Error Proofing and Poka Yoke

Prevent Errors in Lean Manufacturing Environments

Error proofing refers to preventing a process from resulting in defects by stopping mistakes at the source, rather than down the line.

Another word for error proofing is poka-yoke (which is Japanese for avoiding inadvertent errors). Poka-yoke design is often used to avoid human error by either warning operators when they are about to make a mistake or preventing them from making a mistake at all. Poka-yoke design makes it virtually impossible for an operator to complete an action incorrectly.

Preventing mistakes at the source can significantly improve productivity by keeping mistakes from becoming bigger problems downstream.

Quality Inspection at the Source

Error-proofing takes quality control to the next level by checking for mistakes and defects before those defects can proceed to the next stage of production. Preventing defects from proceeding from one stage of production to the next avoids wasted time and resources spent working on defective parts.

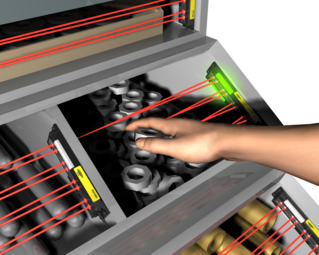

In manual processes, such as bin picking, visual warnings clearly indicate to operators when their actions are correct or incorrect using colored and/or animated lights. Light-guided assembly is an excellent example of using visual indication for error-proofing.

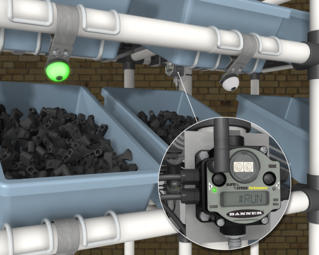

Meanwhile, in more automated processes, error proofing solutions like sensors and vision systems can be used to ensure poblems are corrected before a process can proceed.

Banner Engineering provides sensor, vision, and light-guided solutions for error proofing to help manufacturers increase efficiency, improve quality, and reduce downtime. Keep reading to learn more, or contact us to discuss your specific application.

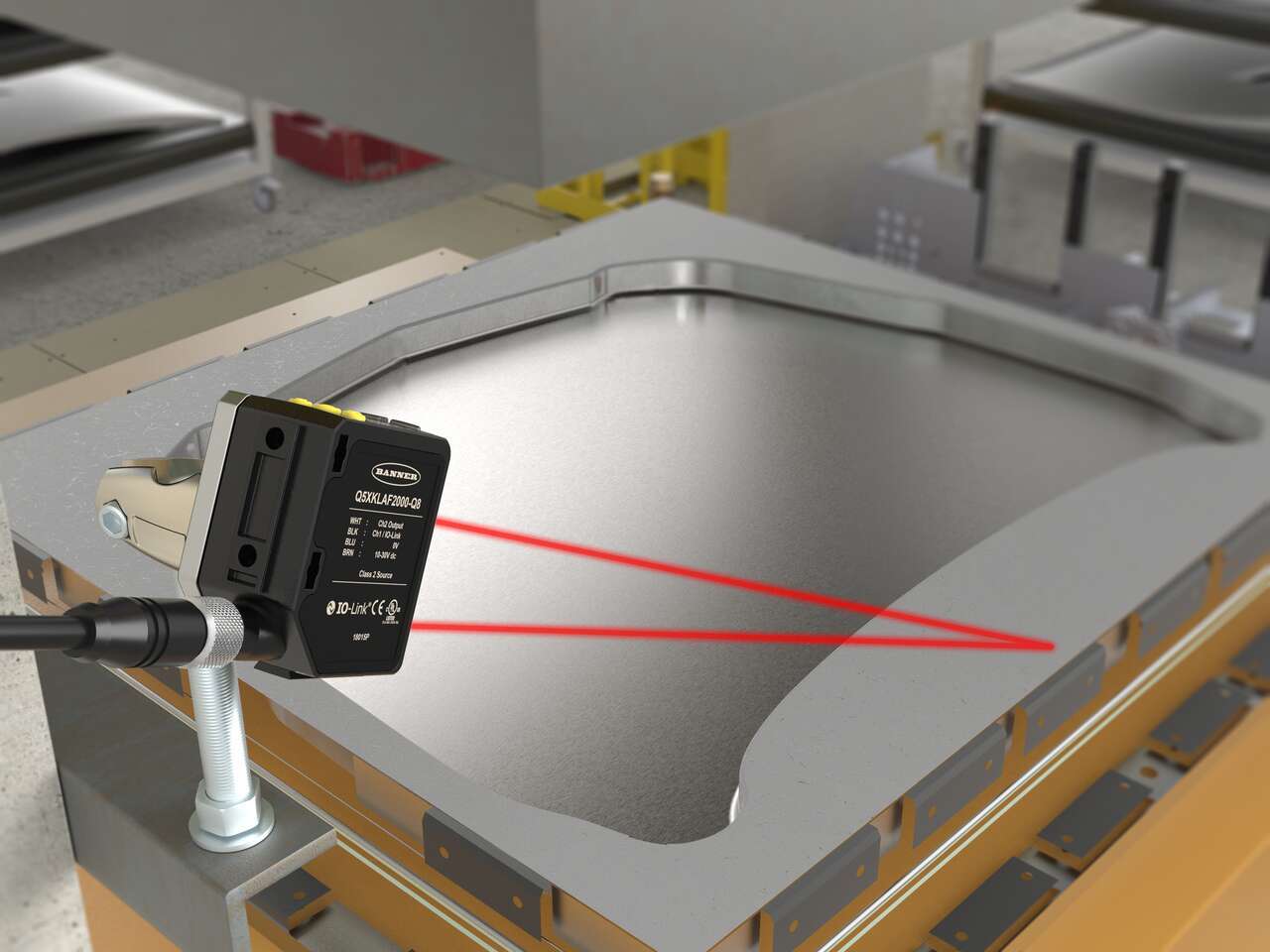

- Laser measurement sensors are often a reliable solution to error-proofing applications.

- Laser sensors from Banner detect and measure the most challenging targets, for error-proofing solutions manufacturers can trust.

- For example, in metal stamping applications, it is critical to ensure that metal sheets are properly indexed on the press before stamping to avoid material waste and damage to the press die.

- The Q5X Series laser sensor reliably detects reflective targets even at an acute angle.

- The press cannot operate until the sensor verifies the leading edge of the material and confirms that the metal sheet is both present and properly indexed.

- In some applications, a vision solution can be an excellent choice for error-proofing.

- For example, in automotive assembly, interior trim pieces are interchangeable, but vary in color, making it easy to install the wrong piece. As assembly progresses, correcting errors becomes more difficult.

- An iVu Color vision sensor verifies that trim colors match the build order for a vehicle.

- If an error is detected (the wrong color trim is placed), the error must be remedied before the automotive assembly can proceed to the next step.

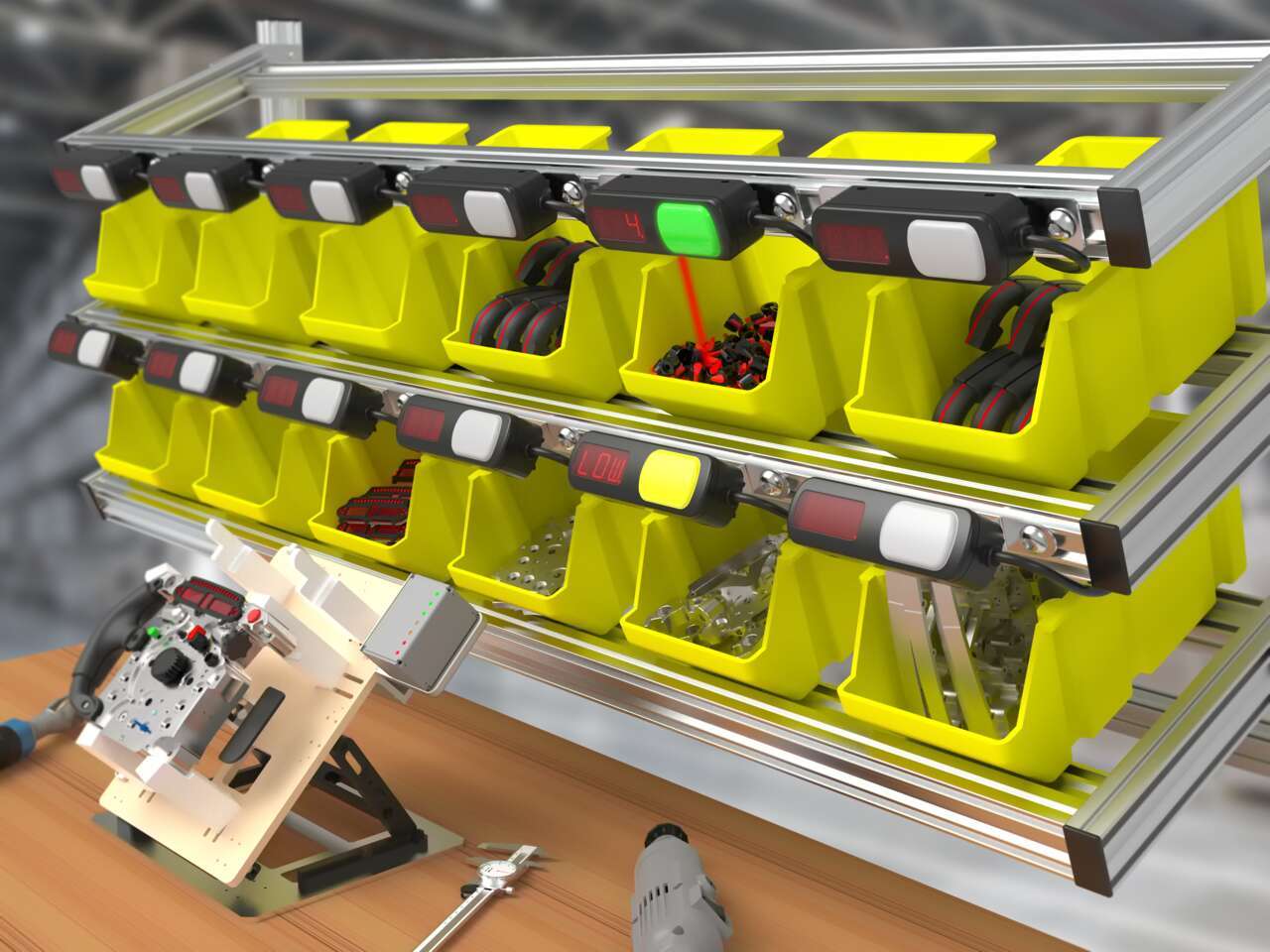

- Perhaps one of the most common error-proofing technologies in assembly processes is light-guided picking, also known as pick-to-light.

- Pick-to-light devices use colored LEDs to visually guide assemblers to pick the correct parts, in the right quantities, and in the proper sequence.

- This reduces the risk of human errors and speeds up build times to ensure high quality while maximizing productivity.

Rugged Laser Distance Sensor

Sensores de distancia láser versátiles y robustos que ofrecen un rendimiento superior y son capaces de detectar cambios en la distancia de un milímetro.

- Salida discreta, analógica (0 to 10 V or 4 to 20 mA), para detección de objetos claros y modelos de IO-Link.

- Rango de detección confiable desde cerca de 25 mm y hasta 610 mm

- Detecta objetivos en una gran variedad de colores, materiales y superficies basado en la distancia

- El modo de enseñanza dual (intensidad + distancia) es ideal para aplicaciones de corrección de error y permite la detección de objetos claros sin necesidad de un retro reflector.

- Carcasa robusta de acero inoxidable clasificada IP69K grado FDA

Vision Sensor

Los sensores iVu de imagen e imagen en color se utilizan para monitorear las piezas en cuanto a tipo, tamaño, orientación, forma, ubicación y color o variaciones de color.

- Una solución completa con cámara, controlador, lentes y luz incluidos en un solo paquete

- Configure en minutos usando el software para PC Vision Manager, la pantalla táctil integrada o la pantalla táctil remota

- Inspeccione múltiples puntos con una variedad de herramientas de escala de grises o color

- Carcasa compacta y resistente, IP67 disponible con luces anulares integradas que incluyen rojo, azul, verde, blanco, infrarrojo o UV

- Lentes intercambiables, incluida la montura C, para una máxima flexibilidad de aplicación

- EtherNet/IP ™, Modbus/TCP, PROFINET®, PCCC y Serial RS-232

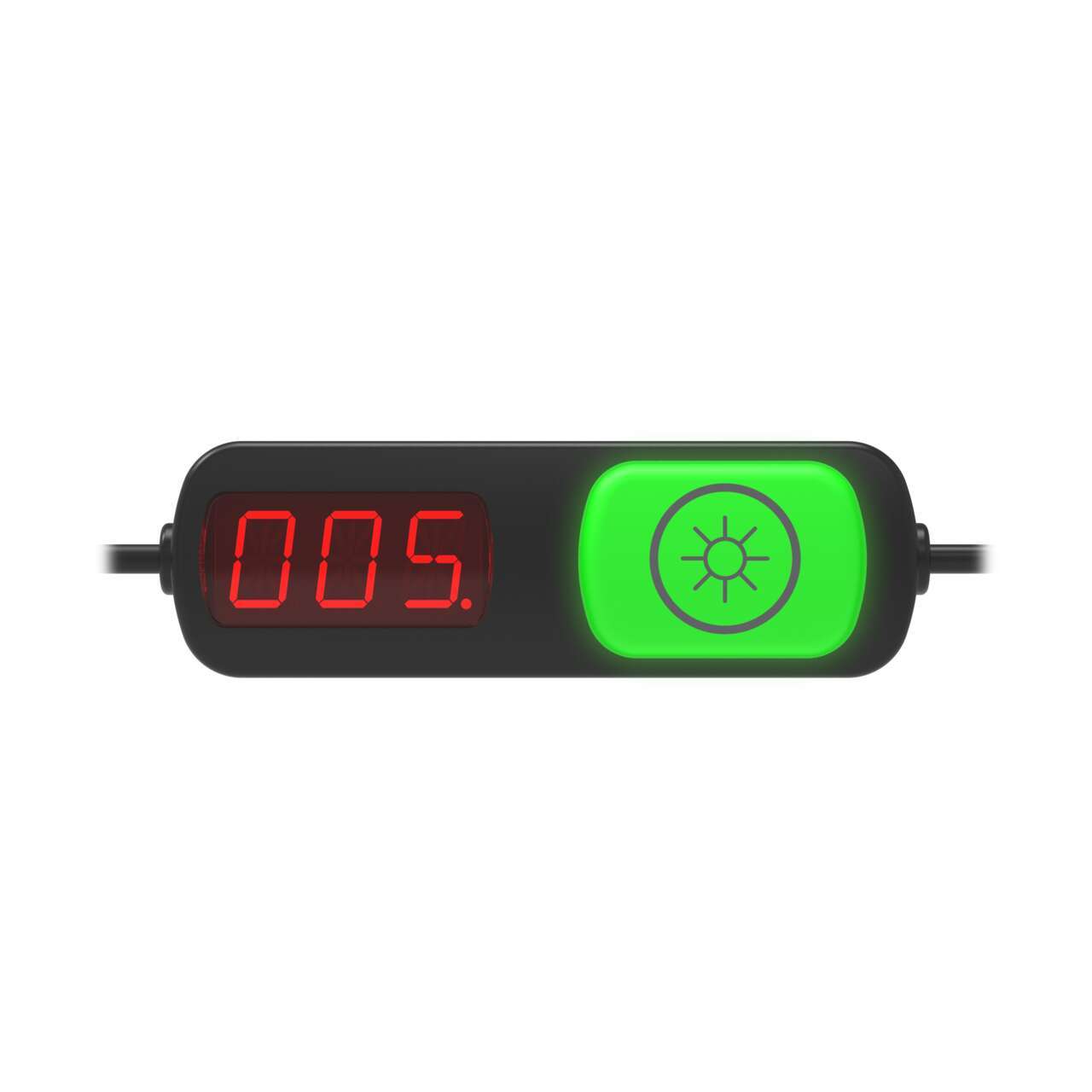

PTL110 Series

Scalable, Versatile Pick-to-Light Devices

Los dispositivos de pick-to-light PTL110 son indicadores multifuncionales con opciones para el botón táctil, el sensor óptico y la pantalla de tres dígitos, conectados en serie para crear un poderoso sistema de picking. Con tiempos de respuesta rápidos y opciones de instalación flexibles, los sistemas PTL110 mejoran la velocidad, la productividad y la calidad en el picking, el kitting y las aplicaciones relacionadas.

- Modelos disponibles con capacidades de sensor óptico y táctil.

- La pantalla alfanumérica opcional de 3 dígitos se puede usar para indicar el recuento de piezas o para proporcionar otras instrucciones.

- Conectores M12 para una instalación rápida y segura de múltiples dispositivos sin necesidad de cables adicionales.

- El indicador proporciona catorce colores y múltiples funciones de animación para diferenciar múltiples condiciones.

- Desarrollado por PICK-IQ ™, un protocolo de bus serie compatible con Modbus diseñado específicamente que utiliza un ID común para reducir la latencia típica que resulta de sondear múltiples dispositivos.

- Se puede combinar con el controlador inalámbrico DXM700 para la implementación en carros y estaciones de recolección móviles.

![Operator Guidance Solution [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/PVD_QS30LE_OTB_K50L_Bin-Pick-for-Transmission-Plate.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)