Remote Monitoring of Edge Devices

What is Remote Monitoring?

Collecting and analyzing data from sensors and other field devices, remote monitoring provides factories with insight and visibility into the performance of their machines, processes, and people. Even sensor data can be accessed in real time from any location, as well as logged for long term analysis.

Keep reading to learn about how remote monitoring technologies are revolutionizing industrial automation, offering smart factories greater visibility into their operations, and enabling better, data-driven decisions.

Wireless sensor networks provide remote monitoring capabilities and allow manufacturers to increase overall process efficiency and productivity.

By eliminating the wire limitations of conventional systems, wireless networking systems improve data logging, process monitoring and control, while maintaining high levels of security and integrity. Wireless sensor networks are especially advantageous where wired solutions are impractical, ineffective, or cost-prohibitive.

While historically wireless systems were difficult to install and complicated to maintain over time, wireless technology has advanced significantly over the years. Today many remote monitoring solutions are available that offer a reliable wireless communication integrated into a single, inexpensive unit. These new wireless I/O devices are easy to install, and then uninstall and move to a new location as monitoring requirements change.

Predict Failures and Prevent Unplanned Downtime

Remotely monitoring conditions like changes temperature and vibration enables predictive maintenance for machines. The benefits of predictive maintenance include:

- Avoiding machine failures by making maintenance decisions based on historical and real-time data from the machine itself.

- Enabling quick intervention to avoid downtime by monitoring time-sensitive conditions like changes in vibration, temperature, humidity, or tank level.

- Initiating real-time alerts to operators so that critical situations can be resolved quickly to avoid extended downtime, scrapped materials, or product recall.

Track and Reduce Causes of Waste

Remote monitoring provides a variety of benefits for facilities seeking to improve the overall efficiency of their operations. For example:

- Remote monitoring technologies provide data for OEE calculations.

- Facilities can reduce waste and minimize its impact thanks to visibility into when and where inefficiencies occur.

- Access to logged data from sensors and indicator lights on machines enables users to track performance trends over time and identify steps for improvement.

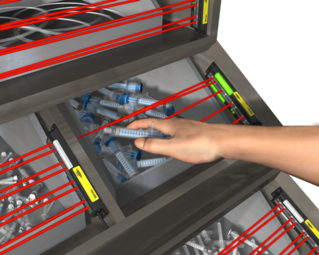

Streamline Call for Parts, Pickup, and More

Remote monitoring technologies are also capable of improving the efficiency of manual assembly and production lines. Some of the benefits of wireless factory notification systems include:

- Allowing managers to remotely monitor multiple lines and work more efficiently by reducing the amount of time spent checking in on lines unnecessarily. This enables managers to quickly respond to issues as they arise and focus their attention where it's needed most.

- Increasing efficiency when managing and responding to call for parts, service, or pickup.

- Reducing the need for workers to leave their workstations and find a manager when they need assistance.

Wireless Controller for IIoT Applications

El controlador DXM es un controlador inalámbrico industrial para facilitar la conectividad Ethernet y las aplicaciones IIoT (Internet Industrial de las Cosas).

- Los radios ISM están disponibles en 900 MHz y 2.4 GHz para las redes inalámbricas locales

- Convierte Modbus RTU a Modbus TCP/IP o Ethernet I/P

- El controlador lógico se puede programar usando reglas de acción y métodos de lenguaje de texto

- Tarjeta micro SD para el registro de datos

- Alertas por correo electrónico y mensajes SMS

- Módulo celular para conectividad a la red telefónica

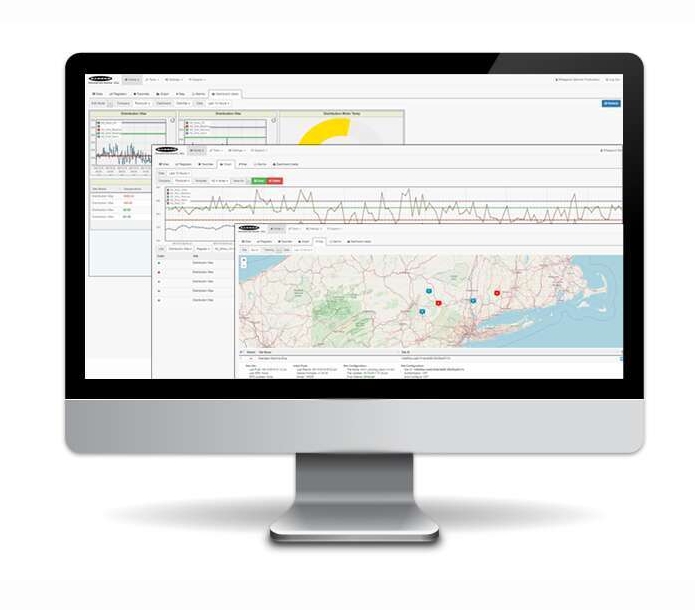

Software for IIoT Applications

El software Connected Data Solutions es una plataforma basada en la web que permite a los usuarios acceder, almacenar, proteger y exportar datos críticos recopilados por los sensores cableados e inalámbricos de Banner. El software complementa nuestra cartera de productos inalámbricos y brinda a los clientes soluciones completas de IIoT de extremo a extremo para resolver los problemas más urgentess de los mercados industriales.

- Con herramientas de análisis y visualización, el software proporciona información útil que le permite resolver desafíos reales en la fábrica.

- Almacenar datos y analizar tendencias a lo largo del tiempo.

- Acceda de forma remota a los datos en cualquier momento y en cualquier lugar mediante un dispositivo conectado a Internet.

- Reciba notificaciones en tiempo real por correo electrónico o mensaje SMS.

Vibration and Temperature Sensor

Los sensores de la serie QM30VT tienen un diseño de perfil bajo y una construcción de metal rígido que reduce la interferencia resonante y aumenta el contacto de la superficie, lo que permite niveles excepcionales de precisión en la medición de velocidad y temperatura RMS. Son capaces de detectar incluso ligeros aumentos en la vibración y la temperatura de la máquina para la identificación temprana de posibles problemas.

- Comunica datos de rendimiento mediante una radio Modbus MultiHop o un nodo serie de 1 cable a un controlador inalámbrico o gateway de la serie DXM

- Detecta problemas potenciales en motores, ventiladores, bombas y cualquier máquina con movimiento giratorio o vibración.

- El diseño ultracompacto cabe fácilmente en espacios pequeños

- Disponible en modelos con carcasa de acero inoxidable 316L o carcasa de aluminio resistente

- Totalmente compatible con el software Connected Data Solutions y el Kit de Soluciones Inalámbricas para Vibración y Temperatura