Monitoring Moisture in Compressed Air Lines

Challenge: Monitoring Moisture in Compressed Air Lines

A contract manufacturer tests, programs, and packages semiconductor components. A failure in the manufacturer’s compressed air dryer caused excessive moisture in the air lines as well as the production equipment’s regulators and cylinders. This in turn triggered product quality problems and a two-day production stop.

Solution: Banner S24 Dew Point Sensor and DXM Controller

To prevent this problem from occurring in the future, the contract manufacturer installed a Banner condition monitoring system to monitor the dew point of its compressed air.

The installation included a Banner S24 Dew Point Sensor in the compressed air line, paired with a DXMR90-X1 Controller. With the solution, the company was able to baseline the performance of its drying system and set up alerts to notify the maintenance team if the performance began to degrade.

Monitors and Protects Air Quality

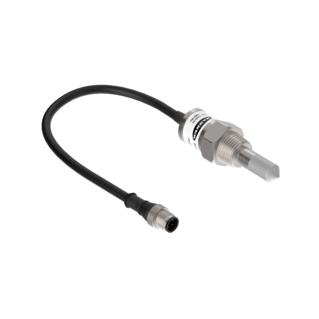

The S24 Dew Point Sensor provides insights into a compressed air system’s air quality to ensure the system is operating properly. When connected to a controller, it can alert staff to problems caused by excess moisture. This can prevent equipment damage as well as product-quality problems caused by excess moisture.

Functions with Banner’s Communications Overlay System

The S24 Dew Point Sensor functions with the Banner Snap Signal communications overlay portfolio of products. Customers can easily deploy and commission a monitoring system on nearly any type of equipment. This allows a user to benefit from a system of products that can be customized to fit their needs.

Robust Construction Withstands Harsh Environments

The sensor’s robust stainless-steel housing ensures it can withstand the harsh conditions found in demanding industrial applications. With a replaceable sintered filter, the S24’s sensing element is protected from physical damage as well as from scale and particulate debris, common in compressed air systems, allowing a reliable product with minimal maintenance. This enables the filter to be serviced in the field if it becomes clogged or damaged.