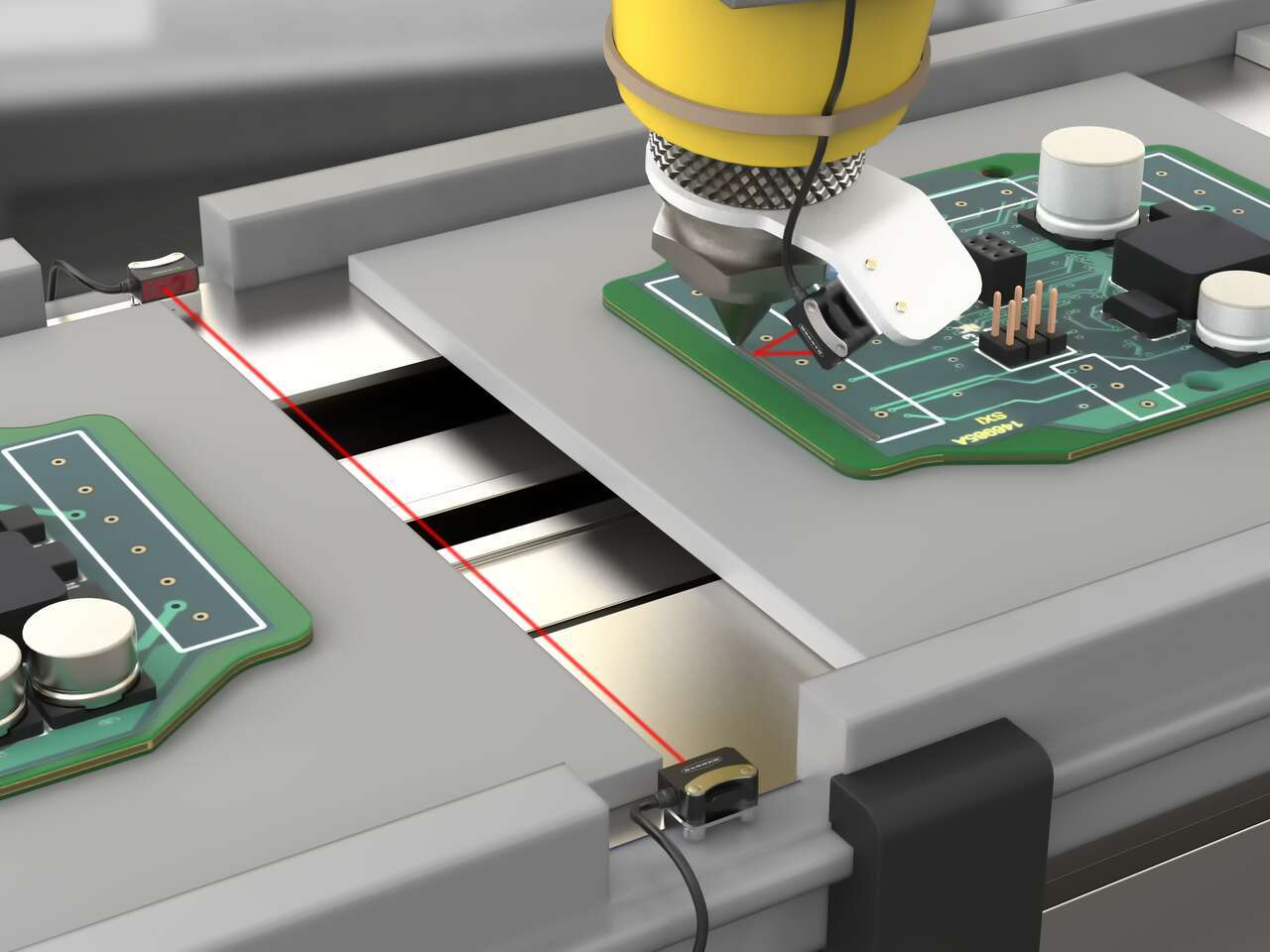

La alta ganancia excedente del campo ajustable Q2X le permite detectar wafers oscuros de manera confiable. La mínima separación entre objetos puede hacer que la máquina mueva la siguiente oblea a su posición tan pronto como la anterior esté fuera del camino. Además, su pequeño formato se adapta fácilmente a la máquina sin estorbar.

- Simplifique la instalación con menos componentes y menos cableado; no requiere objetivo ni receptor retro

- Ignore los objetos en segundo plano con una distancia de corte ajustable entre 18 mm y 150 mm

- Detecta objetivos oscuros y desafiantes utilizando emisores potentes con alto exceso de ganancia

- Detecte características precisas con el pequeño LED rojo brillante o el emisor láser de clase 1

- Evite la interferencia al montar varios sensores muy cerca gracias al algoritmo avanzado de inmunidad a la diafonía

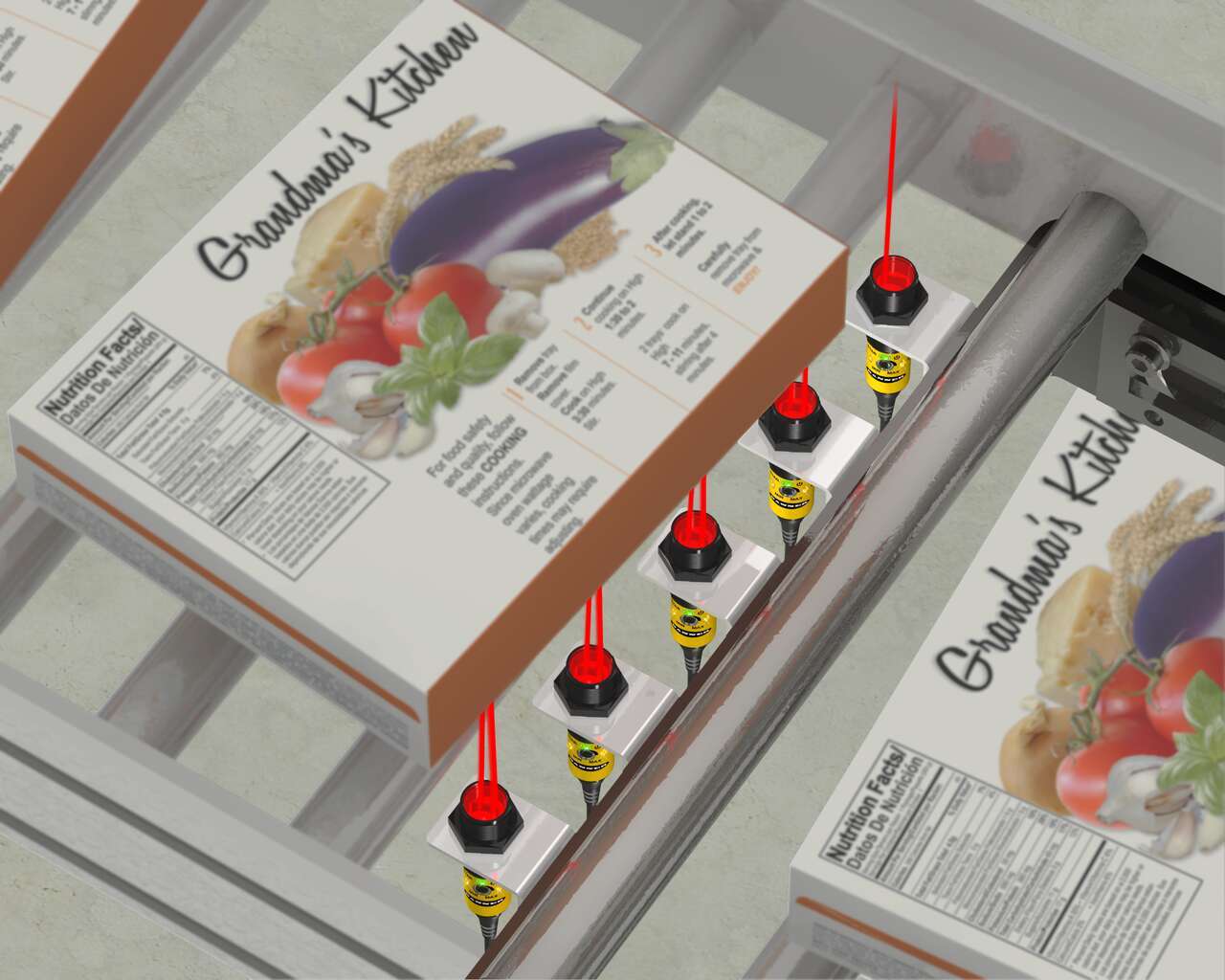

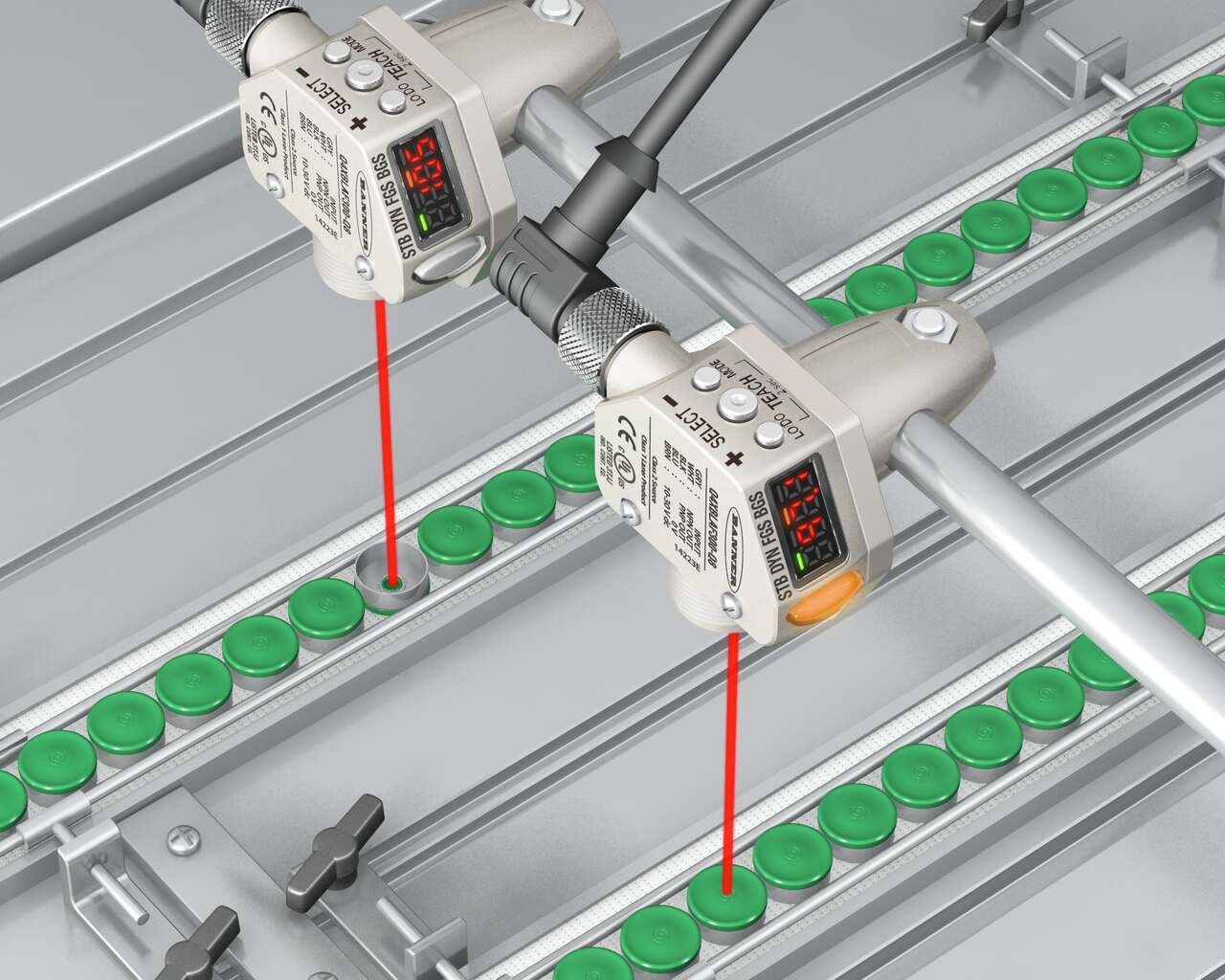

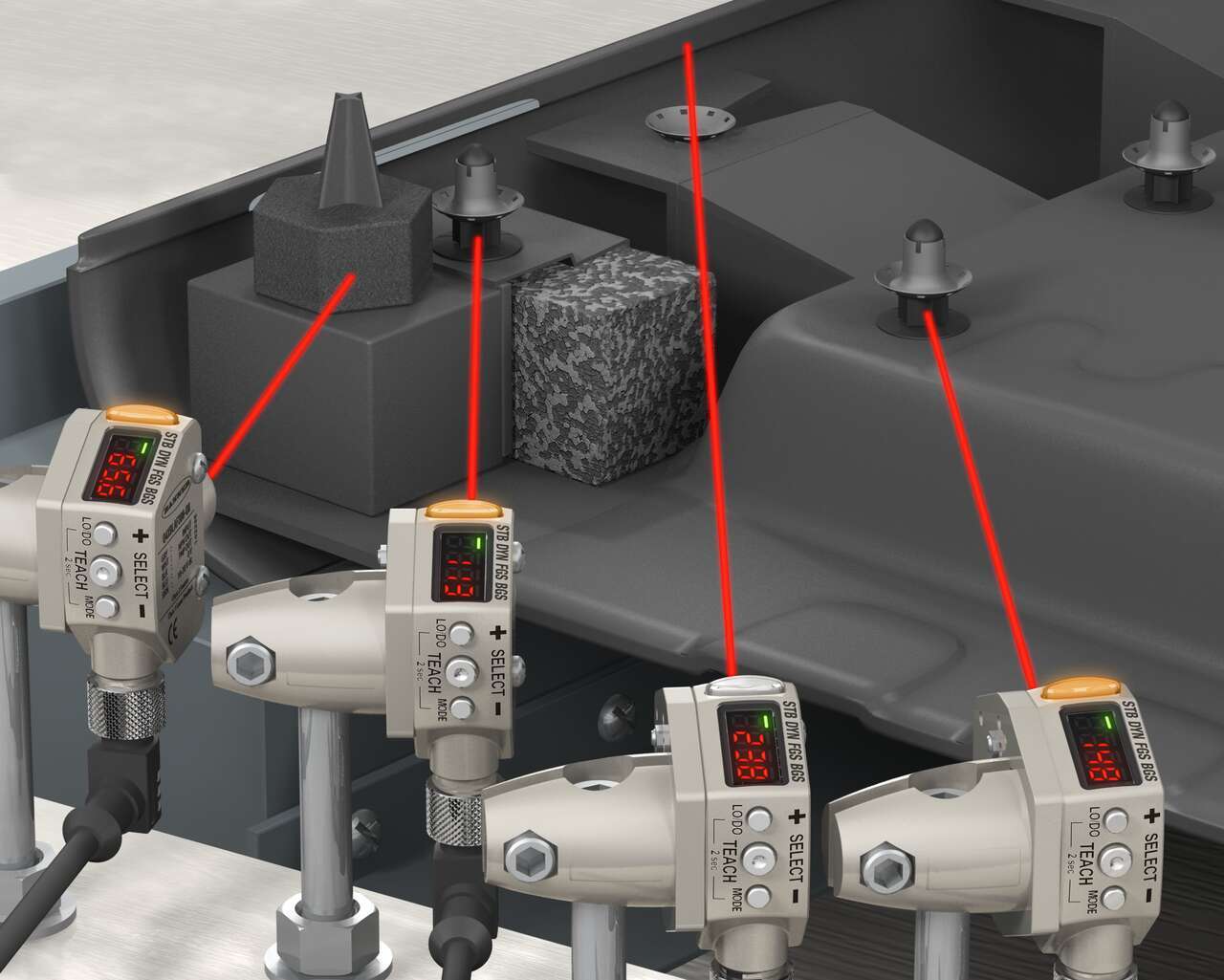

Los sensores de supresión de fondo (BGS) son un sensor de tipo difuso con un límite definido en su rango de detección, ignorando cualquier objeto que se encuentre más allá de ese rango. Hay dos tipos de sensores de supresión de fondo: de campo fijo y de campo ajustable. Ambos tipos usan la triangulación para determinar la distancia de corte que permite que el sensor ignore cualquier cosa más allá de ese punto. El exceso de ganancia disponible dentro del campo de detección fijo suele ser alto, lo que permite la detección de superficies menos reflectantes. Un sensor de supresión de fondo a menudo puede detectar un objetivo oscuro sobre un fondo blanco, siempre que el fondo esté más allá del límite del sensor.

- Detecta objetos a una distancia de detección establecida

- Ignora los objetos de fondo

- Sensibilidad al color muy baja

El exceso de ganancia es una medida de la cantidad de energía luminosa que detecta el elemento receptor. Un sensor necesita una ganancia en exceso de uno para que la salida del sensor se encienda o apague. Sin embargo, los contaminantes en el entorno de detección, como la suciedad, el polvo, el humo y la humedad, pueden provocar la atenuación de la señal, por lo que se requerirá mayor ganancia adicional para recibir una señal válida. El exceso de ganancia puede verse como la energía de detección adicional disponible para superar esa atenuación.

Un gráfico de ganancia excesiva muestra cuánta energía luminosa está disponible a una distancia determinada. Cuanto más sucio esté el entorno, más exceso de ganancia se necesitará para superarlo. Los gráficos son logarítmicos, lo que permite una descripción general concisa de los datos que varían en varios órdenes de magnitud. Cada tick menor aumenta en un factor de 1, y cada tick principal aumenta en un factor de 10. Por ejemplo, comenzando en el origen y subiendo por el eje Y, las marcas del gráfico representan 1, 2, 3, etc. Una vez que el tick llega a 10, los ticks representan 10, 20, 30, etc. Cuando el tick llega a 100, los ticks representan 100, 200, 300 y así sucesivamente.

Los sensores fotoeléctricos están disponibles con una variedad de haces de detección, incluidos LED visibles, LED infrarrojos, LED infrarrojos de longitud de onda larga y láseres, cada uno de los cuales tiene sus beneficios. Debido a que las aplicaciones rara vez son las mismas, la elección del tipo y patrón del haz variará de una a otra. Banner ofrece una amplia línea de sensores fotoeléctricos para resolver incluso los requisitos de detección más desafiantes.

LEDs Visibles

Los LED visibles ayudan en la alineación y configuración de un sensor, ya que el haz visible proporcionará un punto en el objetivo. El rojo es el color más común para los sensores fotoeléctricos, porque los diodos rojos son económicos de fabricar y los fotodetectores en los receptores son muy sensibles a la luz roja.

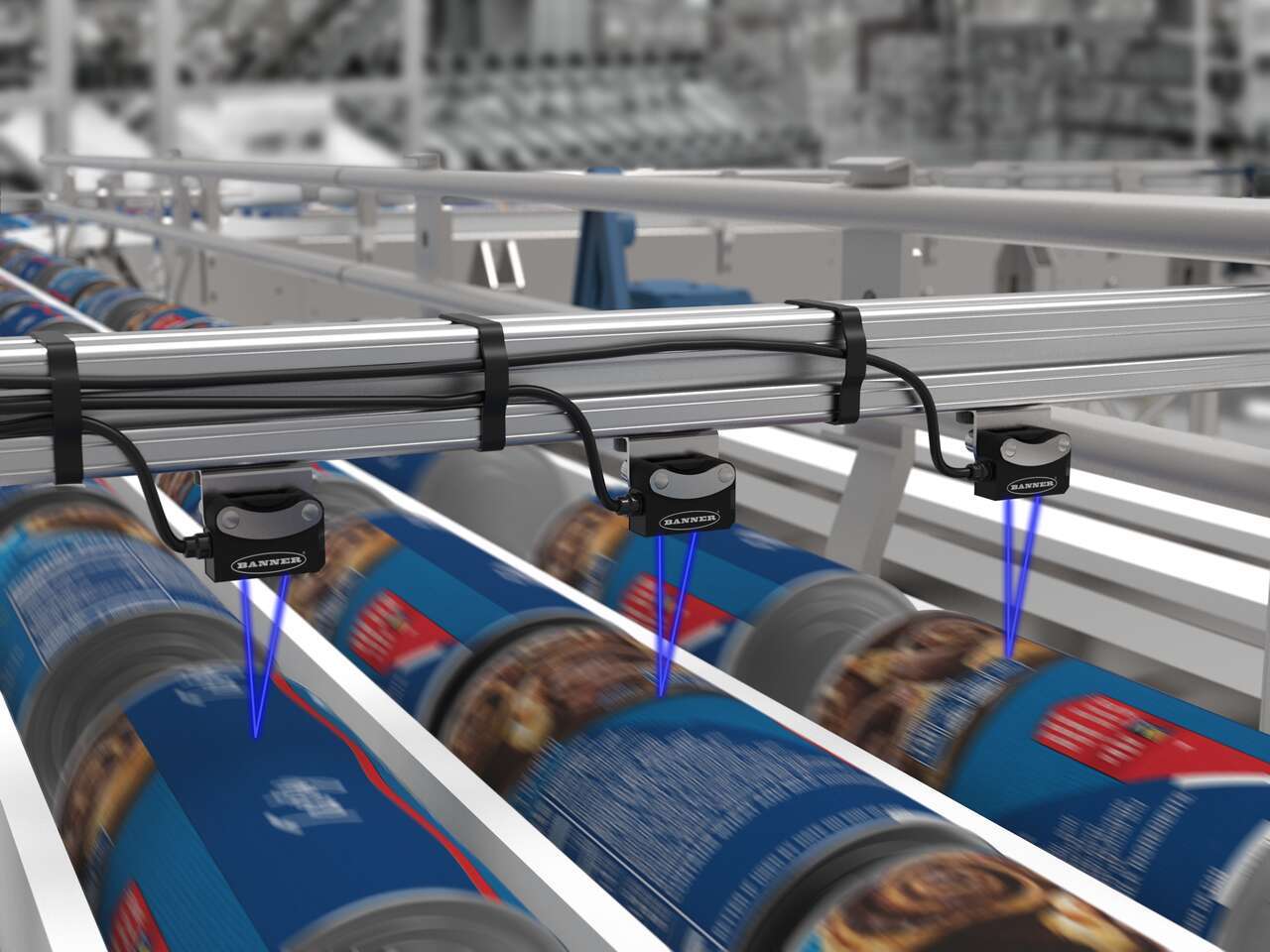

Los materiales actuarán de manera diferente a diferentes longitudes de onda de luz. Cierto material puede absorber una longitud de onda de luz mientras refleja otra, o el contraste entre dos colores es bajo. En estos casos, probar con un LED de un color diferente, como el azul, puede ser una solución sencilla al problema.

LEDs Infrarrojos

Los LEDs infrarrojos (IR) son invisibles para el ojo humano pero son muy eficientes para producir luz. Esta eficiencia puede ayudar a los sensores IR a ver más lejos que los LEDs visibles. Sin embargo, debido a que el haz es invisible, puede dificultar la alineación.

LED infrarrojos de longitud de onda larga

Por lo general, los sensores fotoeléctricos no pueden ver el agua porque es transparente a la luz en el espectro visible. Afortunadamente, el agua absorbe eficientemente la longitud de onda específica de 1450 nm, lo que permite la detección. Ciertos sensores de Banner utilizan LEDs infrarrojos de longitud de onda larga (LIR) que funcionan a 1450 nm para detectar líquidos que contienen agua, mientras ignoran (queman) los recipientes transparentes u opacos.

Láser

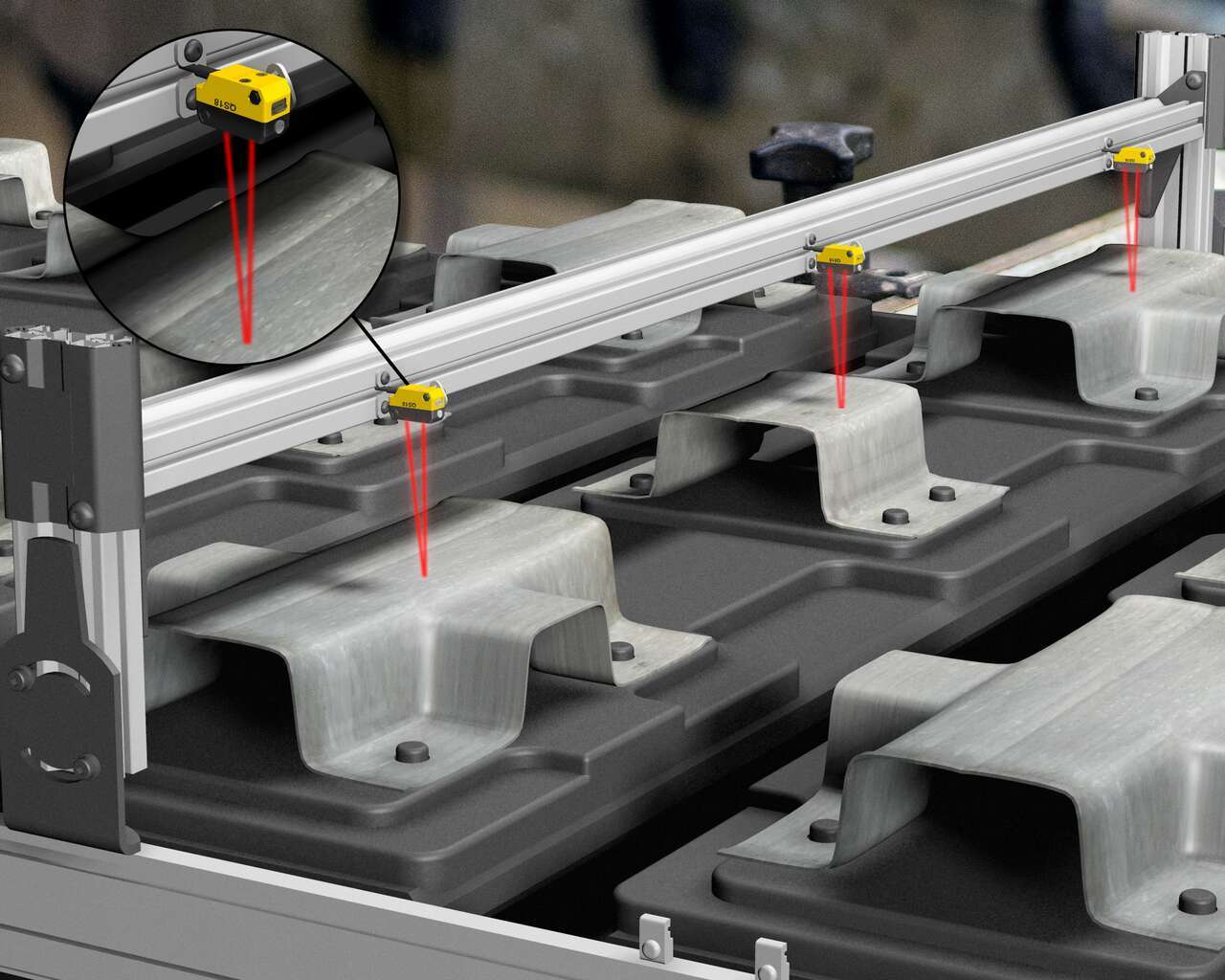

Muchos sensores Banner usan láseres para sus haces emitidos. Los láseres utilizan un punto de haz pequeño, lo que proporciona una mayor precisión que resulta ideal para detectar objetos o características muy pequeños. Este haz permanece muy ajustado incluso en grandes distancias, lo que proporciona una detección precisa a mayor distancia.

El patrón de haz representa el límite dentro del cual el sensor responderá a un objetivo. En modo opuesto, el receptor puede estar en cualquier lugar dentro de este patrón y detectará la luz del emisor. En el modo retrorreflectante, el patrón del haz depende del reflector que se utilice. Un reflector más pequeño reflejará menos luz, lo que da como resultado un alcance más corto y un patrón de haz más estrecho. En el modo difuso, el objetivo debe estar dentro del patrón del haz para ser detectado. En el modo difuso, el patrón del haz se crea utilizando una tarjeta blanca al 90 %, por lo que los objetivos de diferentes colores afectarán el patrón del haz.

Los sensores también tienen un haz efectivo, que es la parte “de trabajo” del haz de luz que se extiende desde el emisor hasta el receptor. Un objeto se detecta cuando rompe el haz efectivo. En el modo opuesto, el haz efectivo se establece entre el emisor y el receptor. En el modo retrorreflectivo, debido a que el emisor y el receptor están alojados en una sola unidad, el haz efectivo se establece entre el emisor, el reflector y el receptor.

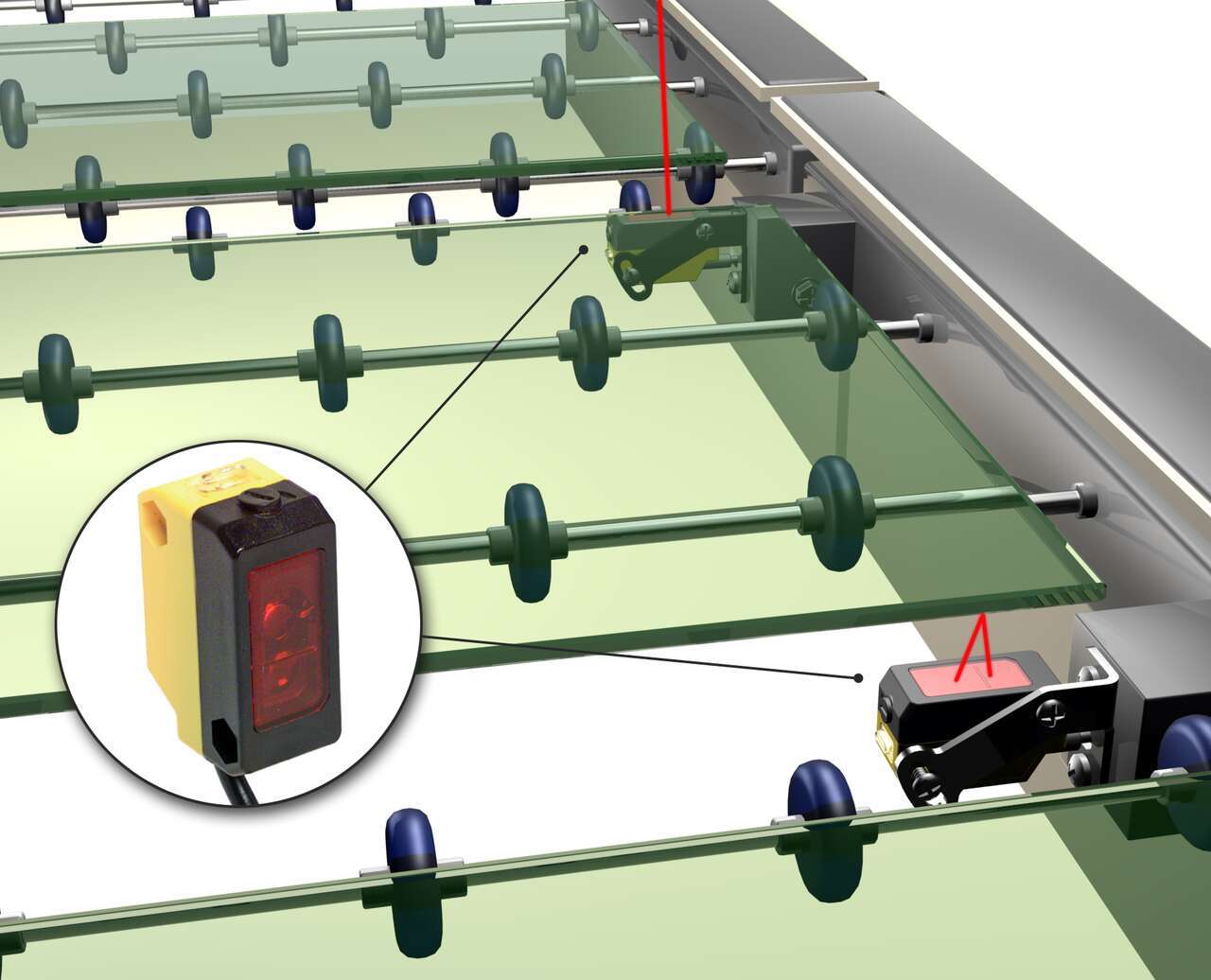

Aplicaciones Fotoeléctricas

-

Accurate Positioning in Medical & Scientific Laboratories

-

Dark Wafer Presence Detection

-

Streamline Labeling Process with a Fixed-Field Sensor

-

Status Indication on Airport Conveyor

-

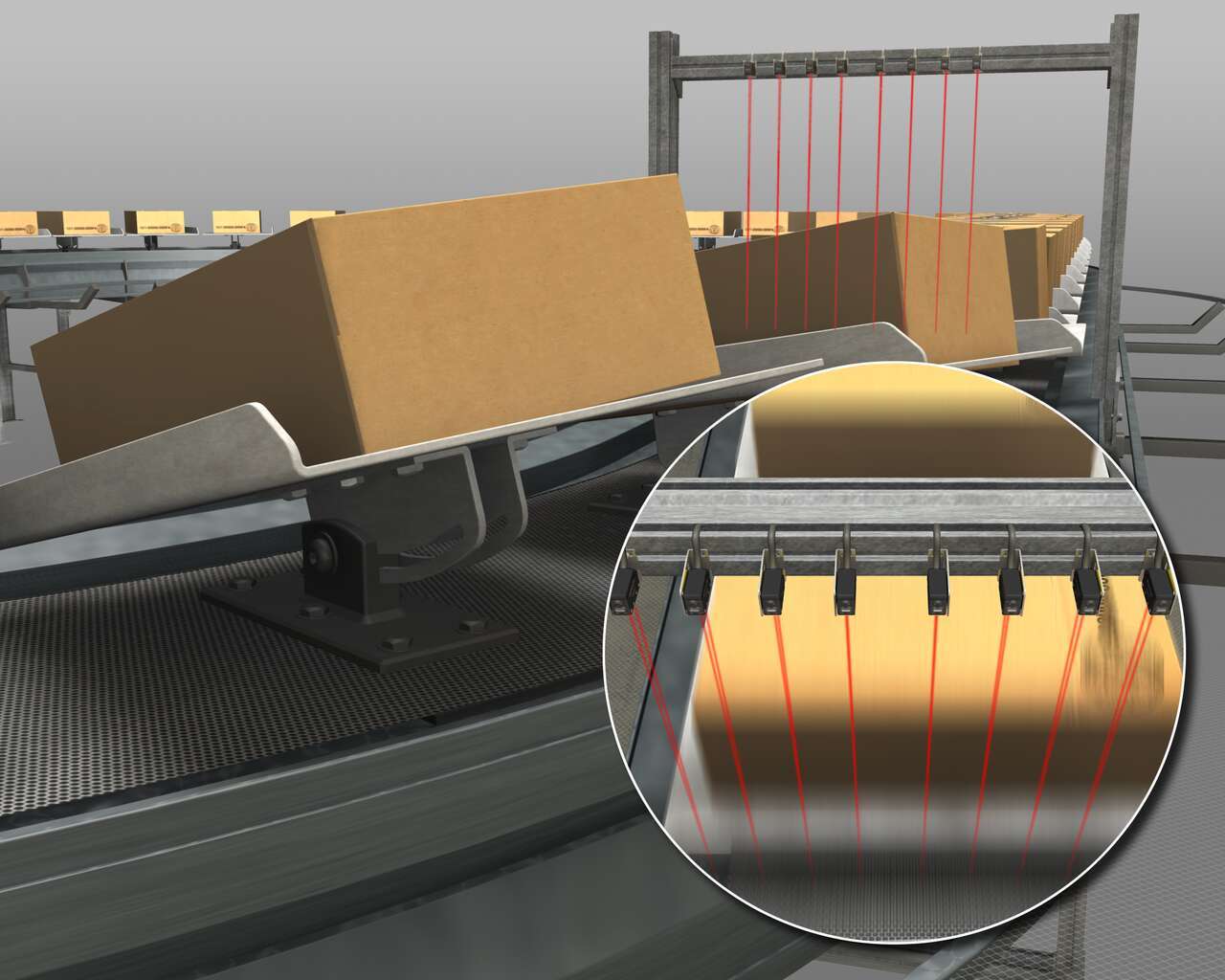

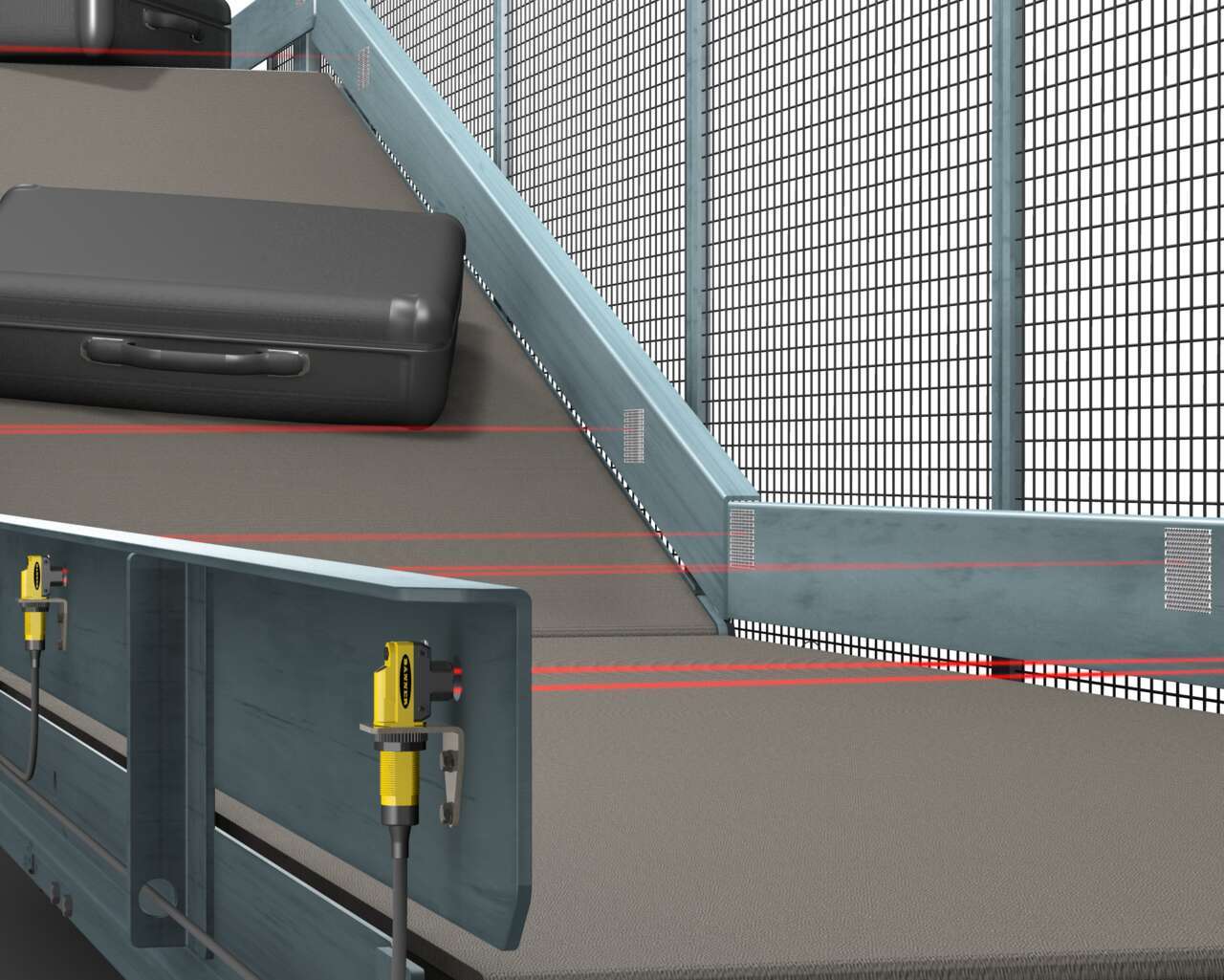

Preventing Jams in Airport Baggage Retrieval Systems

-

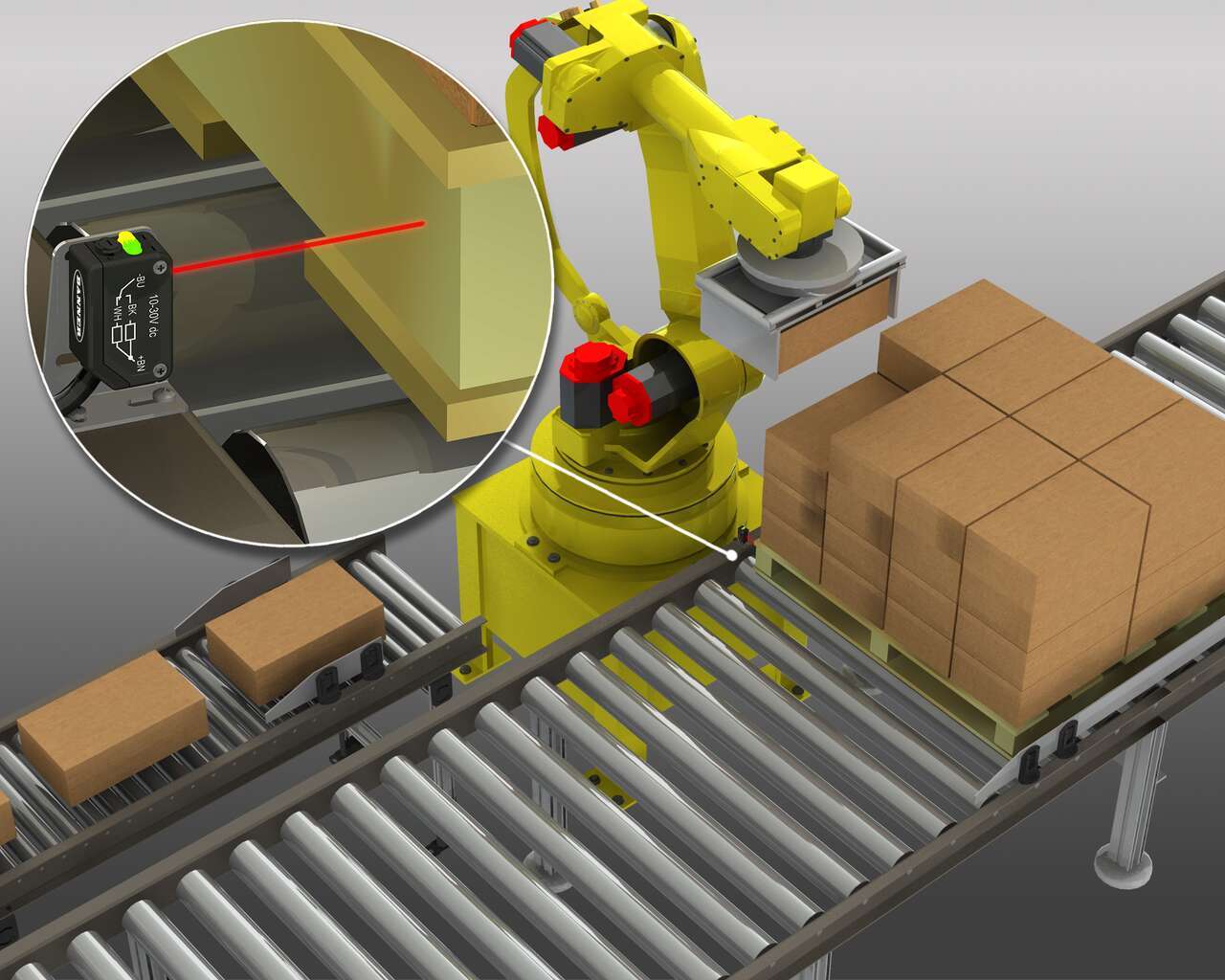

Positioning Pallets for Unloading by Robot Arms

-

Illuminated Forklift Guidance

-

Jam Detection on a Conveyor with Only AC Power

-

![Detección consistente de botellas de plástico transparentes a lo largo de una cinta transportadora [Caso de Éxito]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/bigstock-Bottle-Industry-30664220.jpg/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

Consistent Detection of Transparent Plastic Bottles Along a Conveyor Machine

-

![Operator Guidance Solution [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/PVD_QS30LE_OTB_K50L_Bin-Pick-for-Transmission-Plate.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

Operator Guidance Solution

-

![Etiquetado Termo Encogido a Altas Velocidades [Caso de Éxito]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/QS18VN6LLPQ5-Shrink-Sleeve-Bottle-Labeling.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

Etiquetado Termo Encogido a Altas Velocidades [Caso de Éxito]

-

![Sensor de LED Azul Detecta Botellas Color Ámbar [Caso de Éxito]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2010/QS18LV-Solid-Dose-Pkng---Perscription-Vial-Detect.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

Sensor de LED Azul Detecta Botellas Color Ámbar [Caso de Éxito]

-

Detección de Nivel de Llenado de Botella

-

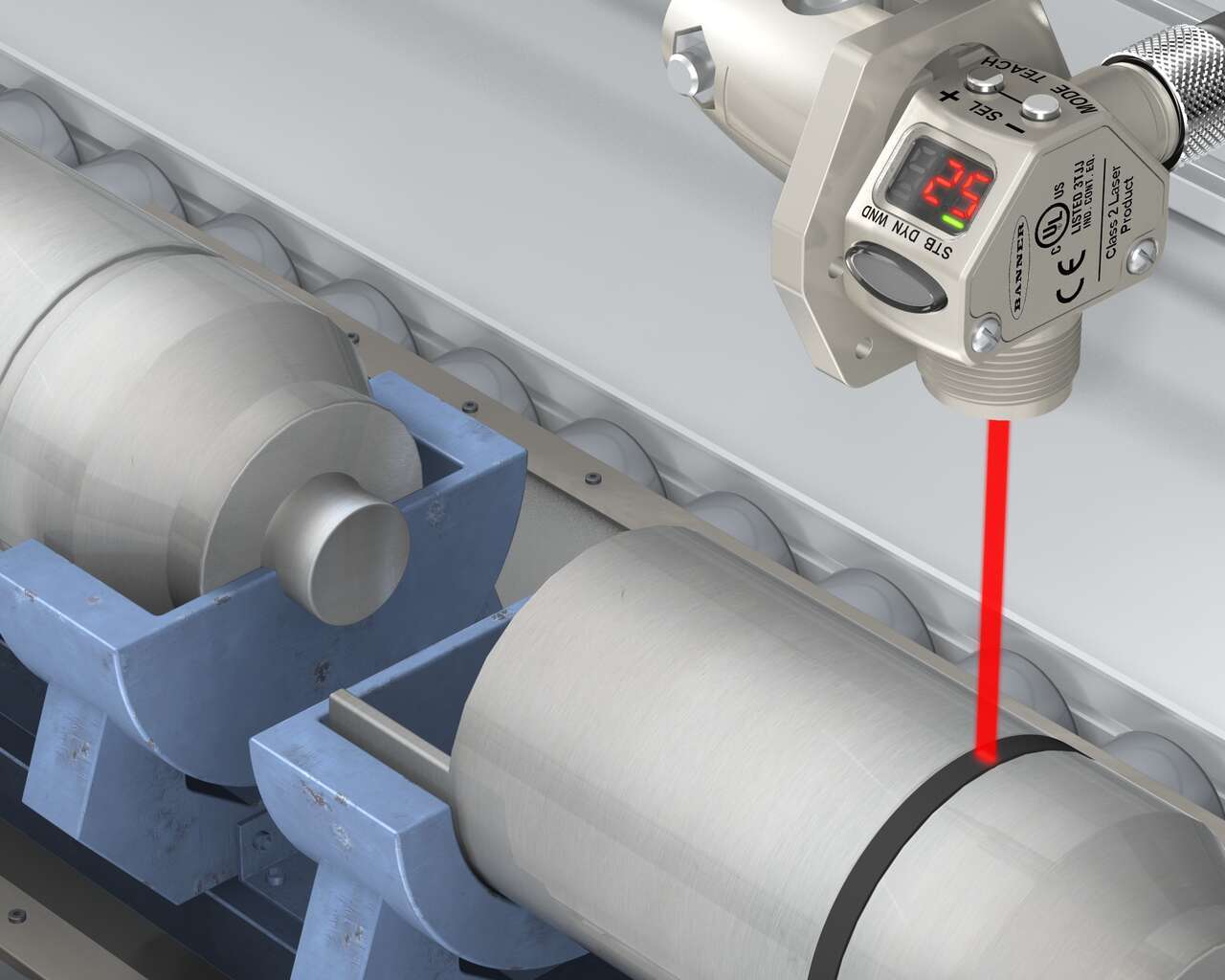

Medición de Nivel

-

Monitoreo de Niveles de Bandeja de Plástico en una Máquina de Denester

-

Verificación de Nivel de Llenado Sin Contacto

-

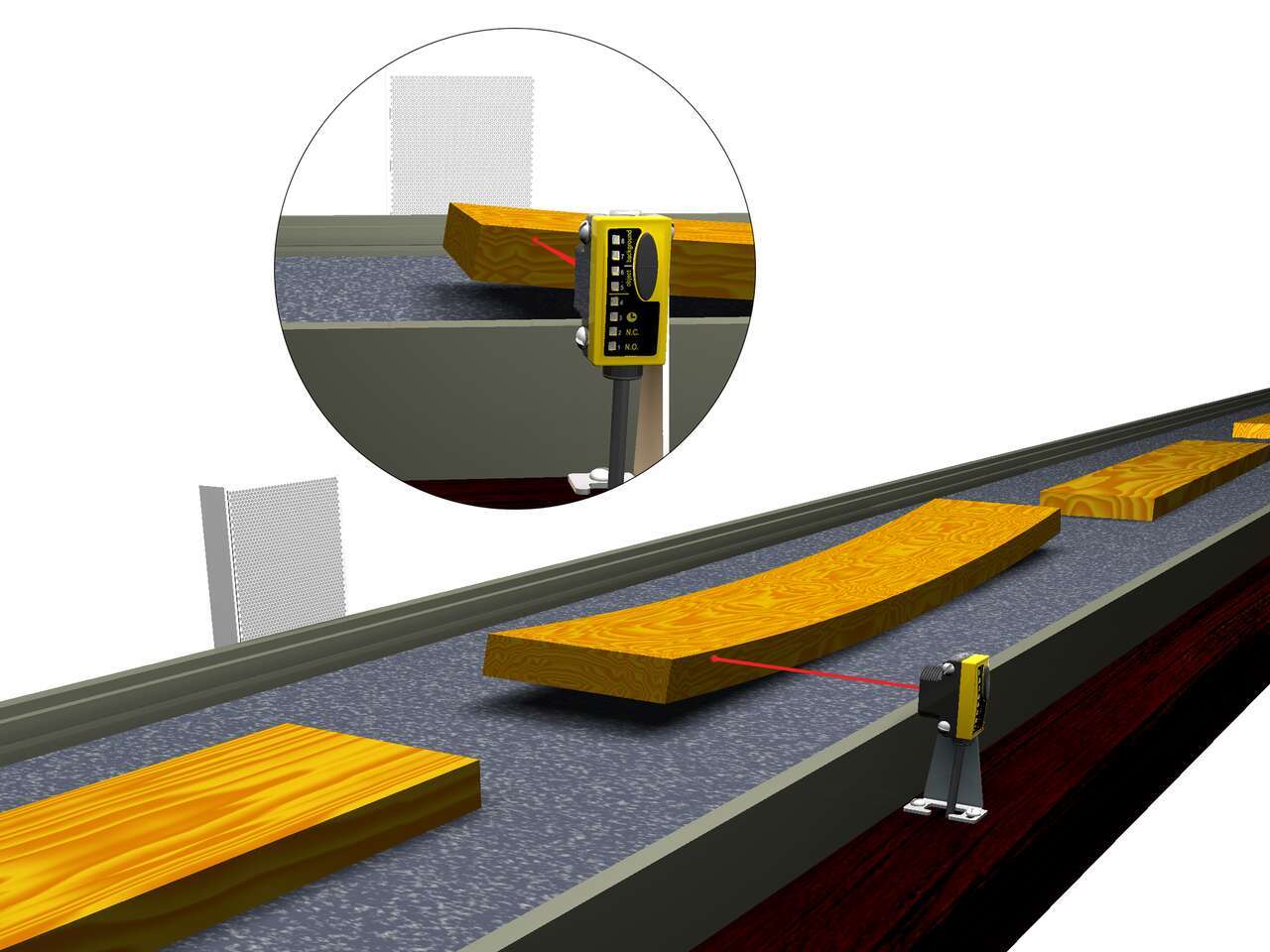

Board Warp Detection with a QS30

-

Clasificación por Color

-

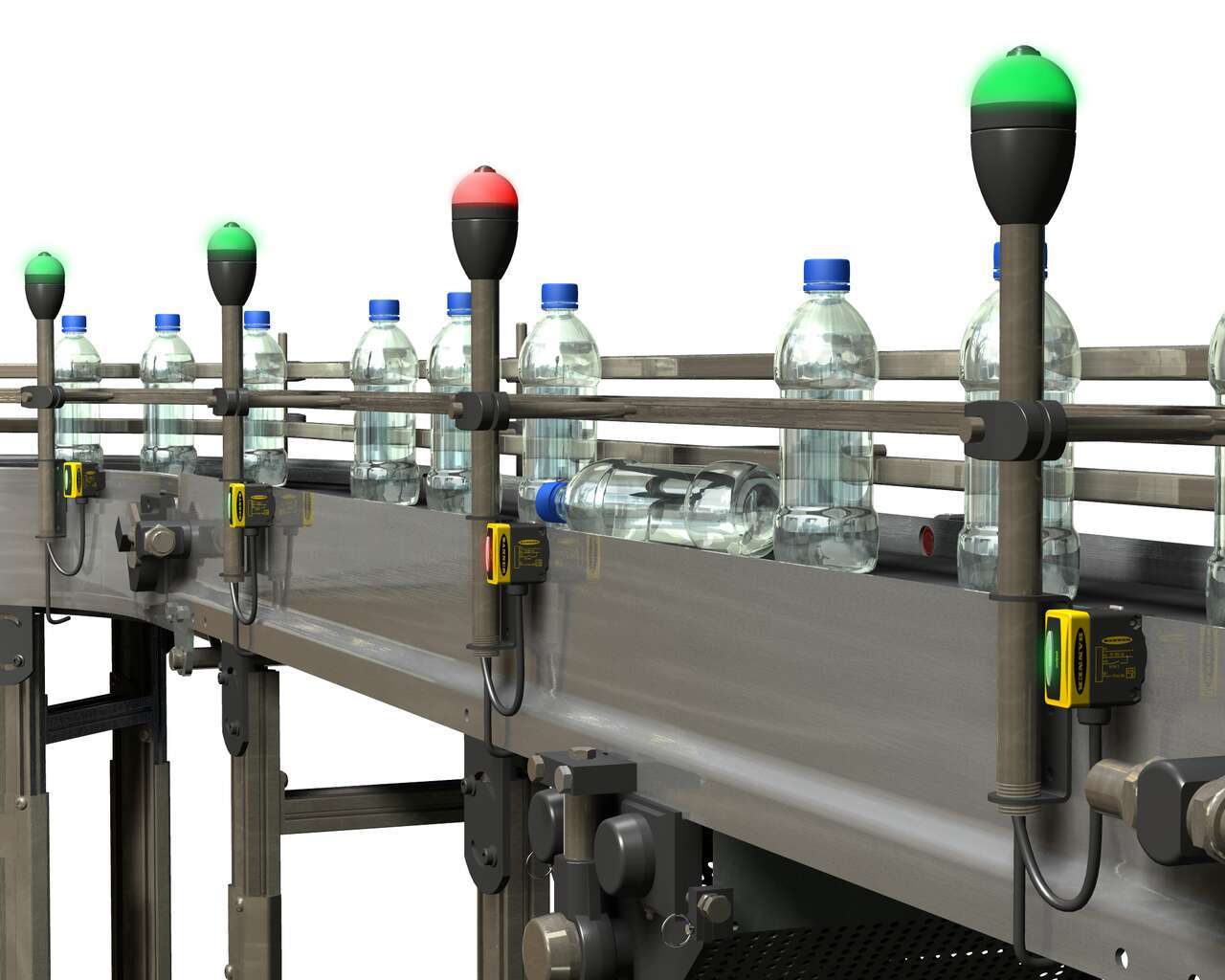

Detección de Atascos en un Transportador

-

Contando Tarjetas de Memoria

-

Detección de Paquetes de Diferente Tamaño en un Transportador

-

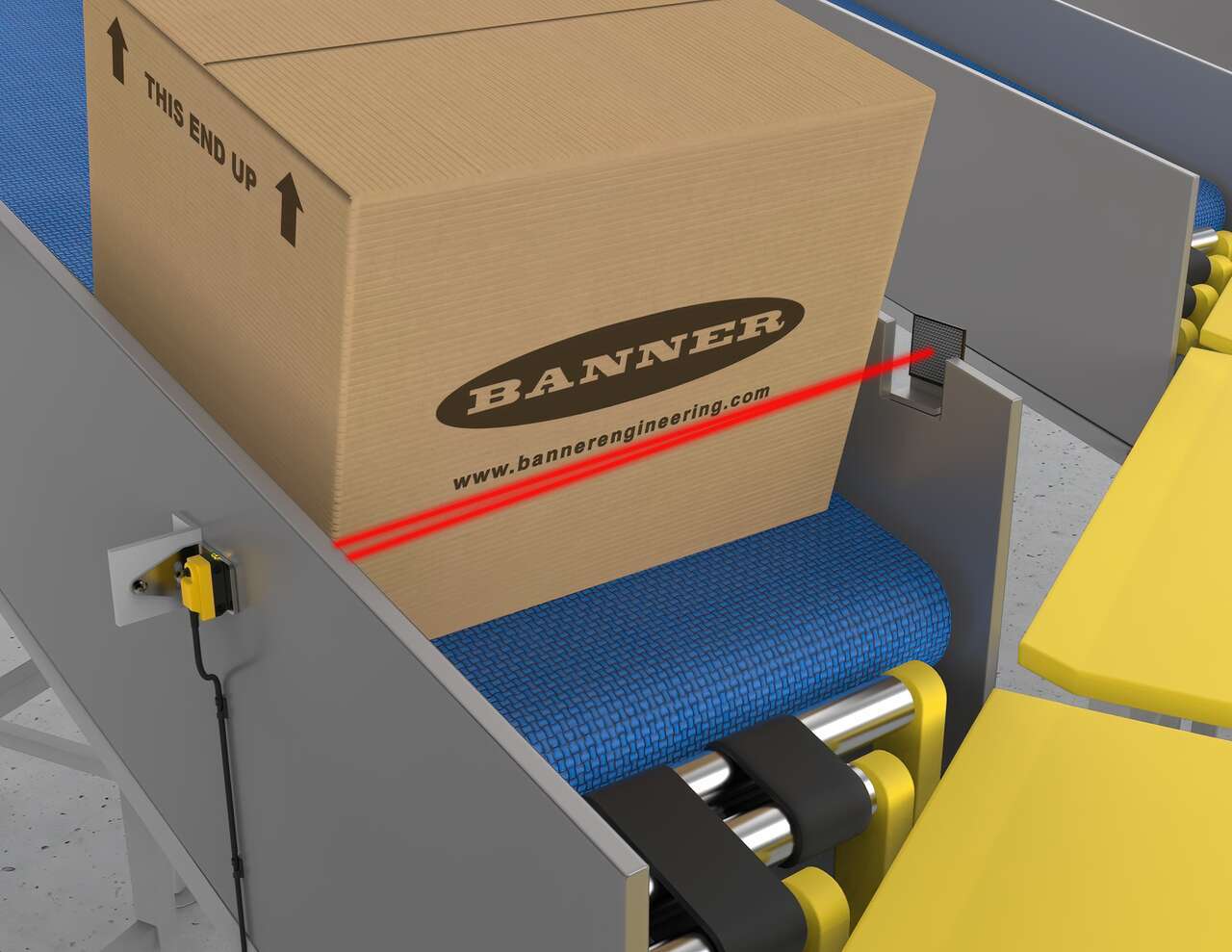

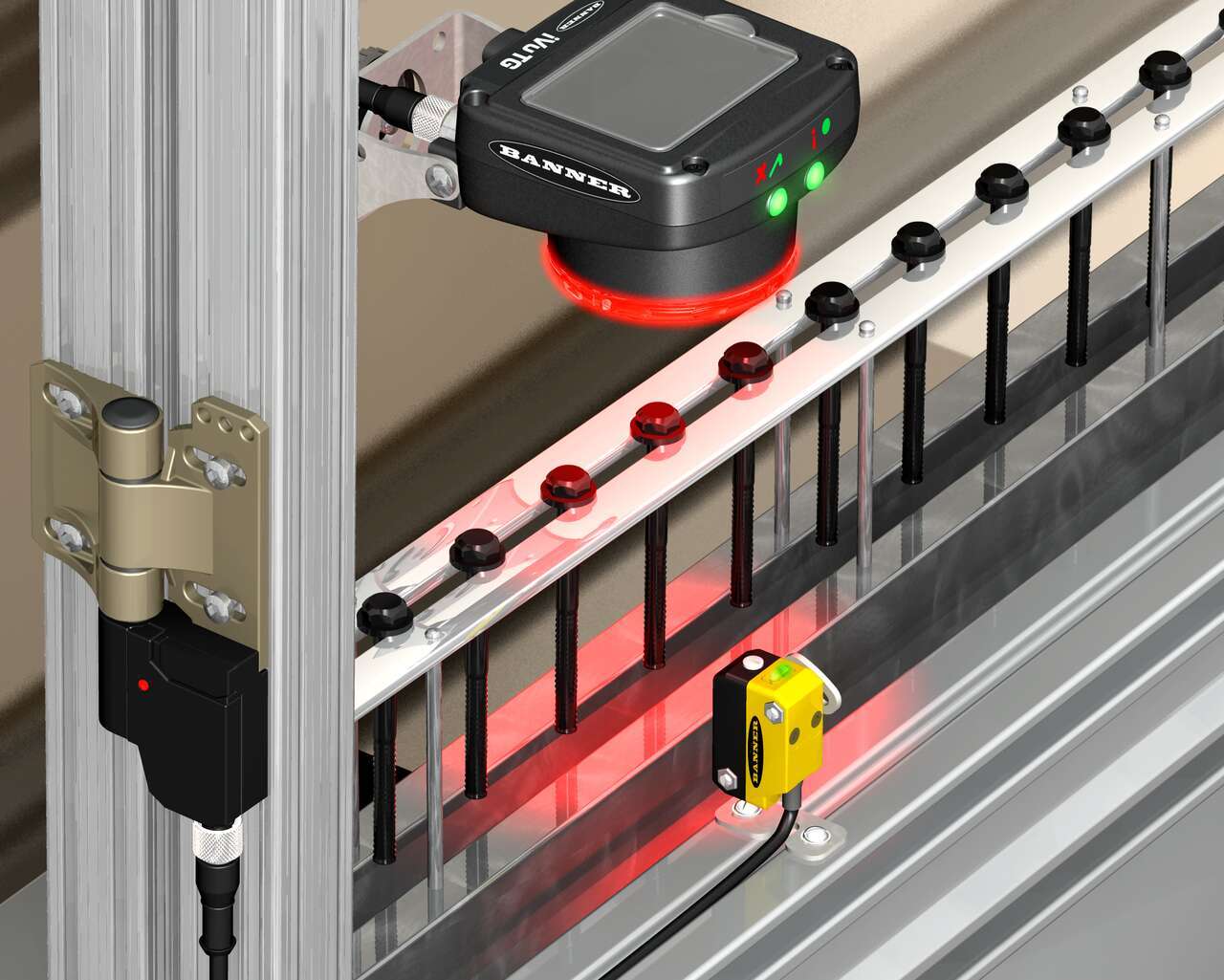

Detección de Objetos en un Transportador de AC

-

Transportador de Alcance Extendido

-

Verificación de Nivel de Llenado en Botellas de Agua

-

Detección de Cartón de Jugo

-

Detección de Fugas de Líquido con un QS18

-

Clasificación de Correo por Tamaño

-

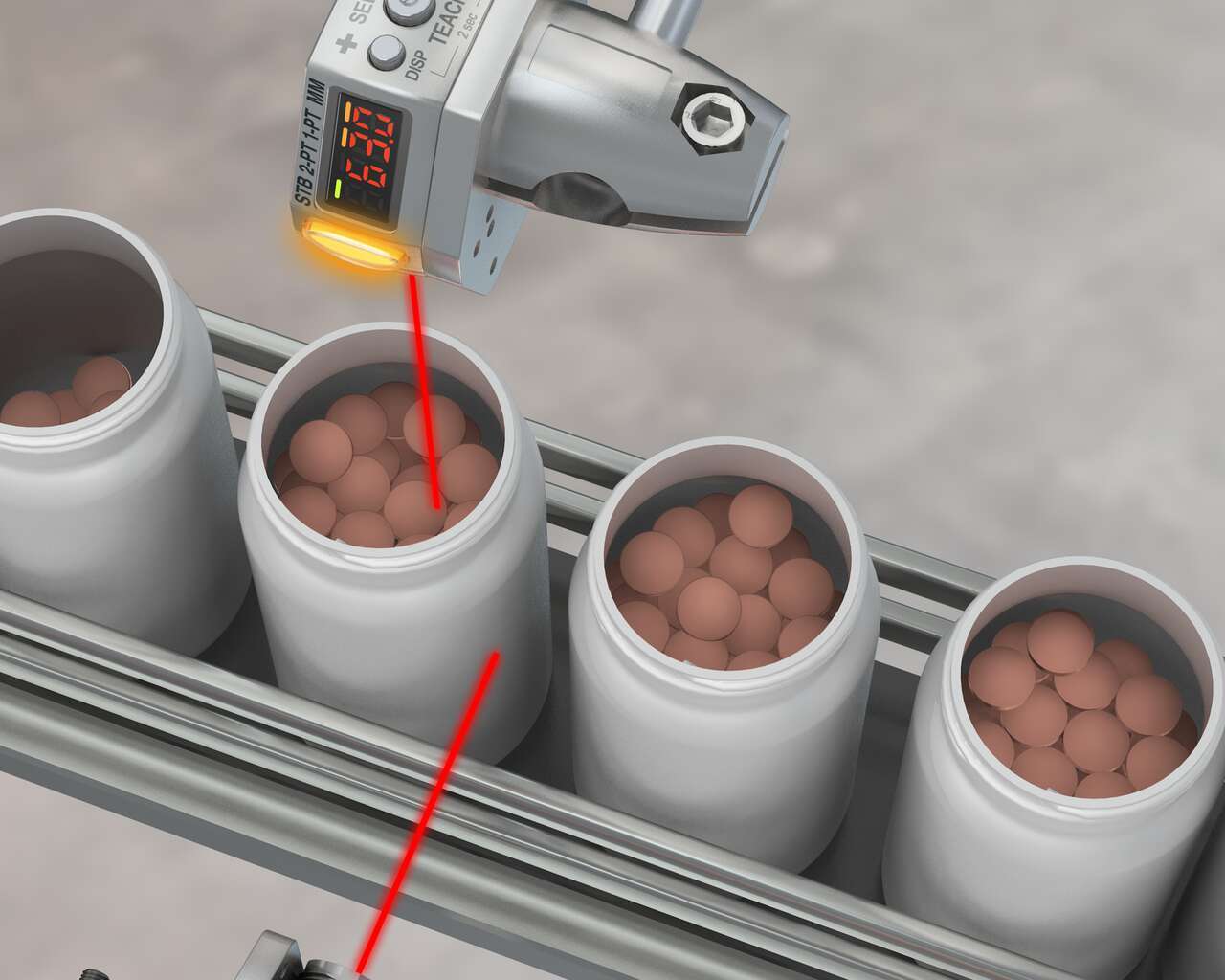

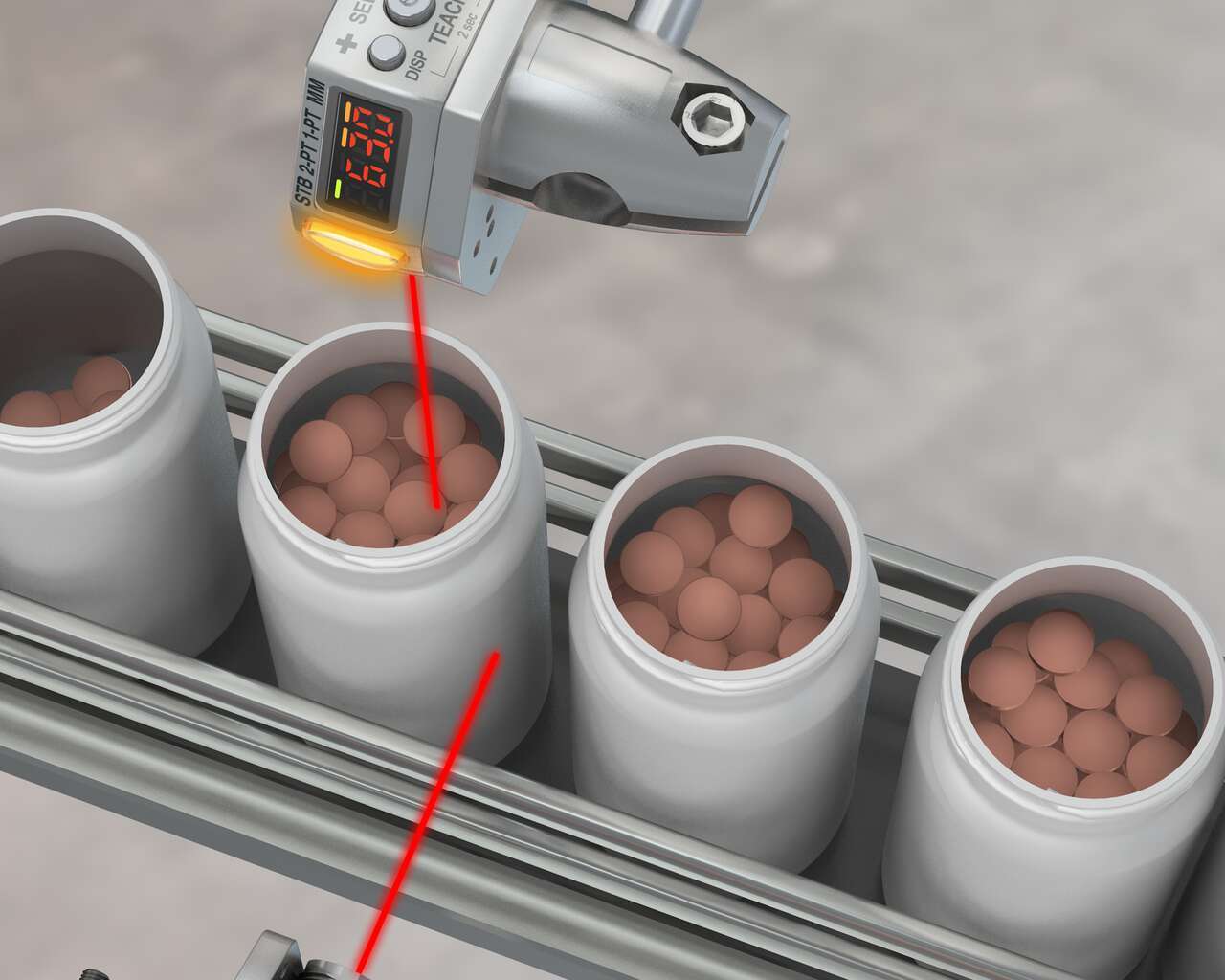

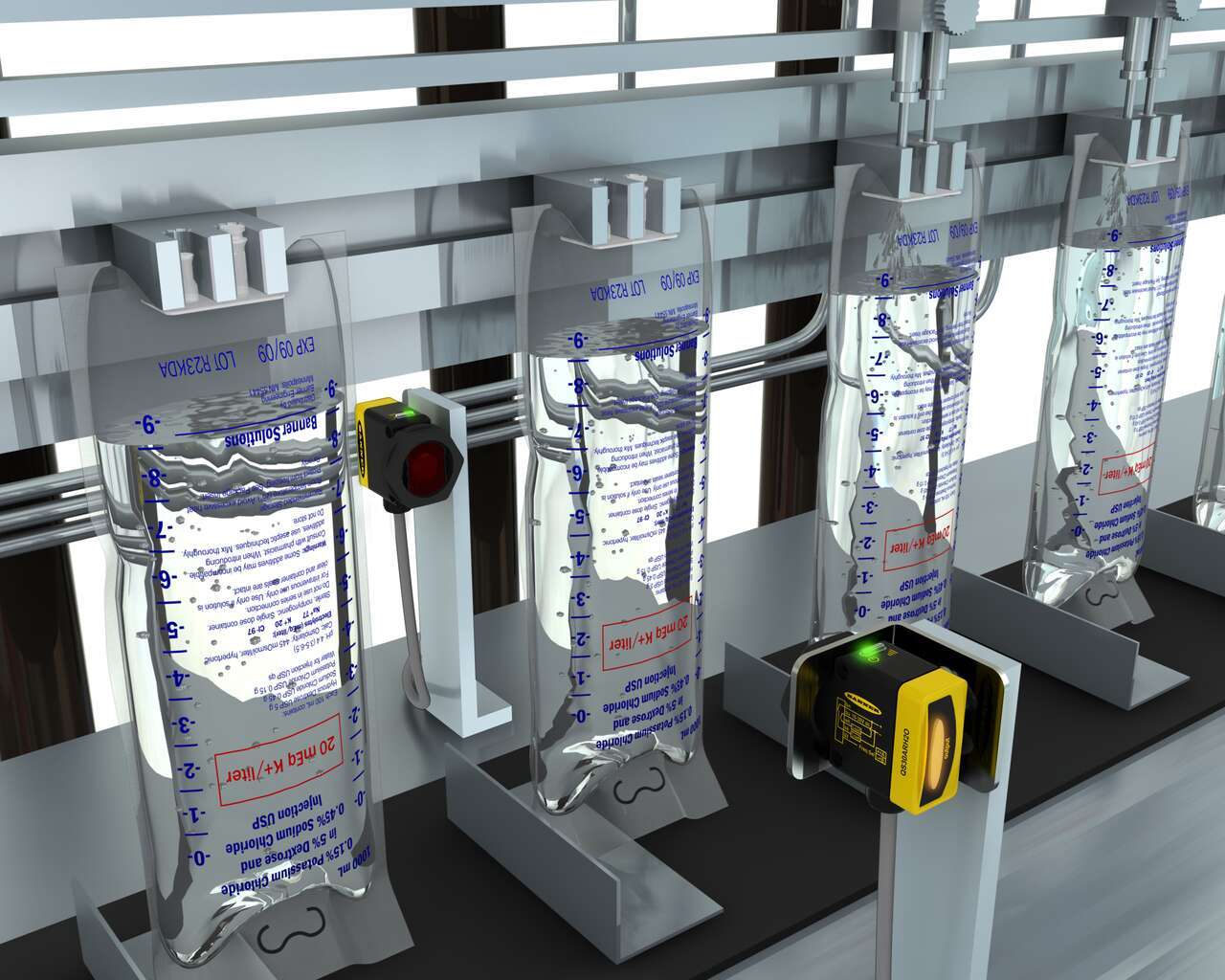

Detección de Llenado en Envase de Medicina

-

Monitoring Clear Film in a Tray Sealer

-

Objetos sobre una Banda Transportadora

-

Evitar Colisión de Paquetes

-

Detección de Piezas en un Tazón Alimentador

-

Estación de Admisión para Auto Clasificación

-

Detección de Altura de Apilado de Piezas Metálicas

-

Detección de O-Ring Negro

-

Detección de Bandejas de Plástico Negro en una Tolva y Estación de Llenado

-

Inspección de Tapa de Botella

-

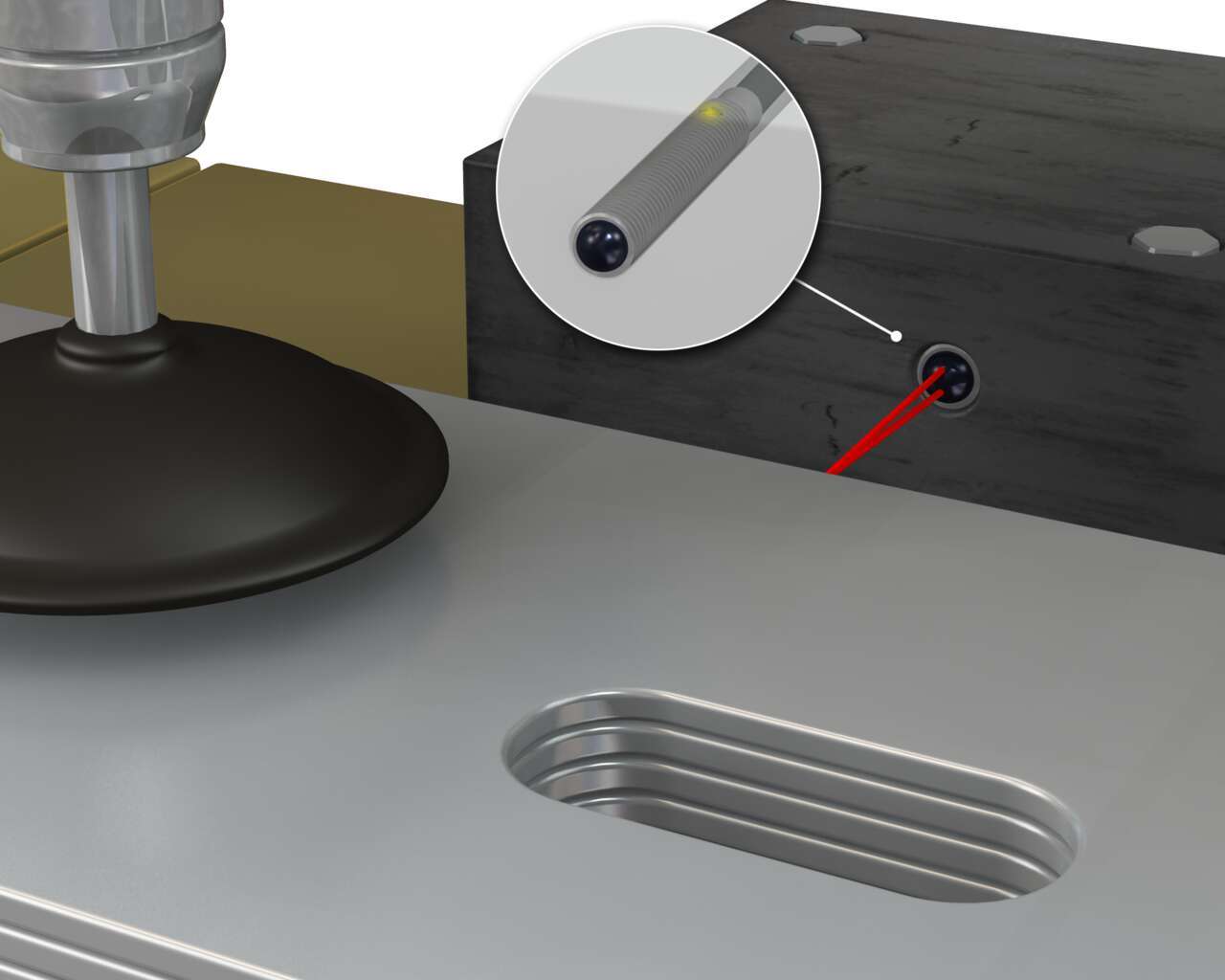

Inspección de Tapas en Áreas Confinadas

-

Verificación de Orientación de Tapa

-

Detección de Partes Negras en el Panel Negro de una Puerta

-

Detección de Tapas de Botellas de Varios Colores

-

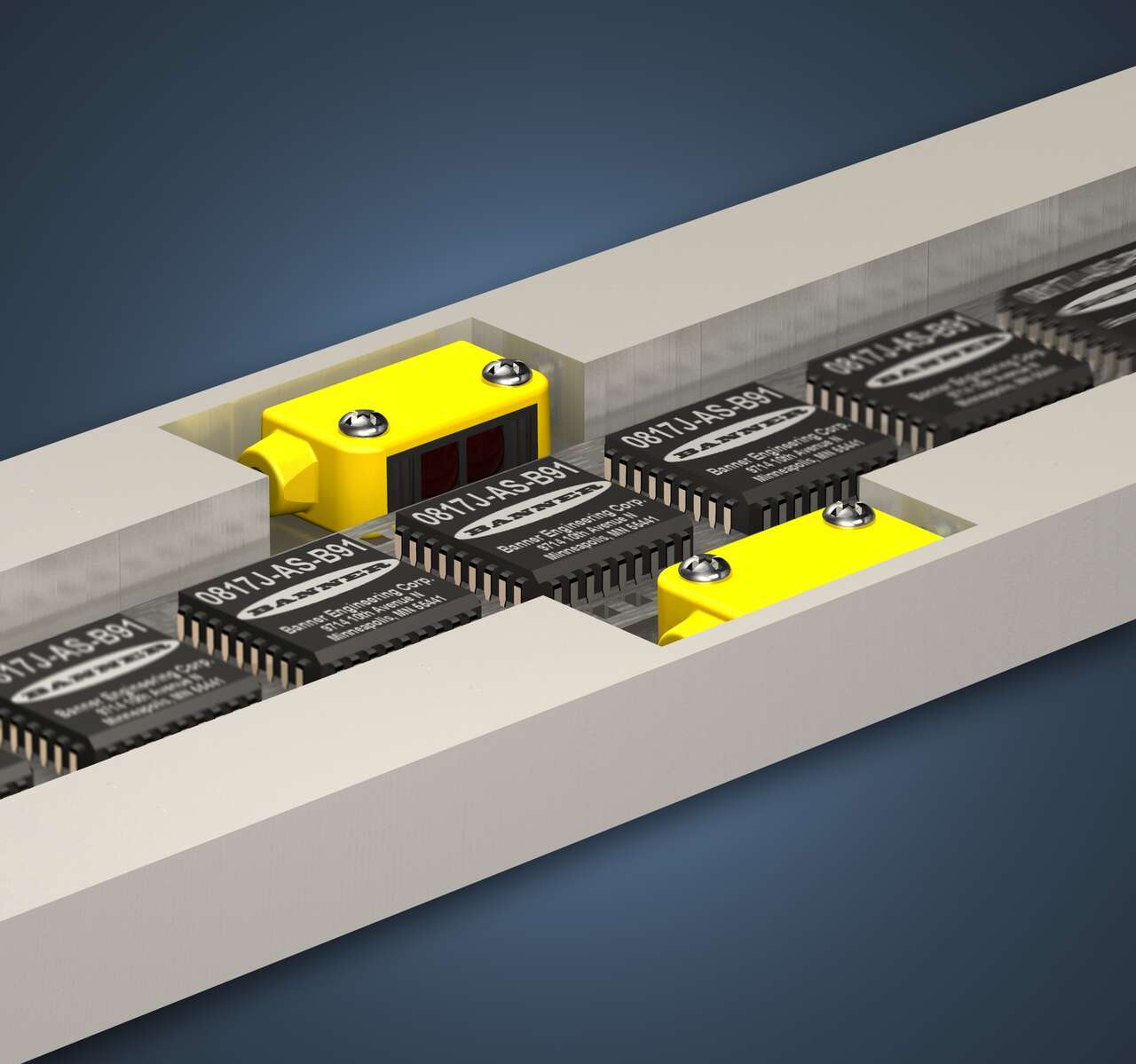

Comprobación de Errores para Chips de Circuito Integrado Cargados en la Cinta de Bolsillo

-

Detección de Pestañas Abiertas en Cenas Congeladas Empaquetadas

-

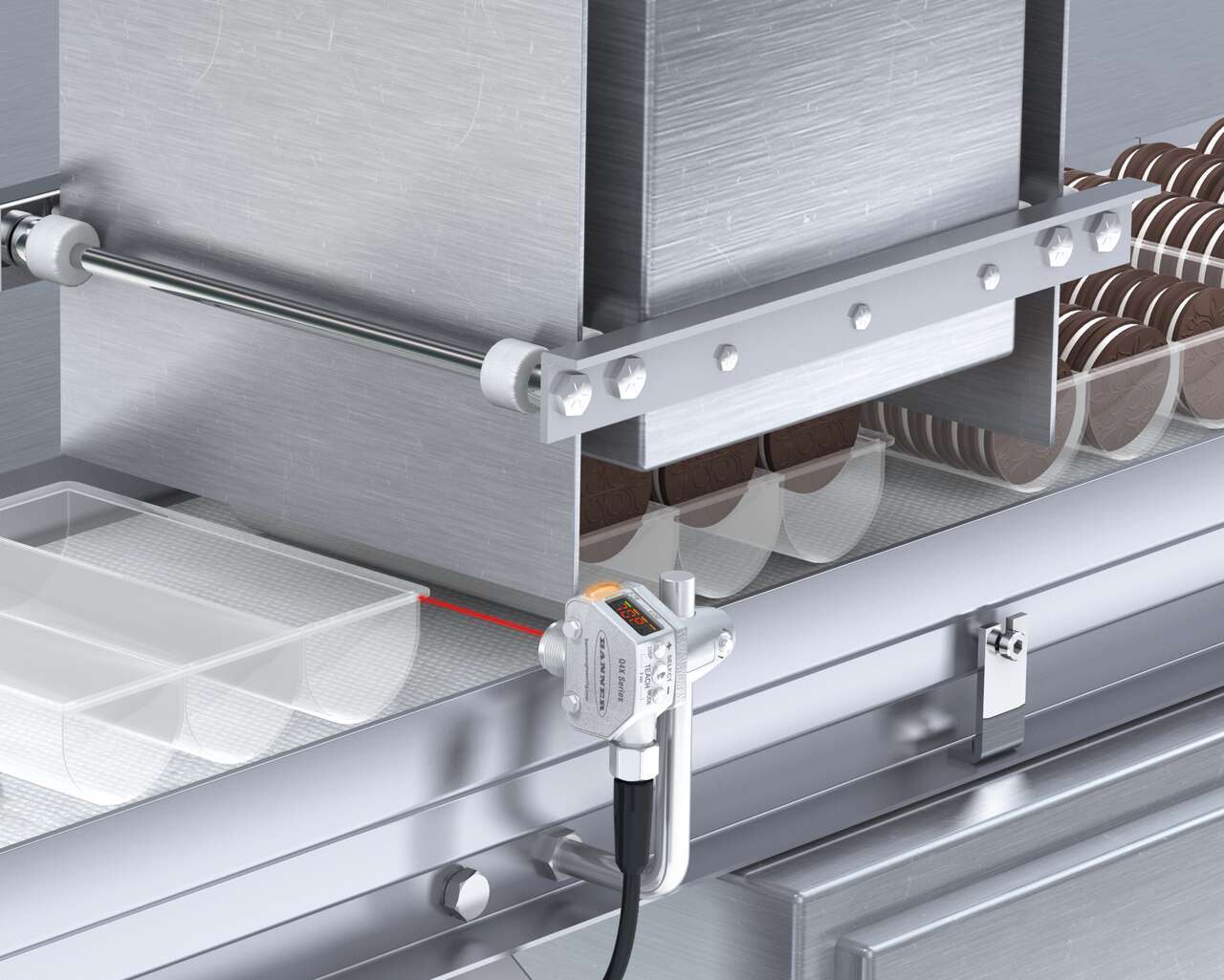

Inspeccionar Chocolates Faltantes en una Línea de Envasado

-

Detección de Etiquetas

-

Verificación de Presencia de Parte

-

Detección de Empaque de Hule en Bloque de Motor

-

Detección de Roscas en Barreno

-

Seguimiento de Frascos a Través de un Laboratorio Clínico Automatizado

-

Detección de Botellas Volcadas en una Línea de Embotellado de Alta Velocidad

-

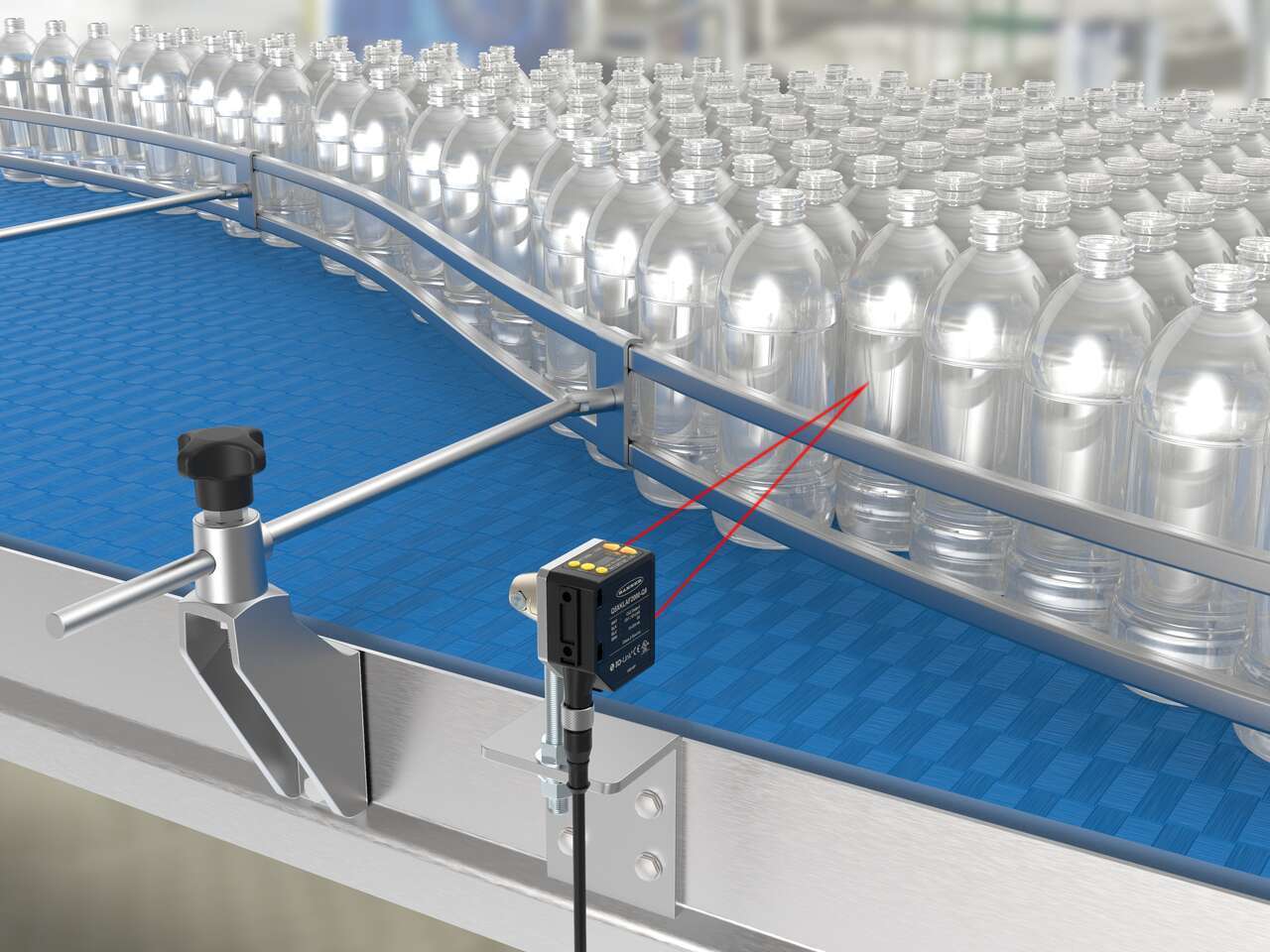

Conteo de Envases de Plástico Transparente en una Banda Transportadora

-

Detección de Bandeja Transparente en la Tolva en las Unidades de Almacenamiento de Alimentos

-

Detectar e Indicar la Presencia de una Botella Ladeada

-

Detecting Clear Glass and Plastic PET Bottles in Washdown Environments

-

Detección de Envolturas Reflectivas en un Transportador

-

Detección de Botellas de PET para Regular el Flujo del Producto

-

In-Line Accumulation on Single Filer

-

Detección de Líquidos Transparentes en Envases Transparentes

-

Altura de Pila de Cartón

-

Detección de Objetos a Largo Alcance

-

Soluciones para Selladoras Verticales (VFFS)

-

Manejo de Equipaje

-

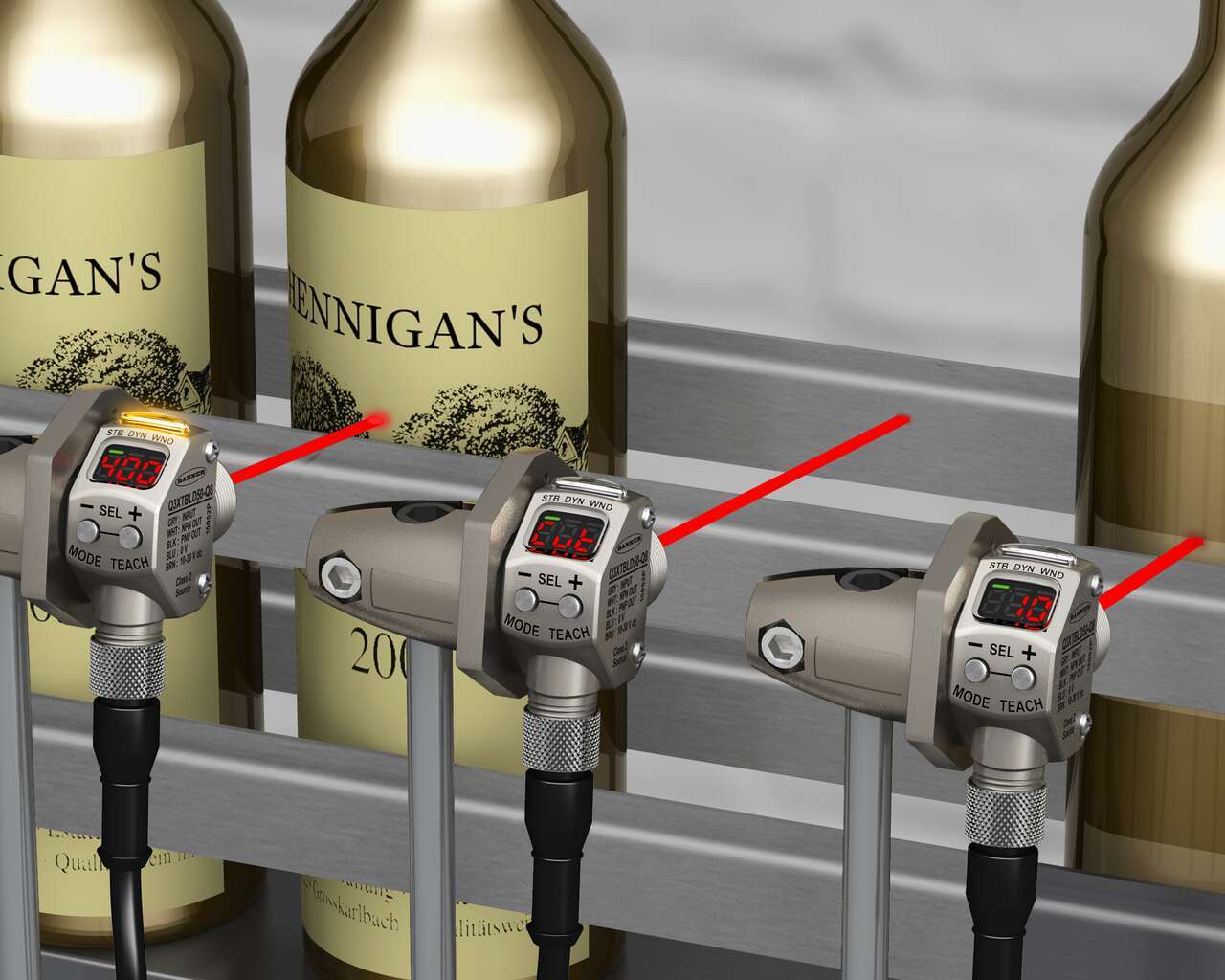

Verificación de las Etiquetas en Botellas

-

Conteo de Cajas de Cartón

-

Activación de una Impresora de Fecha/Lote en Cajas de Cartón

-

Contando Circuitos Integrados

-

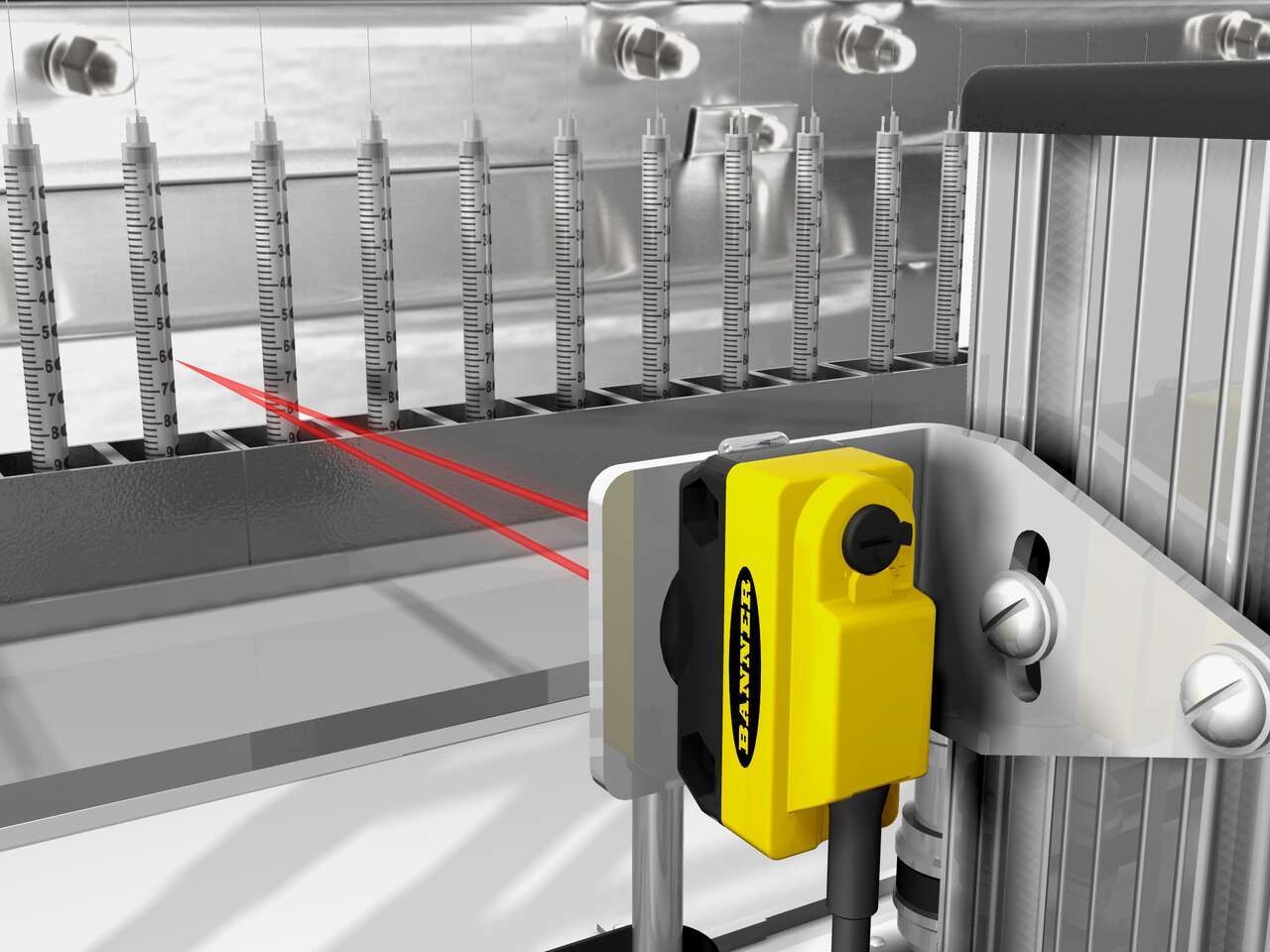

Conteo de Jeringas Utilizando Supresión de Fondo

-

Detección de Páneles de Vidrio

-

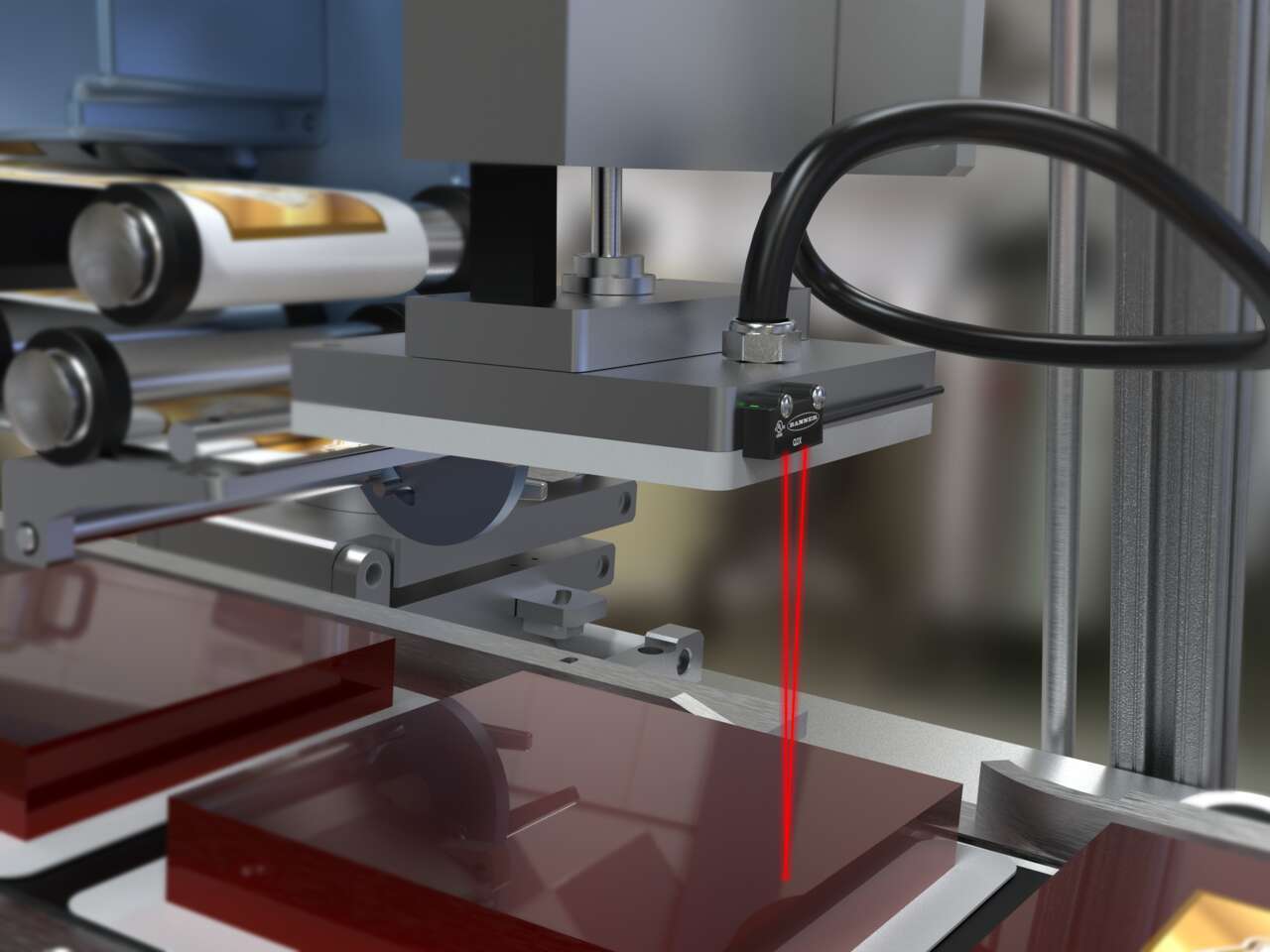

Disparo para Inspección en Impresora

-

Load Station Pallet Detection

-

Detección de Motor

-

Posicionamiento del Transportador de Carga

-

Control de Flujo en Lata de Refresco

-

Detección de Adhesivo de PCB Durante el Proceso de Ensamblaje

-

Cierre de Proximidad de Pruebas de Error en la Línea de Montaje

-

Detección de Roles de Desayuno Refrigerados en un Transportador de Varios Líneas

-

Detección de la Orientación de Tapas

-

Detección de Disco Duro

-

Inspección de Paquetes Utilizando un Sensor Láser Difuso

-

Inspección de Piezas en un Alimentador Lineal

-

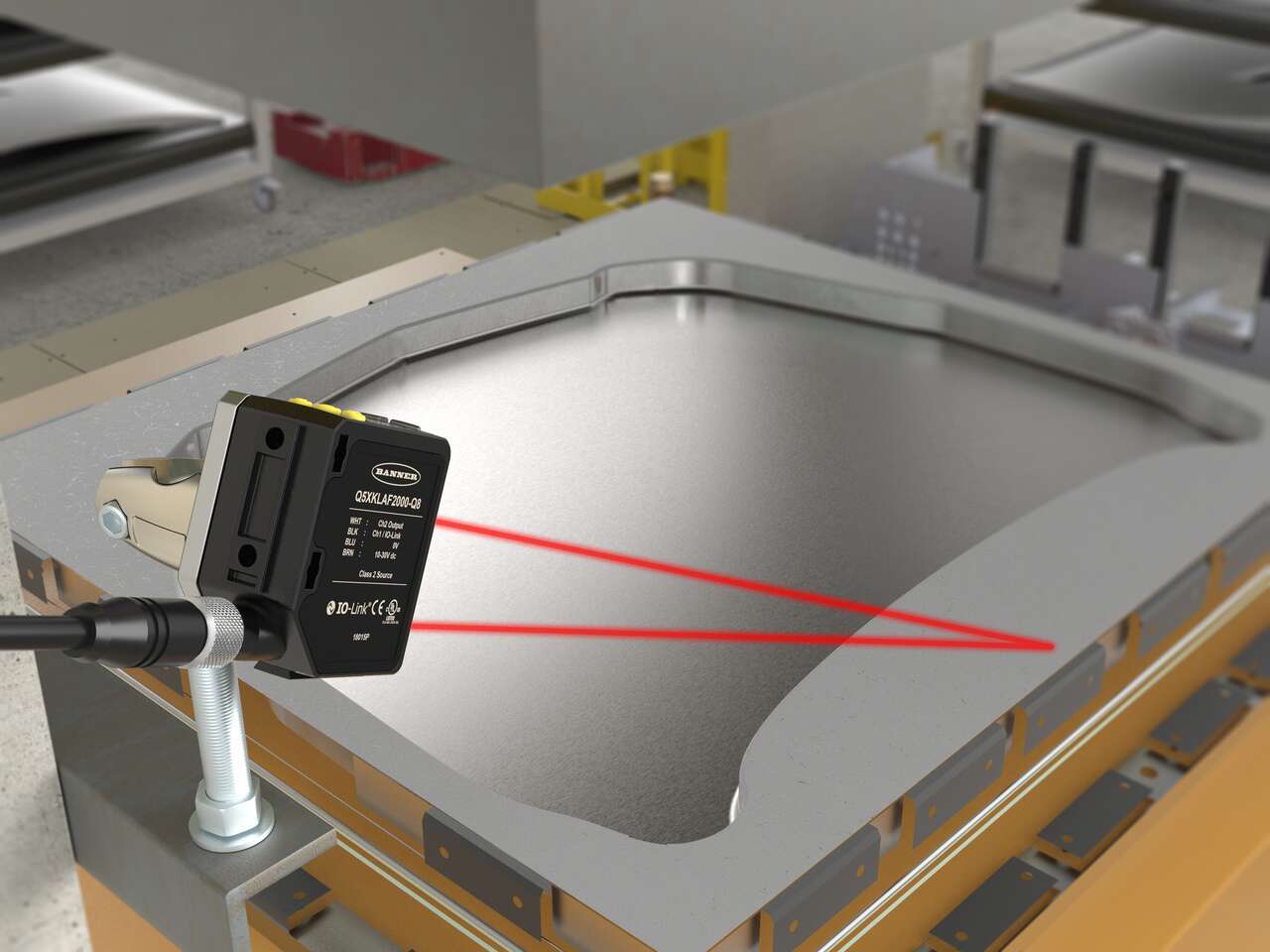

Verificación de las Hojas de Metal en una Prensa de Estampado

-

Detección de Envase de Vidrio Transparente para Alimentos y Bebidas Splash Zone

-

Detección de Envases Plásticos Transparentes para Alimentos en un Entorno Sanitario

-

Control de la Presión en la Línea de Separación de Bandejas Transparentes de Comida

-

Conteo de Anillos Reflectantes

-

Objetivos Obscuros y de Bajos Contraste

-

Sensores Higiénicos para Detectar Frascos de Vidrio en Entornos con Químicos Abrasivos

-

Detección de Botellas Transparentes en un Entorno de Lavado a Presión

-

Packaging Frozen Dinners on a Cartoner

-

Indicación de Atasco en un Tobogán de Salida

-

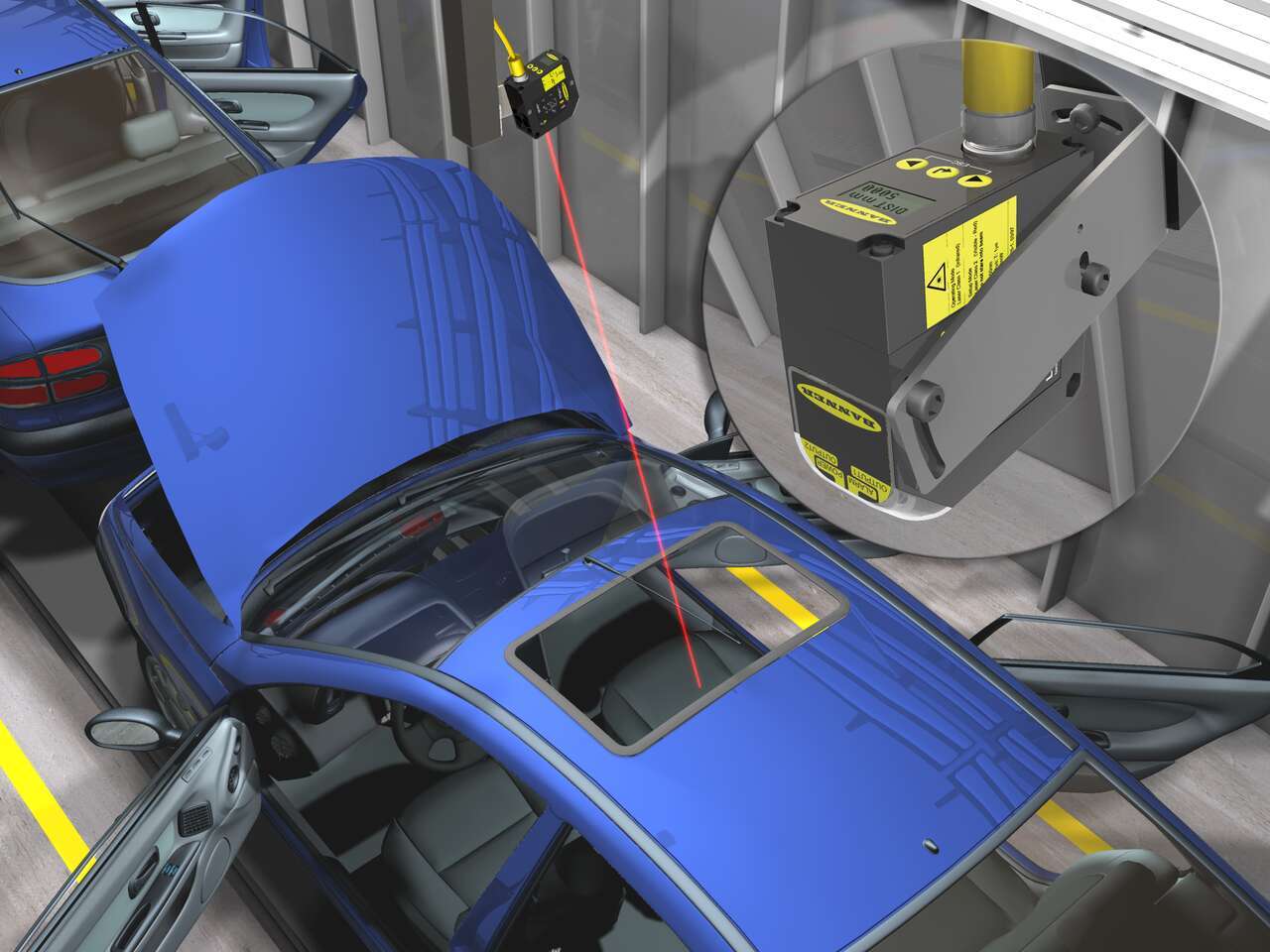

Lavado de Auto

-

Accurate Counting of Transparent Pharmaceutical Bottles

-

Posición del Vehículo en el Lavado Automático con Ambiente Extremo

-

Objetivos Claros y Reflectantes.

Resources

El último folleto de Soluciones de Sensores Fotoeléctricos explora los diferentes tipos de sensores Banner y cómo elegir el adecuado para su aplicación, ya sea conteo de objetos, control de calidad, presencia o ausencia de objetos u otra necesidad de automatización.