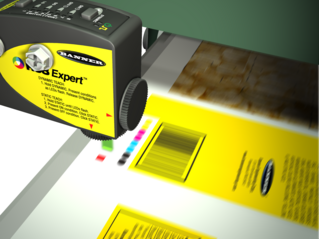

Multicolored Targets and Product Changeover

Multicolored targets are increasingly becoming the norm, especially in consumer packaged goods industries. The various types of packaging used include shiny, glossy, or other unpredictable surfaces.

For example, reflective, multicolored, and wrinkled material such as foil or film is frequently used in food and beverage packaging and can cause inconsistent sensor readings.

Multicolored targets are challenging for many sensors to consistently detect. This is because some colors, such as very dark colors, are more difficult for traditional photoelectric sensors to see because darker colors reflect back less light back to the sensor compared to lighter colors. Multicolored targets also have frequent color transitions and varying amounts of reflectivity that further impact sensing reliability.

Product changeover creates additional challenges because sensors must be able to reliably detect a variety of color combinations. To keep up with consumer demand, manufacturers require flexible sensing solutions that can detect all colors and that can be quickly updated with each new "recipe" during product changeover to keep production lines moving.

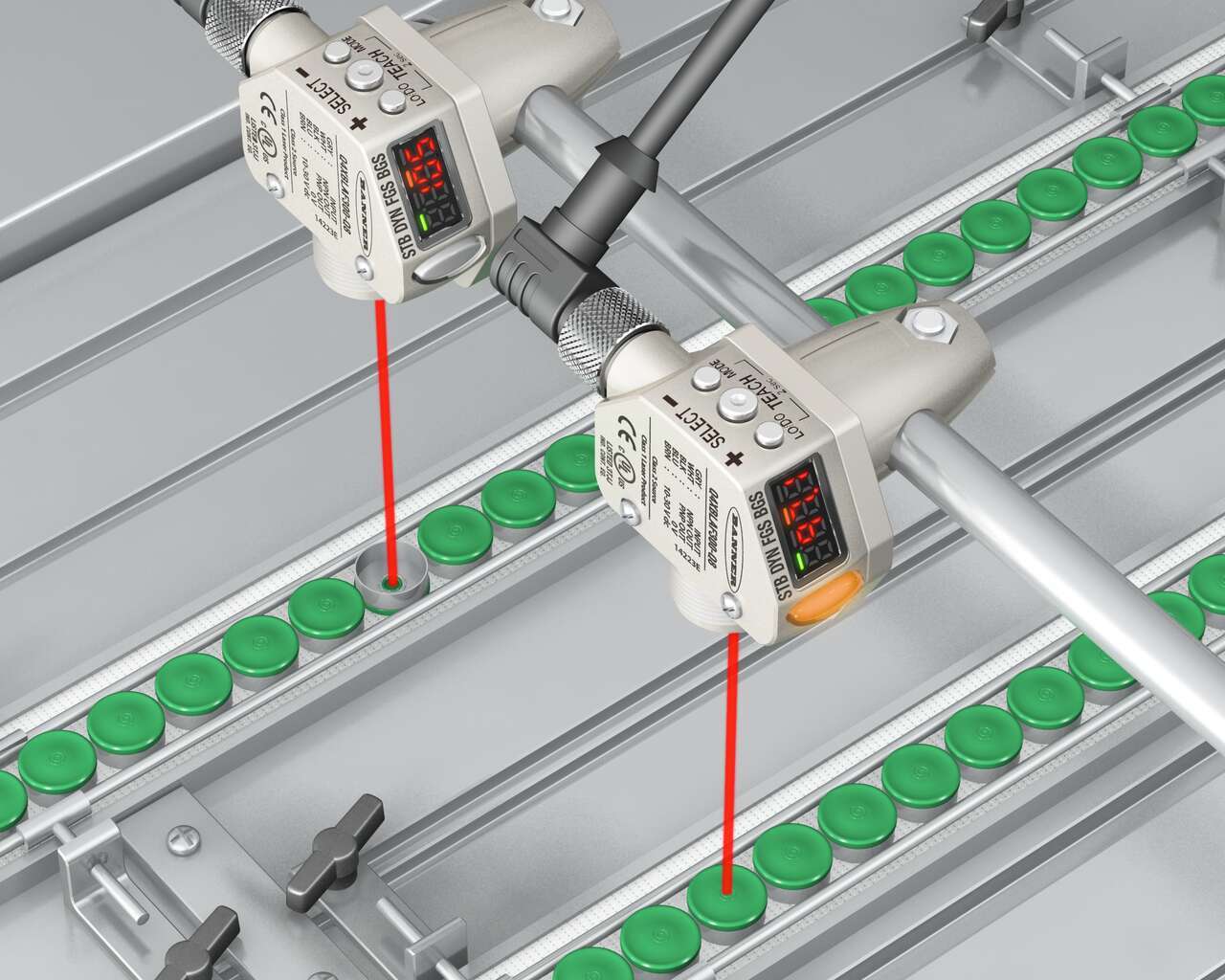

Laser distance sensors are an excellent choice for detecting multicolored packaging because cause they determine target presence or absence using distance. Laser distance sensors are unaffected by color transitions, and they can reliably detect all different varieties of packaging, regardless of color or reflectivity.

In addition, many laser distance sensors from Banner Engineering feature exceptionally high excess gain to reliably detect very dark colors, as well as automatic gain adjustment to dynamically increase or decrease sensing power depending on target reflectivity.

With IO-Link, users can easily read and change device parameters through the control system software, enabling fast configuration and commissioning that saves time and resources.

In addition, IO-Link sensors can accommodate multiple recipes that can be quickly and dynamically changed from the control system as needed—such as in the case of product changeover. For example, a line that runs products of different sizes at different times will require changes to sensors’ distance thresholds.

Manufacturers use many terms to describe sensor performance, but not all manufacturers use the same specifications, which can make it challenging to compare different models of sensors. Read the article to learn tips for choosing the right sensor for any application.

Laser Distance Sensor with IO-Link, 25-610 mm

Sensores de distancia láser versátiles y robustos que ofrecen un rendimiento superior y son capaces de detectar cambios en la distancia de un milímetro.

- Salida discreta, analógica (0 to 10 V or 4 to 20 mA), para detección de objetos claros y modelos de IO-Link.

- Rango de detección confiable desde cerca de 25 mm y hasta 610 mm

- Detecta objetivos en una gran variedad de colores, materiales y superficies basado en la distancia

- El modo de enseñanza dual (intensidad + distancia) es ideal para aplicaciones de corrección de error y permite la detección de objetos claros sin necesidad de un retro reflector.

- Carcasa robusta de acero inoxidable clasificada IP69K grado FDA

Laser Distance Sensor with IO-Link, 9.5 cm to 2 m

El láser de supresión de fondo Q5X es un potente sensor de resolución de problemas en un dispositivo económico con una carcasa rectangular estándar de la industria.

- Rango de 9.5 cm (4 pulgadas) a 2 m (6 pies 6 pulgadas)

- El exceso de ganancia excepcionalmente alto permite que el sensor detecte de manera confiable los objetos más oscuros (<_6 de="de" blancos="blancos" negros="negros" reflectantes="reflectantes" li="li">

- Detecta de manera confiable objetivos negros contra un fondo negro, blancos negros contra un fondo metálico brillante, objetos claros y reflectantes, empaques multicolores y blancos de todos los colores

- El modo de aprendizaje dual mide la distancia más la intensidad de la luz para resolver las aplicaciones más difíciles